Soldering flux and preparation method thereof

A flux and co-solvent technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of low corrosiveness, uninhibited, high surface insulation resistance, and achieve low corrosiveness, oxidation prevention, and high wetting rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of polyaniline-sodium polystyrene sulfonate complex

[0034] Dissolve sodium polystyrene sulfonate in water, add dilute hydrochloric acid under stirring to acidify, quickly spin-dry, add concentrated hydrochloric acid to dissolve again, suction filtration, the filtrate is spin-dried and vacuum-dried at 60°C to obtain sodium polystyrene sulfonate template solid powder; The weight ratio of said sodium polystyrene sulfonate: dilute hydrochloric acid: concentrated hydrochloric acid is 1:0.01:0.01; at 15°C, the solid powder of polystyrene sulfonate template is dissolved in water, and aniline monomer is added to polymerize The molar ratio of sodium styrene sulfonate and aniline is 10:7. Adjust the pH to 3 with dilute hydrochloric acid. After stirring quickly for 10 hours, slowly add ammonium persulfate solution. The molar ratio of ammonium persulfate to aniline is 4:10. After dripping in 2h, continue the reaction for 10h, filter to remove unreacted monomer ...

Embodiment 2

[0035] Example 2 Preparation of polyaniline-sodium polystyrene sulfonate complex

[0036] Dissolve sodium polystyrene sulfonate in water, add dilute hydrochloric acid under stirring to acidify, quickly spin-dry, add concentrated hydrochloric acid to dissolve again, suction filtration, the filtrate is spin-dried and vacuum-dried at 60°C to obtain sodium polystyrene sulfonate template solid powder; The weight ratio of said sodium polystyrene sulfonate: dilute hydrochloric acid: concentrated hydrochloric acid is 1:0.005:0.01; at 10°C, the solid powder of polystyrene sulfonate template is dissolved in water, and aniline monomer is added to polymerize The molar ratio of sodium styrene sulfonate and aniline is 10:7, adjust the pH value to 4 with dilute hydrochloric acid, stir quickly for 12h, slowly add ammonium persulfate solution, the molar ratio of ammonium persulfate to aniline is 4:10, After dripping in 2h, continue the reaction for 8h, filter to remove unreacted monomers and inso...

