Method of preparing biological diesel oil containing side chain fatty acid ester

A branched-chain fatty acid ester and biodiesel technology, which is applied in the field of biodiesel preparation, can solve problems such as inappropriateness, impact on product quality, and high price, and achieve the goals of reducing difficulty and cost, improving low-temperature fluidity, and increasing calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

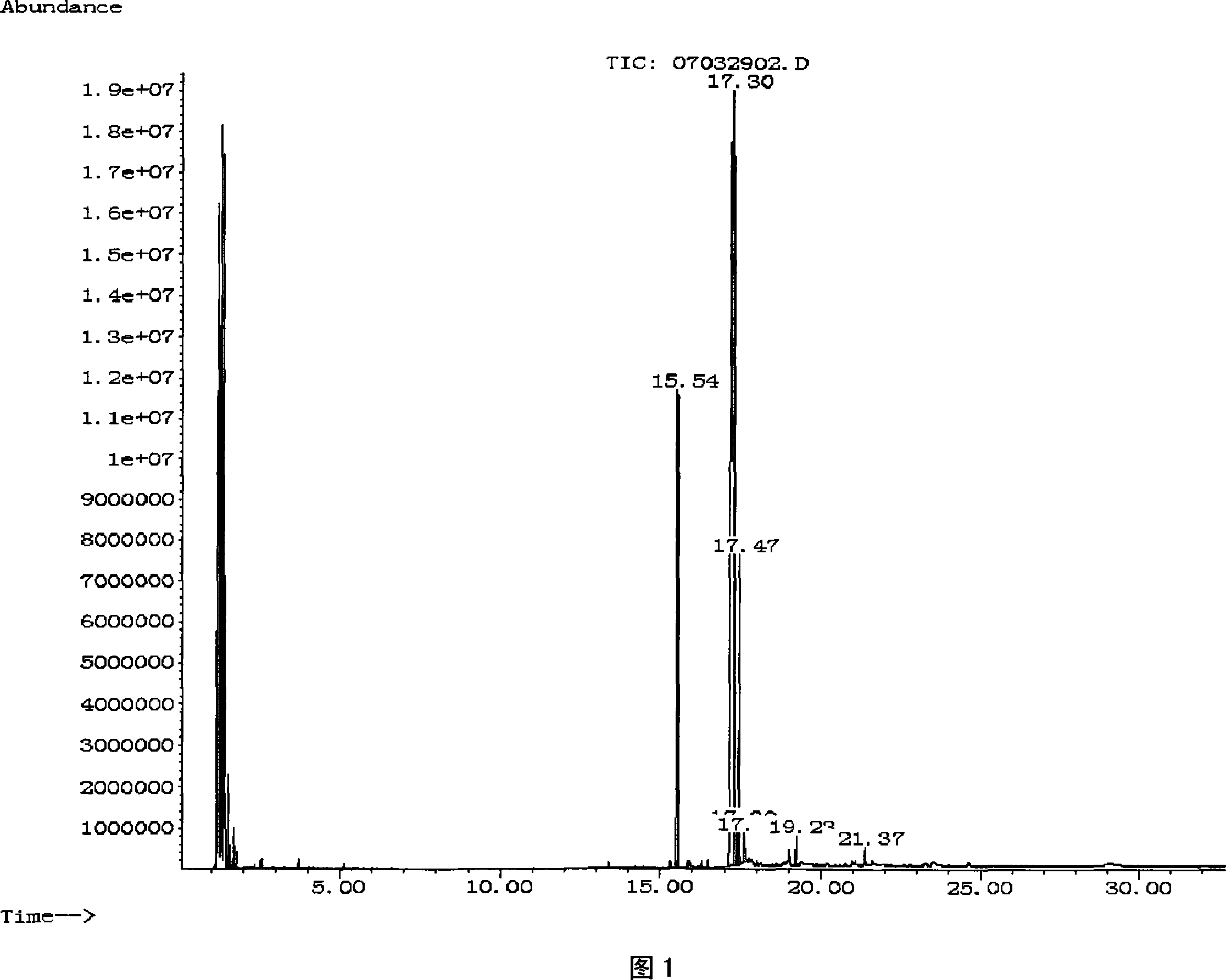

Embodiment 1

[0018] Mix natural oil, frying waste oil or waste oil with methanol and a branched chain alcohol, add a catalyst at a temperature of 40-100°C, and react for 20-180 minutes to obtain a fatty acid ester with a branched chain. A biodiesel product with excellent low temperature flow properties. Wherein the branched chain alcohol is a primary alcohol or a secondary alcohol, the number of carbon atoms in the alkyl group is between 3 and 7, the boiling point is below 155°C, and there is no branch on the α carbon atom of the secondary alcohol; the catalyst can be (strong acid such as sulfuric acid and phosphoric acid ) or strong bases (such as metal hydroxides and alkoxides of potassium and sodium). The molar ratio of methanol to oil is 1:1 to 6:1, the molar ratio of branched alcohol to oil is 3:1 to 25:1, and the amount of catalyst accounts for 0.3% to 5% of the weight of oil. The product is distilled under normal pressure or reduced pressure (vacuum degree 0.1MPa), and the unreacte...

