Drive unit for rotating outer ring and fixing inner ring of airplane wheel bearing

A technology of bearing outer ring and driving device, which is applied in the direction of mechanical bearing testing, etc., can solve the problems that cannot meet the test requirements of aircraft wheel bearings, and achieve the effects of shortening the development cycle, bearing large loads, and high rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

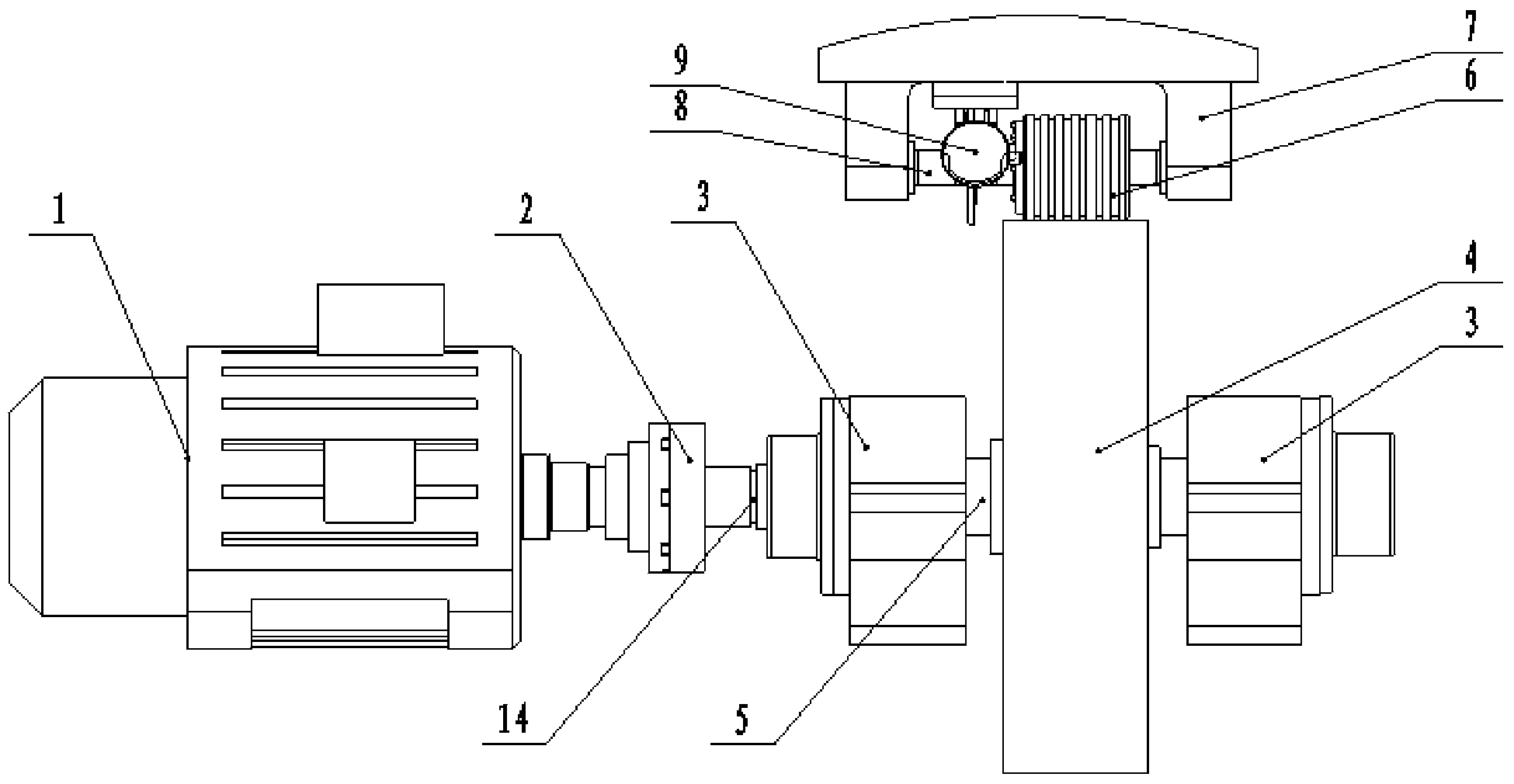

[0034] This embodiment is a driving device used in a certain aircraft wheel bearing load impact testing machine, and the driving device passively drives the wheel bearing by means of counter-rolling rotation. This embodiment includes a motor 1, a clutch 2, a bearing housing 3, a drum 4, an axle 5, a rubber wheel 6, a brake 9 and a coupling 14. The motor 1 adopts a three-phase AC variable frequency speed regulation asynchronous motor.

