Patents

Literature

31results about How to "Solve overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

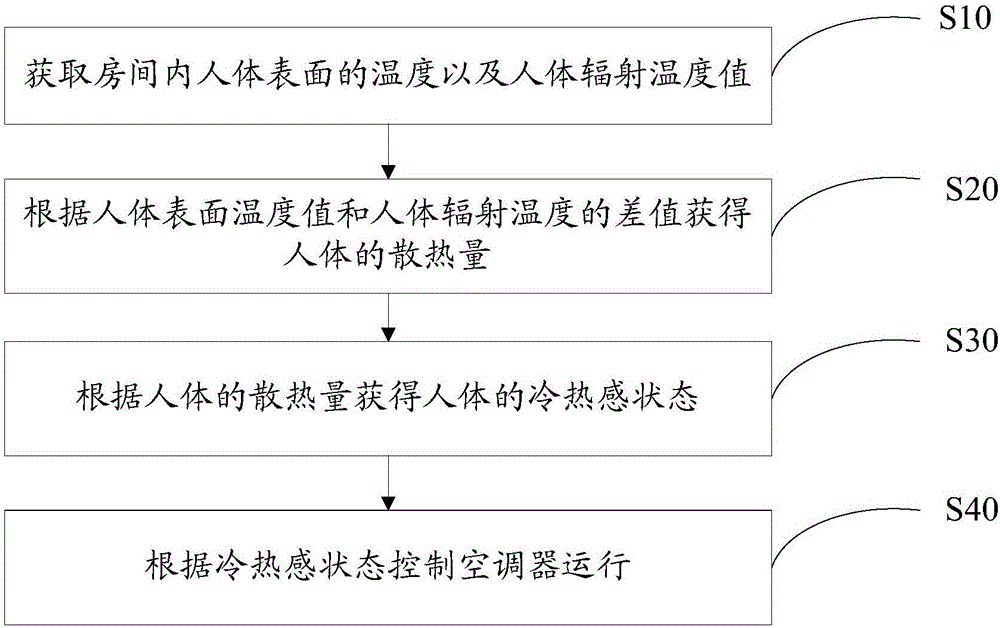

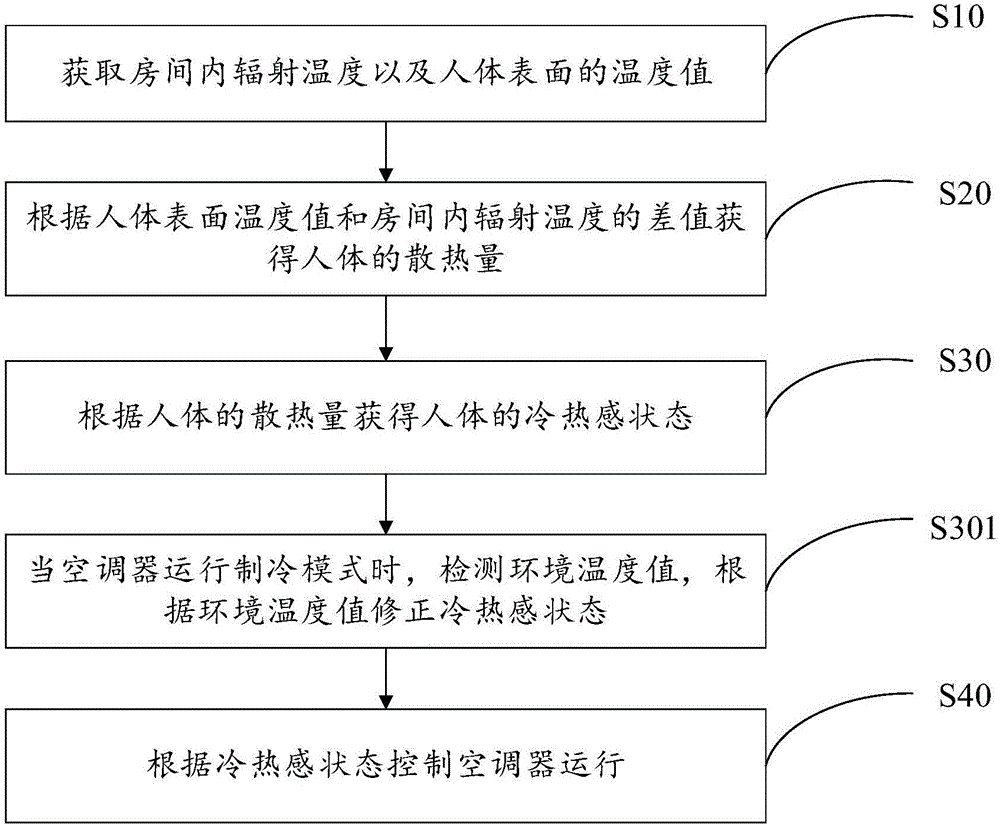

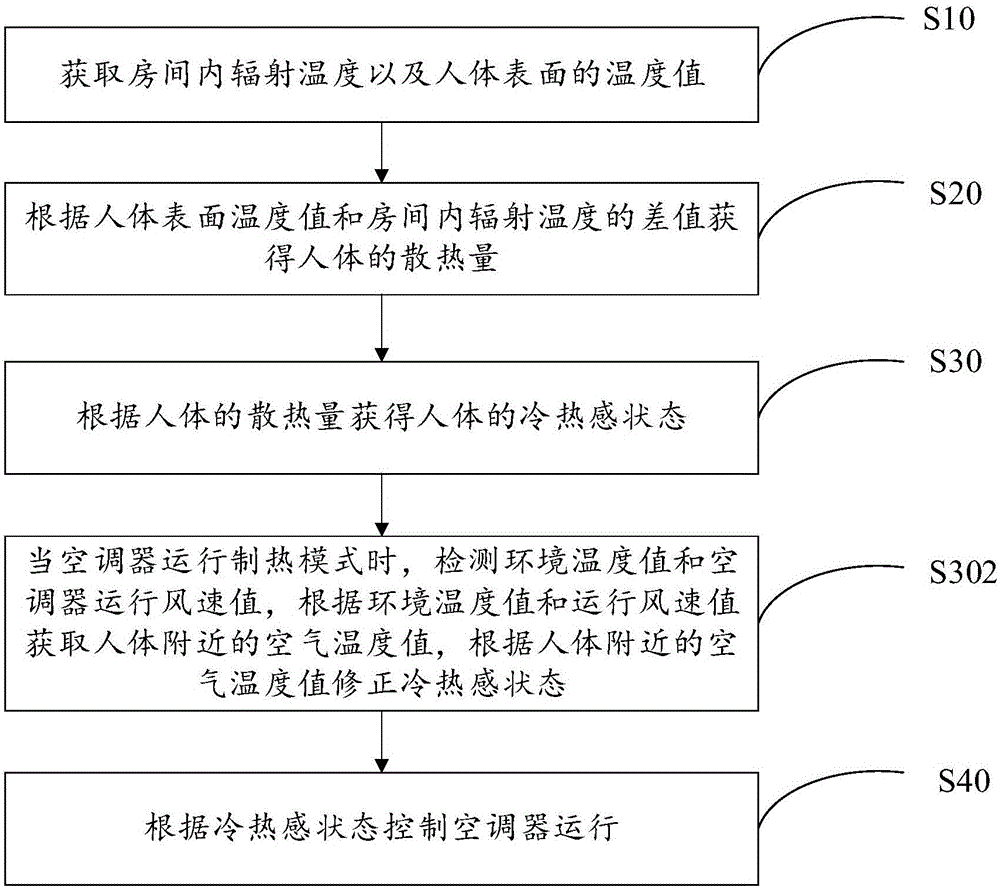

Control method of air conditioner and air conditioner

InactiveCN106196484ASolve overheatingImprove comfortMechanical apparatusSpace heating and ventilation safety systemsRadiation temperatureEngineering

The invention discloses a control method of an air conditioner. The control method of the air conditioner comprises the following steps: obtaining indoor radiation temperature and human body surface temperature value; obtaining the heat-dissipating capacity of the human body according to the difference value between the human body surface temperature value and the radiation temperature; obtaining the cold and hot feeling status of the human body according to the heat-dissipating capacity of the human body; and controlling operation of the air conditioner according to the cold and hot feeling status. The invention also discloses an air conditioner. According to the invention, the operation parameter of the air conditioner can be automatically adjusted according to the current cold and hot feeling status value of the human body, so that the human body is in a comfortable status, and the problem about overcooled or overheated discomfort caused by the fact that a user adjusts the operation parameter of the air conditioner manually is solved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

