Two-stage type bulk curing process for flue-cured tobaccos

A technology of intensive roasting and roasting process, applied in the field of flue-cured tobacco roasting, can solve the problems of high miscellaneous gas and irritation, insufficient aroma of tobacco leaves, long drying period of gluten, etc. Tobacco leaves, the effect of reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

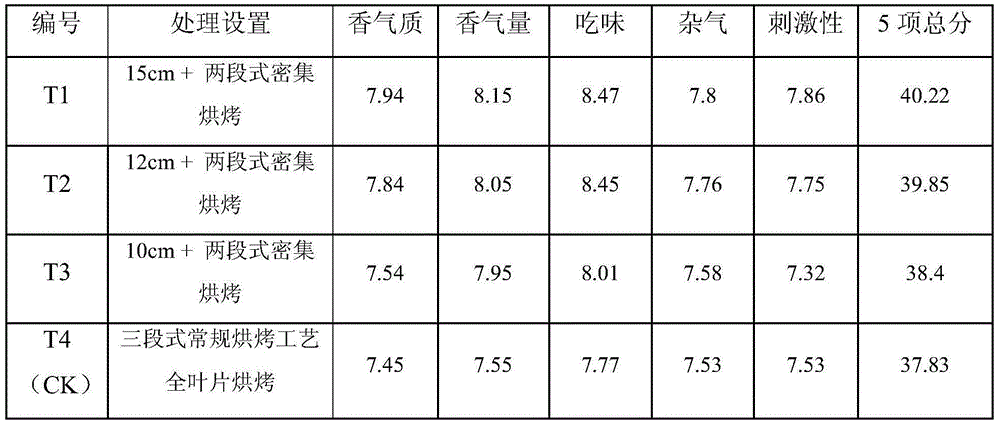

[0033] Example 1: Application of two-stage intensive roasting process of flue-cured tobacco Nanjiang No. 3 variety

[0034] In 2014, the central tobacco leaves of the flue-cured tobacco Nanjiang No. 3 variety planted in Fuquan City, Guizhou Province were selected, and the base 15 cm of the harvested tobacco leaves were removed, and the tobacco leaves were loaded into the barn by loose leaf cuttings, and the flue-cured tobacco of the present invention was used for two-stage intensive drying. Baking process for baking.

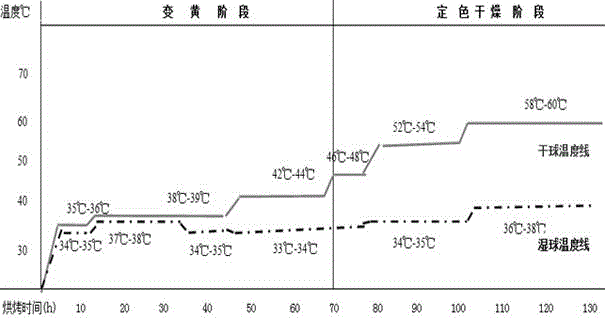

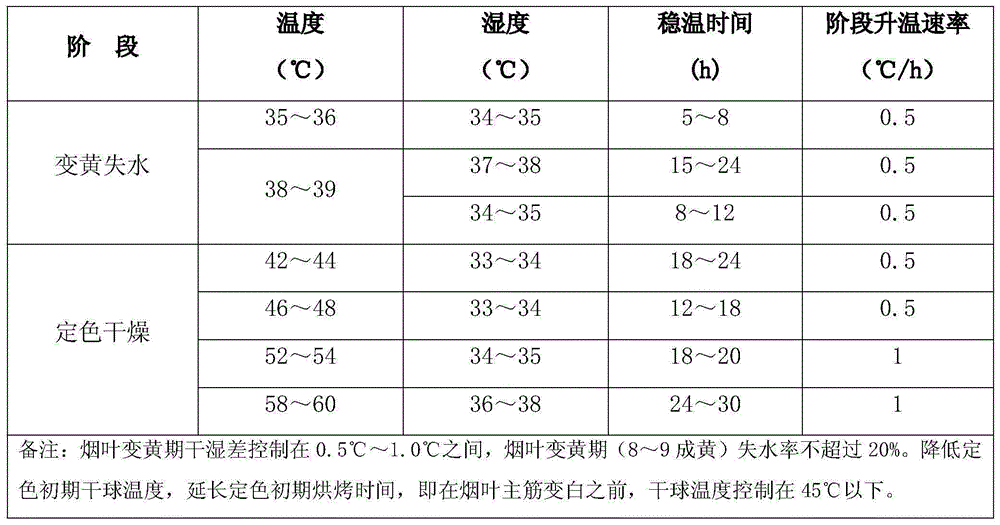

[0035] Yellowing and dehydration stage:

[0036]Step 1: After the tobacco leaves are loaded into the barn, close the doors, windows and air inlets, raise the dry bulb temperature to 35°C at a heating rate of 0.5°C / h, and the wet bulb temperature to 34°C, and bake at a steady temperature for 8 hours;

[0037] Step 2: Raise the dry bulb temperature to 39°C and the wet bulb temperature to 38°C at a heating rate of 0.5°C / h, and bake at a steady temperature for 20 h...

Embodiment 2

[0050] Example 2: Application of two-stage intensive curing process of flue-cured tobacco Bina No. 1 variety

[0051] In 2015, the central tobacco leaves of the flue-cured tobacco Bina No. 1 variety planted in Fuquan City, Guizhou Province were selected, and the bases of 10cm, 12cm and 15cm of the harvested tobacco leaves were removed, and the tobacco leaves were loaded into the barn by stacking loose leaves, and the flue-cured tobacco of the present invention was used. Two-stage intensive baking process for baking.

[0052] Yellowing and dehydration stage:

[0053] Step 1: After the tobacco leaves are loaded into the barn, close the doors, windows and air inlets, raise the dry bulb temperature to 36°C at a heating rate of 0.5°C / h, and the wet bulb temperature to 35°C, and bake at a steady temperature for 6 hours;

[0054] Step 2: Raise the dry bulb temperature to 38°C and the wet bulb temperature to 37°C at a heating rate of 0.5°C / h, and bake at a steady temperature for 18 h...

example 3

[0064] Example 3: Necessity analysis of removing the 10-15cm base of fresh tobacco leaves for baking

[0065] Remove the base of the fresh tobacco leaves by 10-15 cm, which is equivalent to cutting the base of the cured tobacco leaves (head part) to a length of 10-12 cm. Within this length range, this part of the leaf base has the following characteristics:

[0066] 1. According to the cut analysis of multiple varieties planted in a large area in Guizhou Province, the leaf content of the most reaches 5%, and the least is less than 1%;

[0067] 2. According to the length of the tobacco leaves, the weight of the cut leaf base accounts for about 15-20% of the weight of the whole handful (sheet) of tobacco leaves;

[0068] 3. For the handle tobacco, the impurity content in the leaf base (handle head) is very high, accounting for more than 50% of the total amount of impurity in the entire tobacco leaf;

[0069] 4. The quality of the tobacco leaves at this part is relatively poor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com