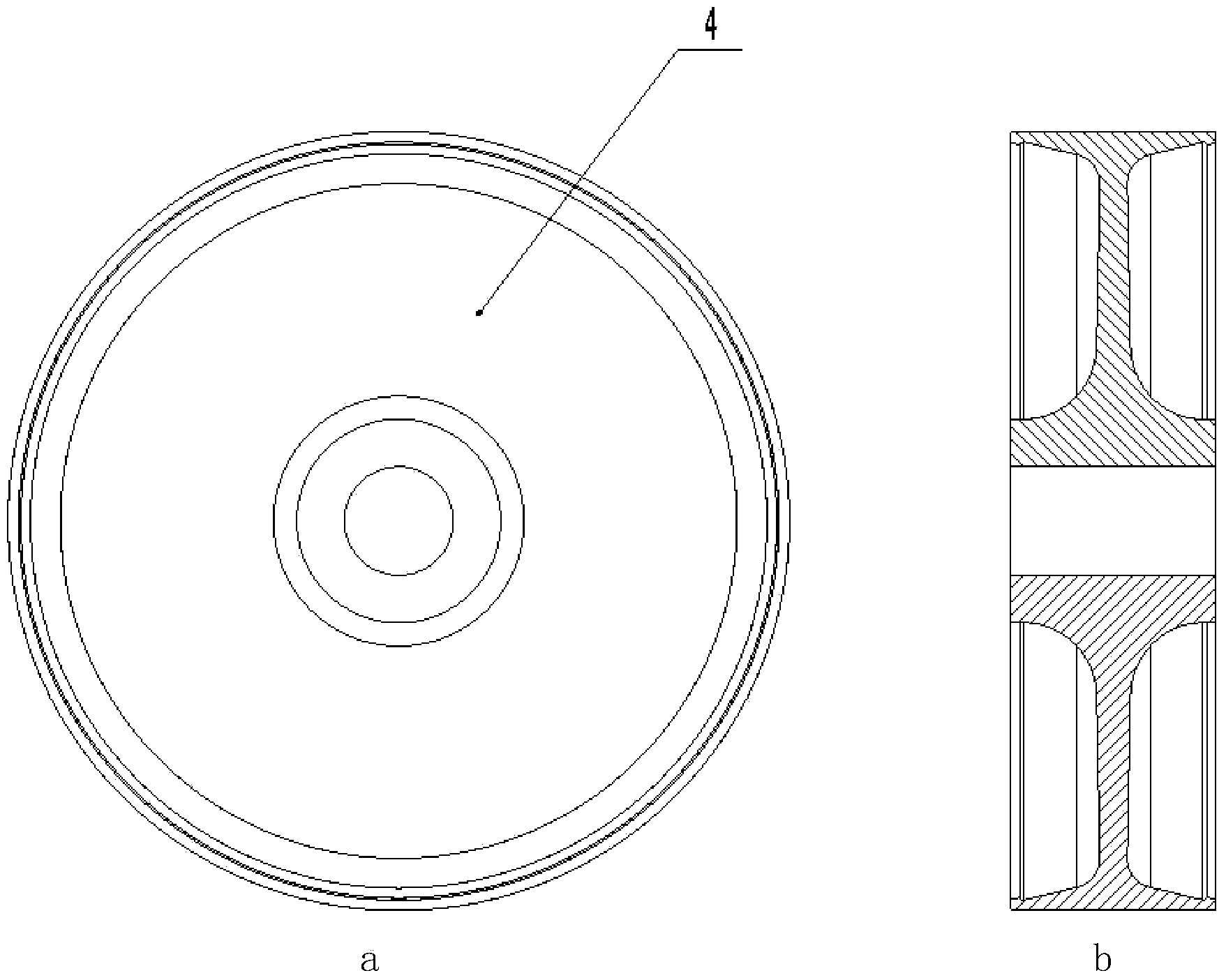

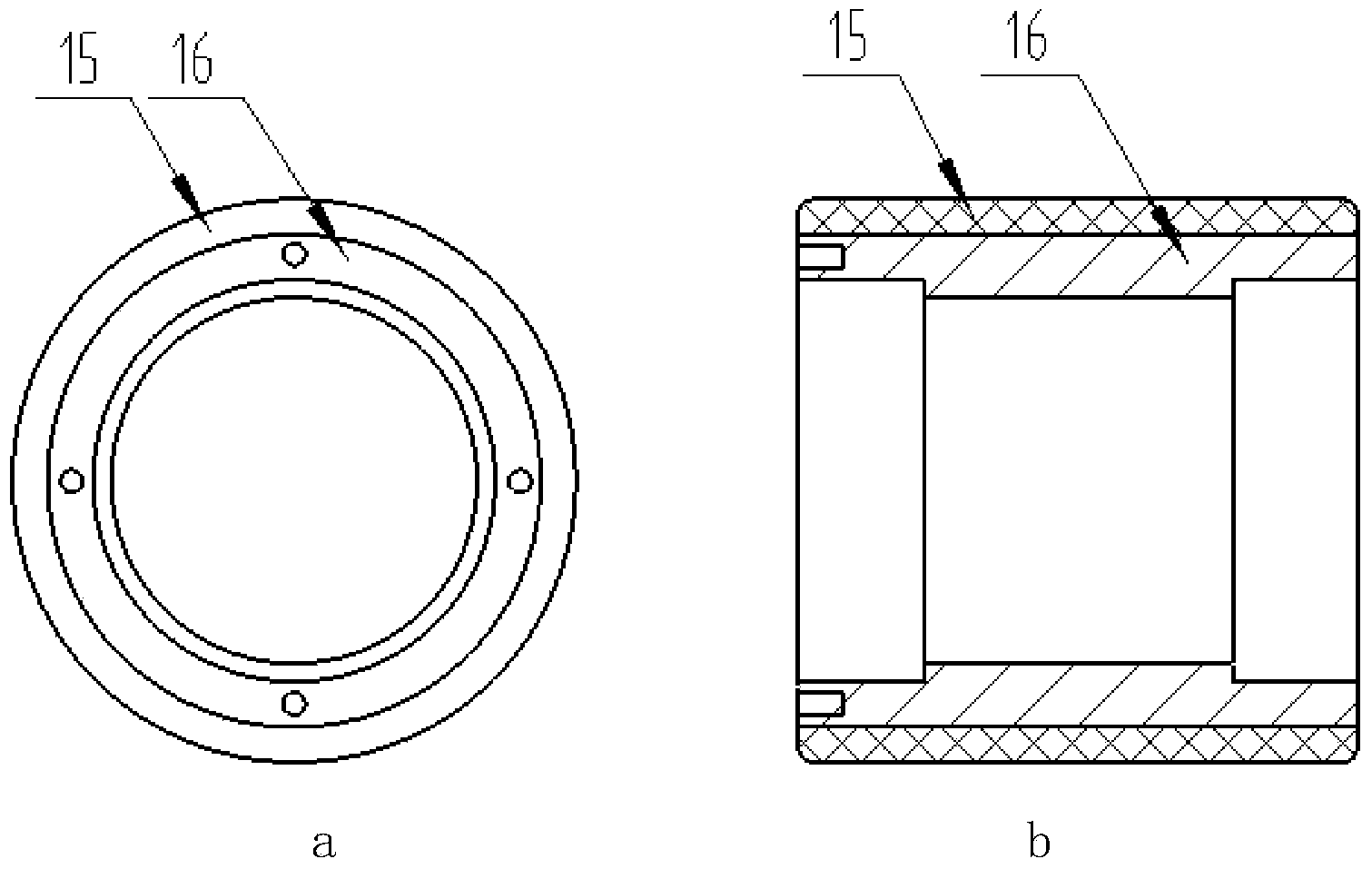

[0035] In this embodiment, the clutch 2 is installed on the output shaft of the motor 1 . The wheel shaft 5 is installed on two bearing blocks, and one end of the wheel shaft is connected with the flange at one end of the clutch 2 through a coupling 14 . The drum 4 is mounted on the axle 5 through a key and is located between the two bearing seats. The outer peripheral surface of the drum 4 is in friction fit with the peripheral surface of a rubber wheel 6 mounted on the loading device. The rubber wheel 6 is sleeved on the outer ring of the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com