Killing apparatus for harmful microbody organisms in water, killing method, and water conveying engineering system

A biological and micro-body technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as rough pipe walls, water pipe wall damage, hidden dangers, etc., to achieve Conducive to the ecological environment, the effect is obvious, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

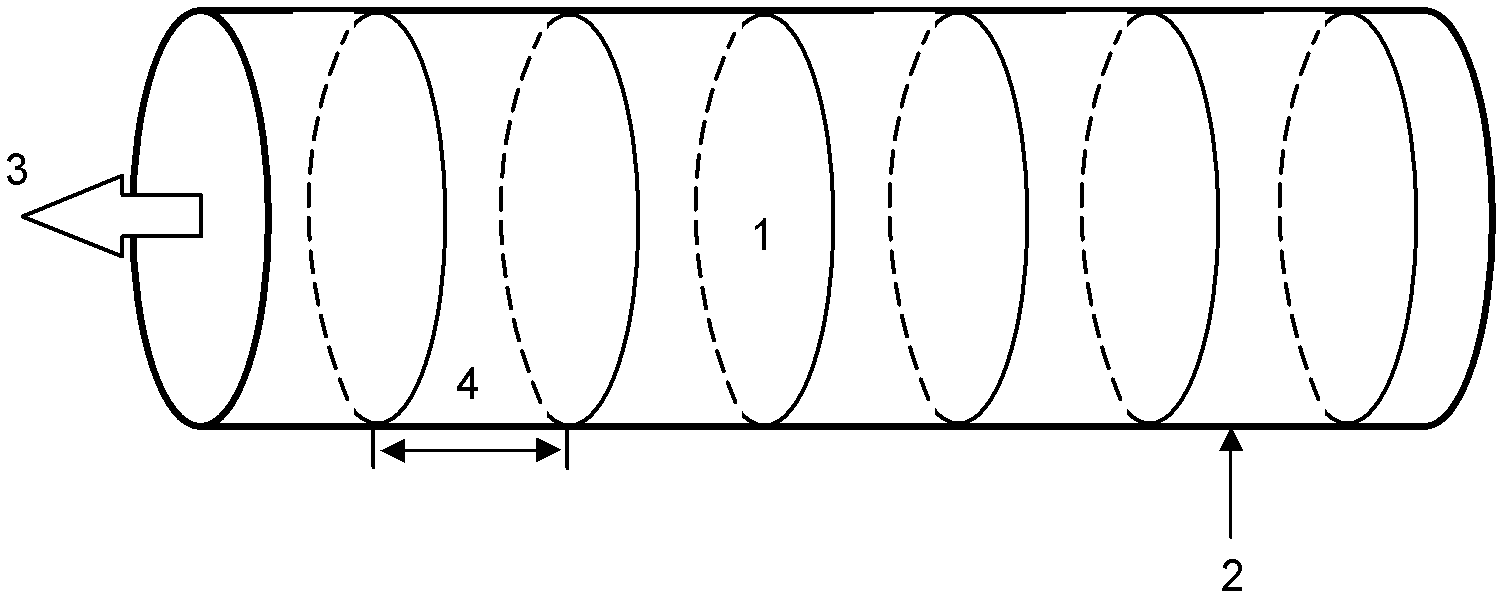

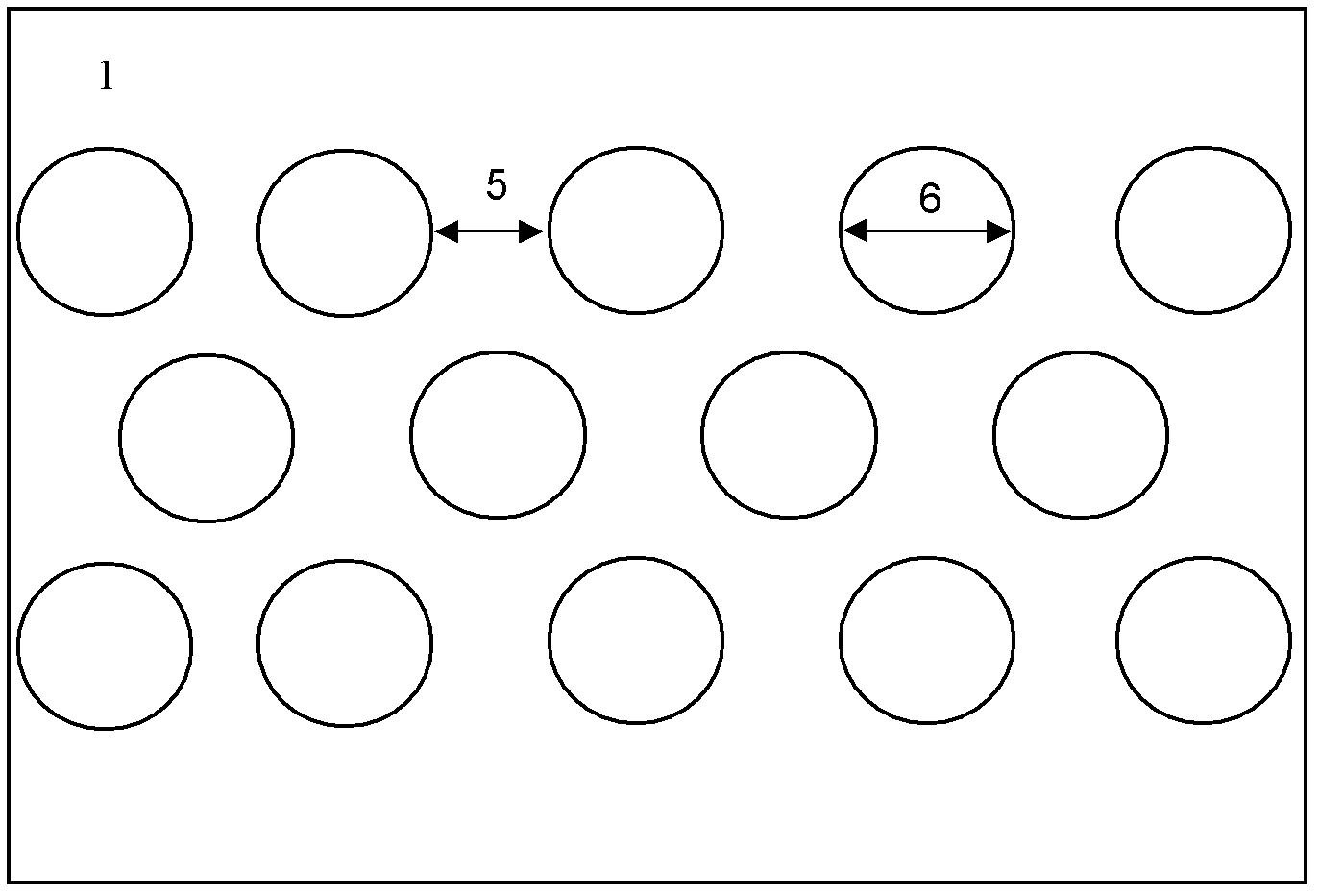

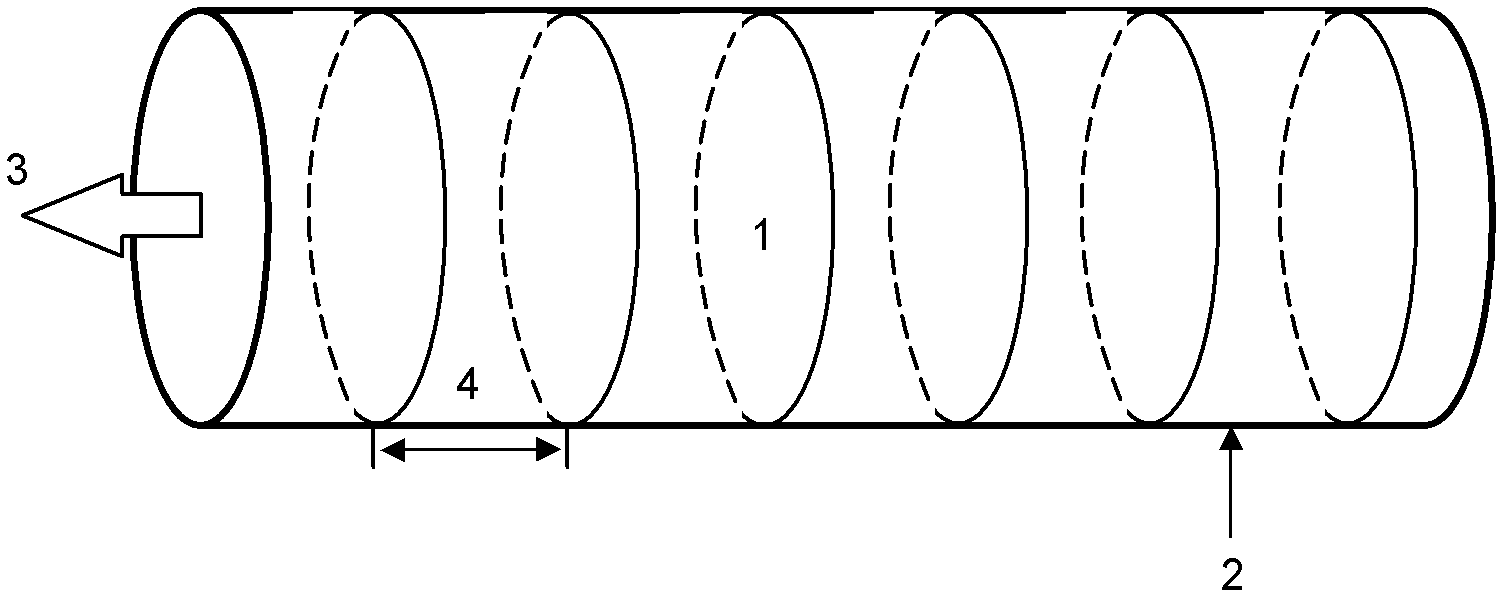

[0044] A device for killing harmful microorganisms in water, comprising an overflow channel and an orifice plate installed therein, the overflow channel can be an overflow pipe (such as a water pipe) or an overflow sink (such as a ditch), and of course it can be Other forms of water passage, such as water flow passages in other devices, such as cooling water pipes. The flow passage includes a water inlet end and a water outlet end, and the water inlet end can be connected with a natural water source or a water inlet pool containing a natural water body or a water treatment device; the water outlet end can be connected with a water device or a water delivery project or a follow-up water Processing device connection. There is a power system to promote the flow of water at the water inlet and / or water outlet, for example, a device for providing or controlling wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com