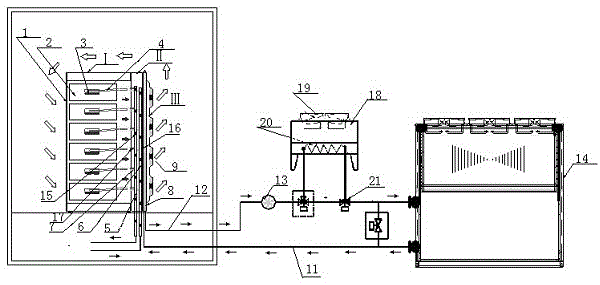

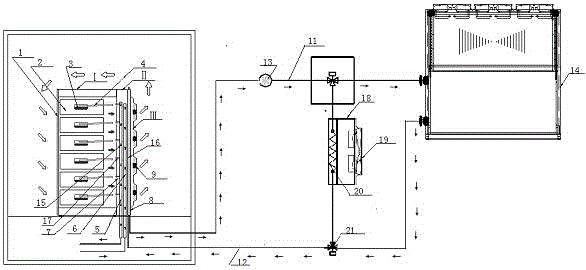

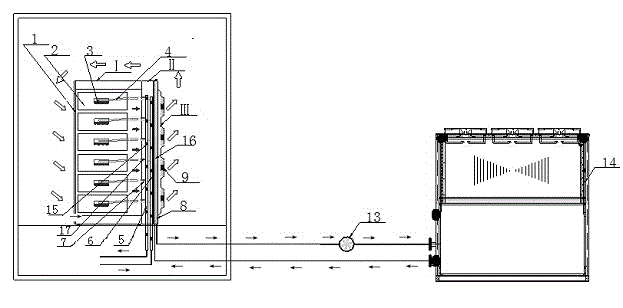

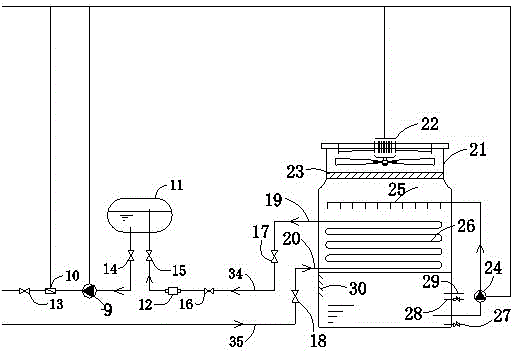

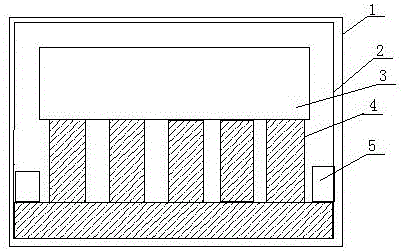

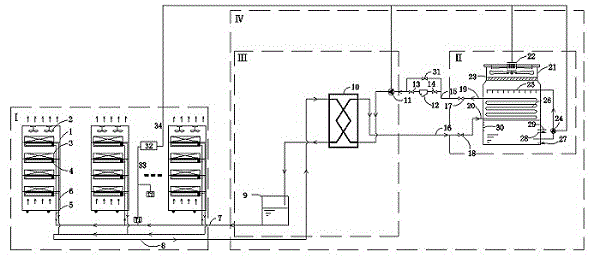

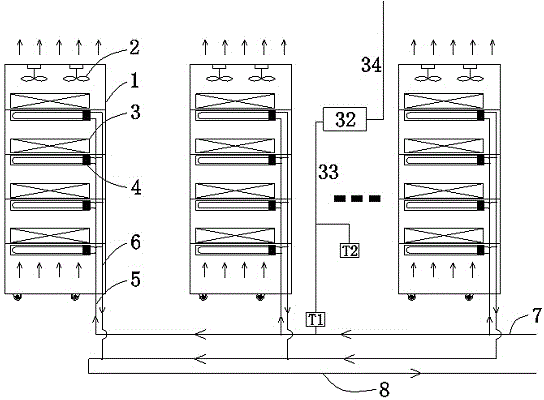

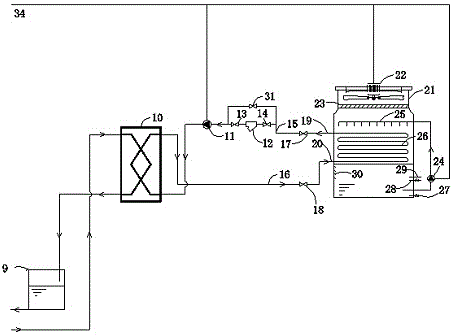

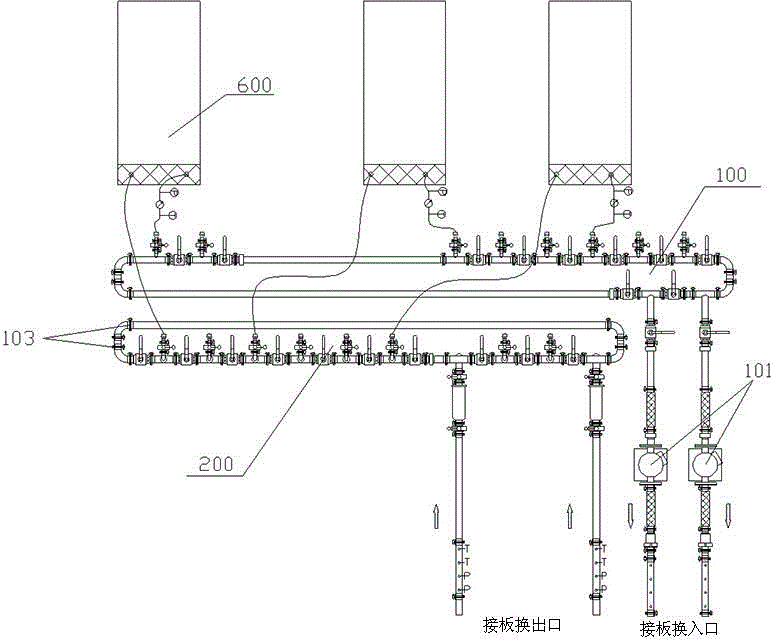

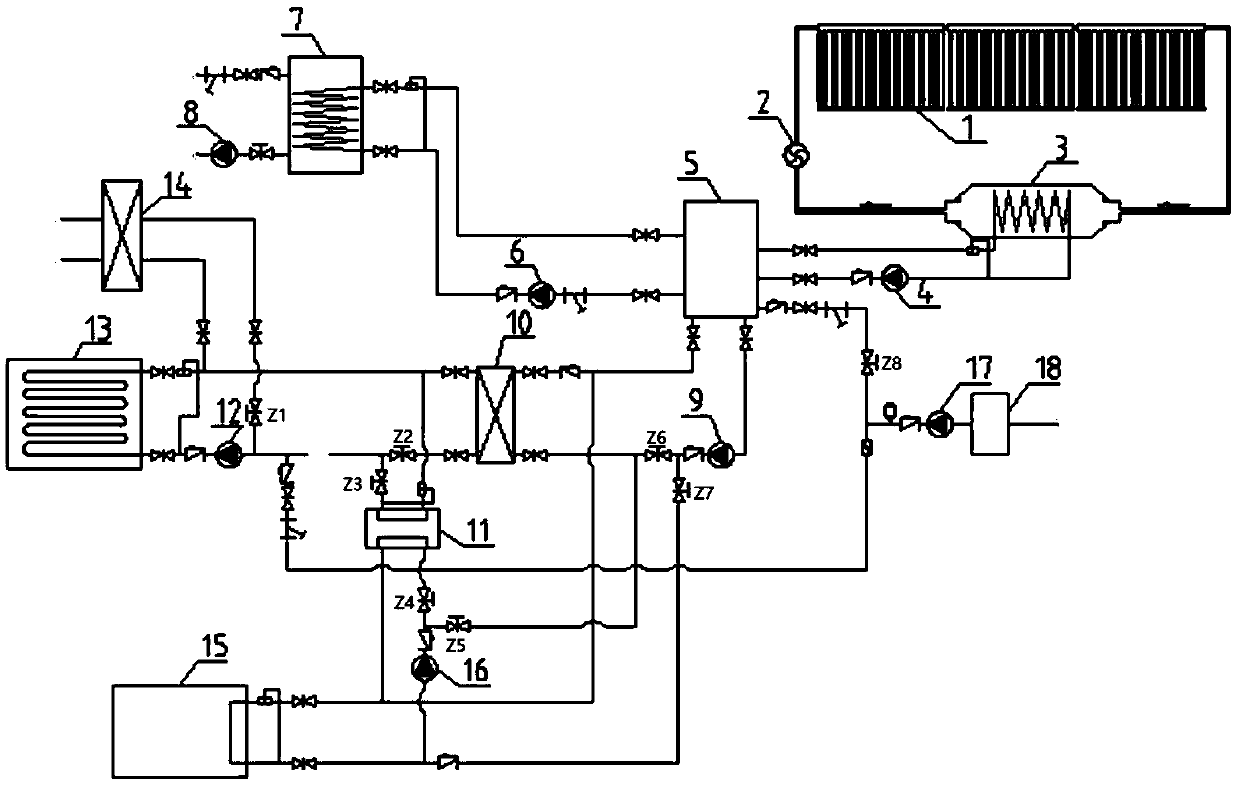

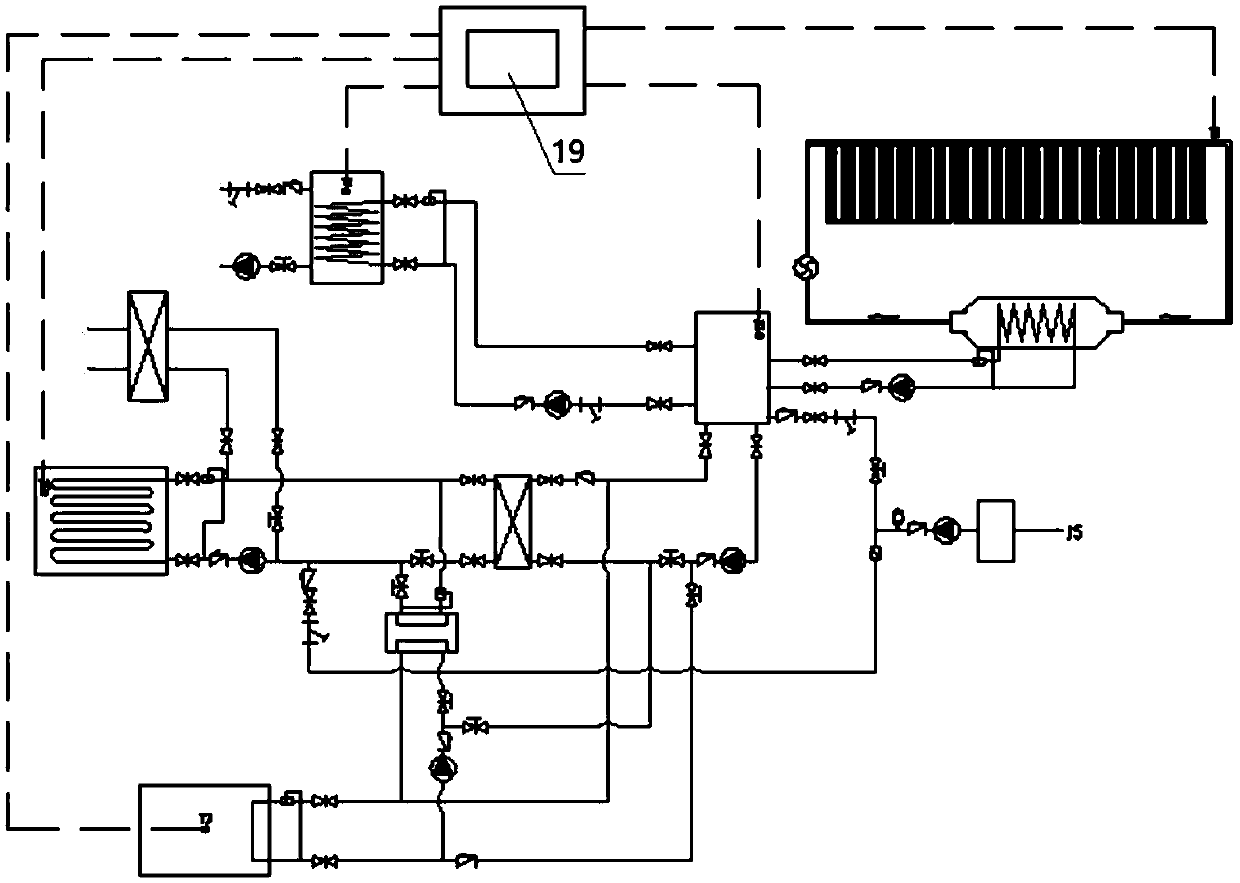

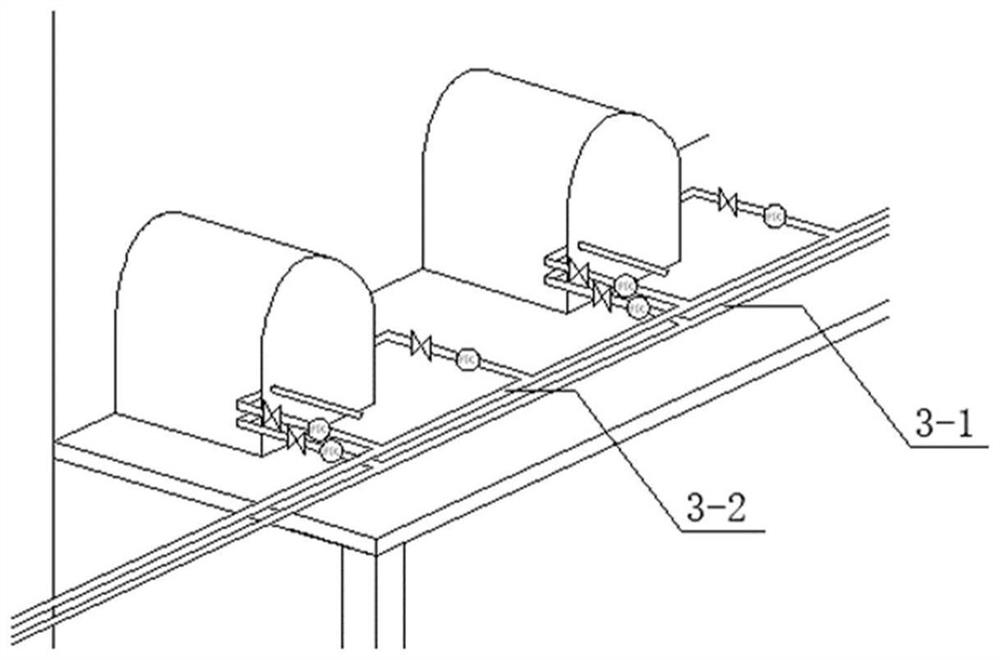

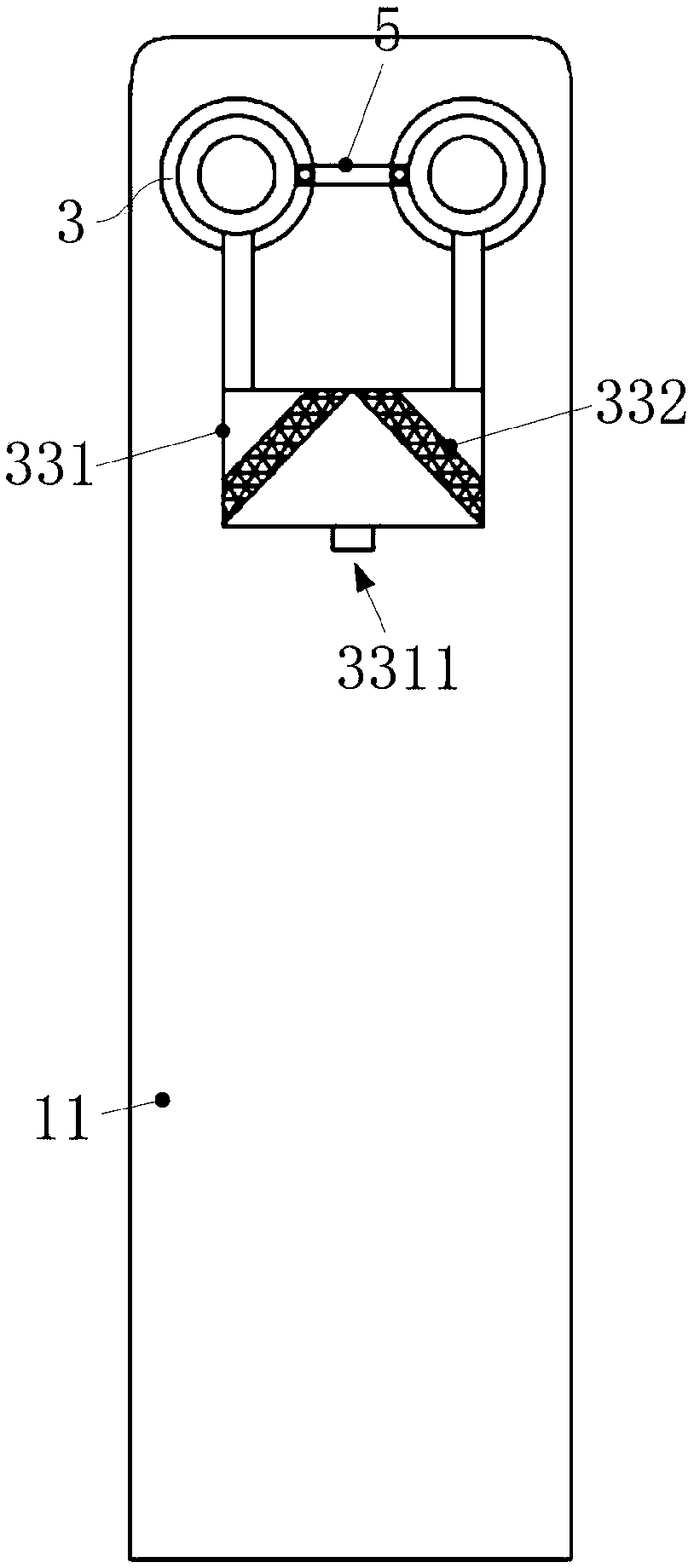

Natural cooling cold water device and liquid cooling device combined server cooling system

ActiveCN104703447AConducive to practical promotionRealize the cooling effectDigital data processing detailsEnergy efficient computingHigh densityDirect liquid cooling

The invention discloses a natural cooling cold water device and liquid cooling device combined server cooling system which comprises a liquid cooling server cabinet. The liquid cooling server cabinet comprises a cabinet body and multiple liquid cooling servers arranged in the cabinet body, is provided with liquid cooling devices for direct liquid cooling and heat dissipation of the liquid cooling servers and is further provided with a natural cooling cold water device for auxiliary heat dissipation. The natural cooling cold water device and liquid cooling device combined server cooling system is capable of performing high-density refrigeration, high in heat exchange efficiency, low in energy consumption, capable of solving local hot points, small in occupied area, high in reliability, small in noise and long in service life.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Lubricating system for gear box of wind generating set

