Volatile aluminum foil stamping oil and preparation method thereof

A technology of volatile stamping oil, applied in the field of stamping oil, can solve the problems of undiscovered patent publications, achieve good lubricity, low odor, and solve the effects of high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned volatile aluminum foil stamping oil, the steps are as follows:

[0032] First heat the antirust agent to 60°C to melt it completely; add the C11 normal paraffin solvent oil and IP60 isoparaffin into the reaction kettle and mix them evenly, then add C14-15 single branch into the reaction kettle in turn Alcohol mixture, C12-15 alcohol benzoate, melted anti-rust agent, oil-soluble wetting agent, anti-corrosion additive, and stir evenly to obtain volatile aluminum foil stamping oil.

[0033] Specifically, the relevant preparation and detection examples are as follows:

Embodiment 1

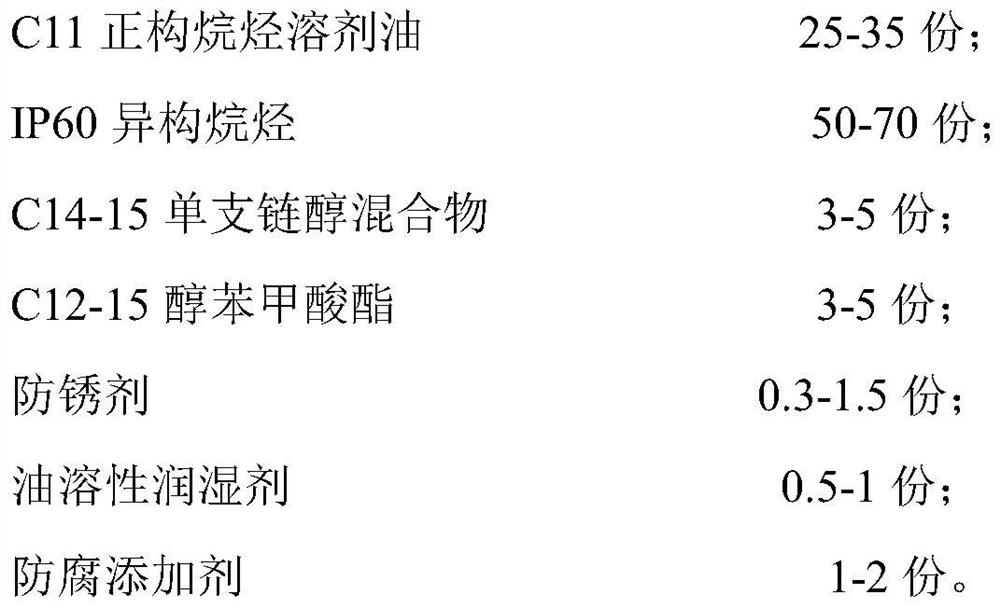

[0035] A volatile aluminum foil stamping oil, its raw material composition and weight are respectively (take 1000g volatile aluminum foil stamping oil as an example):

[0036]

[0037]

[0038] The preparation steps of the above-mentioned volatile aluminum foil stamping oil are as follows: before production and preparation, first heat dodecenylsuccinic acid and barium petroleum sulfonate to 60 degrees Celsius to make them melt completely. Add the C11 normal paraffin solvent oil and IP60 isoparaffin into the reaction kettle and mix evenly, then add the C14-15 single branched chain alcohol mixture, C12-15 alcohol benzoate, and melted Dodecenylsuccinic acid, barium petroleum sulfonate, NP-4, and benzotriazole derivatives can be stirred evenly.

Embodiment 2

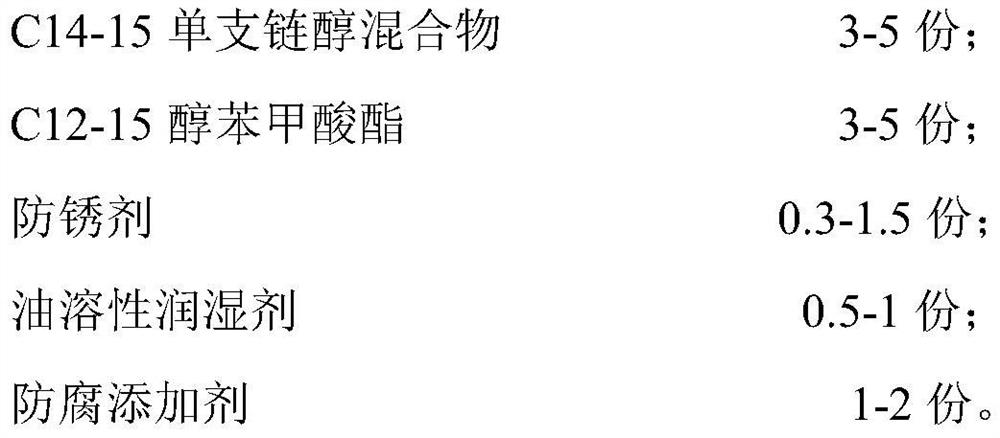

[0040] A kind of volatile aluminum foil stamping oil, its raw material composition and parts by weight are:

[0041]

[0042] The preparation steps of the above-mentioned volatile aluminum foil stamping oil are as follows: before production and preparation, the calcium petroleum sulfonate is heated to 60 degrees Celsius to make it completely melted. Add the C11 normal paraffin solvent oil and IP60 isoparaffin into the reaction kettle and mix evenly, then add the C14-15 single branched chain alcohol mixture, C12-15 alcohol benzoate, and melted Calcium petroleum sulfonate, Siben-60, and benzotriazole derivatives can be stirred evenly.

[0043] The relevant detection of the volatile aluminum foil stamping oil of the present invention can be shown in Table 1.

[0044] Table 1 Comparison table of physical and chemical indicators of volatile aluminum foil stamping oil of the present invention and imported oil

[0045]

[0046]

[0047] After practical application, it is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com