Ion liquid catalyst of esterification reaction, preparation method and usage

A technology of esterification reaction and ionic liquid, which is applied in the field of esterification reaction catalyst and its synthesis, can solve the problems of low conversion rate of esterification reaction, complex synthesis of ionic liquid, and a large amount of organic solvents, etc., and achieve environmental friendliness, high purity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

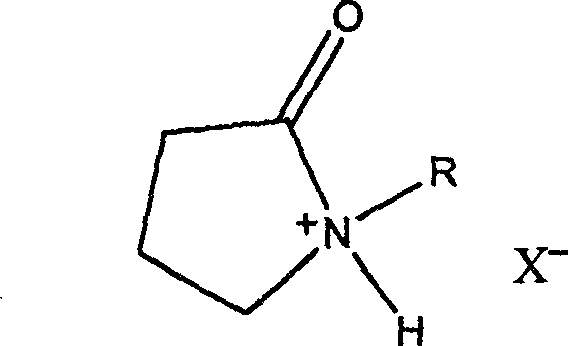

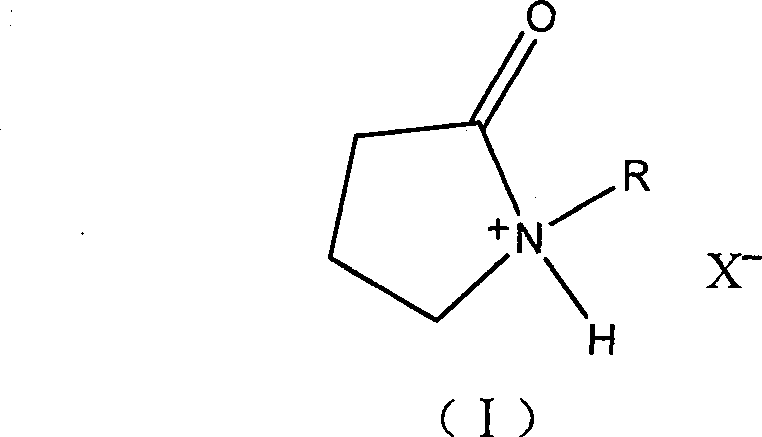

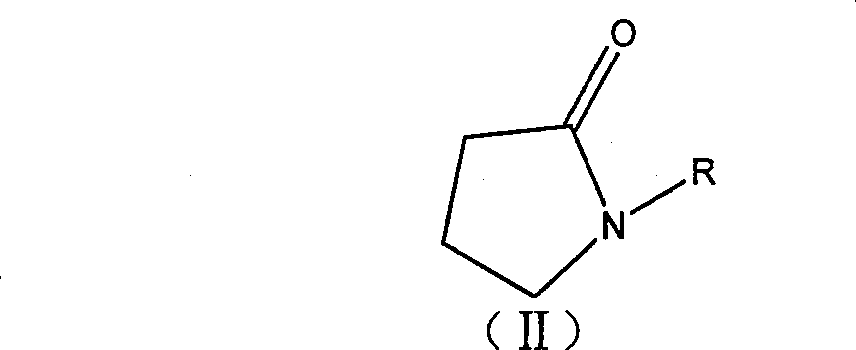

Method used

Image

Examples

Embodiment 1

[0028] Weigh 16.9 g (0.1 mol) of N-butyl-2-pyrrolidone and dissolve it in benzene, slowly add 9.6 g (0.1 mol) of methanesulfonic acid dropwise under stirring at 20°C, drop it in 30 minutes, continue stirring at 50°C for reaction 4 After 1 hour, the benzene was removed by heating under vacuum to obtain a light yellow liquid, which was the product N-butyl-2-pyrrolidone methanesulfonic acid ionic liquid. Stable to water and air, the yield is 97%. Density 1.1021 g / ml, conductivity 1.07×10 -3 S / cm, the melting point is -54°C.

Embodiment 2

[0030] Weigh 19.8 grams (0.2 mol) of N-methyl-2-pyrrolidone, slowly add 19.2 grams (0.2 mol) of methanesulfonic acid dropwise under stirring at 0°C, drop it in 3 hours, continue to stir and react at 80°C for 5 hours, that is The product N-methyl-2-pyrrolidone methanesulfonic acid ionic liquid was obtained. Stable to water and air, density 1.154 g / ml, conductivity 2.64×10 -3 S / cm, the melting point is -46°C. Yield 100%.

Embodiment 3

[0032] Weigh 12.8 g (0.1 mol) of N-isopropyl-2-pyrrolidone, slowly add 30 mL of a toluene solution of 9.6 g (0.1 mol) of methanesulfonic acid dropwise under stirring at 20°C, drop it in 30 minutes, and continue to stir the reaction at 100°C After 2 hours, the toluene was removed under vacuum by heating to obtain the product N-methyl-2-pyrrolidone ionic liquid. Stable to water and air, the yield is 98%. Density 1.134 g / ml, conductivity 2.54×10 -3 S / cm, the melting point is -56°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com