Multi-functional heating furnace

A heating furnace and multi-functional technology, applied in the field of heating furnace, can solve the problems of short service life and achieve the effects of reasonable structure, reduced maintenance time and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

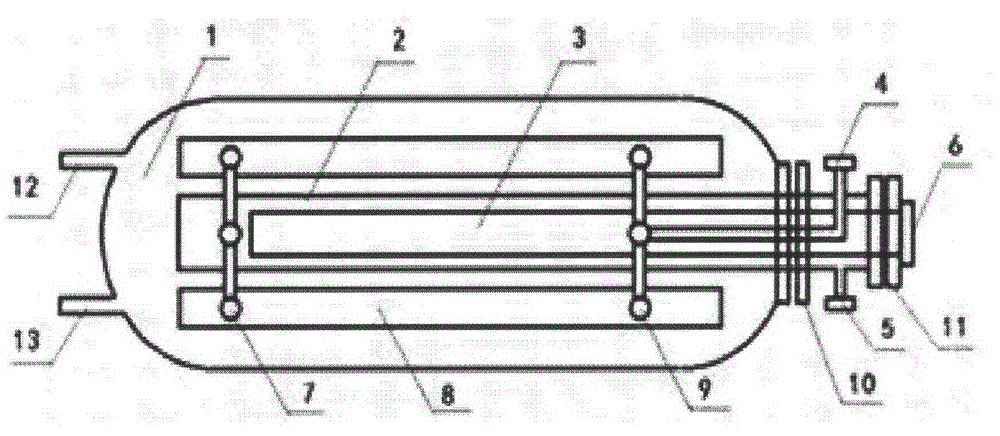

[0017] Such as figure 1 As shown, the multifunctional heating furnace includes a heating furnace shell 1 , a heat exchange cylinder 2 , a heating pipe 3 , and a power interface 6 . There are wing cylinders 8 on both sides of the main cylinder, the main cylinder and the left end of the wing cylinder are connected by a connecting pipe 7, the right end of the wing cylinder is connected with the outlet pipeline 4 at the upper right end of the main cylinder, and there is a circulating nozzle pipeline 5 at the lower right end of the main cylinder , the main cylinder and the shell are connected and sealed with the flange 10, and the main cylinder and the heating pipe are connected and sealed with the flange 11. There is a production fluid inlet pipeline 12 at the upper left end of the housing, and a production fluid outlet pipeline 13 at the bottom.

[0018] According to actual needs, the above multifunctional heating furnace can be further optimized or / and improved:

[0019] as att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com