ActiveCN101979872AImprove cooling effectSolve overheatingGear lubrication/coolingWind energy generationWind forceHeating system

The invention discloses a lubricating system for a gear box of a wind generating set. The system comprises an oil tank and the gear box, and is characterized in that: the oil tank is externally arranged independently, is provided with a circulation heating system, and is communicated with the gear box through a flexible rubber joint or a metal hose; oil pipes are arranged in the oil tank and are respectively connected with an electric pump I, an electric pump II and a mechanical pump; lubricating oil enters one-way valves I, II and III through each of the pumps, converges and enters a three-way temperature control valve after passing through filters I, II and III, and directly enters the gear box and / or enters the gear box through a panel cooler; and the panel cooler is connected in parallel with a circulating water system which consists of an air cooler I, an air cooler II, a water pump, a temperature sensor, a pressure tank, a pressure relay and a safety valve II. The system has the characteristics of high cooling effect, low vibration, improvement on heating efficiency, prolongation of lubricating service life and supply of early warning, and is suitable to be used in the lubricating system of the gear box of a large-scale fan.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

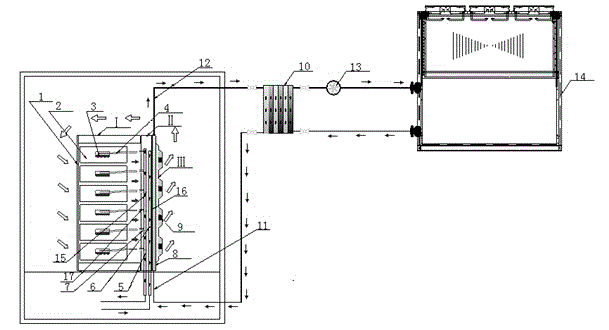

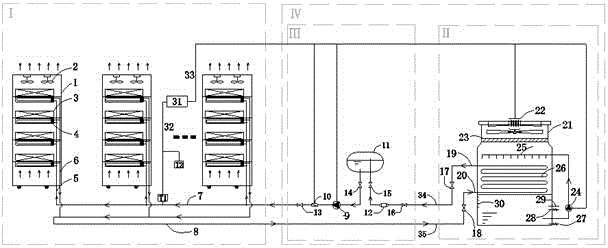

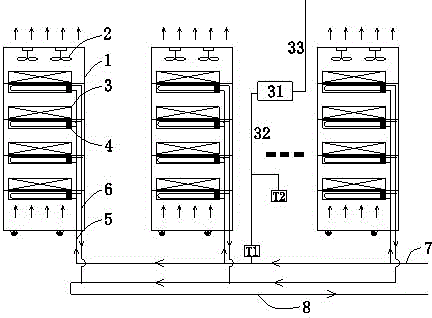

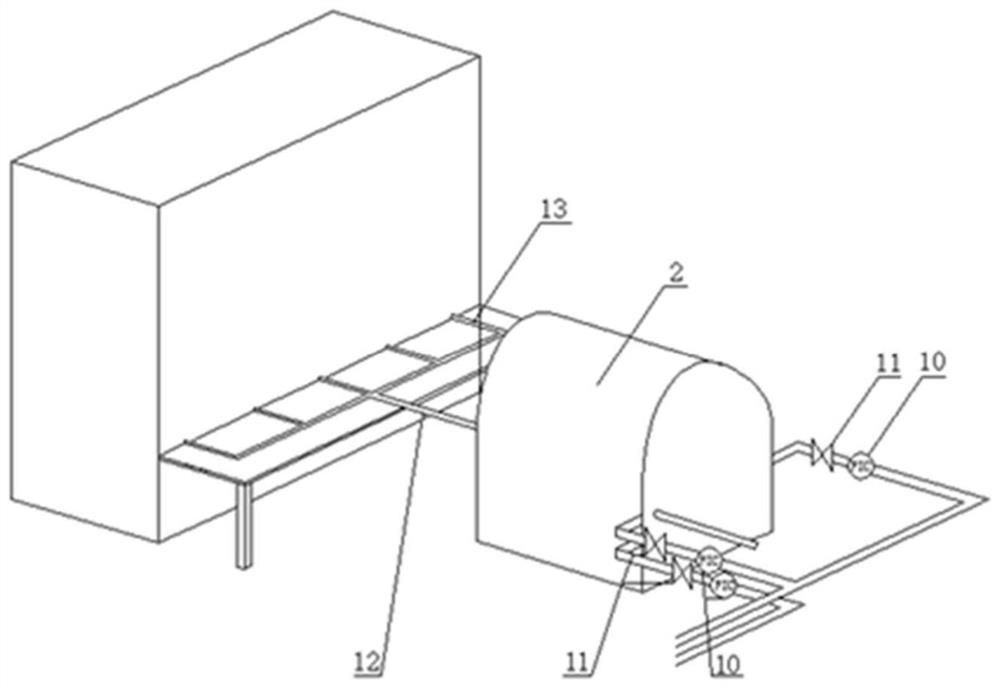

Server cabinet cooling system with combined gate-type heat pipe air-conditioner and liquid cooling device

