Patents

Literature

74 results about "Branched chain alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cosmetics having excellent usability and stability and a method for making the same

InactiveUS20090280077A1Improve usabilityGood storage stabilityCosmetic preparationsHair cosmeticsBranched chain fatty acidsBranched chain alcohol

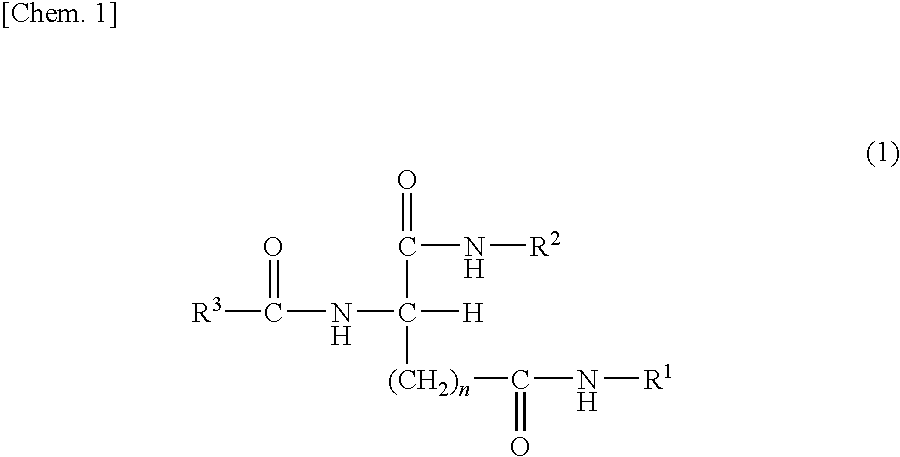

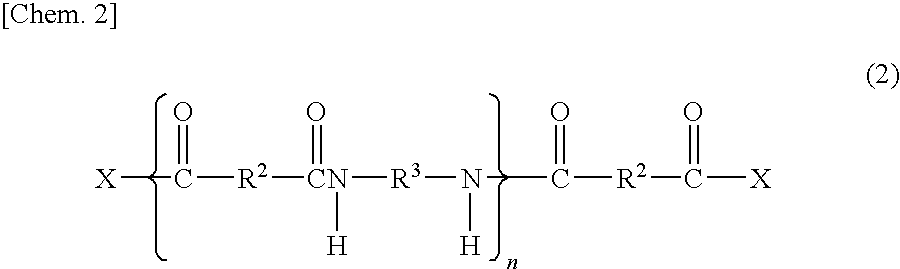

In a prior cosmetic, a cosmetic product provided with sufficient storage stability together with excellent usability can not be realized, and it has been an actual state that a cosmetic product having sense of non-tackiness etc. and excellent usability has poor storage stability. In the present invention, as a cosmetic, a cosmetic for producing a cosmetic product having more excellent usability and storage stability, and a method for making the same, are provided.The cosmetic of the present invention is characterized in that it comprises an amino acid oil gelling agent, a polyamide resin and one or more monoesters selected from a monoester having a C9 to C24 linear chain or branched chain fatty acid residue and / or a C9 to C24 linear chain or branched chain alcohol residue, and thereby, a cosmetic product having excellent usability and sufficient storage stability in combination can be realized.

