Method of attaching ring gear to differential case, jig, and differential case

A technology for differential case and ring gear, which is applied in differential transmission, manufacturing tools, household appliances, etc. It can solve problems such as cracks on the inner peripheral surface of the riveted fixed part, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

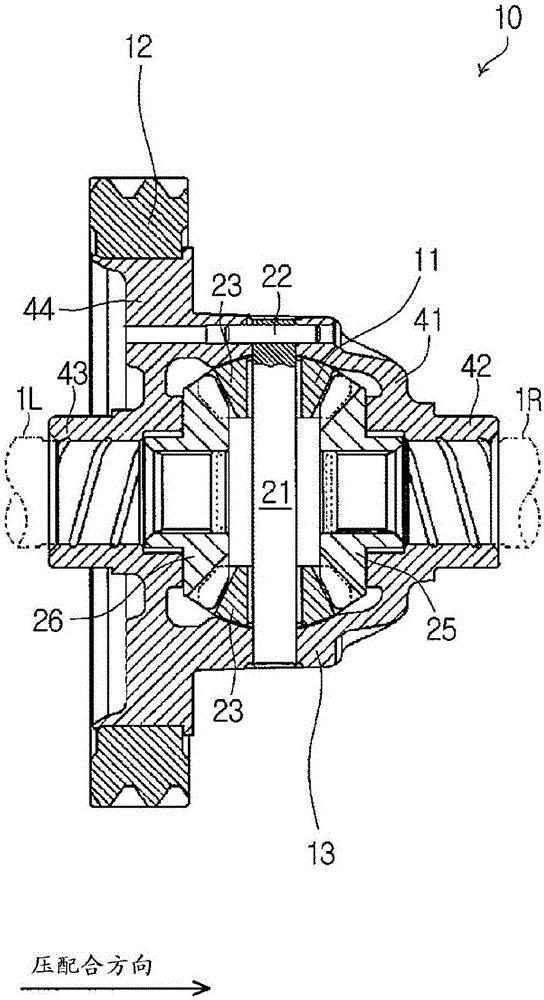

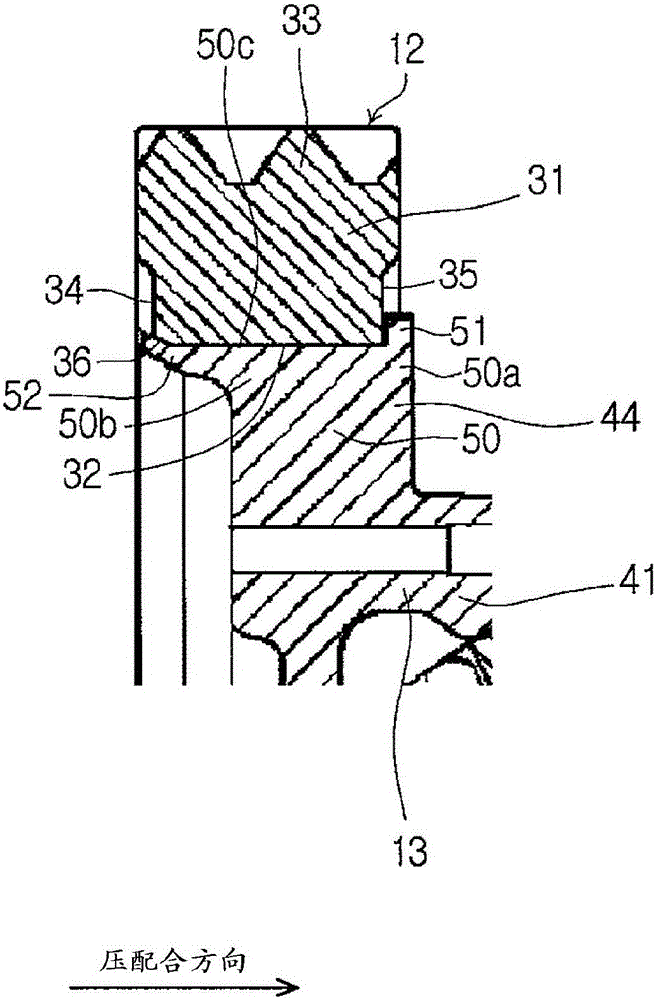

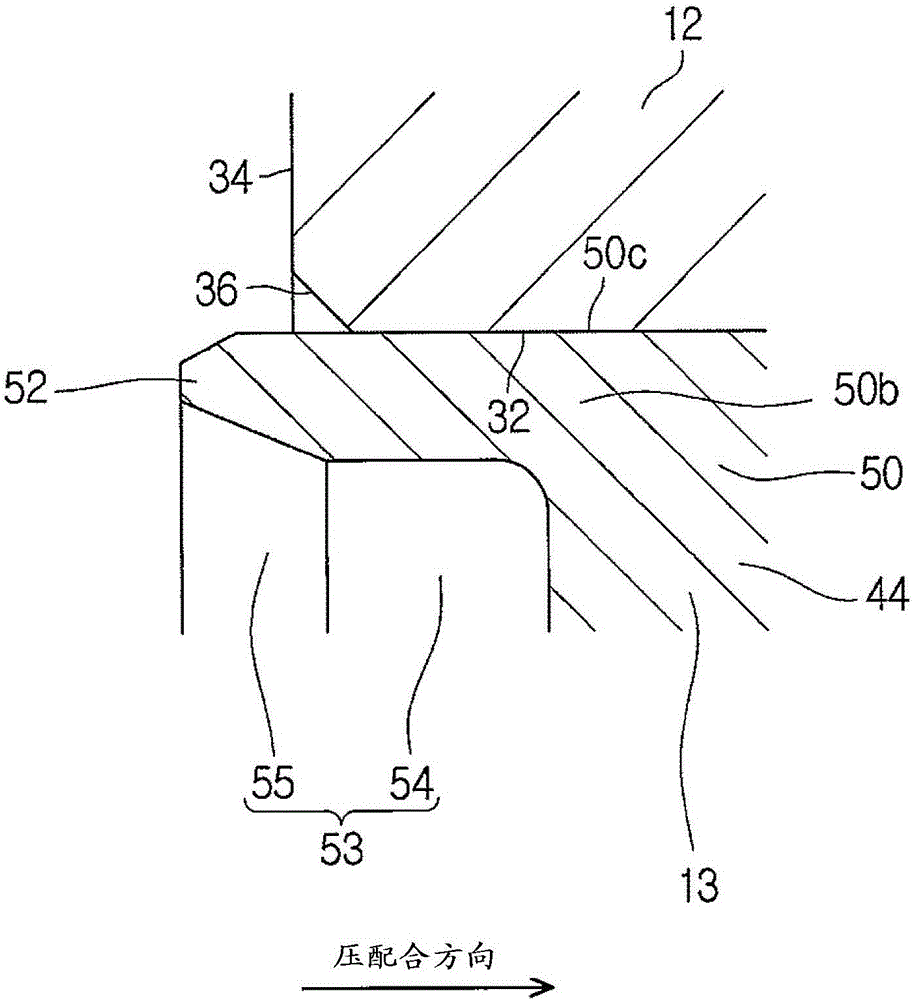

[0045] In the following, reference will be made to Figure 1 to Figure 11 The first embodiment will be described. Such as figure 1 As shown in , the differential 10 includes a differential mechanism 11 , a differential case 13 and a ring gear 12 , wherein the differential case 13 accommodates the differential mechanism 11 and the ring gear 12 is joined to the differential case 13 . The differential 10 transmits the power input to the differential 10 from the engine to the right drive wheel and the left drive wheel via the ring gear 12 . In addition, this differential 10 allows right and left drive wheels to rotate at rotational speeds different from each other through a differential mechanism 11 .

[0046] The differential mechanism 11 includes a pinion shaft 21 , a fixed pin 22 and a pair of pinion gears 23 . The pinion shaft 21 is supported by the differential case 13 . The fixing pin 22 fixes the pinion shaft 21 to the differential case 13 . A pair of pinion gears 23 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com