Embodiment 2

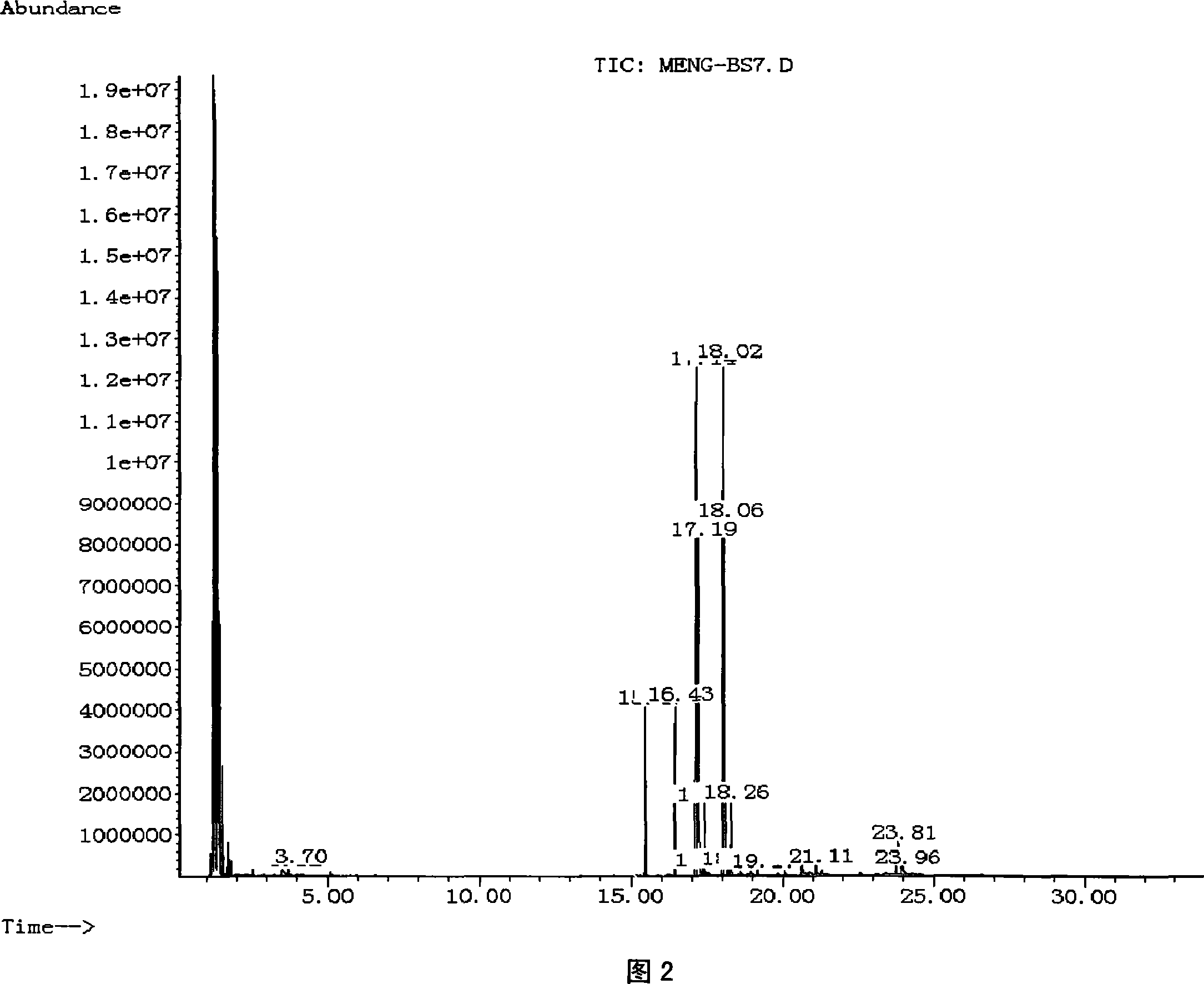

[0022] Take 100g of soybean oil with an acid value of 0.5 and a water content of 0.2%, add 5ml of methanol, 150ml of isopropanol and 1g of KOH into a 500ml three-neck flask, heat to 70-80°C, react for 1 hour, and distill off the unreacted alcohol under reduced pressure to obtain biological Diesel oil 103.5g, the product is analyzed by GC-MAS, and the relative content of isopropyl ester is 49.8%. Its kinematic viscosity at 40°C is 4.3mm 2 / s, the condensation point is -10°C, and the cold filter point is -7.5°C. The product is added with methanol, and it is found that it can dissolve about 23.5% of methanol at most, and a certain amount of methanol can be added to the product as a fuel.