Owner:KOKYU ALCOHOL KOGYO

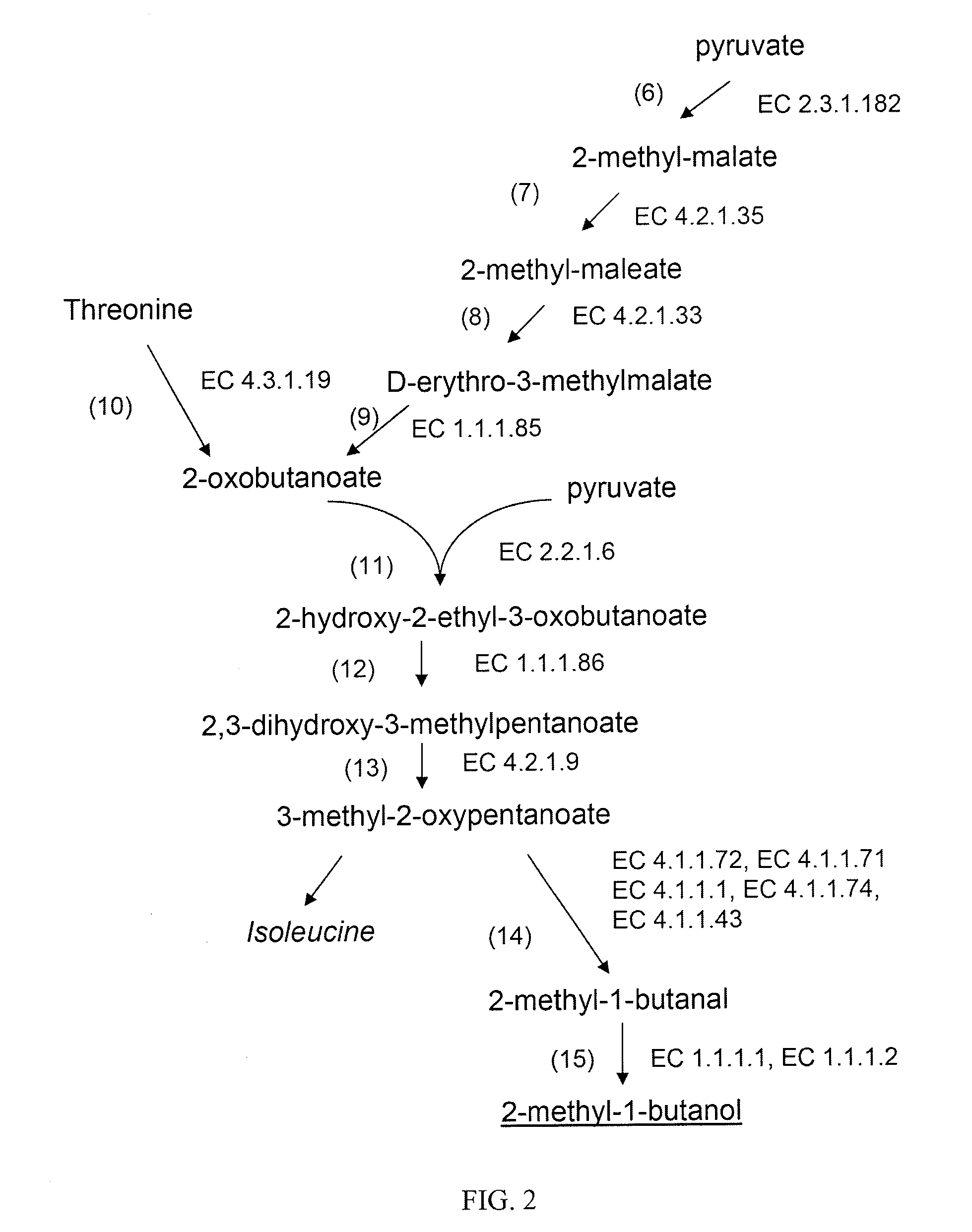

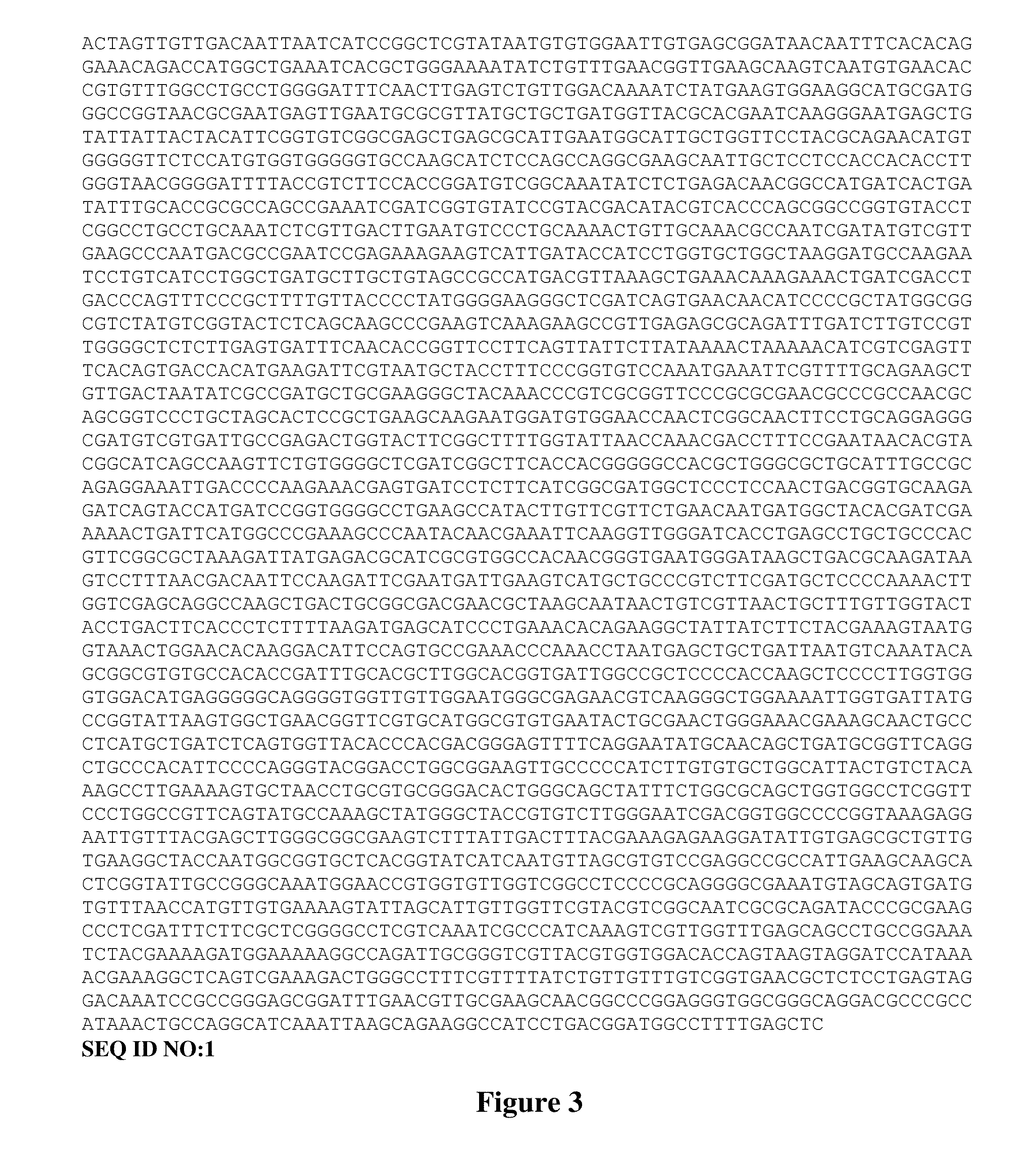

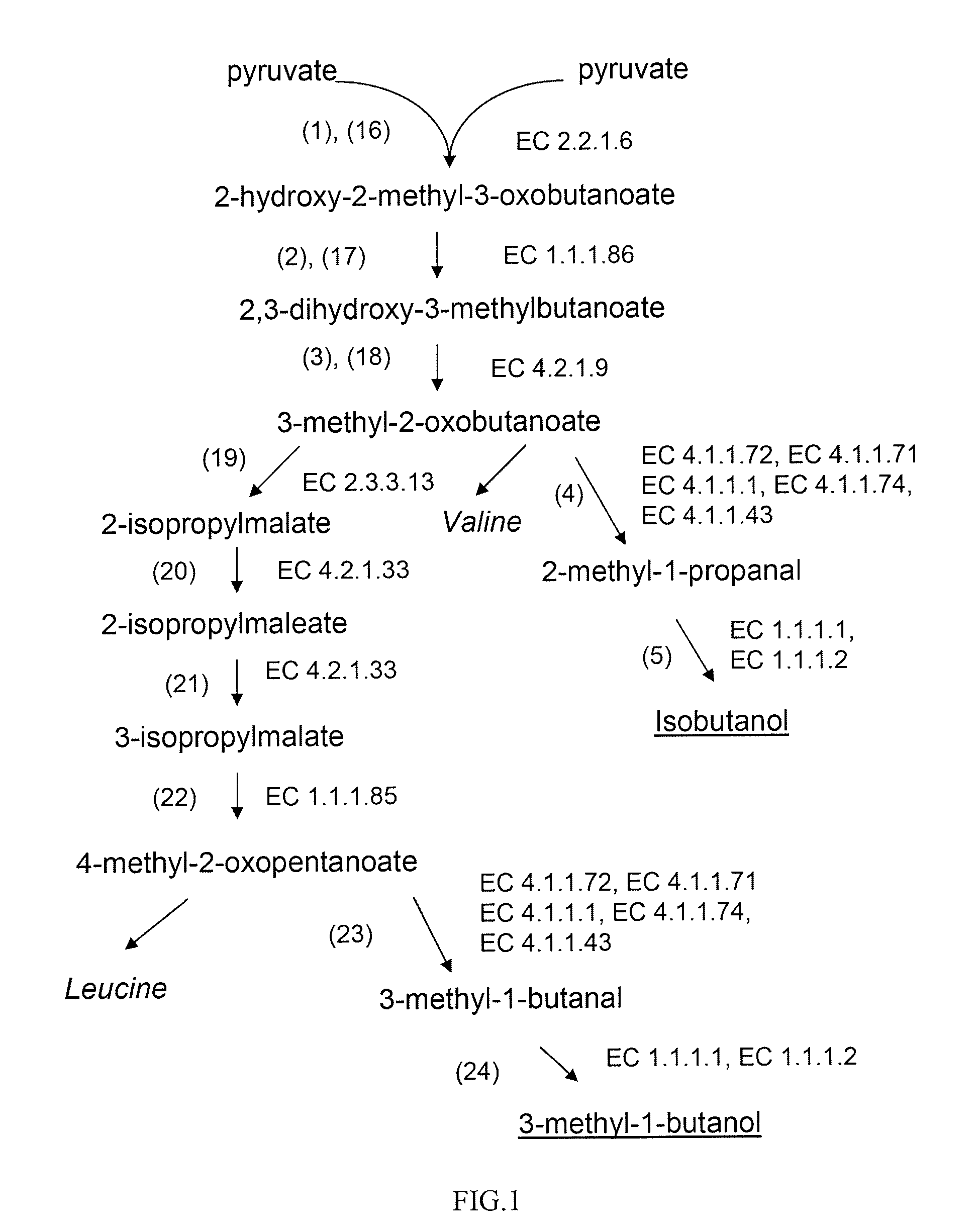

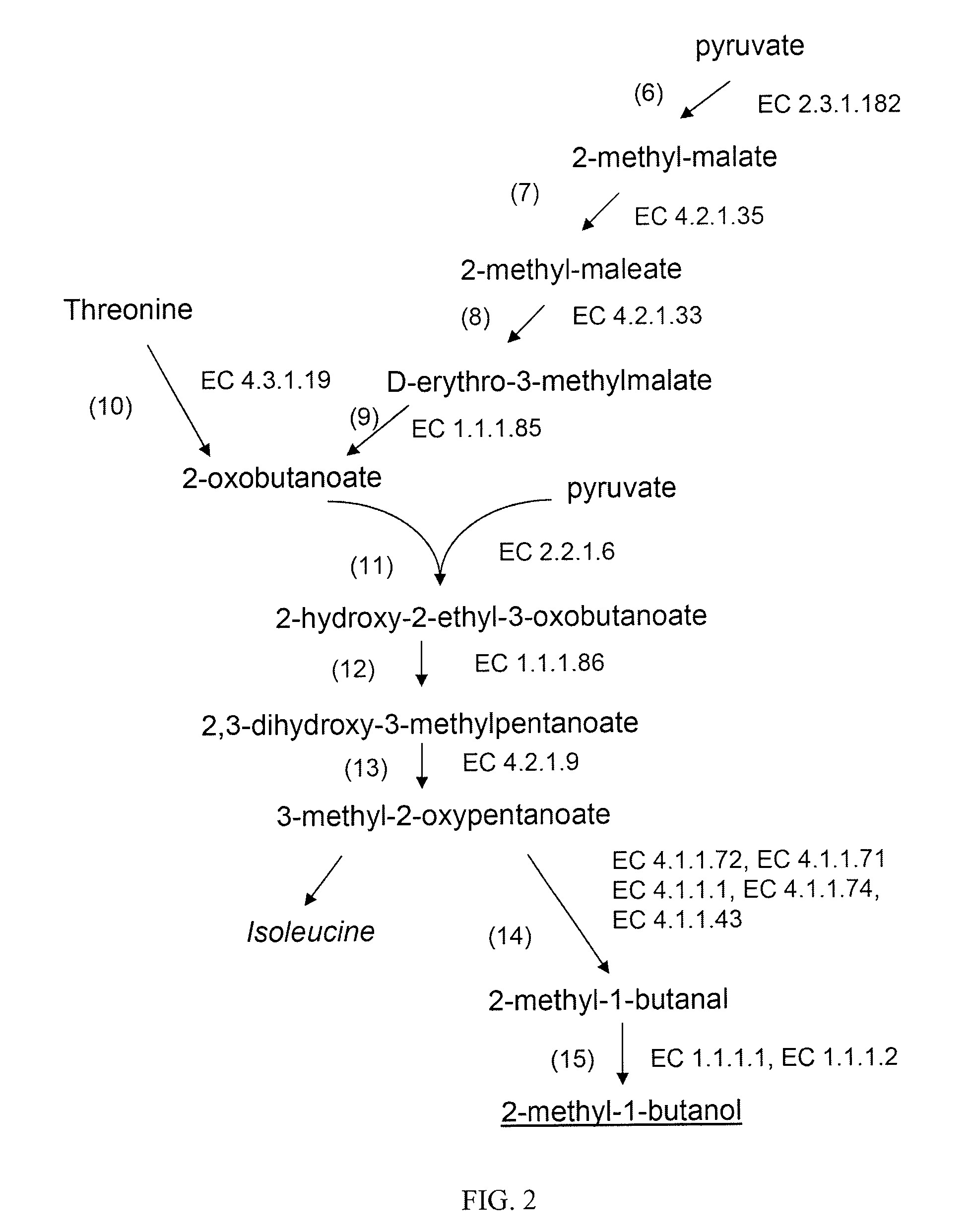

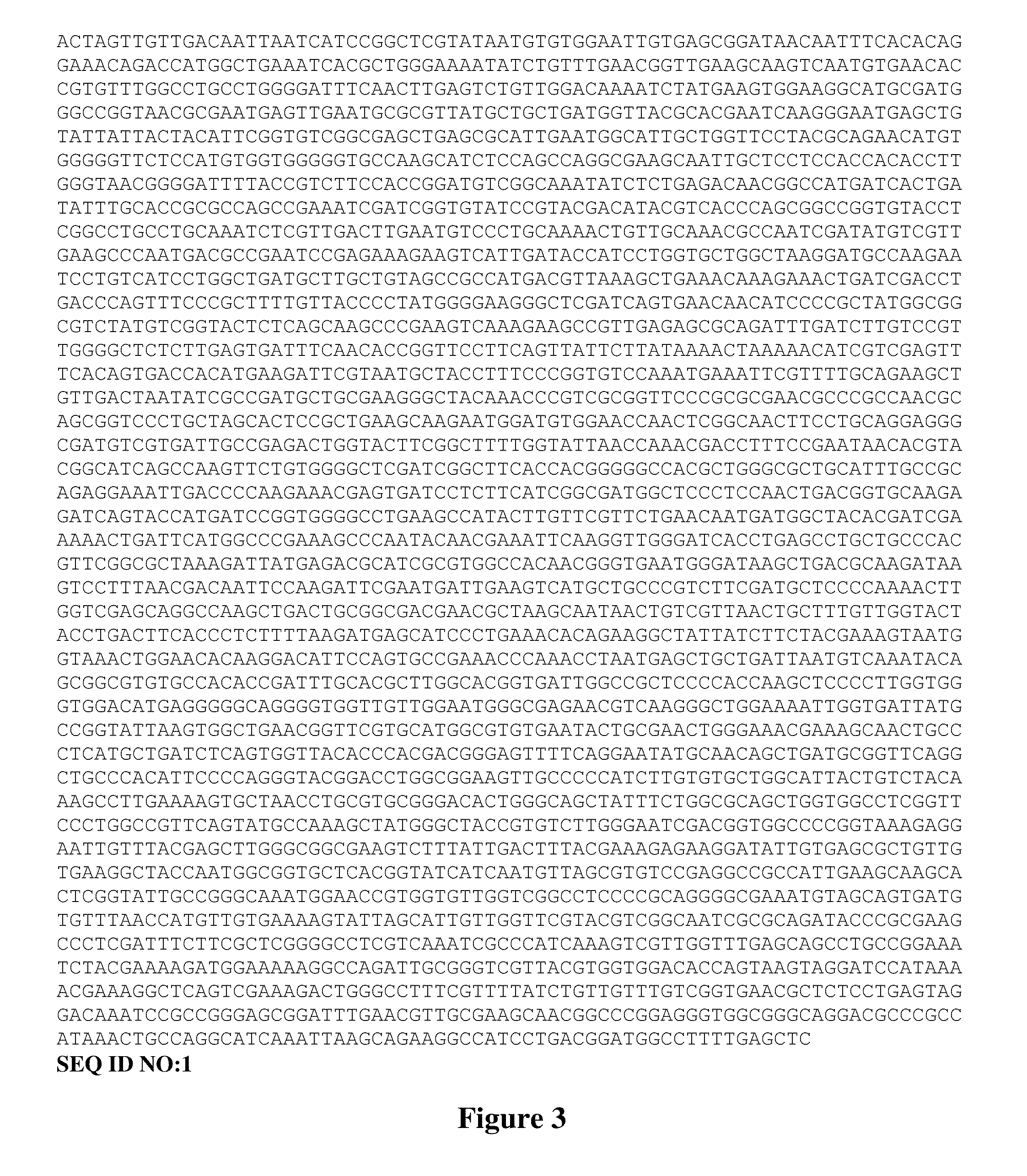

Production of branched-chain alcohols by photosynthetic microorganisms

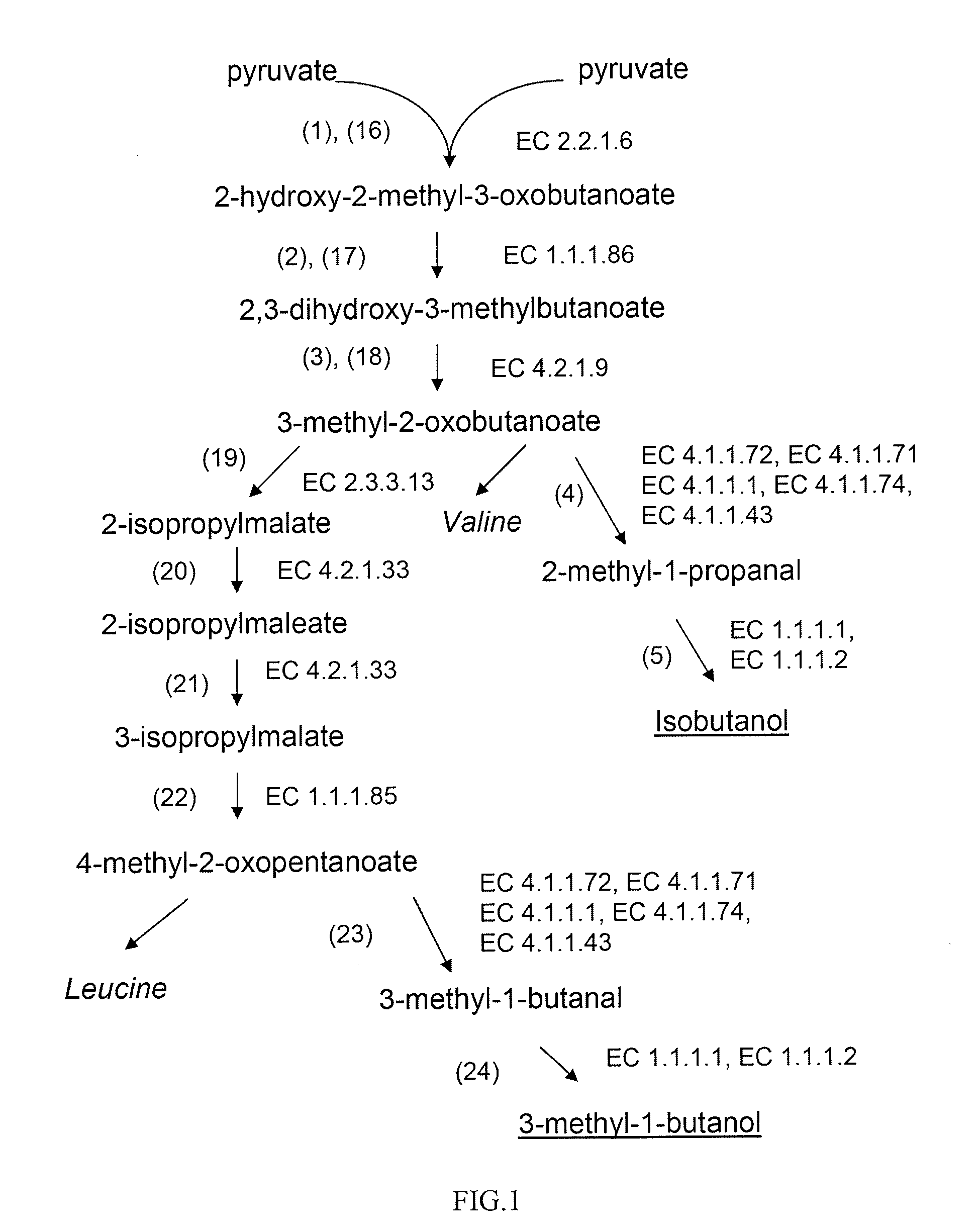

The present invention provides genes, polypeptides and expression constructs therefor, recombinant photosynthetic microorganisms, and method of use thereof, such as for the production of branched-chain alcohols (including 2-methyl-1-butanol, 3-methyl-1-butanol, and isobutanol) and derivatives thereof for a variety of uses.

Owner:SYNTHETIC GENOMICS INC

Dispersing agent

InactiveUS20100280162A1Attaining color developmentAttaining freeze/thaw stabilityTransportation and packagingDuplicating/marking methodsAlcoholPigment

A dispersing agent and a composition including a pigment and the dispersing agent are provided. The dispersing agent includes a branched alcohol alkoxylate having the following formula (I):X(Y)m(Z)nH (I)In the formula (I), X is a C6 to C16 branched chain, Y represents a propyleneoxy group, butyleneoxy group, or combination thereof, Z represents an ethyleneoxy group, propyleneoxy group, butyleneoxy group, or combination thereof, subject to the proviso that the molar ratio of ethyleneoxy groups to propyleneoxy groups and / or butyleneoxy groups in (Z)n is at least 2.9:1. Also in formula (I), m is on average from about 1.8 to about 5 and n is on average from about 8 to about 25. The dispersing agent is capable of attaining color development, freeze / thaw stability, and reduced water sensitivity similar to that achieved by widely-used APEOs.

Owner:BASF AG

Method for preparing emulsion composite antioxidant

The invention relates to a method for preparing an emulsion composite antioxidant, which comprises the following steps: feeding materials in a mass part ratio that DLTDP:(Wingstay.L:1076) is equal to 4:2, wherein Wingstay.L:1076 is equal to 0.5-1.5:1.5-0.5, based on the total weight of a raw material A, namely 100 percent, adding 3 to 8 percent of stearic acid and 0.5 to 1.5 percent of C4 to C18 straight chain alcohol or branched chain alcohol or the mixture of the straight chain alcohol and the branched chain alcohol, heating to perform reaction with stirring at the speed of 300 to 400rpm, adding KOH when the temperature reaches 70 to 90 DEG C, and controlling the pH value to be between 7 and 11; adding deionized water to make the solid content of the whole system be 53 to 56 percent, adding 30 percent of deionized water, adjusting the stirring speed to be between 180 and 250rpm, adding the rest of deionized water, and naturally cooling to room temperature. By adopting the method, an aqueous emulsion of the composite antioxidant of which the solid content is 53 to 56 percent, the pH is 7 to 11 and the viscosity is less than or equal to 1,200mpa.s (BROOKFIELD PV-11+Pro) is synthesized, and has high oxidation resistance, low viscosity and good dispersity.

