Selecting method of stress suspender used for hydraulic lifting and leveling of circular structure

A technology of hydraulic lifting and lifting force, applied in the direction of lifting devices, etc., can solve problems such as hidden dangers of construction and installation, breakage of booms, overload of booms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for selecting a stressed suspender used for hydraulic lifting and leveling of a circular structure, comprising the following steps:

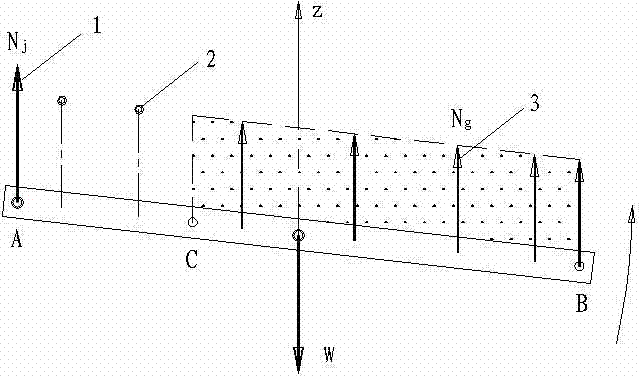

[0044] (a) Assuming that the total number of suspenders installed on the disc or ring structure is Z, the area where the Z suspenders are located is divided into a working area and a non-working area. The number of suspenders in the working area is Zg, and the non-working area The number of booms inside is Zf, and Zf=Z-Zg, where Z, Zg, and Zf are all positive integers;

[0045] (b) Assume that m sets of jacks are placed in series on each boom, the lifting force of a single jack is Pg, and the force of each working boom is Ng, then, Ng=m×Pg;

[0046] (c) Find the distance rc from the total resultant force Nc to the centerline of the disc or ring structure;

[0047] (d) Find the functional relationship between the lifting force Pg of a single jack and the number of jacks m, the number of booms Zg in the work area, the total number...

Embodiment 2

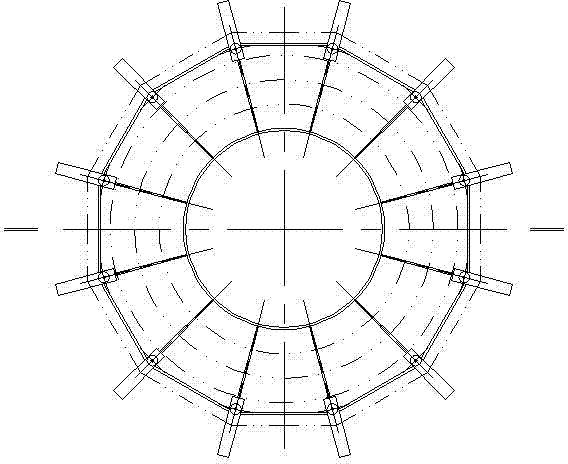

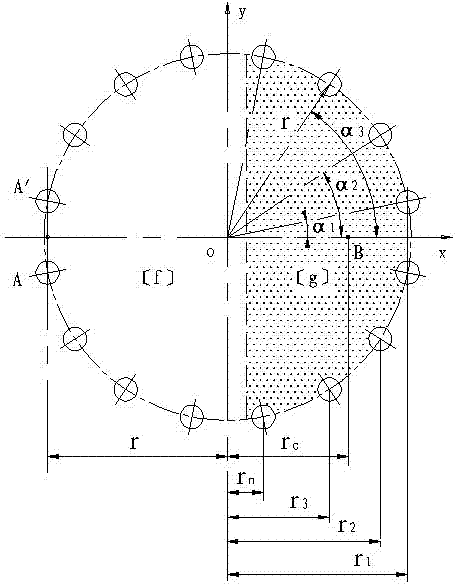

[0052] Such as image 3 , Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, the number of suspenders is firstly optimized so that the total number of suspenders Z is an even number equal to or greater than 8, and then the position of the suspenders is optimized so that the suspenders It is distributed in a circular shape on a circular structure, and the distance between two adjacent suspenders is equal, which is convenient for direction adjustment and standardization, and at the same time, the force is more reasonable.

[0053] Next, refine the entire selection method:

[0054] First, calculate the position of the resultant force.

[0055] According to the principle of moment balance, the sum of the product of the stress Ng of each working boom and the corresponding stress arm Li is equal to the product of the self-weight W of the disc or ring structure and the corresponding stress arm r, that is (1-1);

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com