Embodiment 3

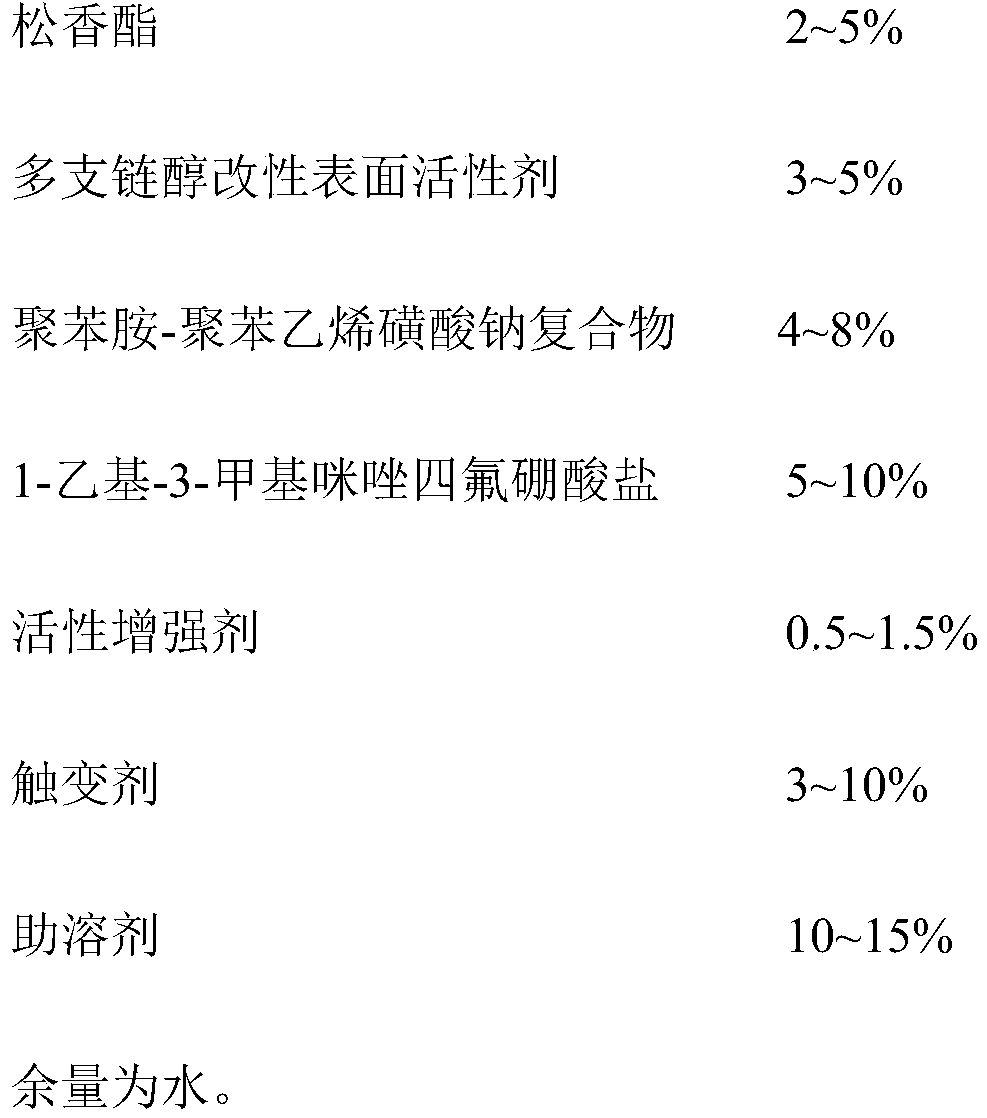

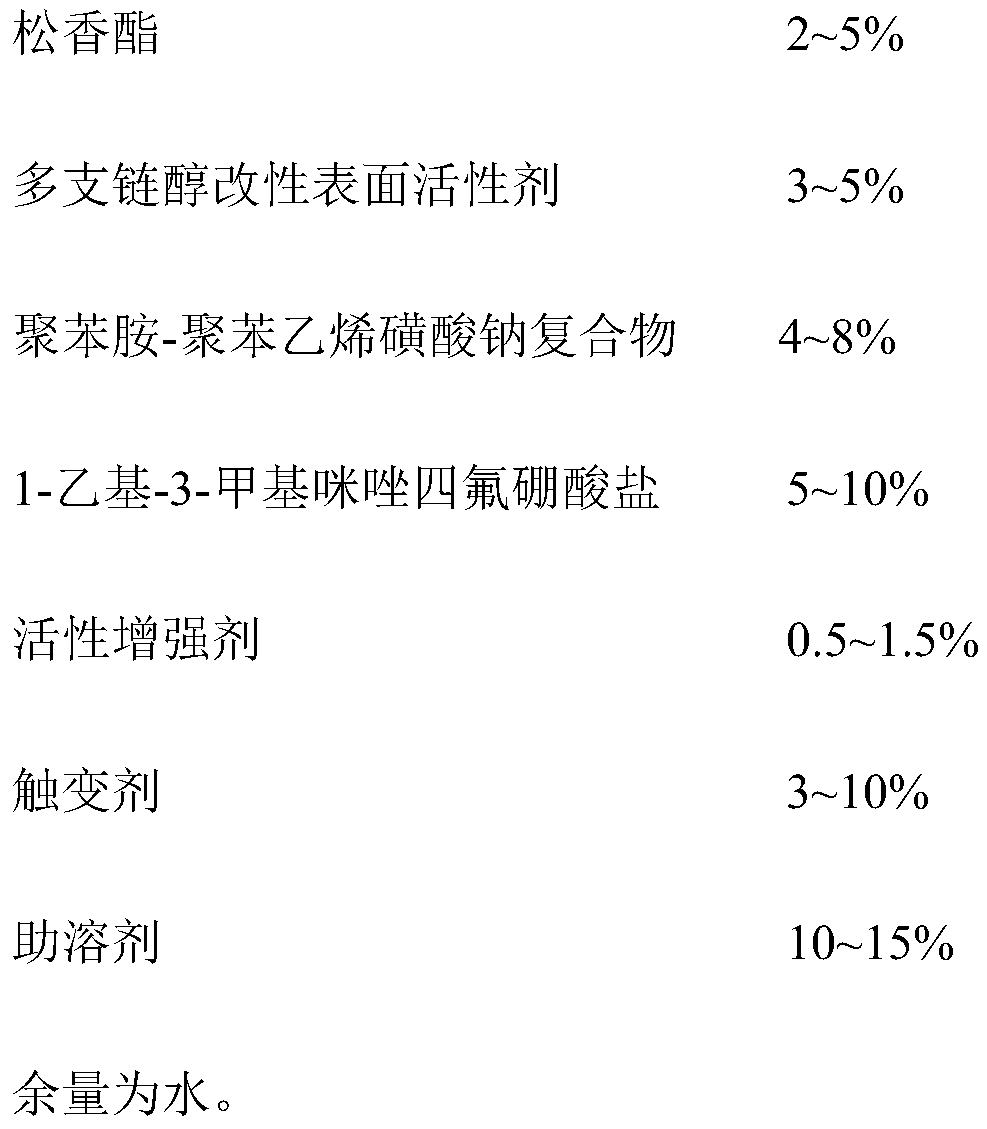

[0037] Example 3 Preparation of flux

[0038] A flux comprising the following components in mass percentage: 1.5% hydrogenated rosin glyceride, 1.5% glyceryl rosin acrylate, DWF-6240 5%, polyaniline-sodium polystyrene sulfonate complex 4%, 1- Ethyl-3-methylimidazole tetrafluoroborate 8%, dodecyl dimethyl amine oxide 1%, amide modified hydrogenated castor oil 7%, diethylene glycol butyl ether 5%, ethylene glycol 5%, the balance is water.

[0039] Preparation steps:

[0040] S1: Mix hydrogenated rosin glyceride, glyceryl rosin acrylate, diethylene glycol butyl ether and ethylene glycol, heat to 110°C, and stir until the rosin ester is completely dissolved to obtain solution A;

[0041] S2: DWF-6240, polyaniline-sodium polystyrene sulfonate complex, 1-ethyl-3-methylimidazole tetrafluoroborate, dodecyldimethylamine oxide, amide modified hydrogenation Castor oil is dissolved in water, heated to 55°C, stirred until the material is completely dissolved, and solution B is obtained;

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com