Owner:天津力生化工有限公司

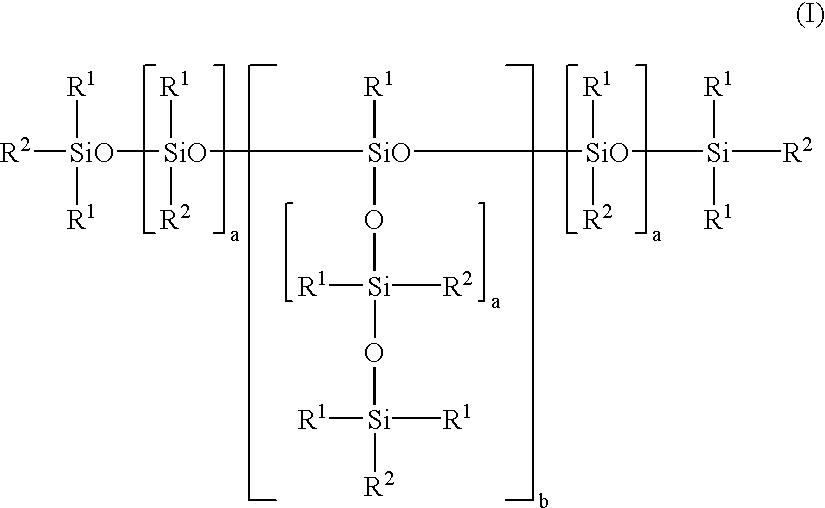

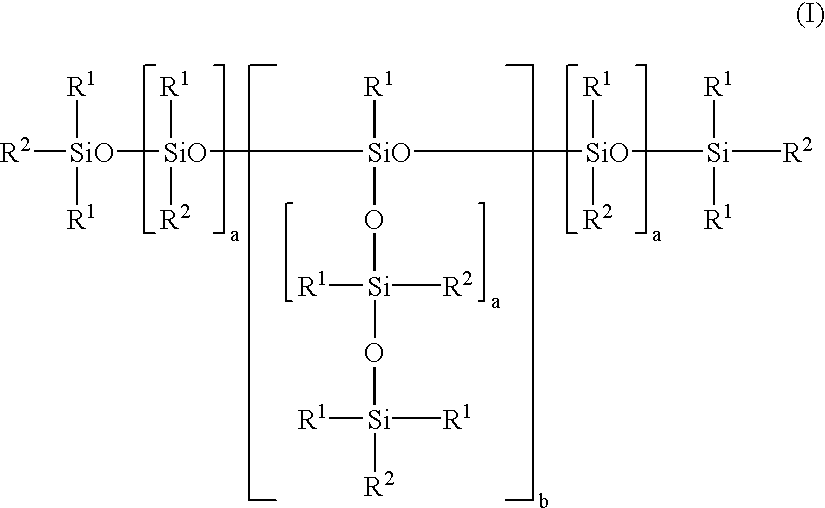

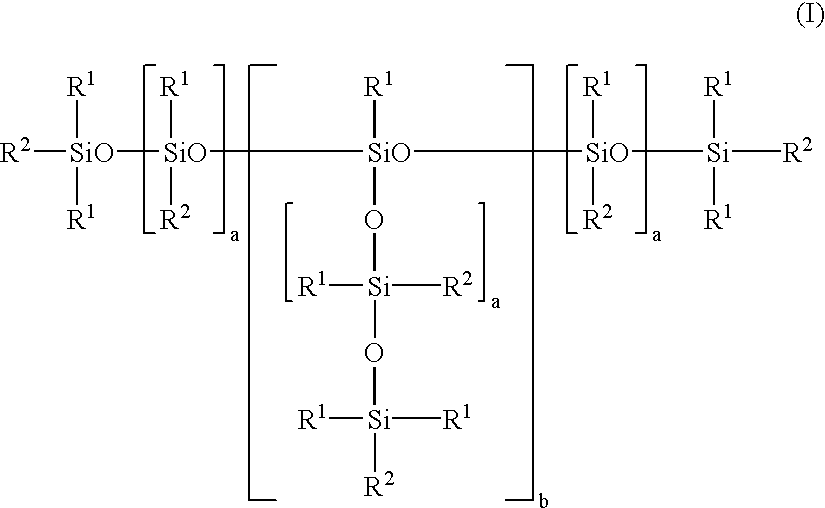

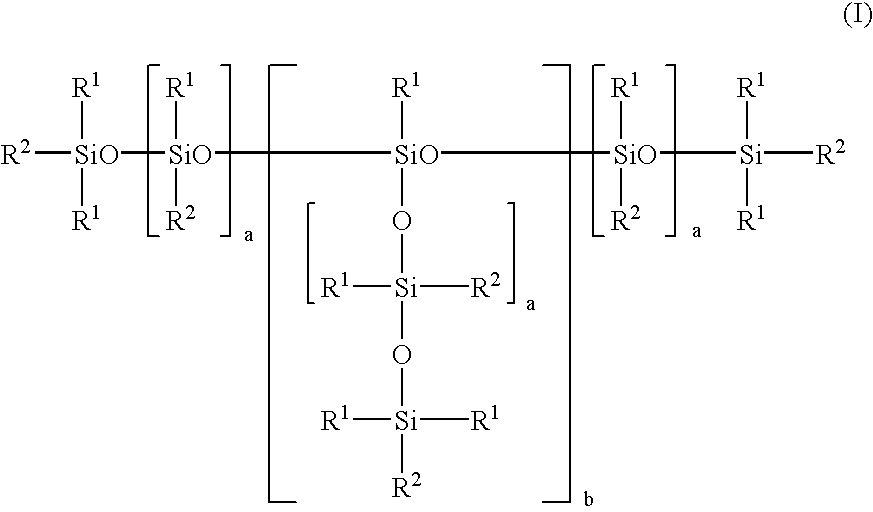

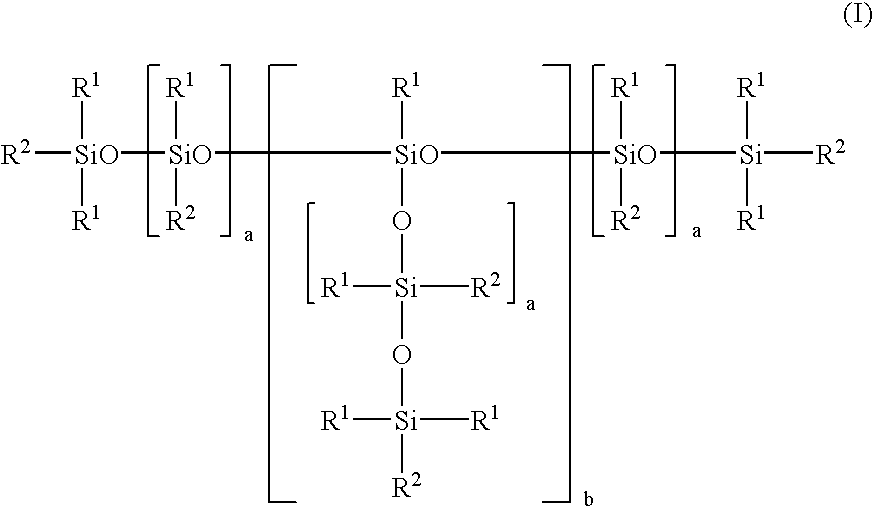

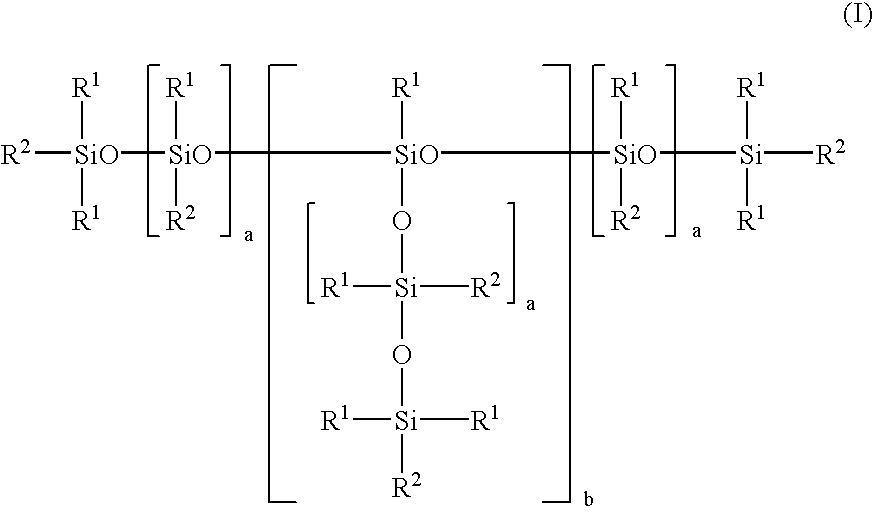

Use of mixtures of organofunctionally modified polysiloxanes with branched alcohols in the production of flexible polyurethane foams

The invention relates to the use of mixtures of organofunctionally modified polysiloxanes with branched alcohols in the production of flexible polyurethane foams.

Owner:EVONIK GOLDSCHMIDT GMBH

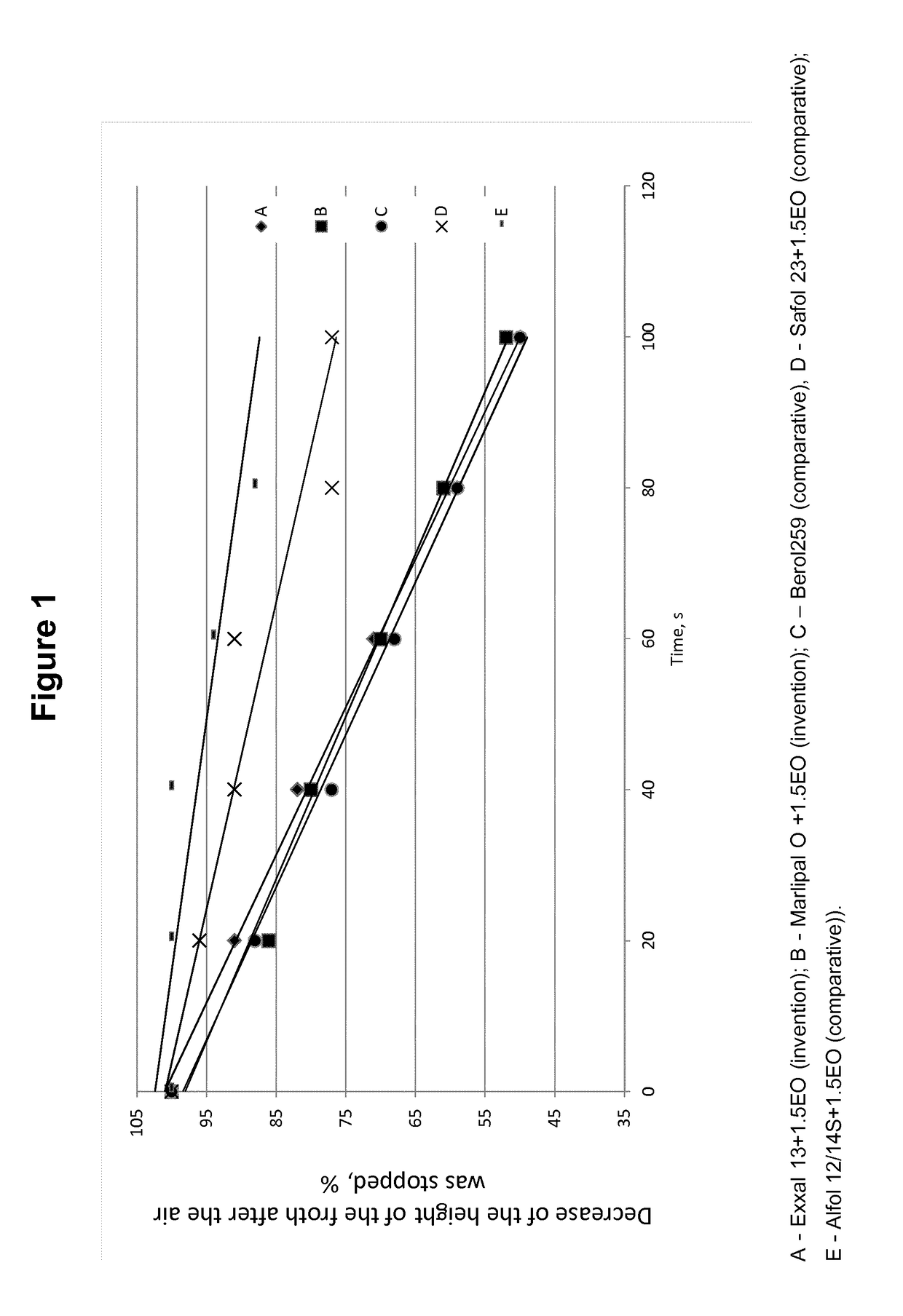

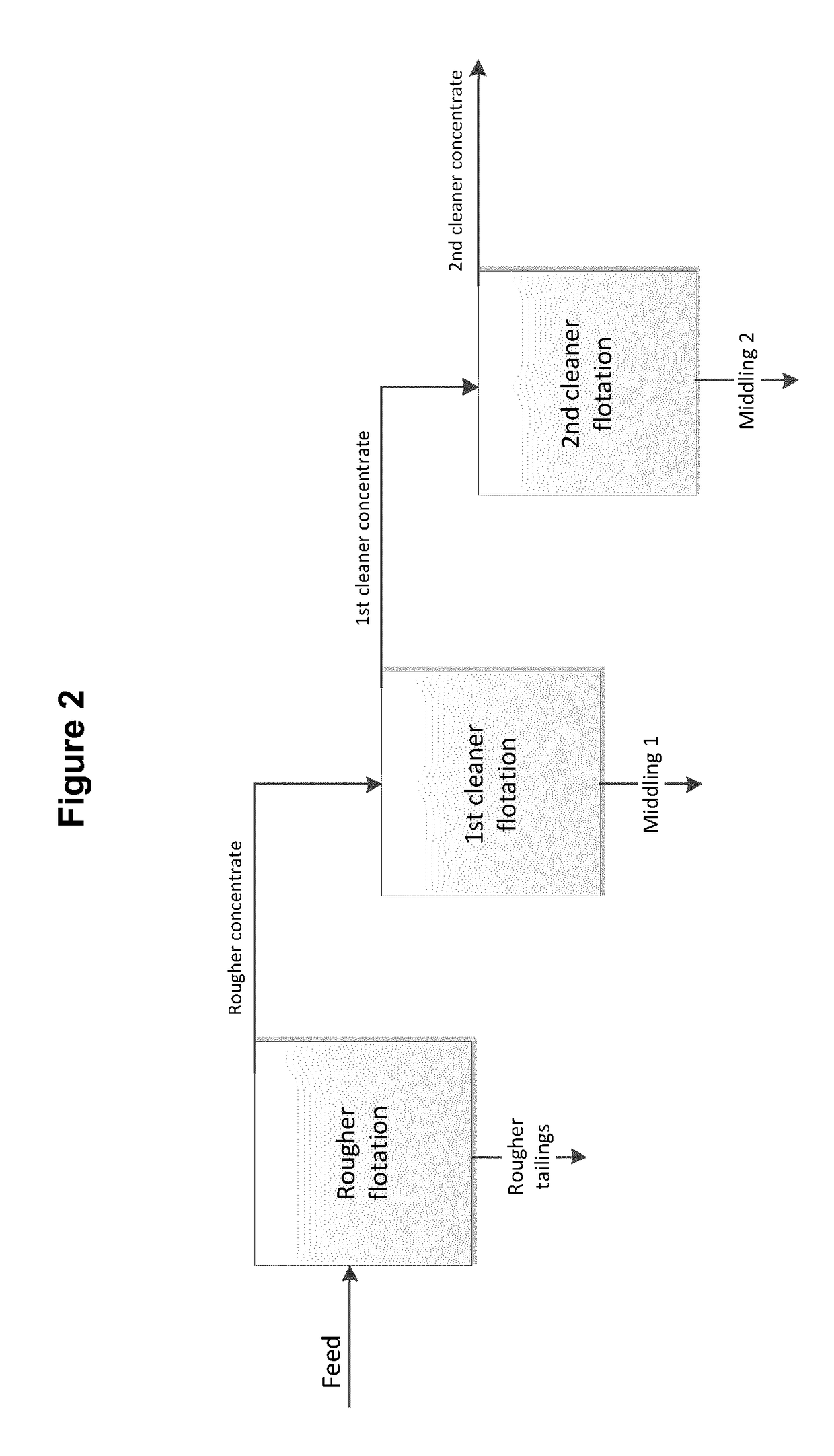

Mineral-floating foaming agent and its prepn

The present invention proposes one kind of mineral-floating foaming agent and its preparation. The foaming agent contains alcohol with branch chain and epoxy ethane and / or epoxy propane in the weight ratio of 1 to 1-6, and the alcohol with branched chain may be isopropyl alcohol, isobutyl alcohol or isoamyl alcohol. It is prepared through mixing alcohol with branched chain and epoxy ethane and / or epoxy propane, adding oxide of K or Na in 0.3-1% of material weight as catalyst, reaction at 0.01-1.2 MPa pressure and 170-190 deg.c temperature for 2-3 hr, decreasing the pressure to nomral pressure, cooling to below 50 deg.c and filtering. The foaming agent is water soluble, good in dispersivity, great in formed foam, favorable to secondary enrichment and recovery of fine mineral and has no environmental pollution.