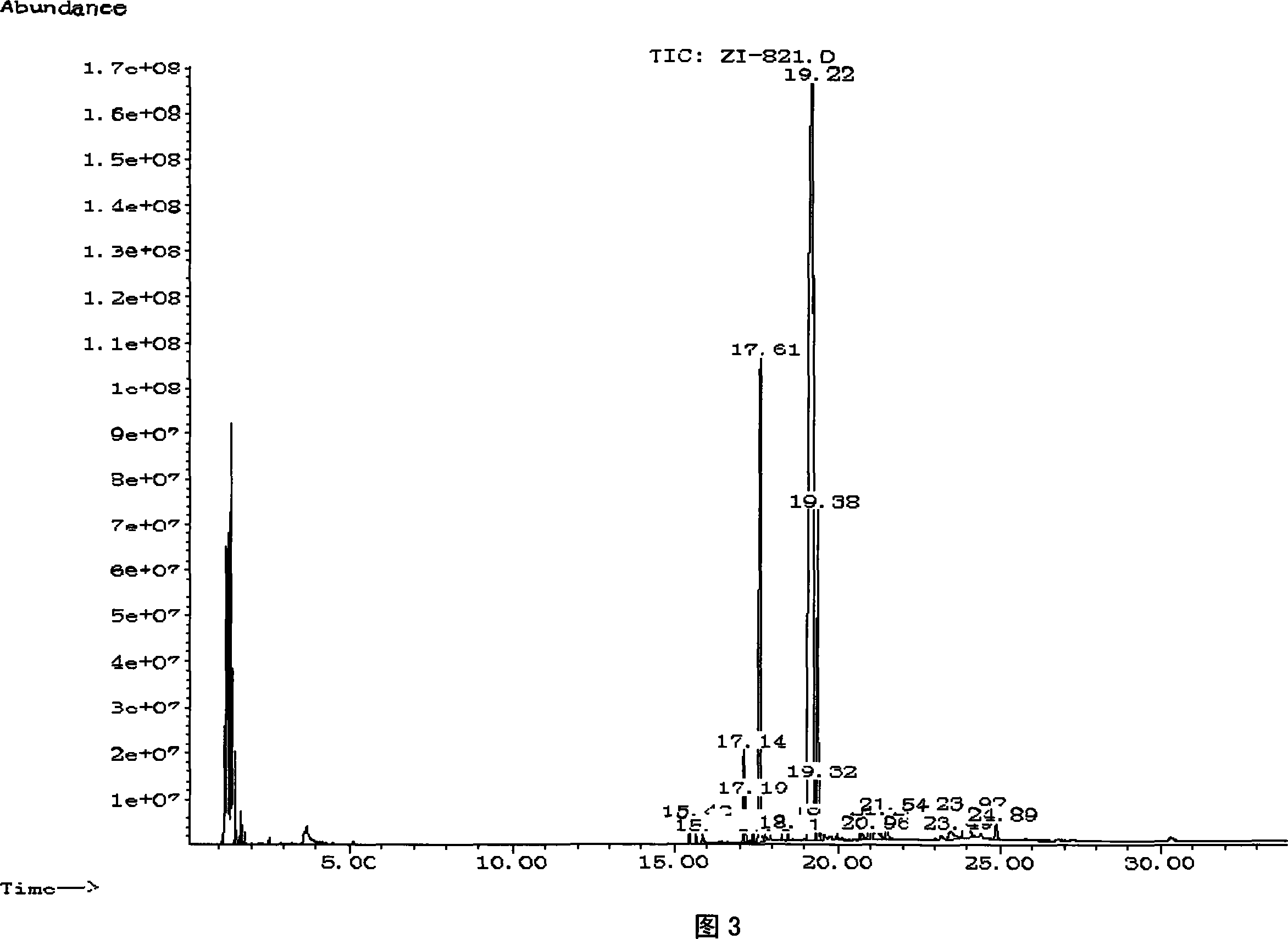

Embodiment 3

[0024] Take 100g of soybean oil with an acid value of 0.5 and a water content of 0.2%, add 28ml of methanol, 26ml of isopropanol and 1g of KOH into a 500ml three-necked flask, heat to 70-80°C, react for 20 minutes, and distill off unreacted alcohol under reduced pressure to obtain 96g of biodiesel, the product was analyzed by GC-MAS, and the relative content of isopropyl ester was 9.8%. Its kinematic viscosity at 40°C is 4.3mm 2 / s, the condensation point is -6°C, and the cold filter point is -5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com