ActiveCN104703449AConducive to practical promotionRealize the cooling effectCooling/ventilation/heating modificationsDirect liquid coolingEngineering

The invention discloses a server cabinet cooling system with combined gate-type heat pipe air-conditioner and liquid cooling device. The system comprises a liquid-cooled server cabinet; the liquid-cooled server cabinet comprises a cabinet body and a plurality of liquid-cooled servers arranged in the cabinet body; the liquid cooling device is arranged to perform direct liquid cooling heat dissipation on the servers; the gate-type heat pipe air-conditioner is further arranged to realize auxiliary heat dissipation. The server cabinet cooling system is high in cooling density, high in heat exchange efficiency, low in energy consumption, capable of solving local heat spots, small in floor area, high in reliability, low in noise and long in service life. A standard server cabinet can be applied to the system.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Server cabinet cooling system with combined gate-type cold water heat exchange device and liquid cooling device

ActiveCN104703448AConducive to practical promotionRealize the cooling effectCooling/ventilation/heating modificationsDirect liquid coolingSmall footprint

The invention discloses a server cabinet cooling system with combined gate-type cold water heat exchange device and liquid cooling device. The system comprises a liquid-cooled server cabinet; the liquid-cooled server cabinet comprises a cabinet body and a plurality of liquid-cooled servers arranged in the cabinet body; the liquid cooling device is arranged to perform direct liquid cooling heat dissipation on the servers; the gate-type cold water heat exchange device is further arranged to realize auxiliary heat dissipation. The server cabinet cooling system is high in cooling density, high in heat exchange efficiency, low in energy consumption, capable of solving local heat spots, small in floor area, high in reliability, low in noise and long in service life.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

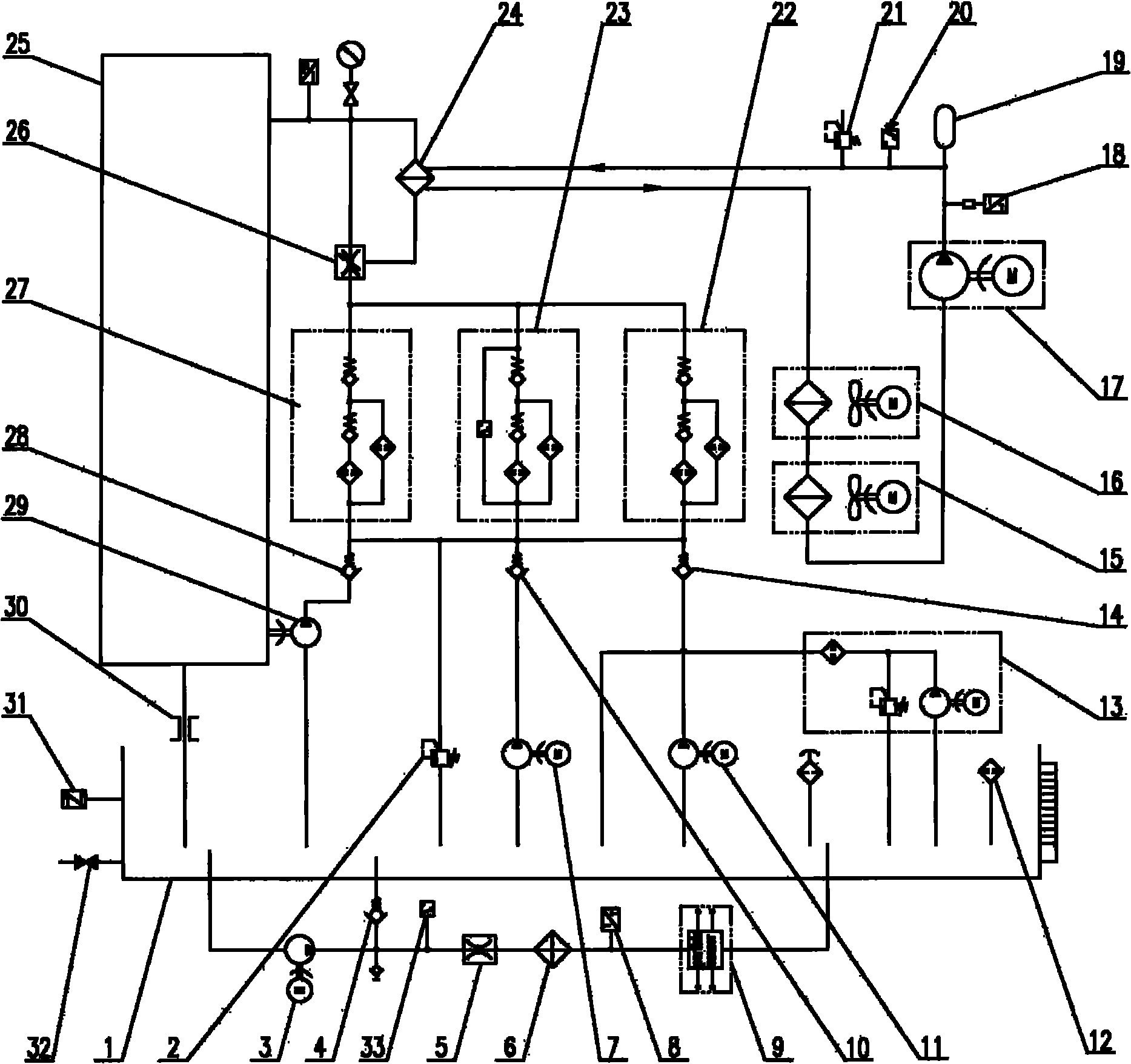

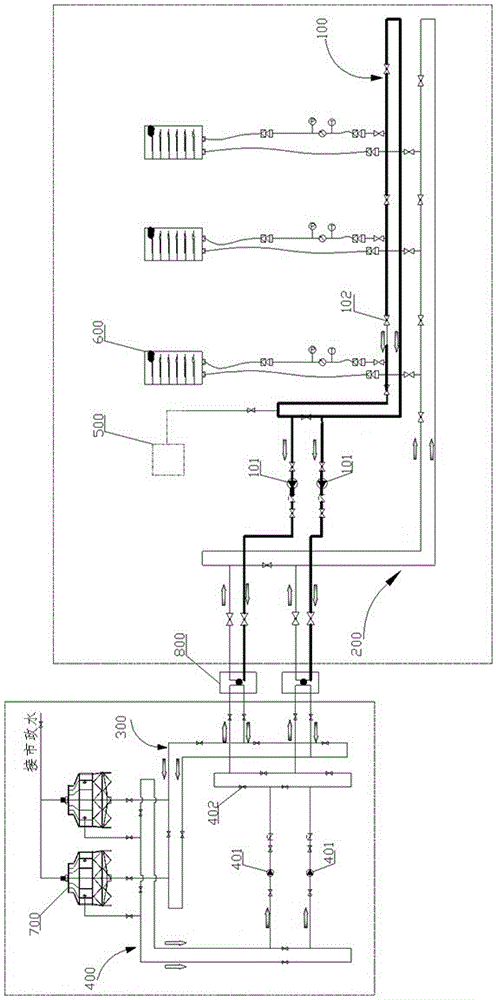

Control method of fluorine-pump primary loop server cabinet heat radiation system

ActiveCN105451509ARealize short-distance precise conveyingSolve overheatingLighting and heating apparatusRefrigeration devicesProcess engineeringPower unit

The invention discloses a control method of a fluorine-pump primary loop server cabinet heat radiation system. The fluorine-pump primary loop server cabinet heat radiation system comprises a machine room unit and a refrigerant fluorine supplying and returning unit, wherein the refrigerant fluorine supplying and returning unit comprises a circulating power unit and a cooling unit; and the machine room unit, the circulating power unit and the cooling unit are connected in sequence to form closed circulation. The control method of the fluorine-pump primary loop server cabinet heat radiation system achieves short-distance accurate transport of cool air of a cabinet, and solves problems of local overheat and existence of hot spots of the server cabinet; meanwhile, a natural cooling measure is adopted so that heat exchange temperature difference is huge and efficiency is high; and active condensation prevention is adopted, so that the system has the advantages of high reliability, low power consumption and low noise, and satisfies an energy saving and environment protecting concept.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