Owner:WUHAN UNIV OF TECH

Composition as an additive to create clear stable solutions and microemulsions with a combustible liquid fuel to improve combustion

InactiveUS6946008B2Improved propertyReduce undesirable elementsLiquid carbonaceous fuelsFuel additivesParticulatesLiquid fuel

The present invention relates to an additive composition for a combustible fuel to produce improved combustion and reduced exhaust pollution of the combusted fuel, which additive composition comprises:a) one or more water-soluble alcohols having between 1 and 5 carbon atoms, in an anhydrous state or as a 0.5-36% aqueous solution, and one or more of the following:b) one or more straight- or branched-chain alcohols having between 6-18 carbon atoms;c) one or more ethoxylated alcohols having between 12 and 18 carbon atoms where the ethylene oxide add-on is less than 5 moles;d) a fatty acid of the structure R—(C═O)—OH having from 10 to 24 carbon atoms withe) a source of nitrogen in an anhydrous state or as an aqueous solution; wherein components a) to e), when combined with mixing with said combustible fuel, form a clear, stable microemulsion having a viscosity similar to the liquid fossil fuel. Combustion is improved and pollutant and particulate levels are reduced.

Owner:SAGA FUEL SYST

Cosmetic formulations of quaternary ammonium compounds incorporating polyhydric alcohols

InactiveUS7074395B2High proportionLow meltingCosmetic preparationsBiocideSolubilityAmmonium compounds

Cosmetic, dermatological and pharmaceutical compositions containing quaternary ammonium compounds, particularly for hair-treatment, require low setting points, good solubility and dispersibility in aqueous media and a low flash point. It has now been found that such compositions can be formulated with quaternary ammonium compounds and polyhydric alcohols. The invention provides compositions comprisinga) at least one quaternary ammonium compound,b) at least one branched alcohol having 8 to 36 carbon atoms or a mixture of at least one branched alcohol and at least one unbranched alcohol having 8 to 36 carbon atoms, andc) at least one polyhydric alcohol having 2 to 6 carbon atoms.The resulting compositions have a low setting point or melting point, good solubility and dispersibility in aqueous media and a low flash point.

Owner:CLARIANT PROD DEUT GMBH

Method of preparing biological diesel oil containing side chain fatty acid ester

InactiveCN101058742AImprove low temperature fluidityLower condensation pointBiofuelsLiquid hydrocarbon mixture productionOil and greaseBranched chain fatty acids

The invention discloses a method preparing for a biological diesel with the branched chain fatty acid ester, which comprises the following steps: mixing the natural grease, the frying scavenge oil or the trench oil with carbinol, alkyl(the range of carbon atomicity is 3-7), the carbinol type branched chain alcohol(the boiling point is under 155Deg. C) or no branched chain carbinol type branched chain alcohol on alpha-carbon atom; adding the accelerant preparing for the biological diesel( the mole ratio of the carbinol and the grease is 1-6:1; the mole ratio of the branched chain alcohol and the grease is 3-20:1; the accelerant consumption of the esterifying reaction is 0. 3%-5% grease weight); reacting 20-90min at 40Deg. C-100Deg. C; getting the product A; distilling the product A; getting the upper layer biological diesel and the lower layer glycerin after stratifying the rest product in the knockout drum. The invention changes the low temperature floating property of the product, which improves the caloric value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Integrated Fischer-Tropsch process for production of linear and branched alcohols and olefins

ActiveUS6982355B2Increase productionHigh yieldHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonAlcoholAlpha-olefin

Owner:REG SYNTHETIC FUELS LLC

Esters comprising branched alkyl groups as lubricants

A process for improving the oxidation stability of lubricants including providing one or more esters containing branched alkyl groups which are reaction products of branched alcohols with a) one or more aliphatic dicarboxylic acids corresponding to general formula (II): HOOC—R2—COOH in which R2 is a branched or unbranched, saturated alkyl group containing 0 to 34 carbon atoms, or b) one or more saturated branched monocarboxylic acids corresponding to general formula (III): R3—COOH in which R3 is a branched alkyl group of 3 to 39 carbon atoms, or c) one or more saturated monocarboxylic acids corresponding to general formula (III) in which R3 is a linear alkyl group of 3 to 29 carbon atoms, or d) a mixture thereof, as lubricants, with the proviso that the esters have an oxidation stability of 1000 hours or more, as determined by the Turbine Oil Stability Test (TOST test) to DIN EN ISO 4263-3.

Owner:COGNIS IP MANAGEMENT GMBH

Method for preparing low temperature epoxy fatty acid branched-chain alcohol ester improver for biodiesel and application thereof

The invention discloses a method for preparing a low temperature epoxy fatty acid branched-chain alcohol ester improver for biodiesel and application thereof. The method comprises the steps of taking natural oil and branched-chain alcohol as raw materials to react in the presence of a catalyst, and carrying out distilling, standing and layering on the product to obtain supernatant fatty acid branched-chain alcohol ester; and then mixing the fatty acid branched-chain alcohol ester with formic acid, adding an epoxidation catalyst, reacting while dropwise adding hydrogen peroxide, and carrying out standing, layering, neutralizing and dewatering on the product to obtain epoxy fatty acid branched-chain alcohol ester. The invention develops an epoxy fatty acid branched-chain alcohol ester improver aiming at the characteristics of biodiesel. The method has the following beneficial effects: by branching bonds of fatty acid ester and introducing a polar group onto the interior double bond structure of the fatty acid ester, the improver can be easily mixed with the biodiesel to form uniform solution, thus being beneficial to blocking further growth of solid crystals; and after different oil-based biodiesels and the improver are mixed, the low temperature fluidity of the biodiesels can be obviously improved, the condensation point and cold filter point can be reduced by 5-15 DEG C, the calorific value can be improved, and the viscosity can be reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Catalyst for synthesizing higher branched chain alcohol and preparation method and application of catalyst

ActiveCN107983356AEasy to separateReduce manufacturing costOrganic compound preparationHeterogenous catalyst chemical elementsSilicon oxideHigh activity

The invention discloses a catalyst for synthesizing a higher branched chain alcohol. The catalyst for synthesizing the higher branched chain alcohol comprises MgO, CuO, M1 and M2, the weight percentage of MgO to CuO to M1 to M2 is 100:(3-10):(5-20):(1-5), the M1 is one of silicon oxide, aluminum oxide, titanium oxide, cerium oxide or zirconium oxide, and the M2 is one of zinc oxide, ferric oxide,nickel oxide, chromium oxide and lanthanum oxide. The catalyst has the advantages of high activity and high selectivity and high stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

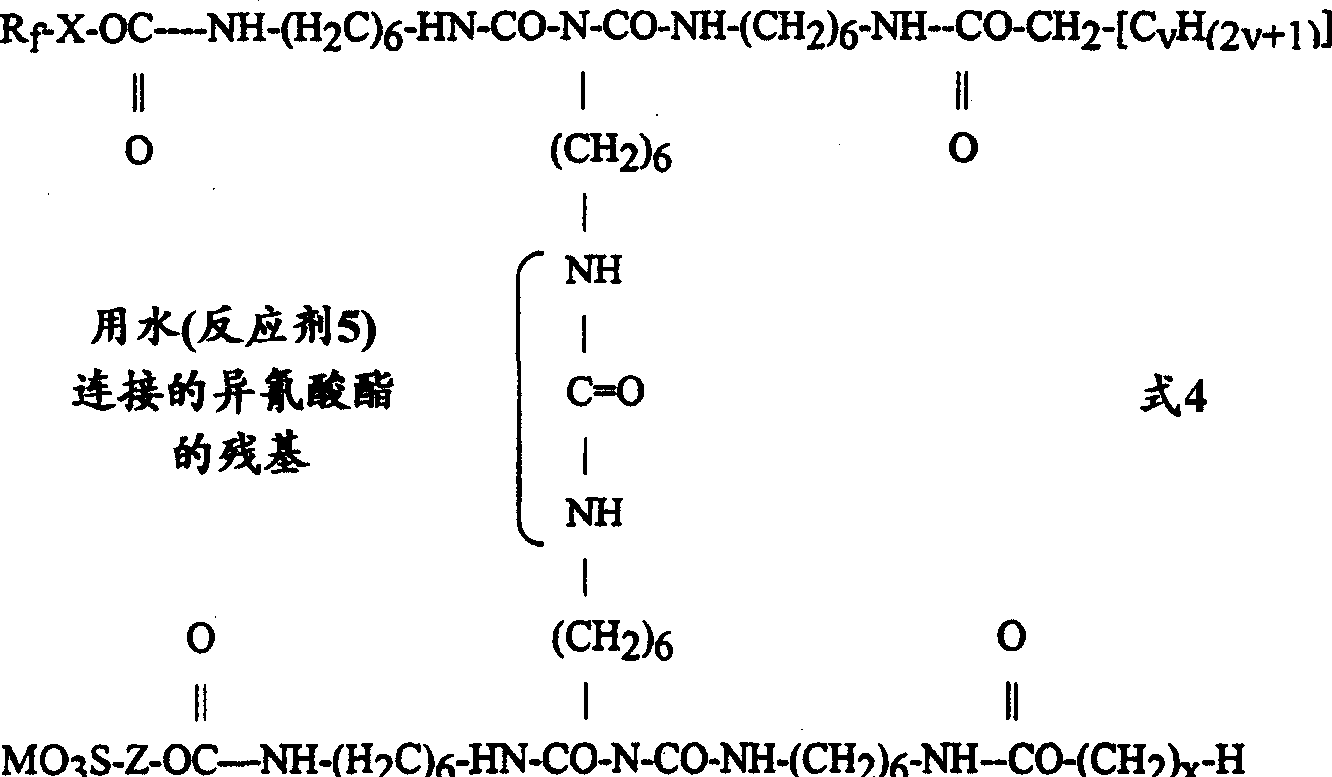

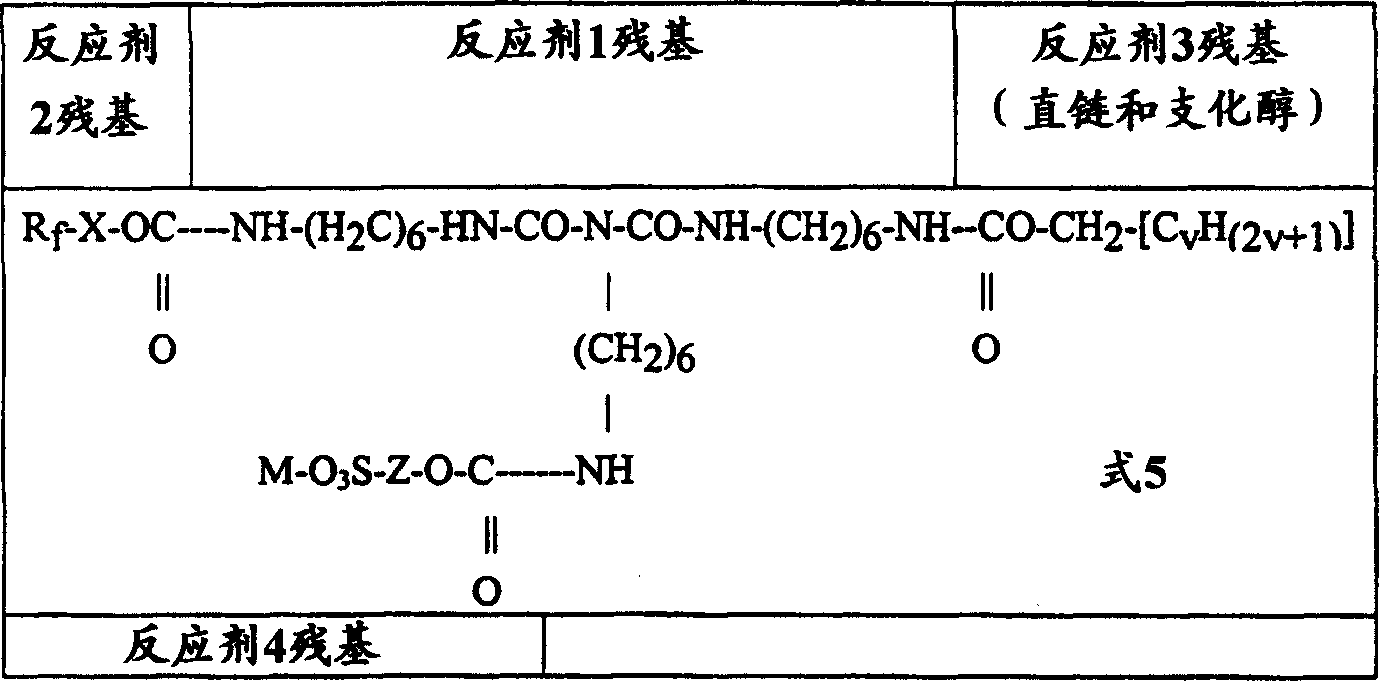

Fluorochemical water and oil repellents

A polymer having at least one urea linkage derived by contacting (1) at least one polyisocyanate, or mixture of polyisocyanates, (2) at least one fluorocarbon alcohol, fluorocarbon thiol or fluorocarbon amine, (3) at least one straight or branched chain alcohol, amine or thiol, and (4) at least one alcohol containing a sulfonic acid group or its salt, and then (5) optionally at least one linking agent useful for imparting oil repellency and water repellency to substrates.

