Testing device and method of soil body II-type fracture damage

A technology of fracture failure and test device, applied in the direction of measuring device, instrument, scientific instrument, etc., can solve the problems of difficulty in precise adjustment, lack of reliable basis for analysis work, increase in error, etc., to achieve accurate and reliable test data, convenient mechanics The effect of analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

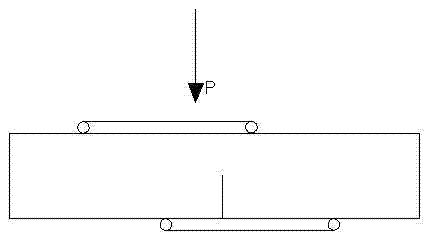

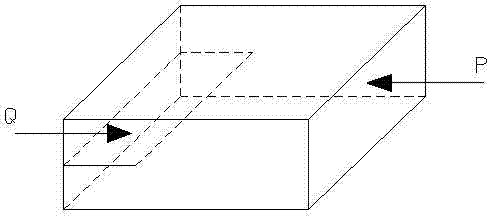

[0019] The device of the present invention is as follows: it is composed of a base 1, a front stopper 2, a thrust plate 3, a load sensor 4, a displacement sensor 5, a thrust providing device 6 and a computer 7; the front stopper 2 and the thrust supplying device 6 are respectively connected to the base Both ends of 1, and the front block iron 2 and the thrust providing device 6, one of the two is slidably connected with the base 1; the power output part of the thrust providing device 6 is connected with one end of the load sensor 4, and the other end of the load sensor 4 Connected with the thrust plate 3; the signal output terminals of the load sensor 4 and the displacement sensor 5 are connected to the computer 7; the load sensor 4 detects the load applied to the sample; the displacement sensor 5 detects the deformation of the sample during the test.

[0020] The thrust providing device 6 uses a thrust cylinder.

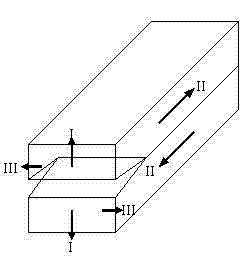

[0021] The sample is a rectangular parallelepiped sample with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com