Two-stage treatment process for landfill leachate based on DTRO and MVR

A landfill leachate and treatment process technology, which is applied in the field of landfill leachate two-stage treatment process based on DTRO and MVR, can solve the problems of complex manufacturing structure of MVR system, easy fouling and clogging of MVR system, low evaporation treatment efficiency, etc., to achieve Adapt to a wide range of working conditions, strong anti-pollution, simple and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

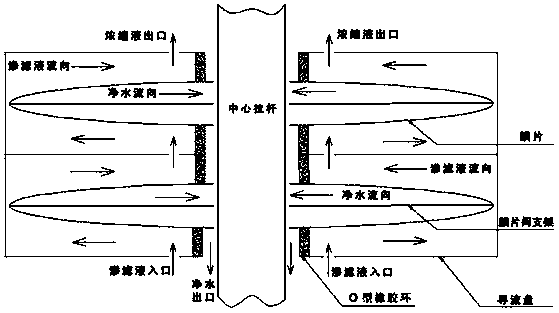

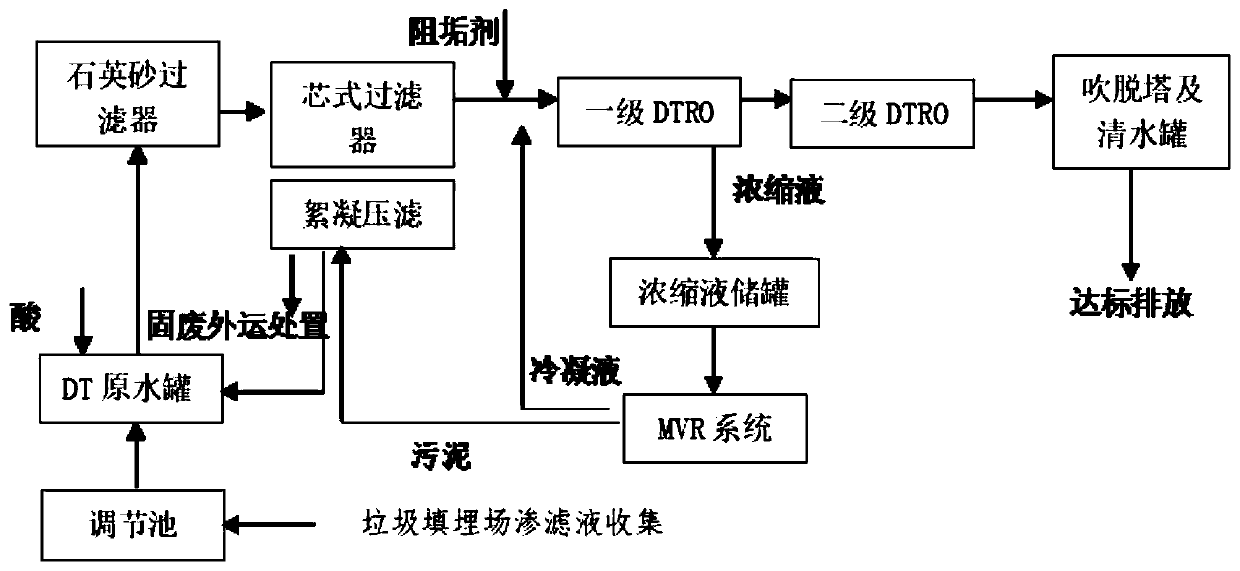

[0027] refer to Figure 1-2 , a two-stage treatment process based on DTRO and MVR landfill leachate, including the following steps:

[0028] S1: Acid conditioning treatment of raw water; the leachate A raw water produced by the landfill is collected by the pipe network, the water quality and quantity are adjusted through the regulating tank, and then lifted to the DT raw water tank by the floating pump, and acid is added to the DT raw water tank to regulate The pH of the raw water of the leachate A is obtained to obtain the leachate B; the acid adjustment of the raw water can reduce the scaling of carbonate inorganic salts and at the same time make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com