Owner:EI DU PONT DE NEMOURS & CO

Production of branched-chain alcohols by photosynthetic microorganisms

The present invention provides genes, polypeptides and expression constructs therefor, recombinant photosynthetic microorganisms, and method of use thereof, such as for the production of branched-chain alcohols (including 2-methyl-1-butanol, 3-methyl-1-butanol, and isobutanol) and derivatives thereof for a variety of uses.

Owner:SYNTHETIC GENOMICS INC

Ion liquid catalyst of esterification reaction, preparation method and usage

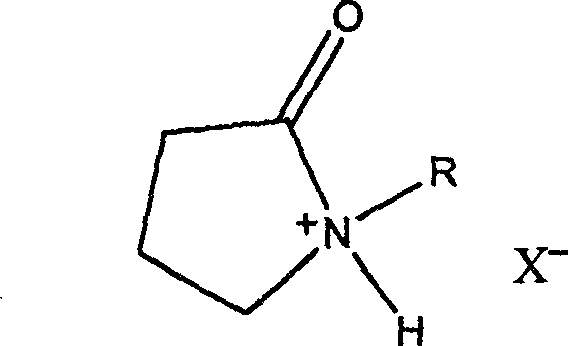

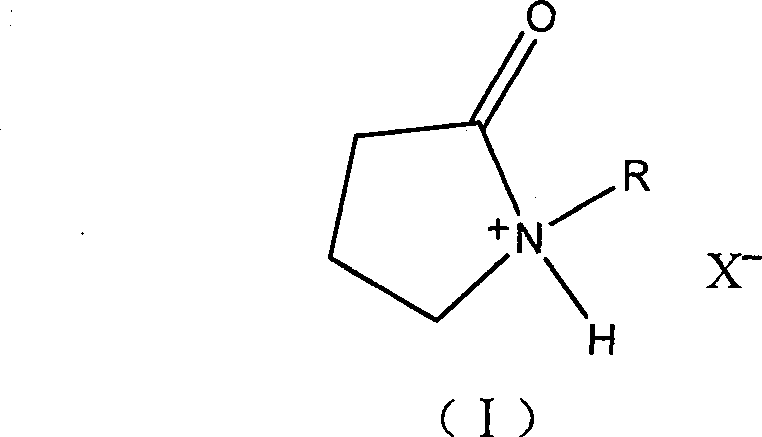

InactiveCN100503043CEasy to synthesizeLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystChemical reaction

A liquid catalyst containing N-alkylpyrrolidone-yl Bronsted acid ions for esterifying reaction has high transform rate, selectivity and cyclic life (more than 20). Said esterifying process includes such steps as providing fatty acid or aromatic acid and straight- or branch-chain alcohol, mixing while adding said catalyst used also as solvent, stirring, heating, laying aside, gravitational depositing, and separating liquid to obtain the esterified product.

Owner:WUHAN UNIV

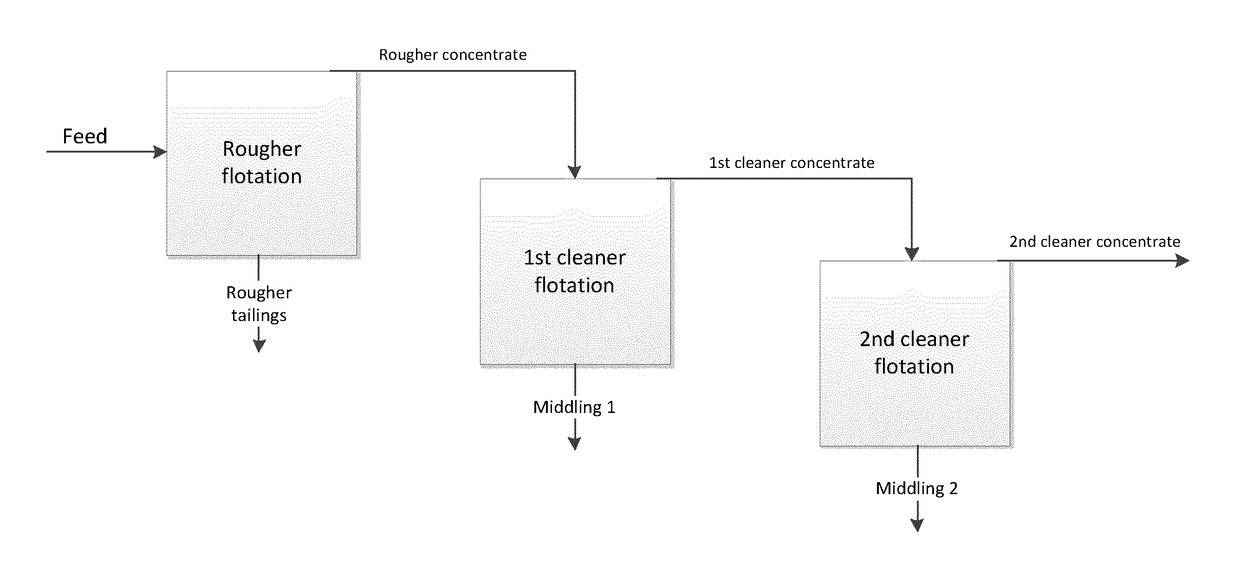

Use of Branched Alcohols and Alkoxylates Thereof as Secondary Collectors

The present invention relates to the use of branched fatty alcohol-based compounds selected from the group of fatty alcohols with 12-16 carbon atoms having a degree of branching of 1-3, and their alkoxylates with a degree of ethoxylation of up to 3, as secondary collectors for the froth flotation of non-sulfidic ores, incombination with a primary collector selected from the group of amphoteric and anionic surface active compounds.

Owner:AKZO NOBEL CHEM INT BV

Method for preparing N-acetylglucosamine

InactiveUS7511134B1Reduce yieldEasy to separateSugar derivativesProtective equipmentAcetic anhydrideSlurry

A method for preparing n-acetylglucosamine starting from glucosamine base having a purity level of at least about 99 wt. % and a maximum halide content of about 0.01 wt %. The glucosamine base is slurried in a diluent comprising a C1-C4 straight or branched-chain alcohol, e.g., isopropyl alcohol, sec. butyl alcohol, tert. butyl alcohol, etc. Thereafter, an acylating agent, e.g., acetic anhydride, present in at least a stoichiometric amount, is slowly added to the slurry while maintaining the reaction mixture at a temperature below about 20° C. The n-acetylglucosamine prepared by the process of the invention will be quite pure, e.g., it will have a purity of at least 98%, as measured by HPLC, a melting point in the range of 196-205° C. and a specific rotation, measured at room temperature after standing in water for several hours, of [α]D=39-43°.

Owner:JF C TECH

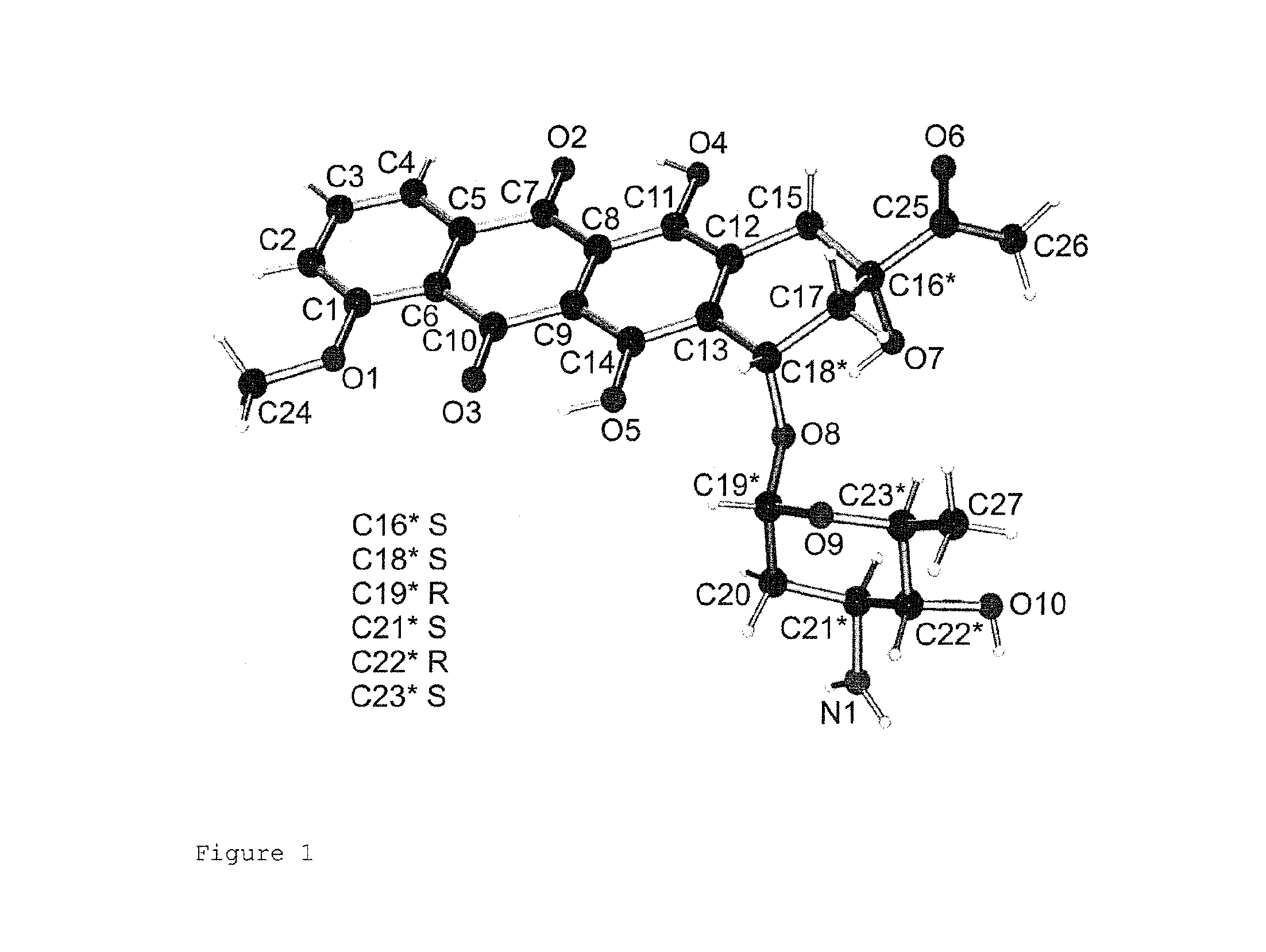

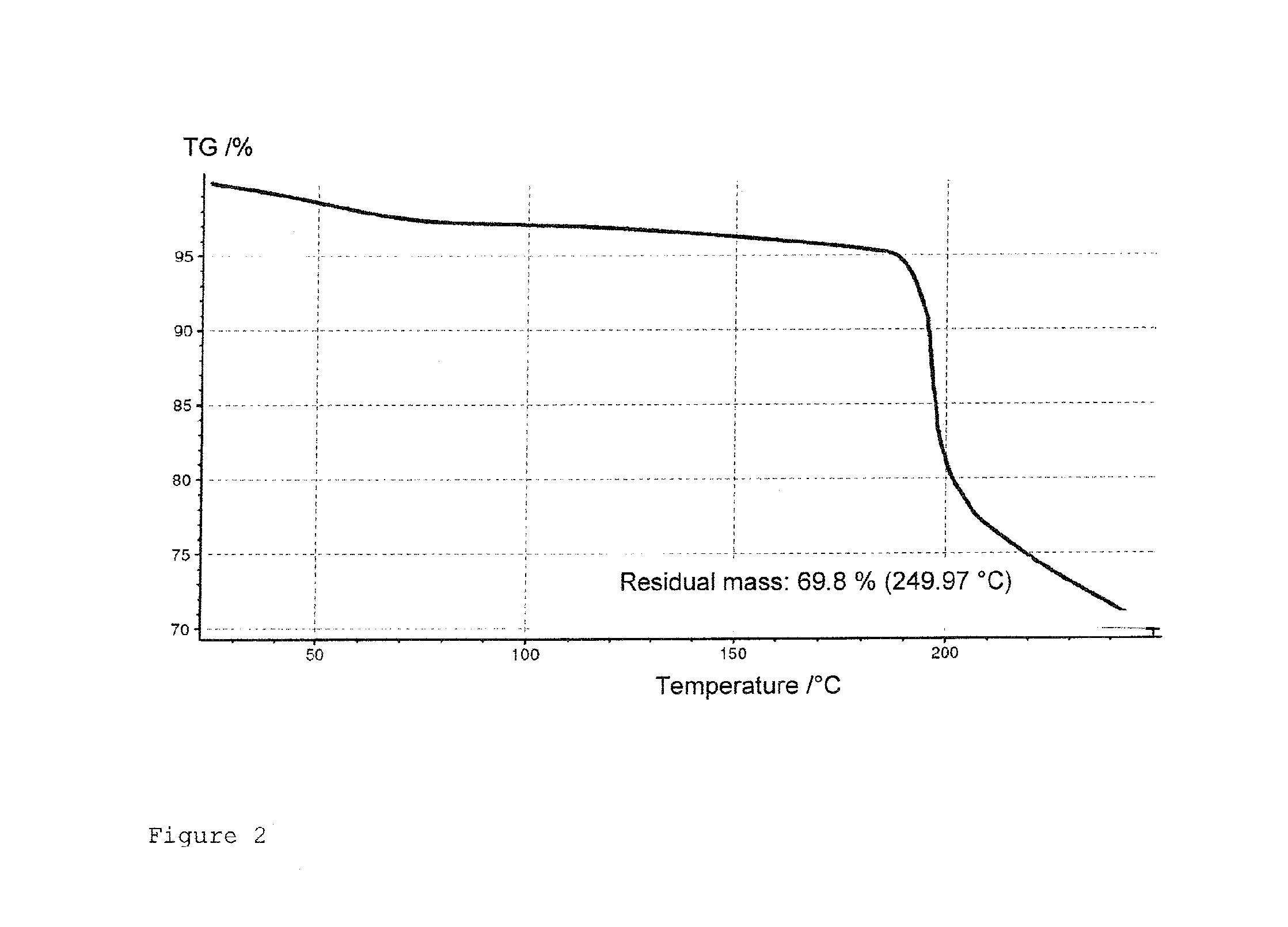

Crystallization of 4′-epidaunorubicin hydrochloride

ActiveUS8686164B2Readily solubleImprove solubilitySugar derivativesOrganic chemistry methodsCrystallographySolubility

4′-epidaunorubicin hydrochloride is provided in a crystalline form which is stable and readily soluble. A process of producing the crystalline form includes crystallizing 4′-epidaunorubicin hydrochloride in a solvent system including (a) solvent A selected from C1 and C2 halogenated solvents and mixtures thereof, (b) solvent B selected from C1-C5 straight and branched alcohols and mixtures thereof, and (c) solvent C selected from C1-C5 straight and branched alcohols and mixtures thereof, wherein solvent C is selected to provide lower solubility to 4′-epidaunorubicin hydrochloride than solvent B.