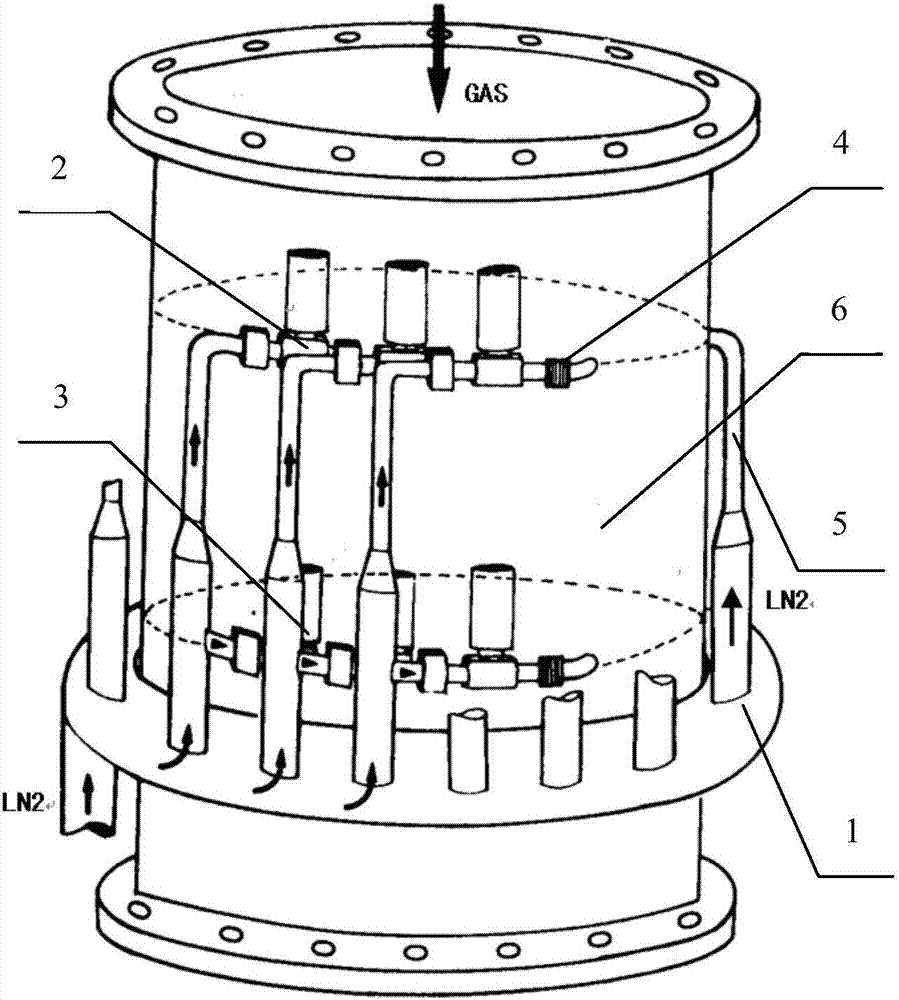

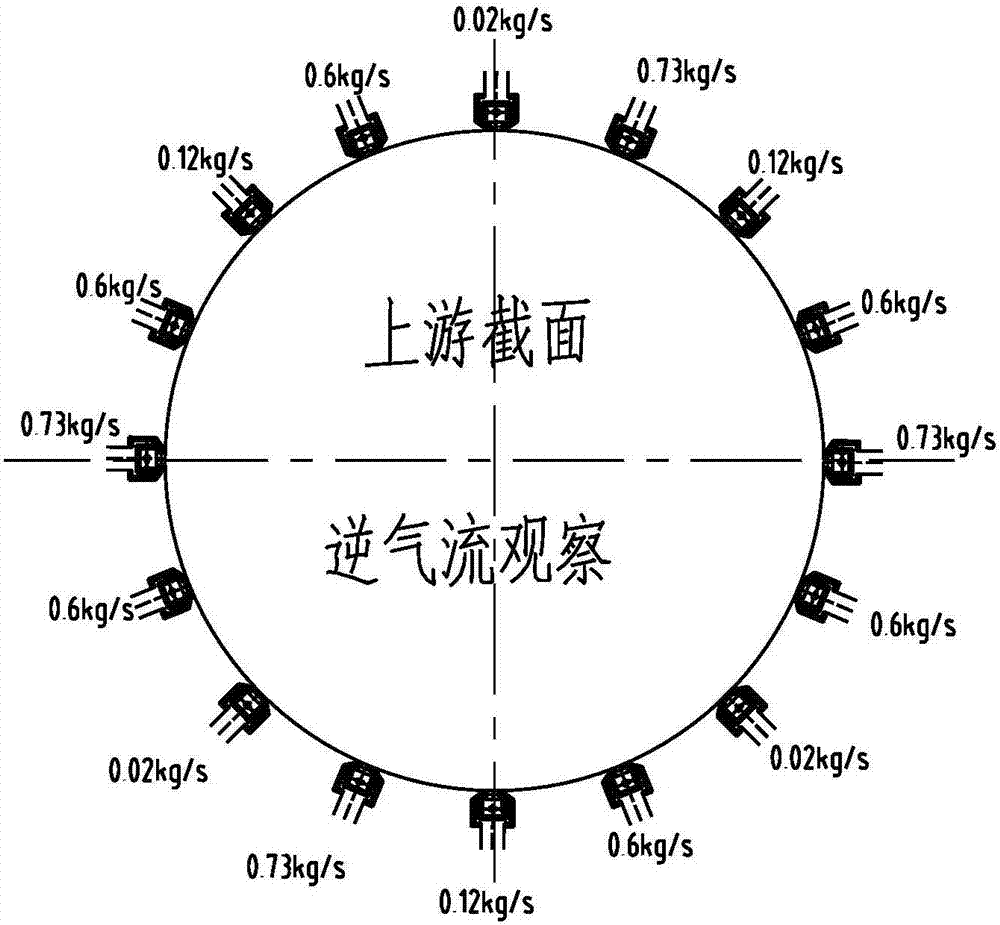

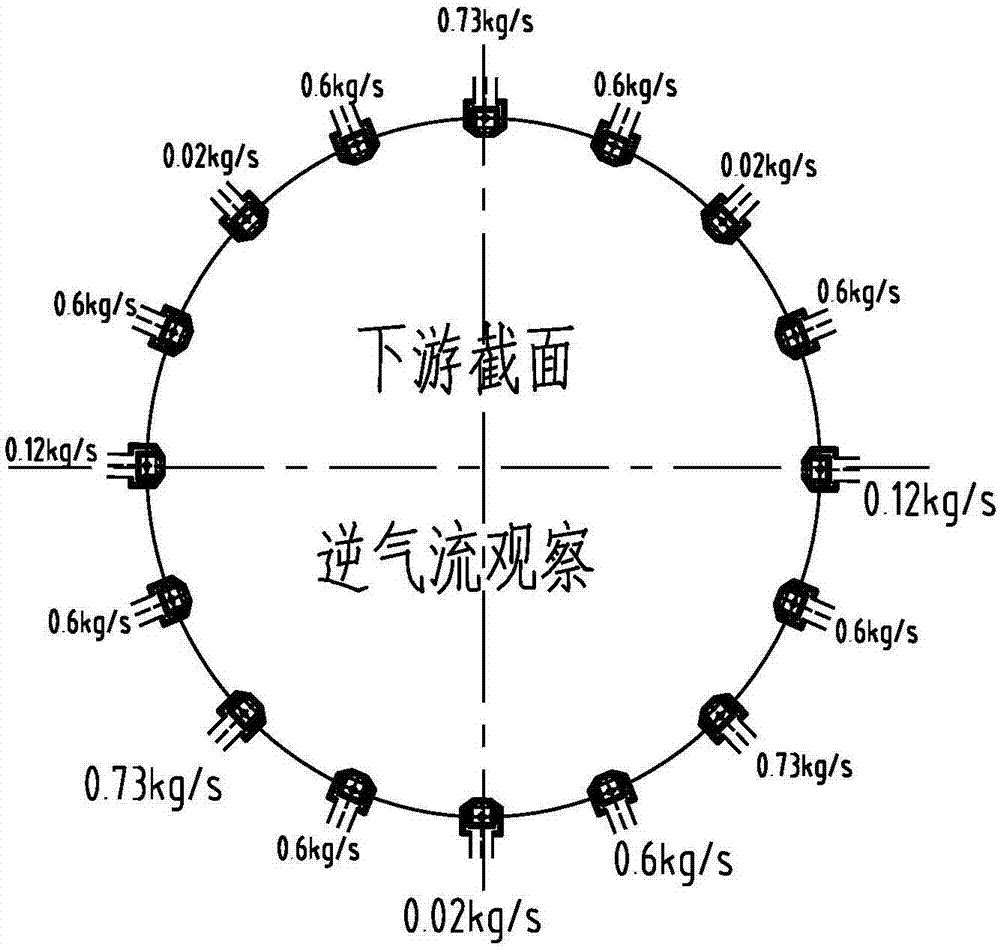

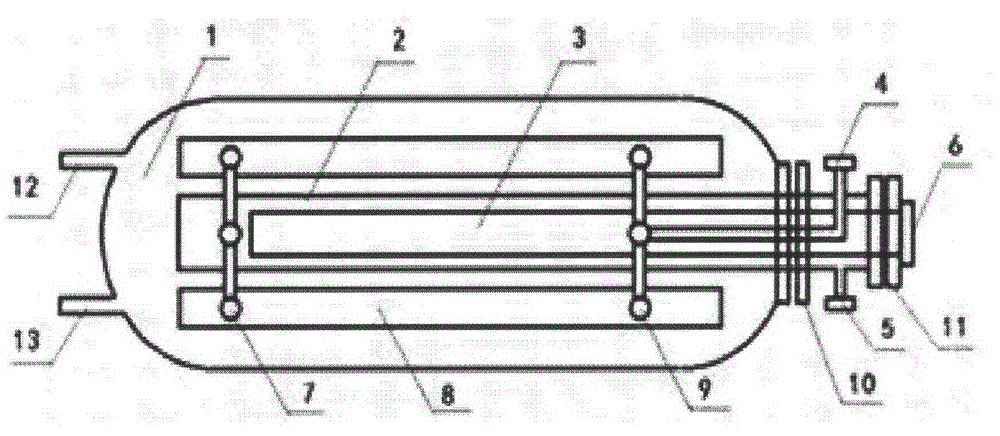

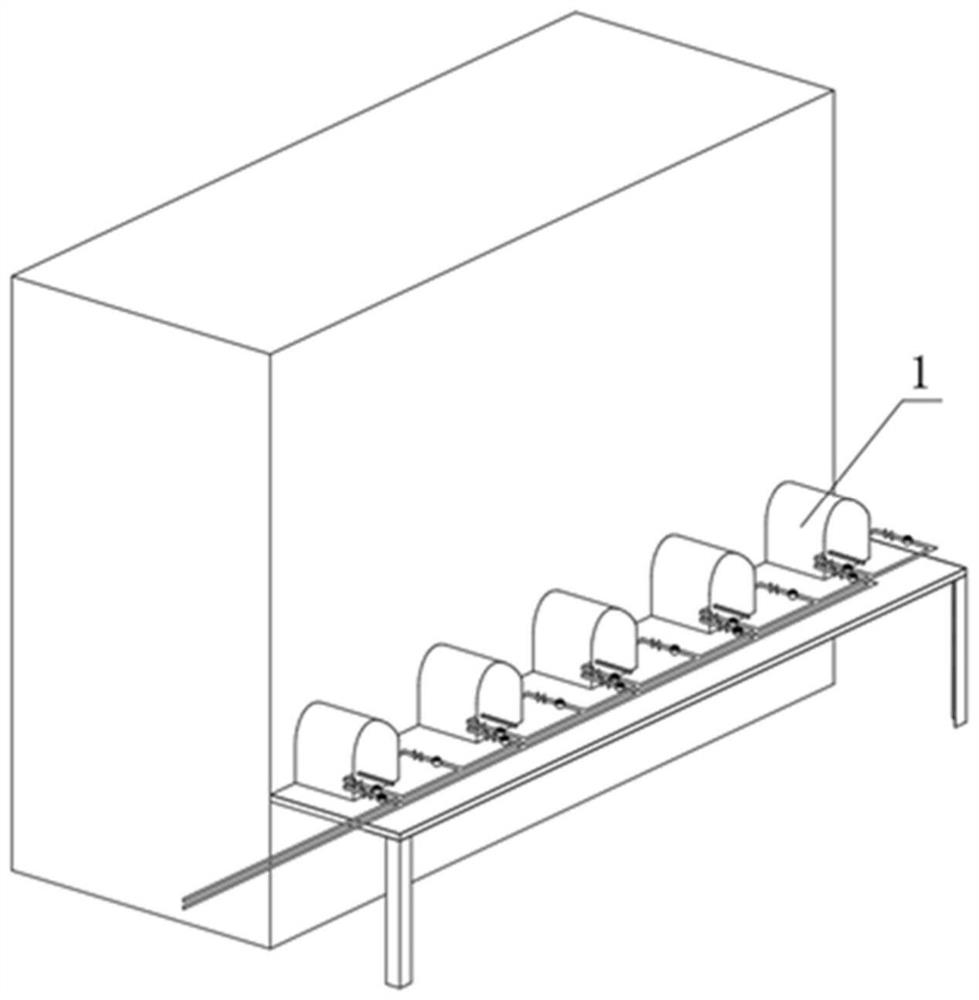

Liquid nitrogen injection device for continuous high-speed wind tunnel cooling system

