Road surface interlayer cementing shearing strength test method

A bonded shear resistance and strength test technology, which is applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve problems such as unreasonable loading methods and large test errors, and achieve accurate and reliable test data , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

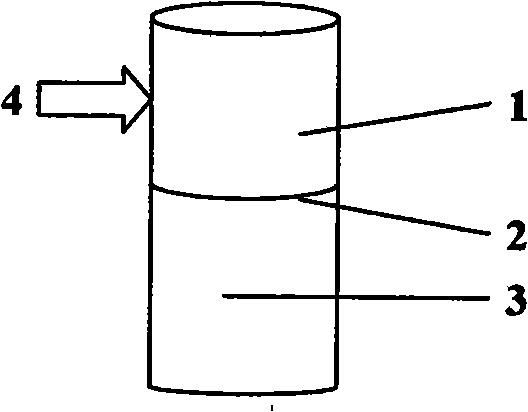

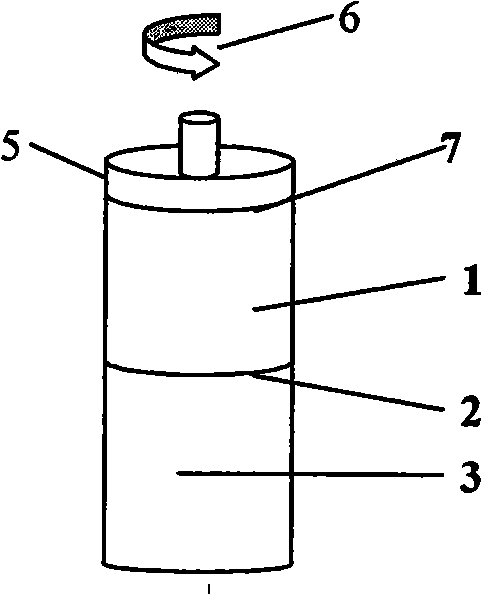

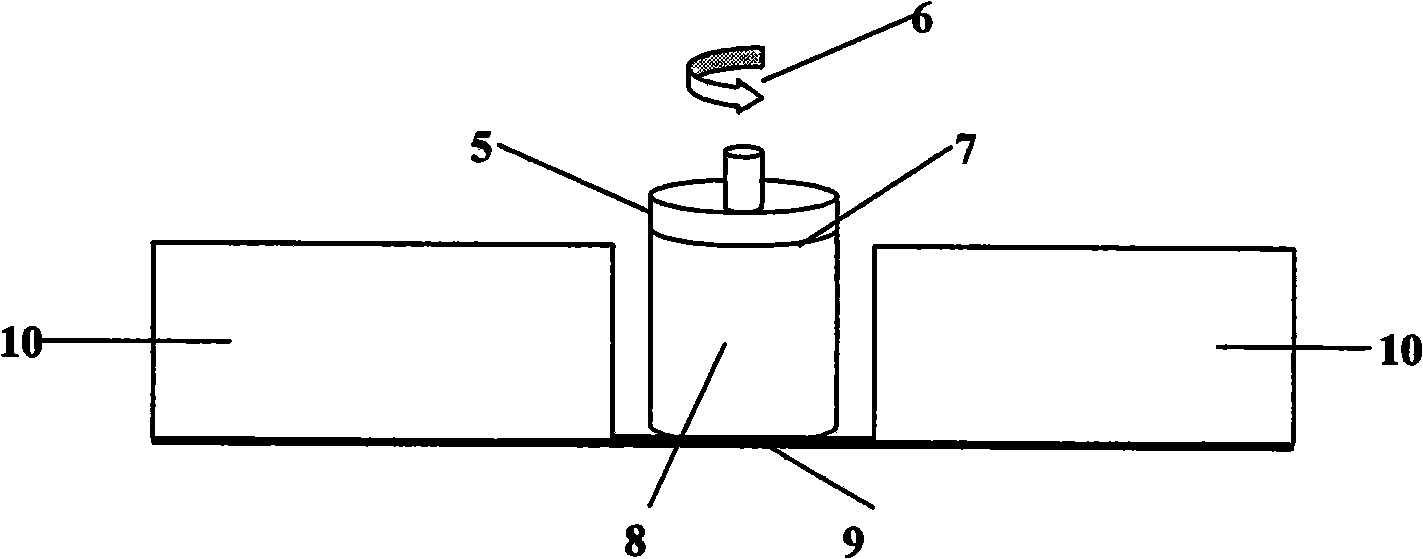

[0022] The test using the present invention to test the interlayer bonding material is specifically divided into indoor and outdoor conditions.

[0023] 1. Indoor test (as attached figure 2 )

[0024] Form Marshall specimens according to the relevant test methods of "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTJ052-2000), and compact each side 75 times. The number of specimens is not less than 6, and each pair is divided into one group. Wipe the two ends of each group of test pieces clean and keep them dry. After painting the surface with a waterproof adhesive layer, glue the two test pieces together.

[0025] Knot together to make a test piece for use. To test the shear strength of the bridge deck pavement waterproof bonding layer, replace one specimen in each group with a specimen made of the same material as the top surface of the bridge deck (such as cement concrete blocks, steel plates, etc.). The specific test steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com