Construction method for steel cofferdams in complex torrential water area

A construction method and technology of steel cofferdams, which are applied in the direction of infrastructure engineering, buildings, sheet pile walls, etc., can solve the problems of turbulent water flow, low recycling rate, difficult positioning and stability, etc., so as to reduce the impact of frontal water flow and Lateral water pressure, simplified construction steps, and obvious advantages in technical benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

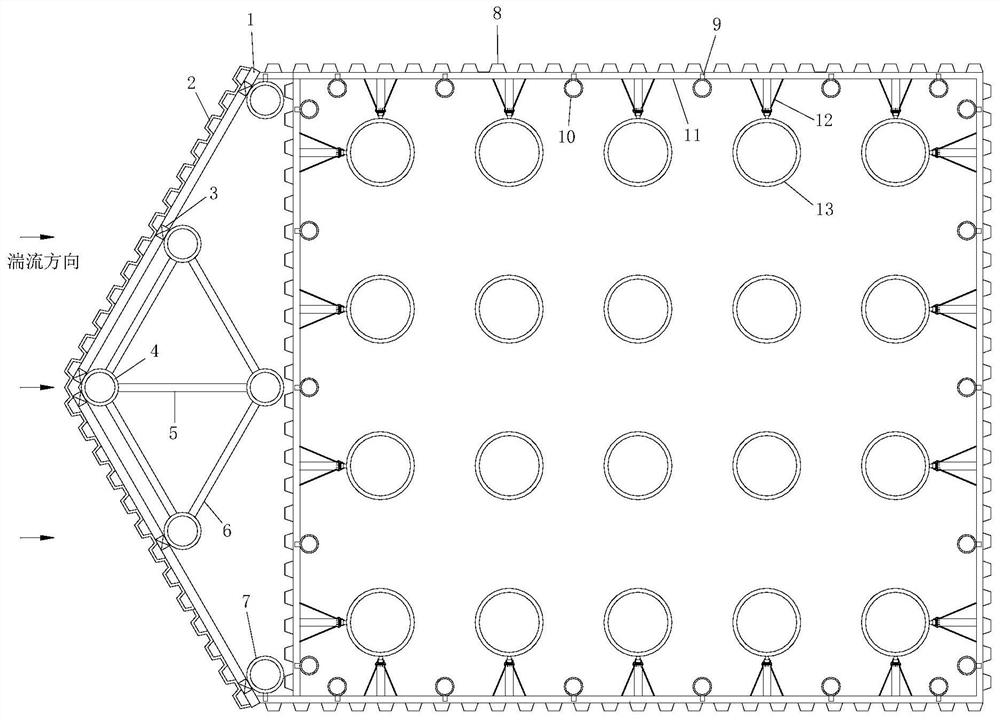

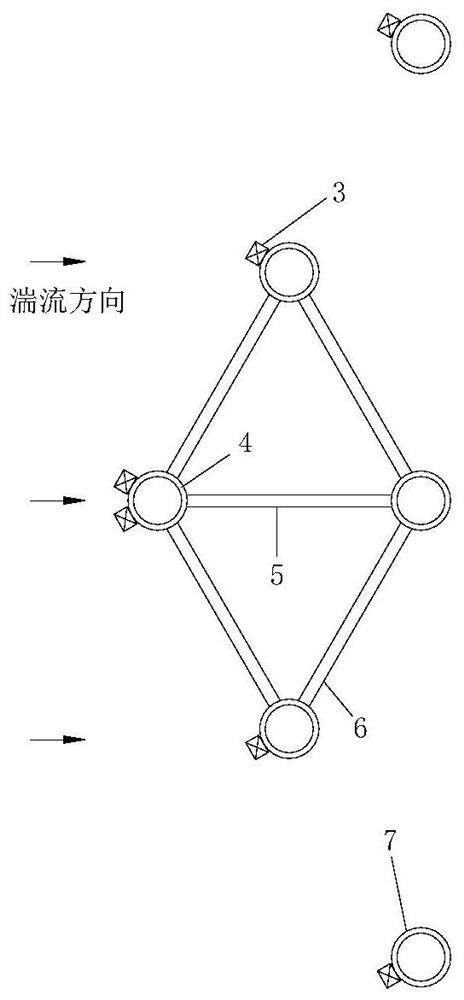

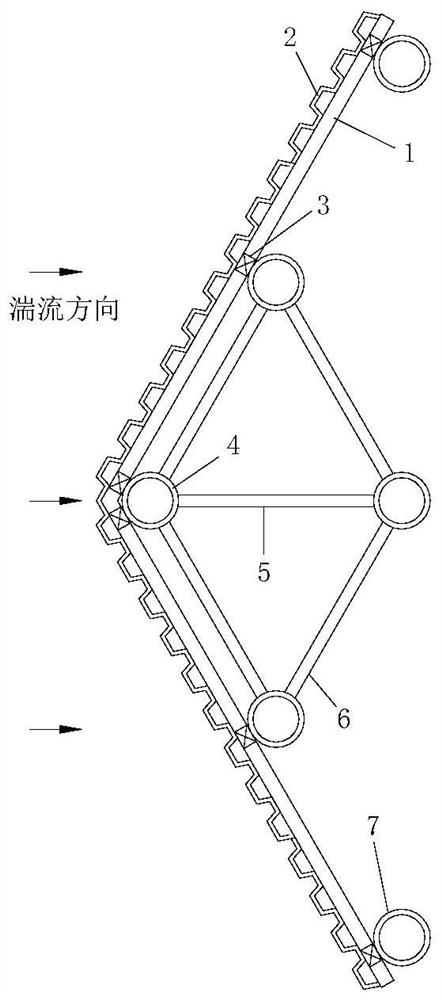

[0036] The steel cofferdam in complex and turbulent waters includes underwater cofferdam support 1, double-layer steel cofferdam 2, underwater bracket 3, diamond-shaped fixed pile groups, corner fixed steel pipe piles 7, and single-layer steel cofferdam 8 , guide bracket 9, guide pile 10, guide beam 11, bracing frame 12 and steel casing 13, described rhombus fixed pile group and corner fixed steel pipe pile 7 are all provided with underwater bracket 3, and described rhombus fixed The pile group and corner fixed steel pipe piles 7 are arranged on the turbulent side of the cofferdam construction of the river widening section, and the corner fixed steel pipe piles 7 are arranged on both sides of the diamond-shaped fixed pile group, and the underwater cofferdam supports 1 is set on the underwater bracket 3, the double-layer steel cofferdam 2 is set and fixed on the outside of the underwater cofferdam support 1, and the side of the corner fixed steel pipe pile 7 is provided with a g...

Embodiment 2

[0042] The construction method of the steel cofferdam in complex turbulent waters firstly carries out the construction of diamond-shaped fixed pile groups and the construction of two corner fixed steel pipe piles, then hangs the underwater cofferdam support on the surface facing the turbulence, constructs a double-layer steel cofferdam, and then Carry out the simultaneous construction of guide piles, guide beams, and single-layer steel cofferdams on both sides and the construction of inner guide piles, guide beams, and single-layer steel cofferdams, and then set up steel casings in the steel cofferdams. The steel casing of the weir is used for the construction of the support frame above the water, which is used for later pumping to resist the external water pressure, followed by the construction of the external guide piles, guide beams, and single-layer steel cofferdam. Finally, the inside of the steel cofferdam is dredged and the underwater concrete is poured The back cover, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com