The invention proposes a liquid nitrogen injection device for a continuous high-speed wind tunnel cooling system, and the device comprises a liquid collection ring, an upstream liquid nitrogen nozzle block, and a downstream liquid nitrogen nozzle block. The liquid nitrogen injection device is installed in a liquid nitrogen injection experiment segment. The liquid collection ring is an annular low-temperature-resistant stainless steel pipe, and the internal diameter of the liquid collection ring is the same as the external diameter of an experimental wind tunnel at an installation position. The liquid collection ring is installed at the experimental wind tunnel in an annular manner, and is used for receiving the low-temperature liquid nitrogen from a main pipe and conveying the liquid nitrogen to the liquid nitrogen nozzle blocks. The upstream and downstream liquid nitrogen nozzle blocks are distributed along the air flow axis of the wind tunnel in a parallel manner. The distance between the upstream liquid nitrogen nozzle block and the upstream end face of the experimental segment is 0.61d, and the distance between the downstream liquid nitrogen nozzle block and the upstream end face of the experimental segment is 1.72d, wherein d is the internal diameter of the upstream end face of the experimental segment. The matching of the device with the whole cooling system of the wind tunnel is good. The technical scheme of the invention provides support for the building of the first Chinese continuous high-speed wind tunnel cooling system.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

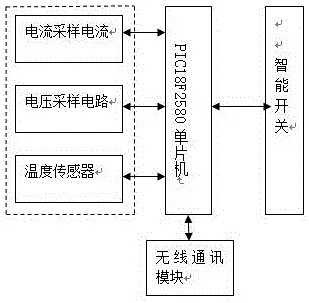

Intelligent solid state relay with efficient protection function

The invention discloses an intelligent solid state relay with an efficient protection function. The intelligent solid state relay comprises a shell and a control system, wherein a heat dissipation device is arranged in the shell; the heat dissipation device is arranged on a bottom board of the shell; a DCB board is arranged on the heat dissipation device; the DCB board is provided with an integrated circuit; the integrated circuit comprises a coupling circuit, a triggering circuit, a switching circuit, an absorbing circuit and a zero pass control circuit; the control system comprises a detection module, a control module and an execution module; the detection module is used for detecting a voltage and current in a relay circuit and temperatures of elements; the control module is used for receiving data of the detection module, comparing the data with a preset threshold, and sending an execution command; and the execution module is used for receiving the execution command sent by the control module to perform over-voltage protection, over-current protection and over-heat protection. Through adoption of the intelligent solid state relay, heat dissipation processing, over-current protection and over-voltage protection can be performed automatically and rapidly, and normal working of the solid state relay is protected effectively.

Owner:CHENGDU DESHANNENG TECH CO LTD

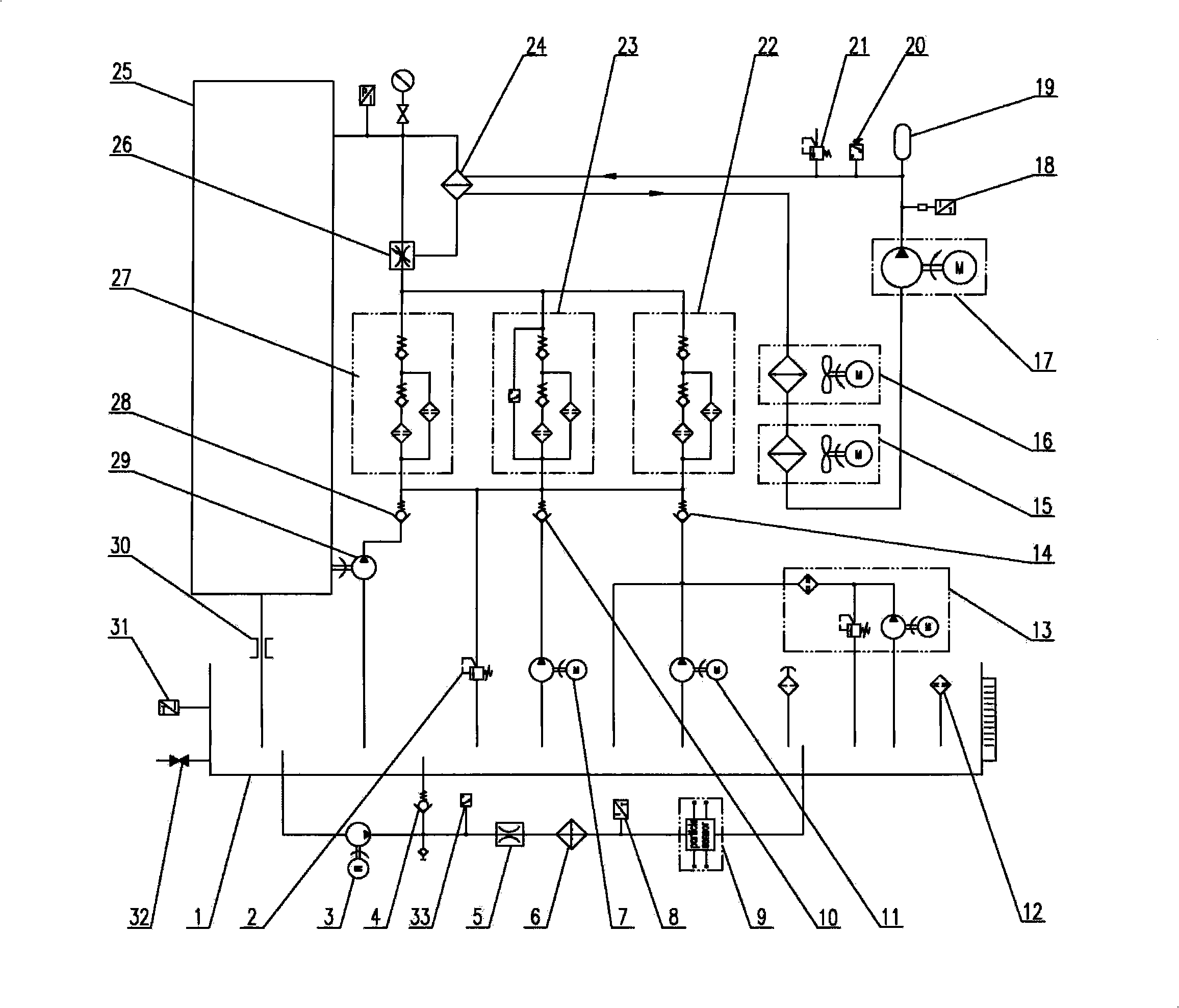

Heat-pipe internal-circulation secondary refrigerant loop server cabinet heat radiation system

InactiveCN105430997ARealize short-distance precise conveyingSolve overheatingMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsProcess engineering

The invention discloses a heat-pipe internal-circulation secondary refrigerant loop server cabinet heat radiation system which comprises a machine room unit and a refrigerant fluorine supplying and returning unit, the refrigerant fluorine supplying and returning unit comprises a circulating power unit and a cooling unit, and the circulating power unit forms closed circulation with the machine room unit through a first refrigerant loop and forms closed circulation with the cooling unit through a second refrigerant loop. The system realizes short-distance accurate transportation of cool air of a cabinet and solves problems of local overheat and existence of hot spots of the server cabinet ; and, at the same time, a natural cooling measure is used so that a heat exchange temperature difference is huge and efficiency is high, and active anti-condensation is adopted so that the system has the advantages of high reliability, low power consumption and low noise and satisfies an energy saving and environment protecting concept.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

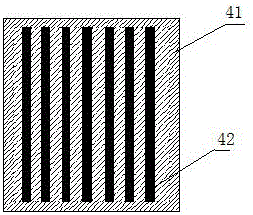

PTC inorganic composite material and preparation method and application thereof

ActiveCN106467412AConductiveRealize the effect of internal insulationHeating element materialsNon-adjustable resistorsGraphite carbonEconomic benefits

The invention provides a PTC inorganic composite material, which is mainly prepared from the following raw materials (by weight): 75-95% of a nano-ceramic material, 1-20% of a graphite carbon material coating agent and 0.5-5% of a dispersant. A preparation method of the composite material comprises the following steps: mixing the nano-ceramic material and the graphite carbon material coating agent, adding the dispersant and a proper amount of ethanol and uniformly mixing to obtain a uniform solution, and carrying out heat treatment under the protection of inert gas at the temperature of no more than 200 DEG C. According to the PTC inorganic composite material of the embodiment, an inorganic material, namely the nano-ceramic material, is compounded with the graphite carbon material coating agent, and the carbon material is used for coating particles of the inorganic material so as to realize conductivity and internal insulation effects of the carbon material. The material can be applied to electrical heating materials, such as carbon crystal heating panels. Properties are more stable, and problems such as aging, bloating, etc. will be avoided. Properties of the carbon crystal panels are subversively enhanced, service life is greatly prolonged, and considerable economic benefit is also generated.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