Owner:MEDAC GES FUR KLINISCHE SPEZIALPRAPAR MBH

Use of mixtures of organofunctionally modified polysiloxanes with branched alcohols in the production of flexible polyurethane foams

The invention relates to the use of mixtures of organofunctionally modified polysiloxanes with branched alcohols in the production of flexible polyurethane foams.

Owner:EVONIK GOLDSCHMIDT GMBH

Detergent for fiber fabric

InactiveCN103897849AStrong decontaminationModerate foamNon-ionic surface-active compoundsDetergent compounding agentsGlycerolDioxyethylene Ether

The invention discloses a detergent fiber fabric, which is made by the weight of raw materials: 10-15 parts of sodium alkylbenzenesulfonate, 10-15 parts of branched-chain alcohol polyoxyethylene ether, 15 parts of sodium laureth sulfate, 5-7 parts of propylene glycol block polyether, 1-2 parts of protease, 0.1-0.3 part of sorbate, 10-15 parts of glycerol, 10-15 parts of ethanol and 0.5-1.2 parts of a stabilizer. The detergent formula provided by the invention utilizes synergistic effect of sodium alkylbenzenesulfonate and protease to realize decontamination and cleaning; the superfine fiber fabric detergent provided by the invention has strong decontamination force, can meet the requirements of hand washing and machine washing, and can be used for cleaning the superfine fiber fabrics such as towels and bath towel, without causing the problems of hardening, yellowing and poor water absorption of the superfine fiber fabric, and the washed superfine fiber fabric has certain anti-electrostatic ability, and does not need a fabric softener, so as to avoid the problems of poor water absorption caused by the fabric softener in the prior art.

Owner:QINGDAO JINLIANXIN BUSINESS & TRADE

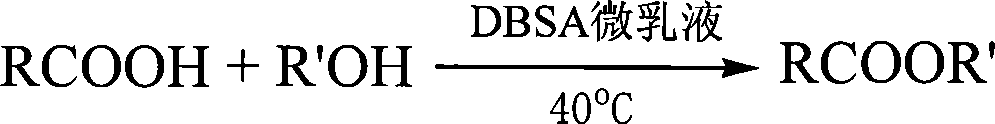

Method for synthesizing ester in dodecyl benzene sulfonic acid reverse micro emulsion

InactiveCN101177396AWide variety of sourcesLow costOrganic compound preparationCarboxylic acid esters preparationChemical reactionSynthesis methods

The invention relates to an ester synthesis method, belonging to an organic chemical reaction method. In the dodecyl benzene sulfonic acid (DBSA) used as catalyst and surface-active material, an esterification reaction is implemented to the fatty acid and straight chain alcohol, the branched chain alcohol and the alcohol with unsaturated link and aromatic alcohol; under mild conditions, the conversion rate of the reaction can reach 74 percent to 99 percent. The invention enables the DBSA to be dissolved into the cyclohexane, the quantitative buffer solution is added into the cyclohexane solution, and then alcohol and acid are added for esterification reaction. The invention has the advantages of high conversion rate, high applicability, simple process, mild condition, recyclability of DBSA and environmental friendliness.

Owner:NORTHEAST NORMAL UNIVERSITY

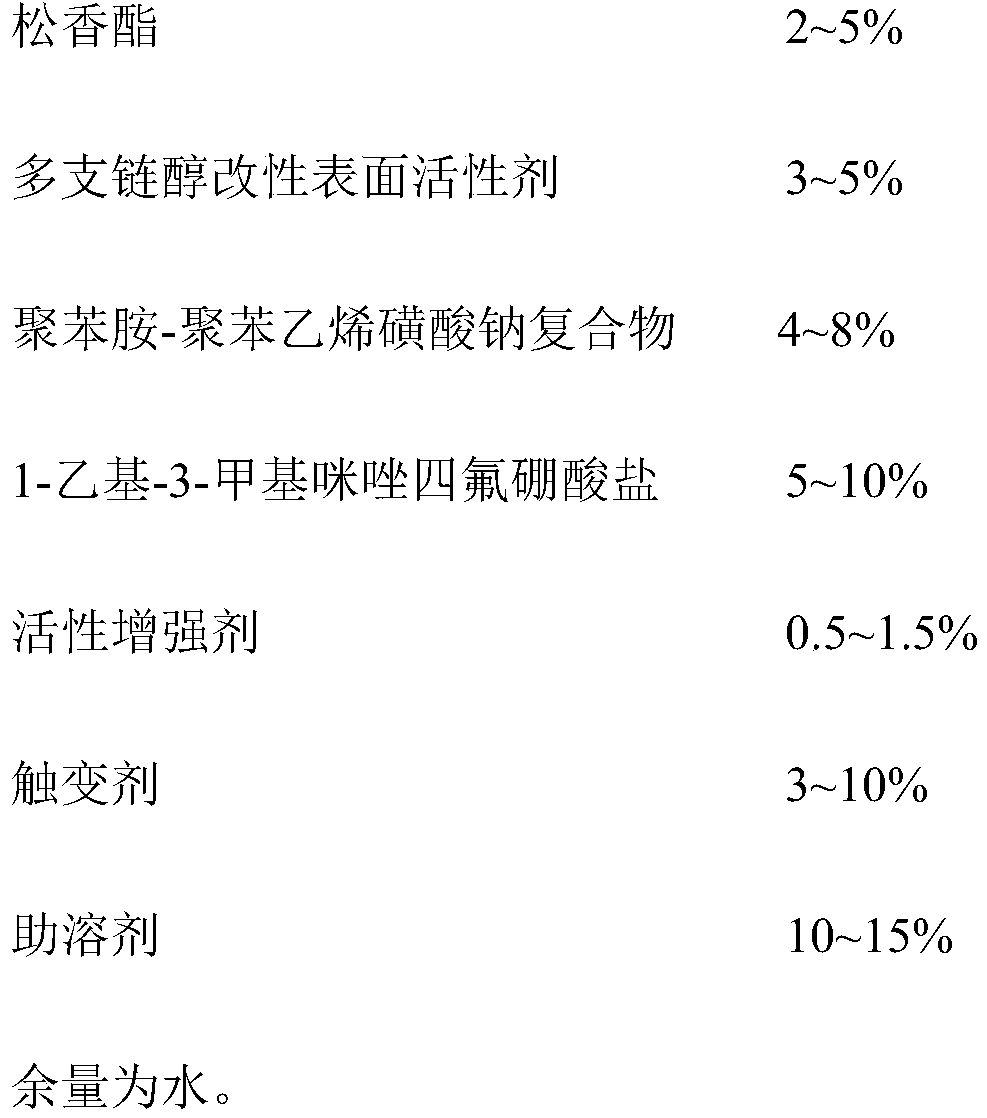

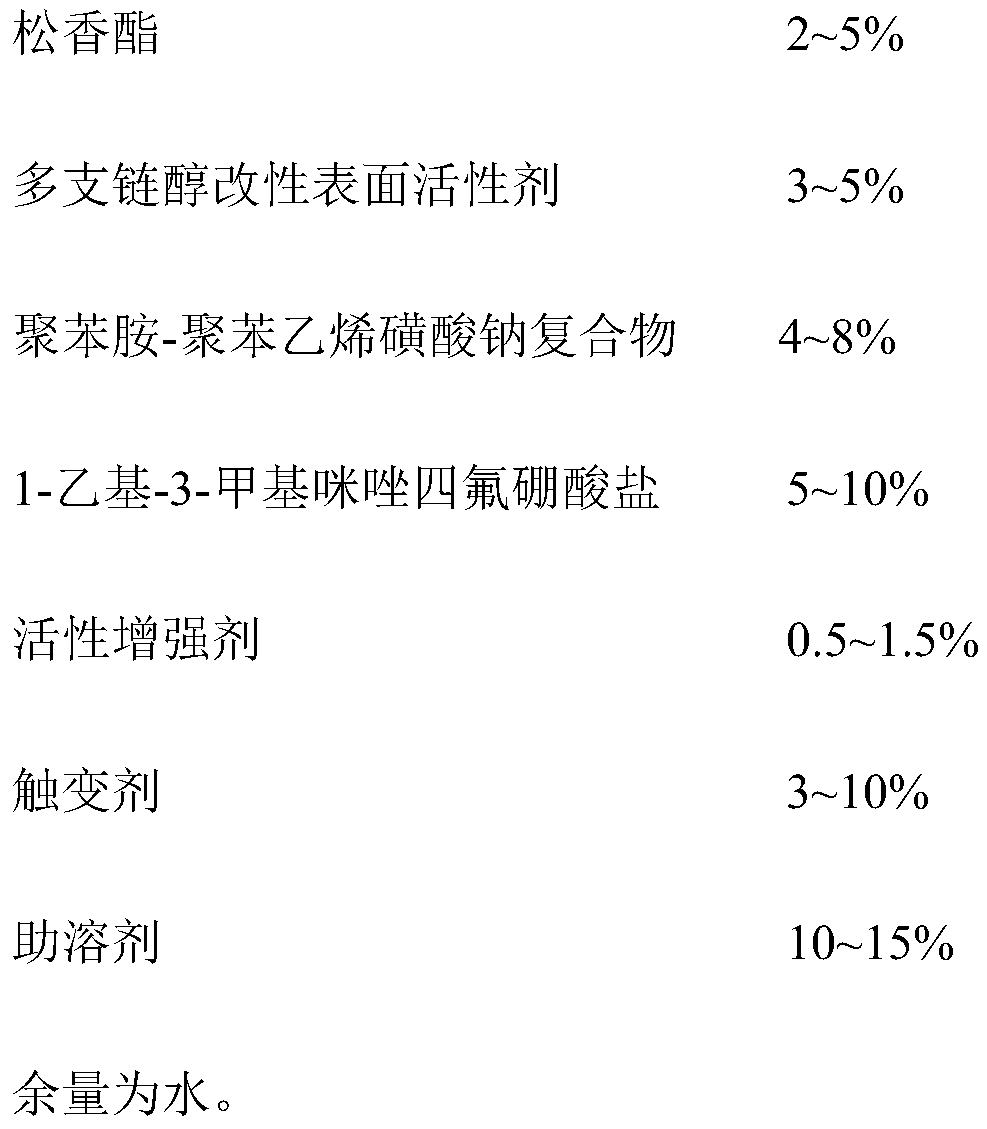

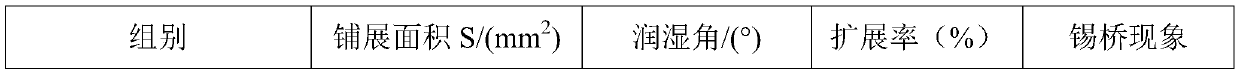

Soldering flux and preparation method thereof

ActiveCN110328467AFumbleGood film formingWelding/cutting media/materialsSoldering mediaWater basedSolvent

The invention discloses a soldering flux and a preparation method thereof. The soldering flux comprises the following components of, in percentage by mass, 2%-5% of rosin ester, 3%-5% of multi-branched-chain alcohol modified surfactants, 4%-8% of polyaniline-sodium polystyrenesulfonate compounds, 5%-10% of 1-ethyl-3-methylimidazolium tetrafluoroborate, 0.5%-1.5% of active enhancers, 3%-10% of thixotropic agents, 10%-15% of cosolvents and the balance water. The soldering flux overcomes the defects that an existing water-based cleaning-free soldering flux cannot inhibit the formation of a tin bridge of a soft solder, and has the characteristics that the soldering flux is high in soldering activity, strong in solderability, less in residue, high in surface insulation resistance, low in corrosivity, good in storage stability, good in applicability to lead-free soldering and free of cleaning requirements.

