Double ventilating regulator and burner nozzle of low NOx combustor system

A regulator, burner technology, applied in burners, burners burning powder fuel, combustion types, etc., can solve problems such as unfavorable environment, achieve easy installation and maintenance, ensure reliability or maintainability, and improve combustion control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

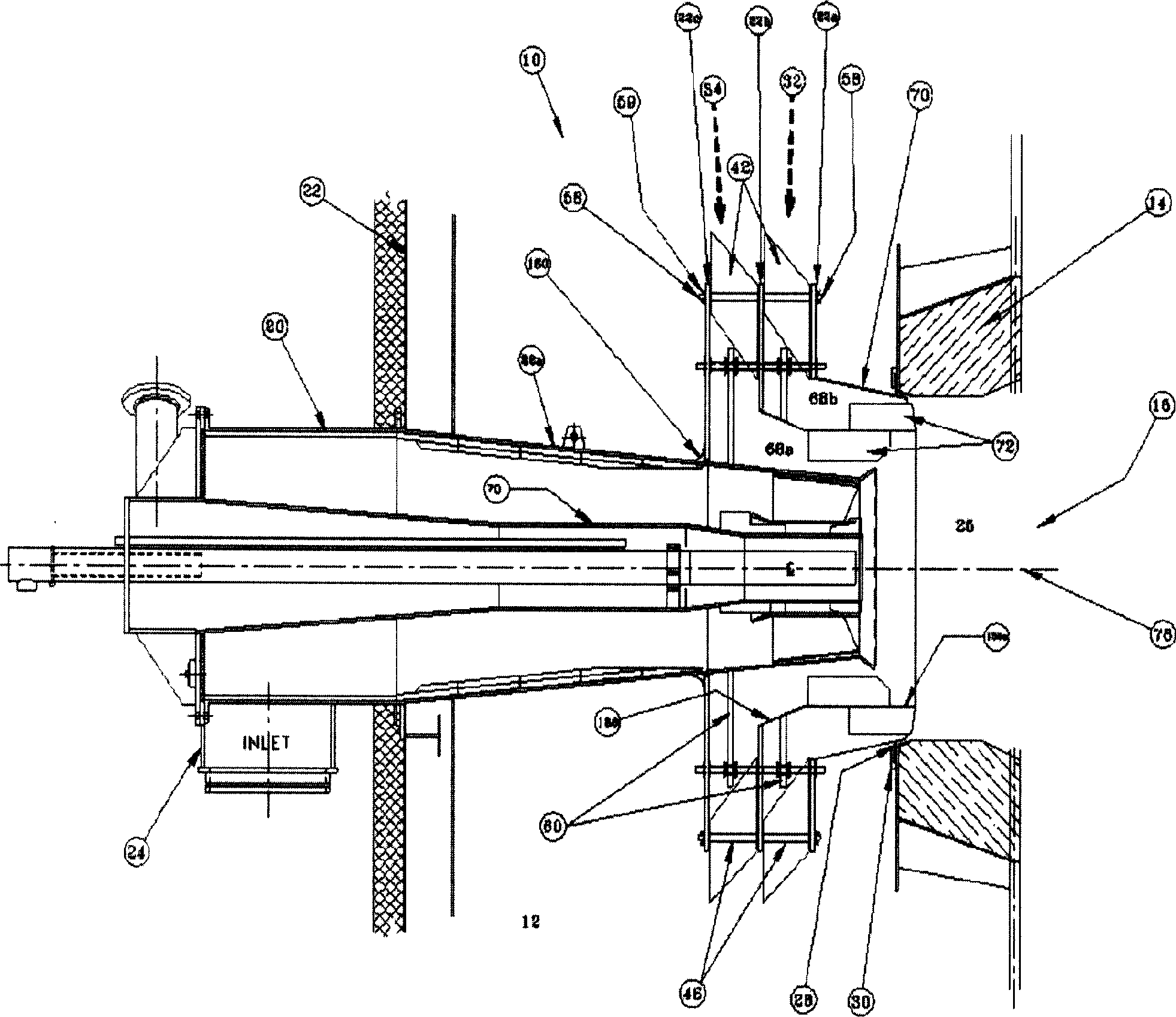

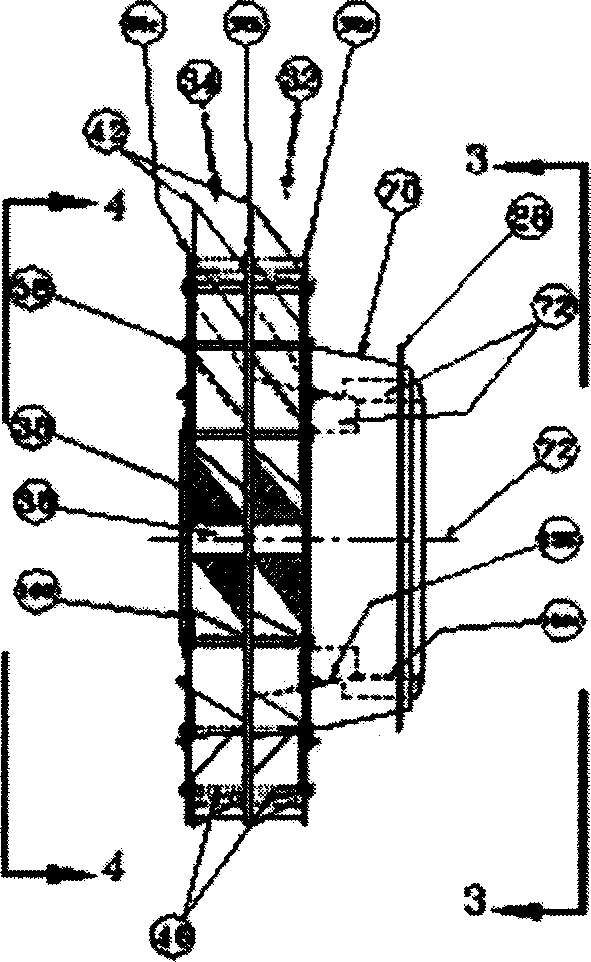

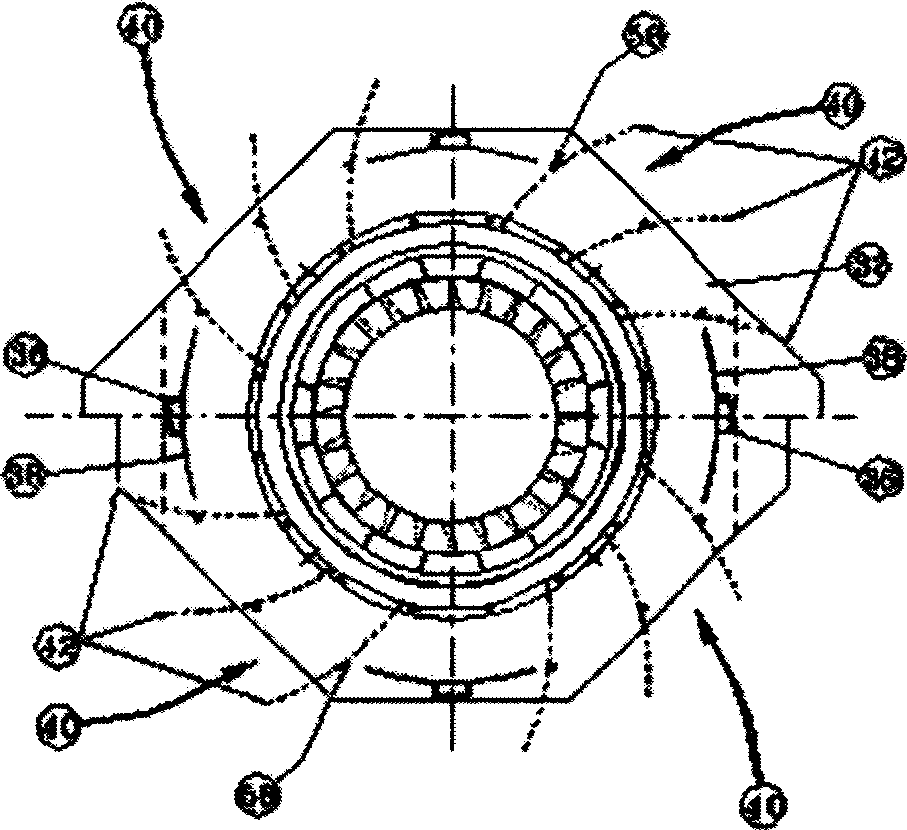

[0044] figure 1 A vent regulator assembly constructed in accordance with a preferred aspect of the invention is shown. The draft regulator assembly 10 is shown aligned with the furnace wall burner ports, attached to the boiler wall 14, and installed inside the "wind box" 12. Fuel pipes 20 protrude from the outside of the outer windbox furnace wall 22 . In this configuration, fuel tube assembly 20 includes outer fuel tube 22a surrounding inner air or fuel tube 70 and aligning them axially. The outer fuel pipe 22a delivers air and fuel to the combustion zone designated by reference numeral 26 . Fuel, which may include pulverized coal, is received through inlet 24 between fuel line 70 and outer fuel line 22a. In such an arrangement, an oil burner (not shown) may be mounted on the inner tube 70 . Burner assemblies can fire coal or oil or a combination, depending primarily on the application and / or boiler conditions. The fuel line assembly is a conventional assembly and is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com