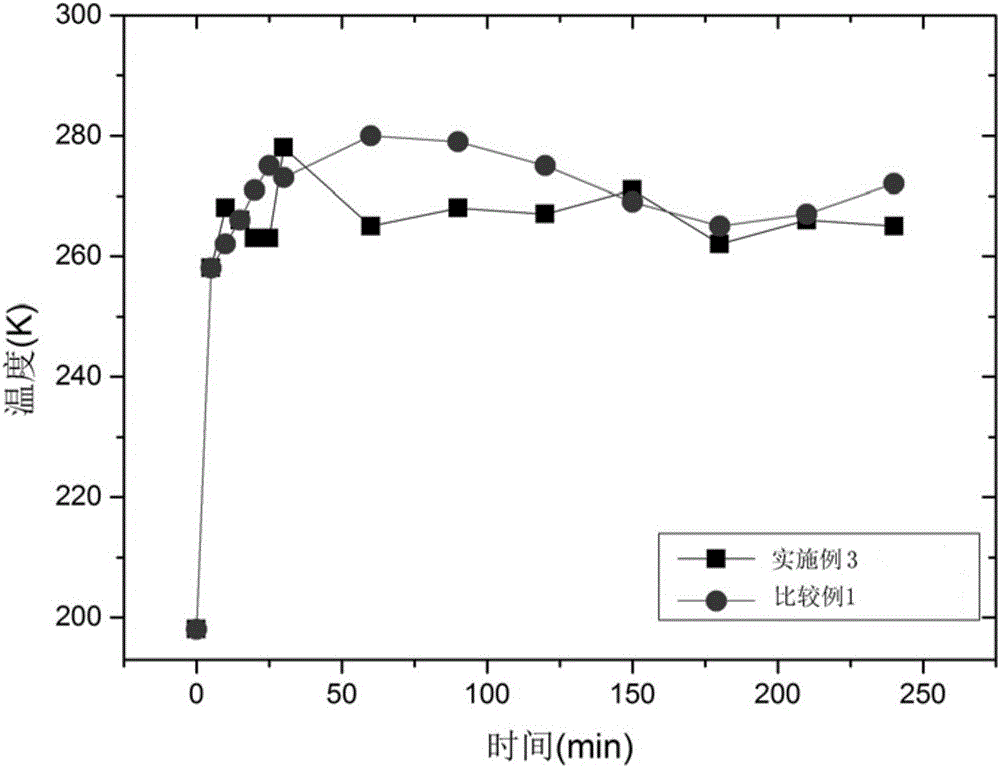

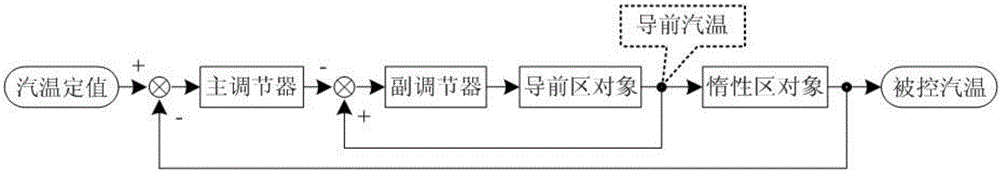

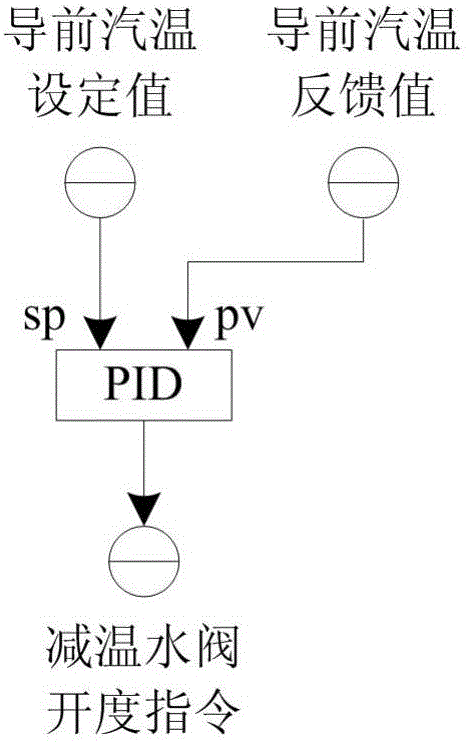

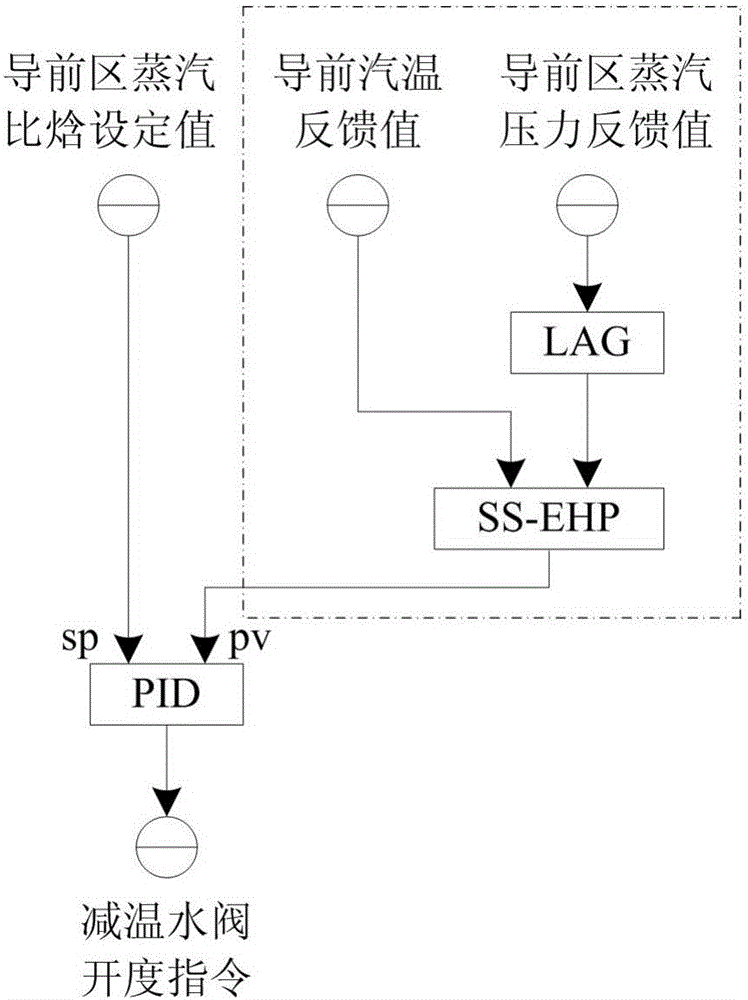

High-quality steam temperature control system for power station boiler

InactiveCN105953207ASolve overheatingSolve quality problemsSuperheating controlBoiler controlSteam pressureEngineering

The invention provides a high-quality steam temperature control system for a power station boiler. A leading segment steam specific enthalphy signal is used as a quick loop feedback signal in the double-loop steam temperature control system, and the control logic of the leading segment steam specific enthalphy feedback loop part of the system is that a leading steam temperature feedback value signal and a leading segment steam pressure feedback value signal obtained after one-order inertia smoothing is conducted are input into a steam specific enthalphy computing module at the same time, the leading segment steam specific enthalphy signal is worked out through the steam specific enthalphy computing module, and then the leading segment steam specific enthalphy signal is used as the quick loop feedback signal in replacement of a leading steam temperature signal to be introduced into the steam temperature control system. According to the high-quality steam temperature control system for the power station boiler, the leading segment steam specific enthalphy replaces the leading steam temperature and serves as the quick loop feedback signal, the problems of reduction of the steam temperature control quality caused by overheat and reheat under the large-amplitude high-speed variable-load working condition of a thermal power generating unit are solved, and the function of stabilizing the steam pressure of the boiler can be played. Furthermore, the high-quality steam temperature control system for the power station boiler has the beneficial effects of being easy to configure and debug and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