Owner:浙江强力控股有限公司

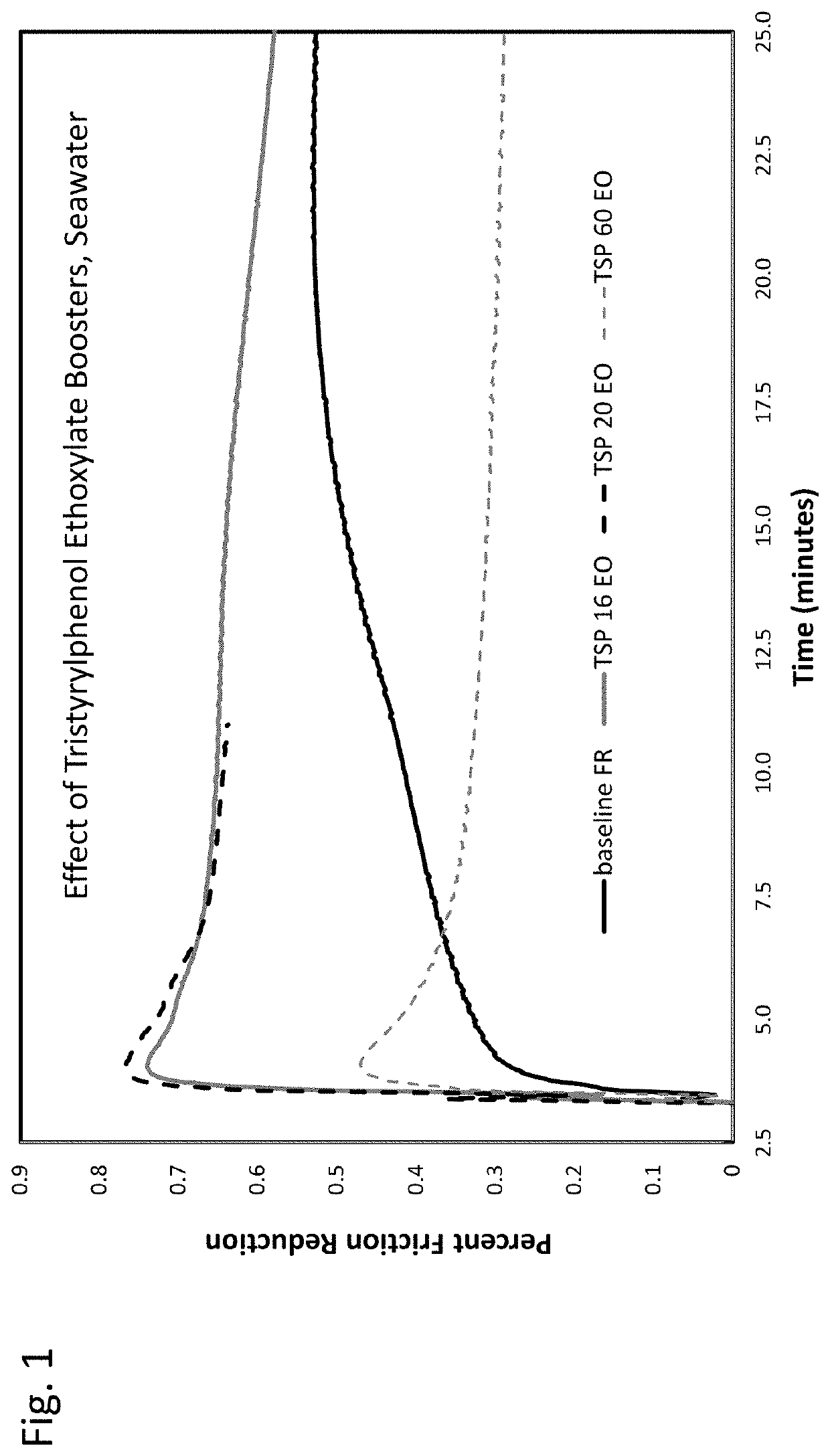

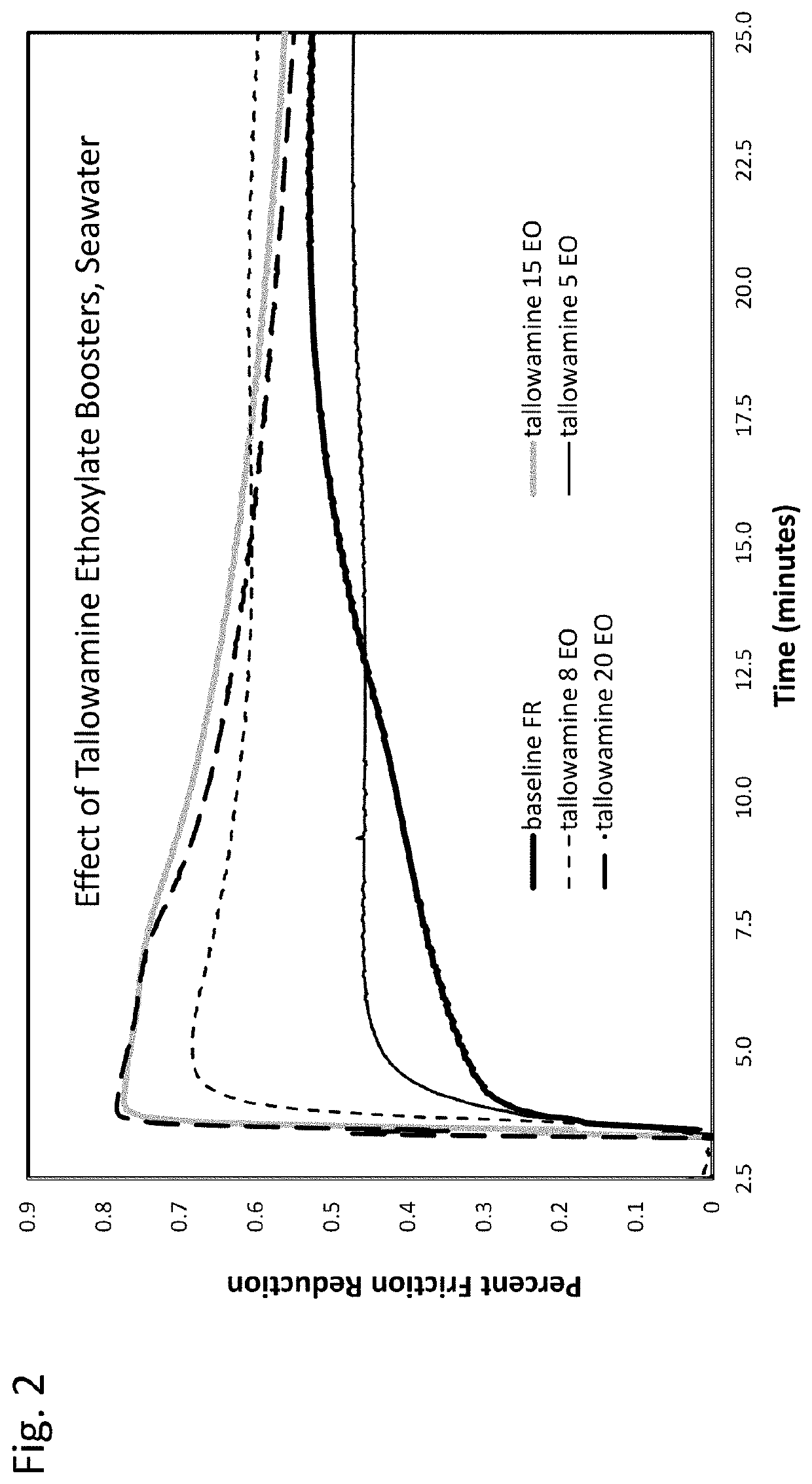

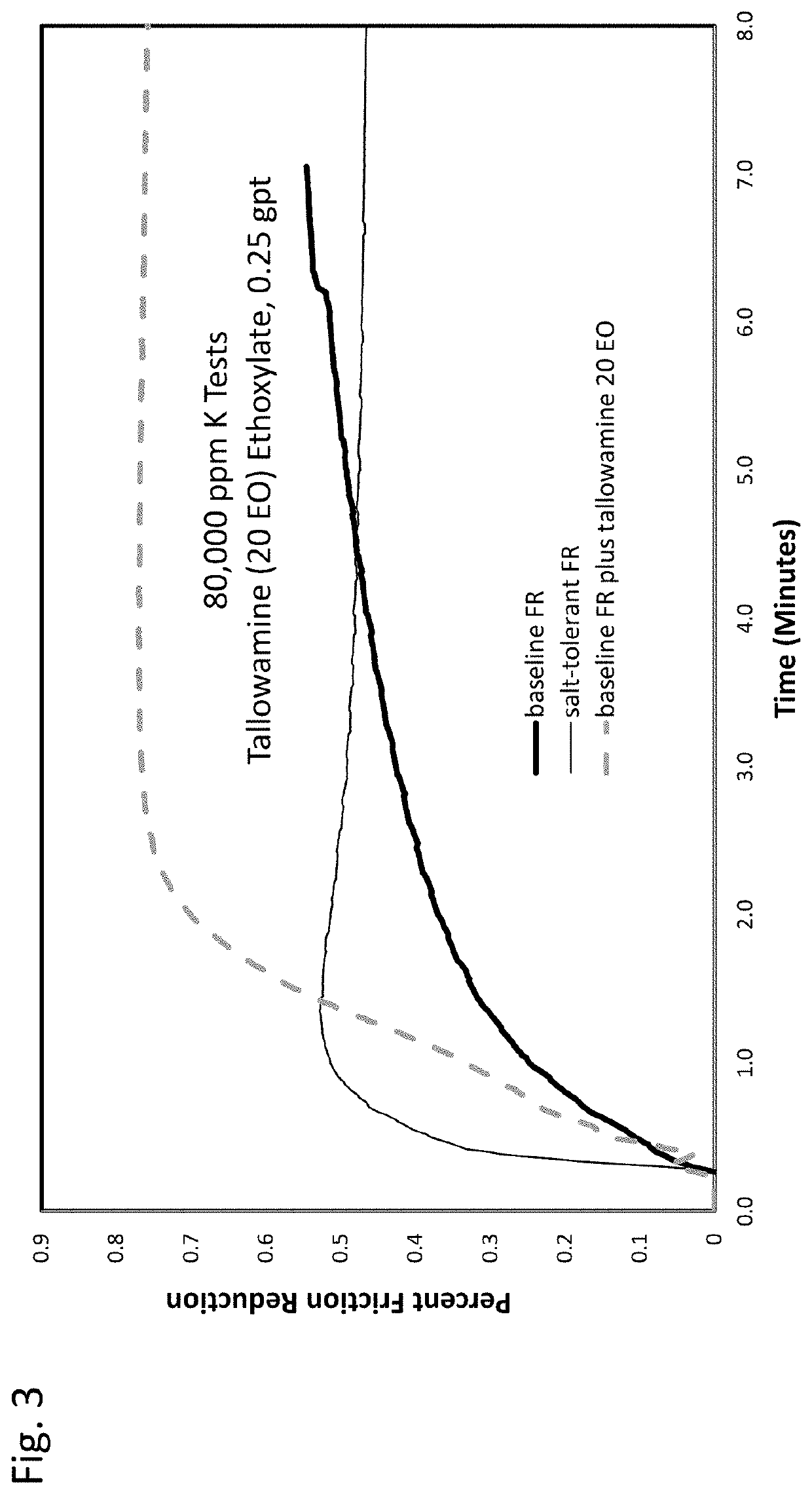

Friction reducer for hydraulic fracturing

ActiveUS20200190397A1Promote rapid inversionGood benefitDrilling compositionLubricant compositionAmine ethoxylateActive agent

Compositions comprising an acrylamide polymer emulsion and a nonionic surfactant suitable for use as friction reducers for hydraulic fracturing are disclosed. The nonionic surfactants include aralkylated phenol ethoxylates, amine ethoxylates, amidoamine ethoxylates, linear or branched alcohol EO / PO alkoxylates, ethoxylated alcohols, alkylphenol ethoxylates, and EO-capped poly(oxypropylene) block copolymers. Improved hydraulic fracturing processes in which an acrylamide polymer emulsion is used as a friction reducer are also described. In these processes, the surfactant is included in the composition with the acrylamide polymer friction reducer, or it is introduced separately into the process. The performance of low-cost polyacrylamide friction reducers can be boosted with a small proportion of certain readily available nonionic surfactants. The inventive compositions are effective in high-salinity environments, and their performance can sometimes exceed that of more-expensive salt-tolerant friction reducers, thereby reducing fresh water demand and enabling greater utilization of produced water.

Owner:STEPAN COMPANY

Production and Use of Monoglycerides

A higher-yielding process for the production of monoglycerides in which triglycerides are enzymatically reacted with a catalytic amount of an esterase, preferably lipase, that has been activated by the addition of alkaline salts, in the presence of linear or branched alcohols containing 1 to 8 carbon atoms, then the esterase may be deactivated and it and the remaining alcohol removed, with the monoglycerides thus produced useful in lubricants, fuel additives, and emulsifying constituents in foods, and cosmetic and / or pharmaceutical formulations.

Owner:COGNIS IP MANAGEMENT GMBH

Composition and methods for processing a sputum sample

The present disclosure relates to a composition and its use for treating a sputum sample suspected to contain mycobacteria. The composition comprises thymol, a linear or branched alcohol, a chaotropic agent, a reducing agent, a detergent, and a buffer, and has a pH value between 8.5 and 10. Also disclosed is a method for treating a sputum sample suspected to contain mycobacteria.

Owner:ROCHE MOLECULAR SYST INC

Polycarbonate polyol and polyurethane

ActiveUS20190315908A1Increase flexibilityGood solvent resistanceOrganic chemistryPolymer scienceBranched chain alcohol

Provided is a polycarbonate polyol used as a raw material of a polyurethane that has an excellent balance of flexibility, mechanical strength and solvent resistance. The polycarbonate polyol includes structural units derived from a polyhydric alcohol and has a hydroxyl value of 20 to 450 mg KOH / g. The polyhydric alcohol includes: a diol (A) containing not less than 70% by weight of a specific oxyalkylene glycol (A1); and a trihydric to hexahydric branched alcohol (B) having 3 to 12 carbon atoms. In the polycarbonate polyol, structural units derived from the branched alcohol (B) is contained in an amount of 0.005 to 5.0% by mole in the structural units derived from the polyhydric alcohol. A ratio of a structural unit (X1) represented by the following Formula (X1) in the structural units derived from the branched alcohol (B) is not higher than 50% by mole.

Owner:MITSUBISHI CHEM CORP

Bactericidal washing soap moderate in performance

InactiveCN104845776AImprove decontamination abilityMild performanceSurface-active non-soap compounds and soap mixture detergentsSodium acetateSodium metasilicate

A bactericidal washing soap moderate in performance is manufactured by, by weight, the following raw materials including salicylic acid 6-14 parts, sodium percarbonate 3-10 parts, ethyl alcohol 3-8 parts, lard oil 8-14 parts, sodium metasilicate pentahydrate 7-11 parts, sodium carboxymethyl cellulose 3-8 parts, protease 2-4 parts, glycine betaine 1-5 parts, sodium perborate 6-10 parts, sodium citrate 3-5 parts, sodium polyacrylate 2-8 parts, sodium stearate 4-10 parts, glycerin 5-10 parts, C14 branched secondary alcohol ethoxylates 5-13 parts, natural soap powder 3-5 parts, nitrilotriacetic acid trisodium salt 8-11 parts and sorbitol 6-12 parts. The bactericidal washing soap moderate in performance has the advantages of being good in dirt-removing power, moderate in performance, free of harm to skin and meanwhile having good bactericidal effect.

