Light-diffusion environment-friendly and inflaming retarding polycarbonate based composition for LED (Light-Emitting Diode) illumination and preparation method thereof

A flame retardant polycarbonate and LED lighting technology, applied in the field of materials, can solve the problems of reducing the impact strength of aromatic polycarbonate, reducing the light transmittance of aromatic polycarbonate, and yellowing of aromatic polycarbonate, etc. Achieve the effect of improving yellowing phenomenon, excellent mechanical properties and processing properties, and avoiding oxidative changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

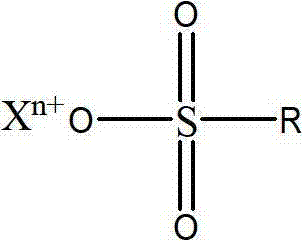

Problems solved by technology

Method used

Image

Examples

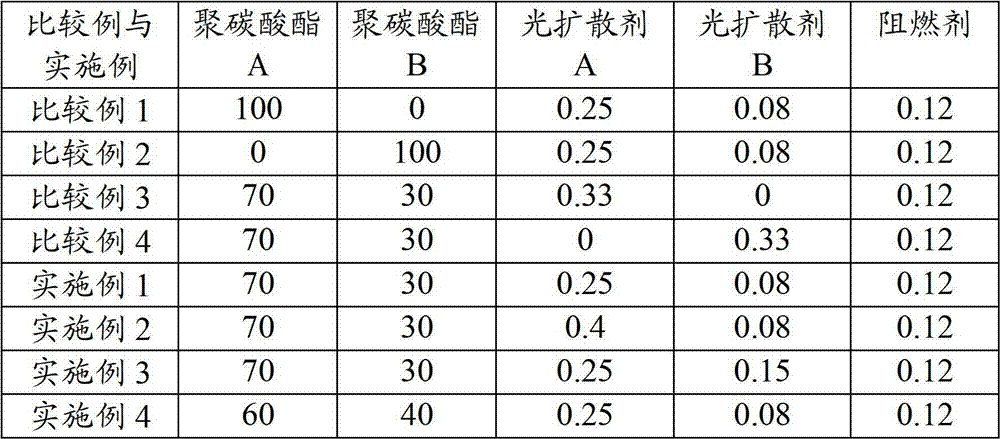

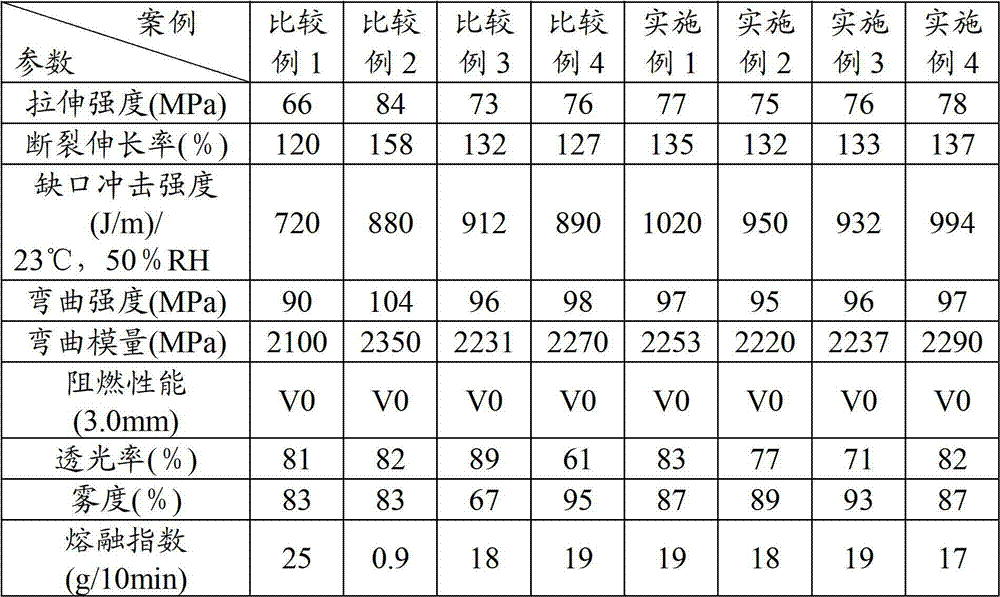

Embodiment 1

[0063] Prepare the premix with the following raw materials in parts by weight: 70 parts of bisphenol A aromatic polycarbonate A, 30 parts of bisphenol A aromatic polycarbonate B, 0.25 parts of bead-shaped cross-linked acrylate light diffusing agent, bead-shaped cross-linked acrylate 0.08 parts of organic silicon light diffusing agent, 0.12 parts of potassium benzenesulfonylbenzenesulfonate, 0.03 parts of n-octadecyl propionate, phosphorous acid 0.06 part of tris(2,4-di-tert-butylphenyl) ester, 0.02 part of 3,4-dibutyl-5-(2,4-dimethylphenyl)benzofuran-2(3H)-one ;

[0064] The mixed premixed material is placed in a parallel twin-screw extruder for melt extrusion and granulation. The processing technology is: the temperature of the first zone of the parallel twin-screw extruder is 195°C, the temperature of the second zone is 255°C, the temperature of the third zone is 275°C, the temperature of the fourth zone is 280°C, the temperature of the fifth zone is 280°C, the temperature ...

Embodiment 2

[0066] Prepare the premix with the following raw materials in parts by weight: 70 parts of bisphenol A aromatic polycarbonate A, 30 parts of bisphenol A aromatic polycarbonate B, 0.4 part of bead-shaped cross-linked acrylate light diffusing agent, bead-shaped cross-linked 0.08 parts of organic silicon light diffusing agent, 0.12 parts of potassium benzenesulfonylbenzenesulfonate, 0.03 parts of n-octadecyl propionate, phosphorous acid 0.06 part of tris(2,4-di-tert-butylphenyl) ester, 0.02 part of 3,4-dibutyl-5-(2,4-dimethylphenyl)benzofuran-2(3H)-one ;

[0067] The mixed premixed material is placed in a parallel twin-screw extruder for melt extrusion and granulation. The processing technology is: the temperature of the first zone of the parallel twin-screw extruder is 195°C, the temperature of the second zone is 255°C, the temperature of the third zone is 275°C, the temperature of the fourth zone is 280°C, the temperature of the fifth zone is 280°C, the temperature of the sixt...

Embodiment 3

[0069] Prepare the premix with the following raw materials in parts by weight: 70 parts of bisphenol A aromatic polycarbonate A, 30 parts of bisphenol A aromatic polycarbonate B, 0.25 parts of bead-shaped cross-linked acrylate light diffusing agent, bead-shaped cross-linked acrylate 0.15 parts of organic silicon light diffusing agent, 0.12 parts of potassium benzenesulfonylbenzenesulfonate, 0.03 parts of n-octadecyl propionate, phosphorous acid 0.06 part of tris(2,4-di-tert-butylphenyl) ester, 0.02 part of 3,4-dibutyl-5-(2,4-dimethylphenyl)benzofuran-2(3H)-one ;

[0070] The mixed premixed material is placed in a parallel twin-screw extruder for melt extrusion and granulation. The processing technology is: the temperature of the first zone of the parallel twin-screw extruder is 195°C, the temperature of the second zone is 255°C, the temperature of the third zone is 275°C, the temperature of the fourth zone is 280°C, the temperature of the fifth zone is 280°C, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com