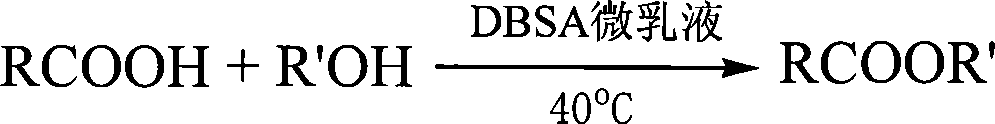

Method for synthesizing ester in dodecyl benzene sulfonic acid reverse micro emulsion

A technology of dodecylbenzenesulfonic acid and inverse microemulsion, which is applied in the field of ester synthesis, can solve problems such as environmental pollution and high requirements for production equipment, and achieve the effects of low cost, pollution avoidance, and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In 100mL 50mmol·L -1 Add acetic acid and n-butanol with a molar ratio of 2:1 to the DBSA inverse microemulsion, the pH of the buffer solution is 7.0, react at 35°C for 3 hours, stop stirring, and evaporate the esterification product n-butyl acetate under reduced pressure, The conversion rate is 99%, and the DBSA is recycled after being distilled off.

Embodiment 2

[0020] In 100mL 50mmol·L -1 Add acetic acid and n-hexanol with a molar ratio of 2:1 to the DBSA inverse microemulsion, the pH of the buffer solution is 7.0, react at 40°C for 3 hours, stop stirring, evaporate the esterification product n-hexyl acetate under reduced pressure, and transform The yield is 99%, and the DBSA is recycled after being evaporated.

Embodiment 3

[0022] In 100mL 50mmol·L -1 Add acetic acid and n-octanol with a molar ratio of 1.5:1 to the DBSA inverse microemulsion, the pH of the buffer solution is 6.8, react at 38° C. for 3 hours, stop stirring, and evaporate the esterification product n-octyl acetate under reduced pressure, The conversion rate is 97%, and the DBSA is recycled after being distilled off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com