Owner:QINGDAO DONGCHANGRUI TEXTILE

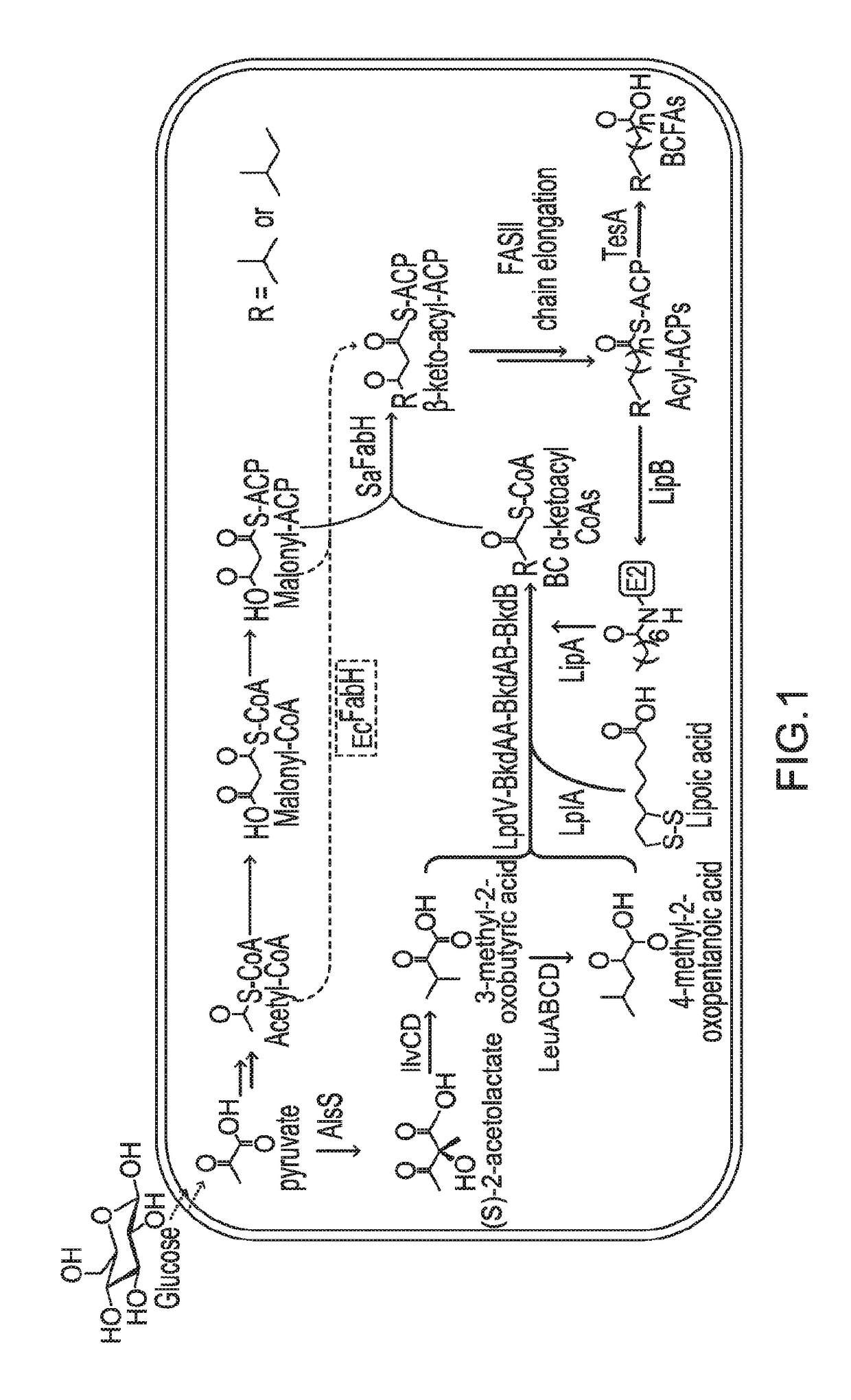

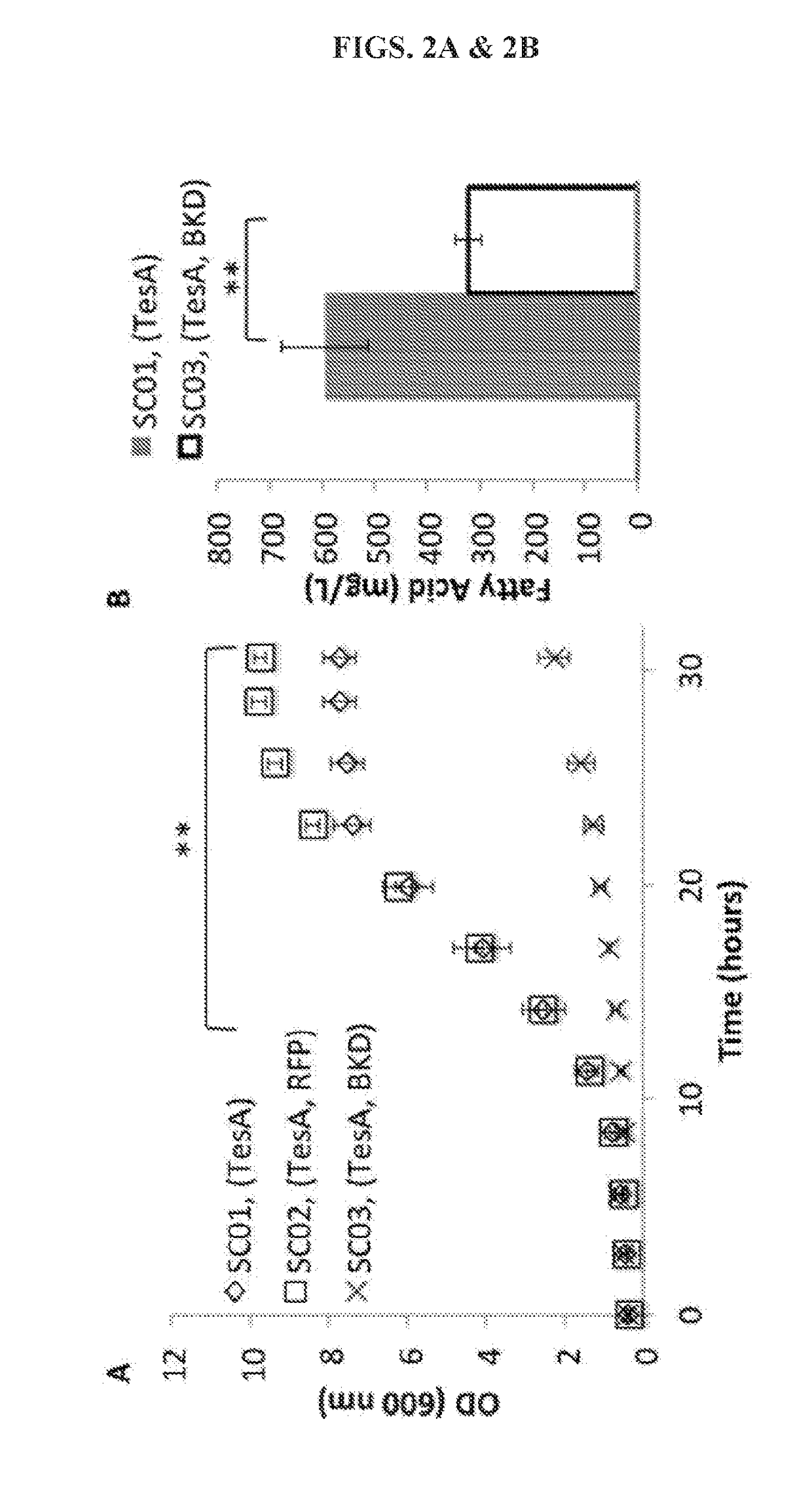

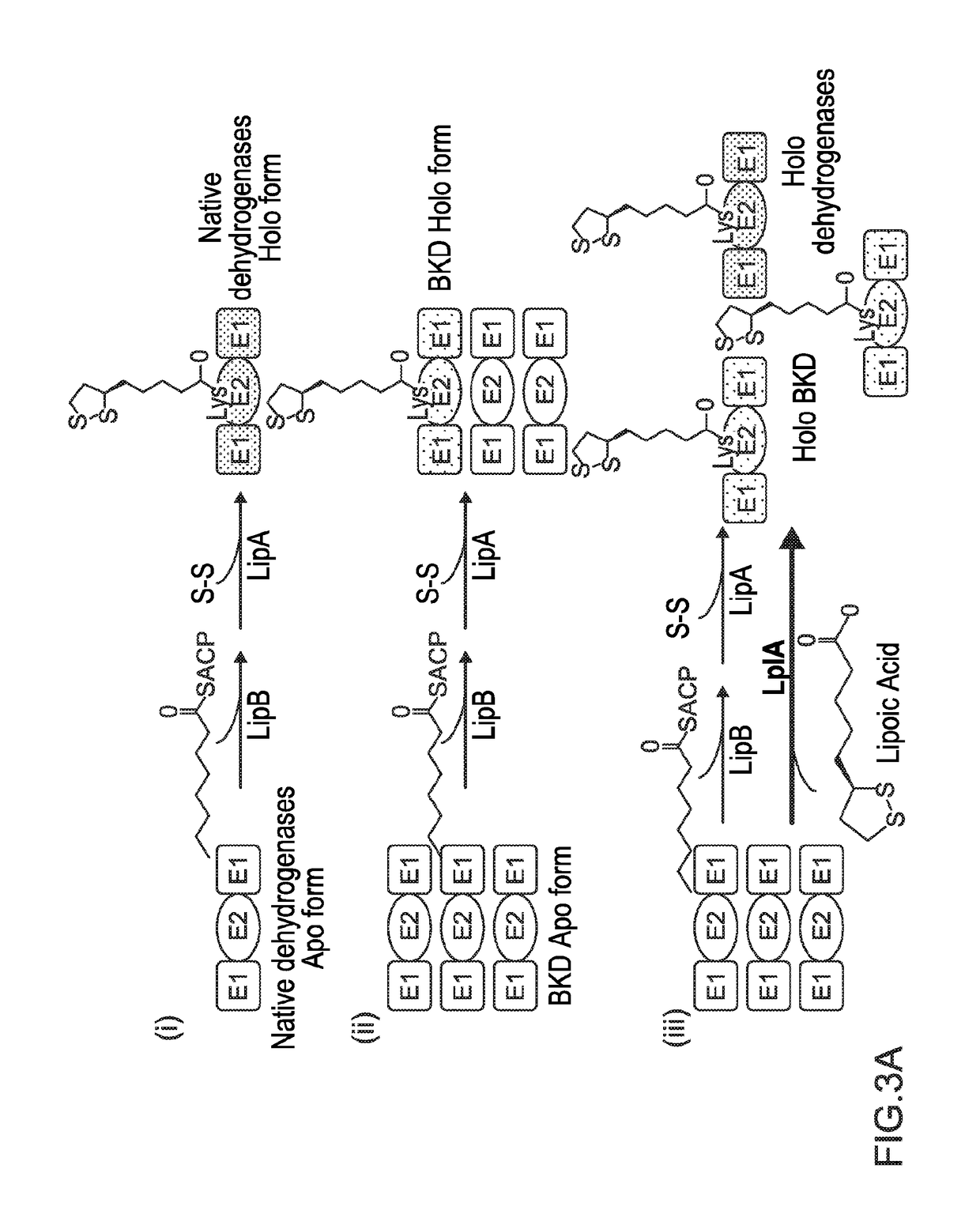

Host cells and methods for producing fatty acid-derivatives with high branched-chain percentage

The present disclosure is generally related to transformed host cells and their use for the production of branched-chain acyl-ACPs, branched-chain acyl-ACP-derived chemicals and fuels, branched-chain fatty acids and producing branched-chain fatty acid-derived chemicals and fuels. More particularly, disclosed herein are transformed host cells and methods for producing branched-chain acyl-ACPs and branched-chain fatty acids in high titer and high percentages. Also disclosed are methods for producing specific branched-chain fatty acid species and producing branched-chain fatty acid-derived chemicals and fuels such as, for example, branched-chain alcohols and branched-chain fatty acid ethyl esters.

Owner:WASHINGTON UNIV IN SAINT LOUIS

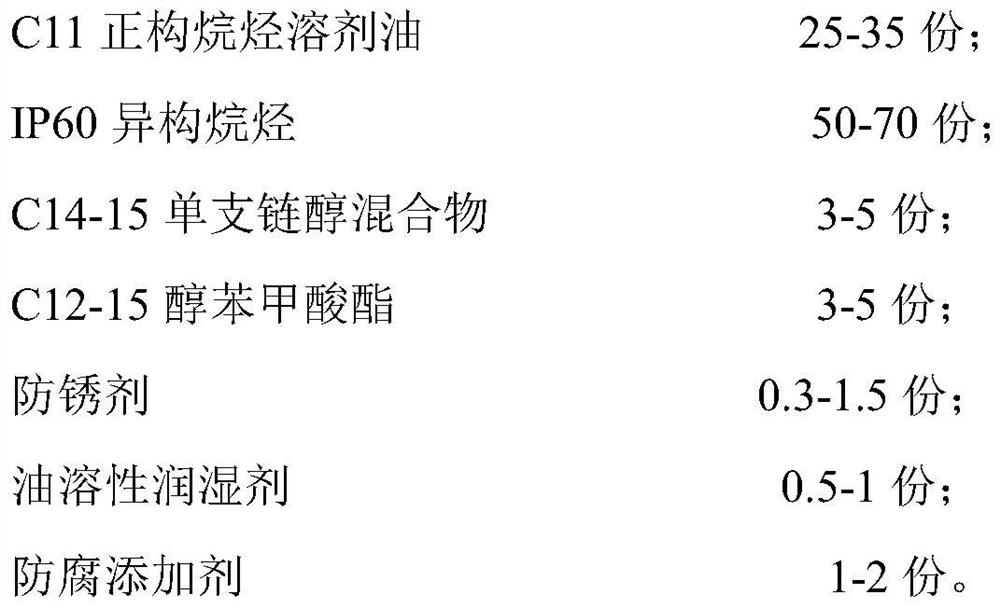

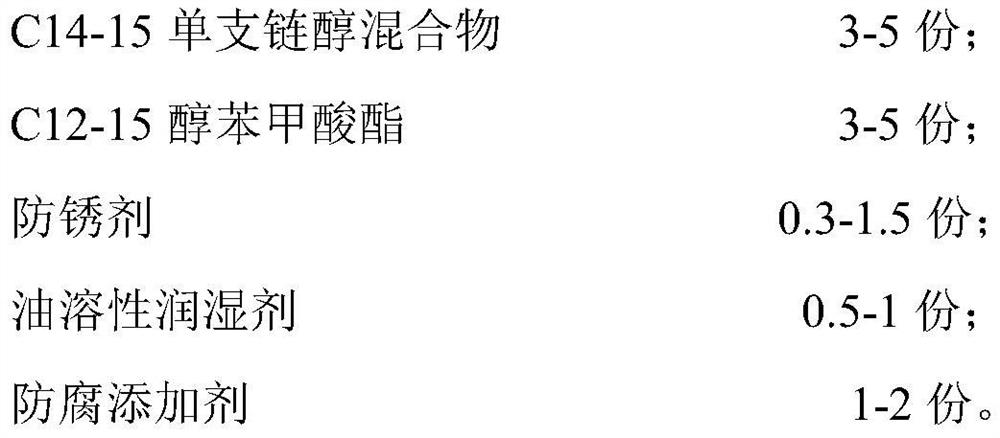

Volatile aluminum foil stamping oil and preparation method thereof

InactiveCN113667523AImprove the lubrication effectGood volatilization effectLubricant compositionAlkaneBranched chain alcohol

The invention discloses volatile aluminum foil stamping oil, which comprises the following raw material components in parts by weight: 25 to 35 parts of C11 n-alkane solvent oil; 50 to 70 parts of IP60 isoparaffin; 3 to 5 parts of a C14-15 single branched chain alcohol mixture; 3 to 5 parts of C12-15 alcohol benzoate; 0.3 to 1.5 parts of an antirust agent; 0.5 to 1 part of an oil soluble wetting agent; and 1 to 2 parts of an anti-corrosion additive. The stamping oil has good lubricity, volatility and corrosion resistance, has the characteristics of high flash point, low odor, safety, environmental protection and the like, and has very excellent application prospects.

Owner:华阳新兴科技(天津)集团有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com