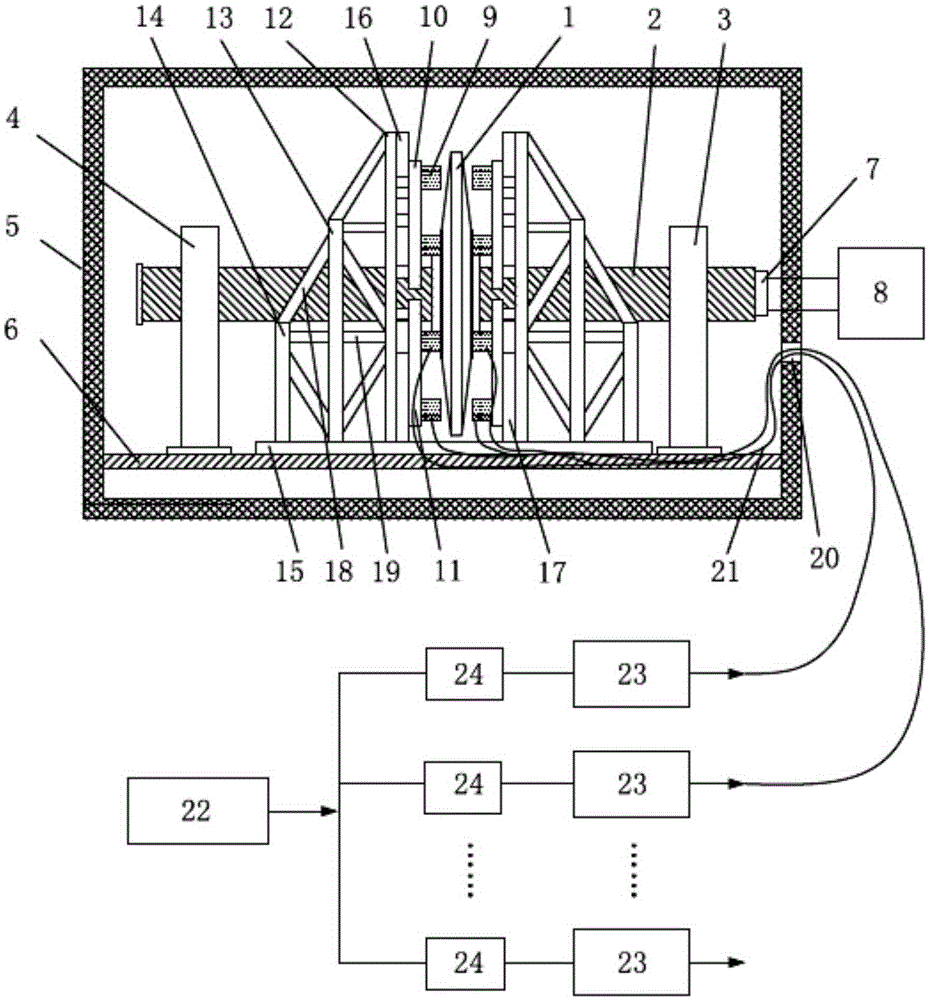

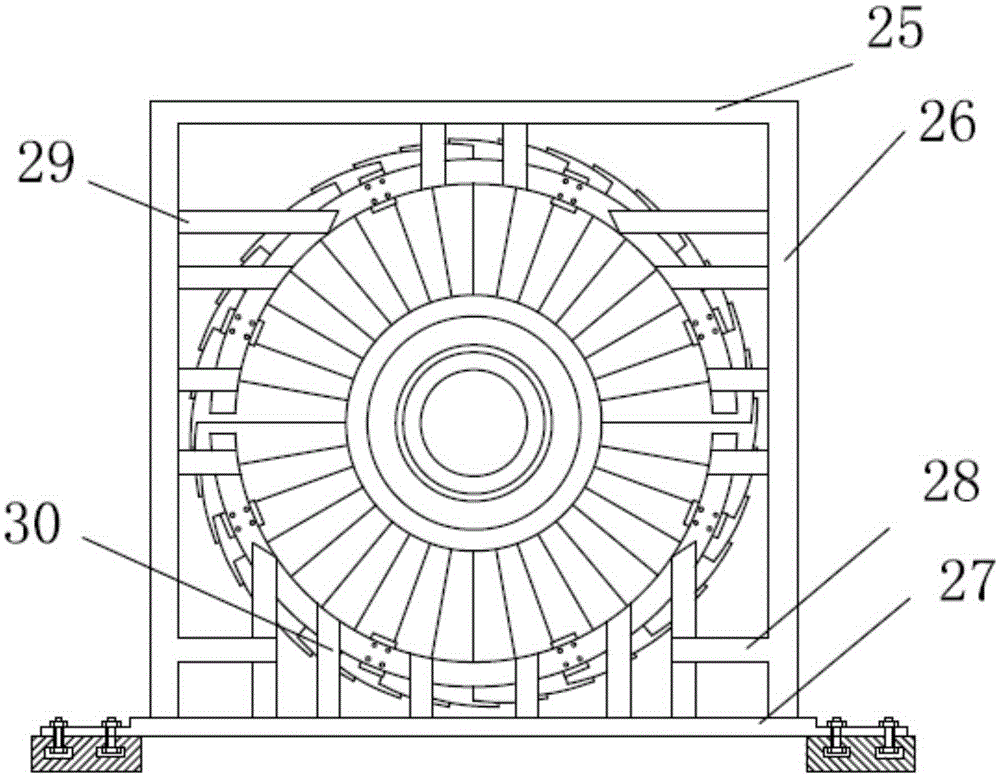

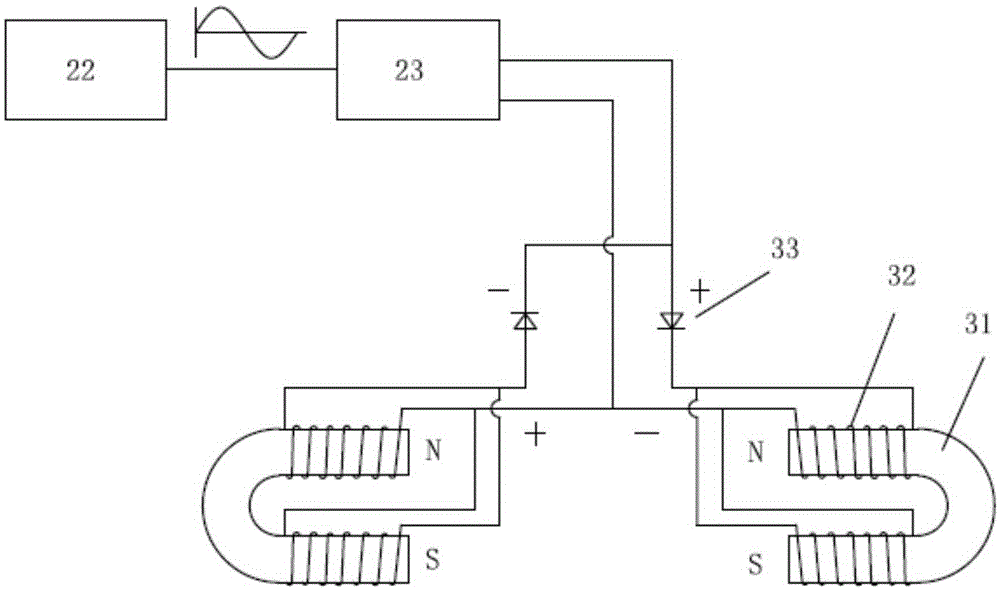

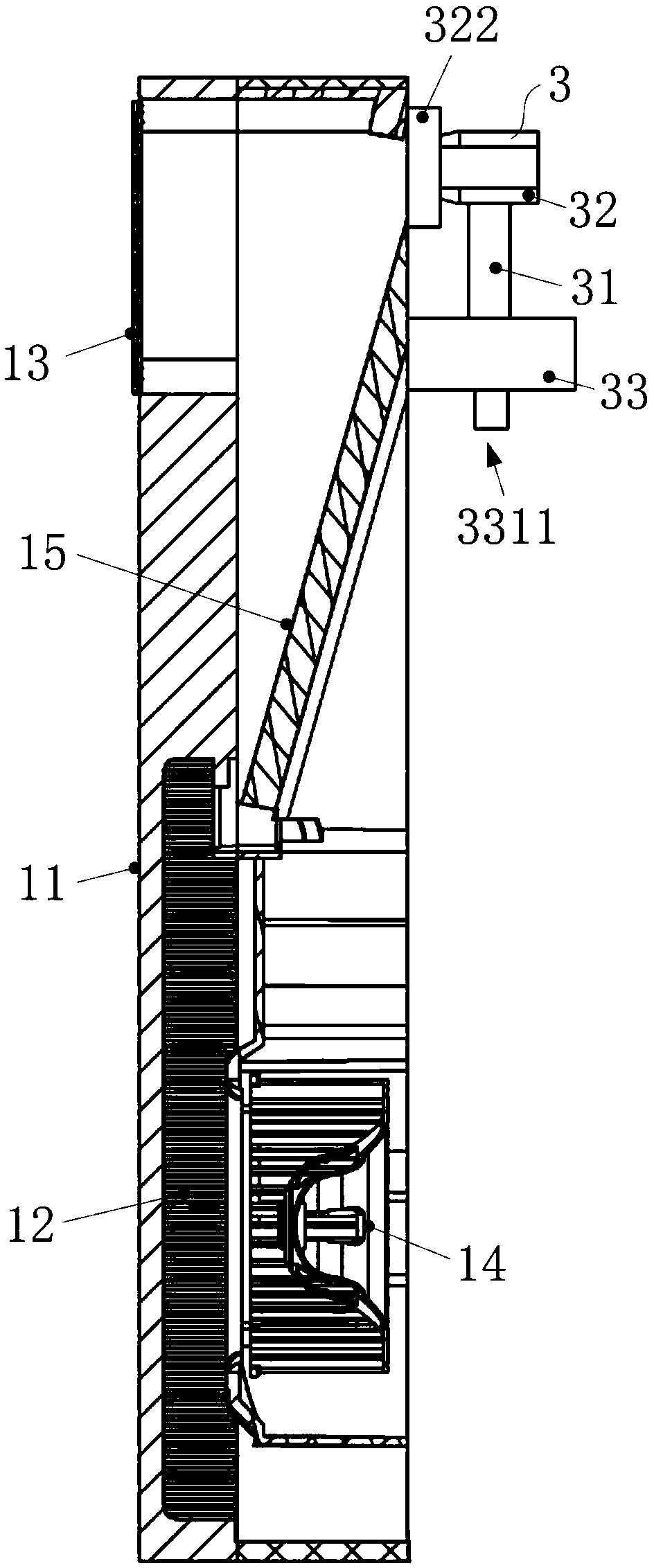

Electromagnetic harmonic wave exciting device for high-speed rotating impeller

ActiveCN105258886ADoes not affect vacuumImprove securityVibration testingImpellerAudio power amplifier

The invention discloses an electromagnetic harmonic wave exciting device for a high-speed rotating impeller. The electromagnetic harmonic wave exciting device comprises electromagnets, coils, installation boxes, electromagnetic exciter supports, power amplifiers and a signal generator. A sinusoidal signal is generated by use of the signal generator, passes through the power amplifiers and is then transmitted to electromagnetic exciters via a rectifier diode, and a sinusoidal excitation force is applied to the rotating impeller. A pair of electromagnetic exciters constitute a group and are symmetrically arranged at front and back of the impeller. A plurality of electromagnetic exciters are arranged along the circumference of the impeller and form circumferential sinusoidal excitation to the high-speed rotating impeller. The invention solves the problems of over temperature and insufficient excitation force due to that a conventional rotating impeller adopts a gas excitation manner, can meet sinusoidal excitation requirements of the impeller in a vibration test of the high-speed rotating impeller, and can adjust the amplitude of the sinusoidal excitation force.

Owner:XIAN THERMAL POWER RES INST CO LTD

Multi-functional heating furnace

InactiveCN104566975ASolve easy foulingSolve overheatingSolar heat devicesStorage heatersHeat conductingSolar water

The invention relates to a multi-functional heating furnace. The heating furnace comprises a heating furnace casing, a heat exchange barrel, a heating pipe, water circulating pipes and an external power source, wherein the heating furnace casing is used for storing oil well output liquid; the heat exchange barrel is directly inserted into the heating furnace casing and immersed into the output liquid, the heat exchange barrel consists of a main barrel and two wing barrels, and the main barrel and the two wing barrels are filled with heat-conducting media; the heating pipe is inserted into the main barrel and immersed into the heat-conducting media so as to heat the heat-conducting media; the output liquid is indirectly heated through the heat exchange barrel. According to the multi-functional heating furnace, the problems that the heating pipe is corroded and scaled and easy to burn out and the service life is short are effectively prevented, in addition, the heat exchange barrel and the heating pipe are respectively sunken in the output liquid and the heat-conducting media, so that heat loss is not generated, and the heating efficiency is improved. The heat exchange barrel is connected with a circulating water inlet pipeline and a circulating water outlet pipeline and can be connected with a solar water heater, and heat media preliminarily heated by the solar water heater are transported to the heating pipe to be reheated, so that solar energy resources are effectively utilized, and electric energy is saved. A power source of the heating pipe can be connected with a wind-energy generating battery and a solar battery, so that the comprehensive utilization of wind, light and electricity is realized, the energy is saved, and the emission is reduced. The heat exchange barrel comprises the two wing barrels, the diameter and the length of each wing barrel can be regulated so as to meet requirements of the heat exchange area, the same ends of the main barrel and the wing barrels are communicated through connecting pipes, after being inserted into the main barrel through the connecting pipes, the other ends of the wing barrels penetrate through sealing flanges of the main barrel and the casing, and penetrate out of the main barrel to be connected with a solar heat source, and the other end of the main barrel is connected with the solar heat source through a connecting pipeline, so that the closed cycle is realized.

Owner:史晨

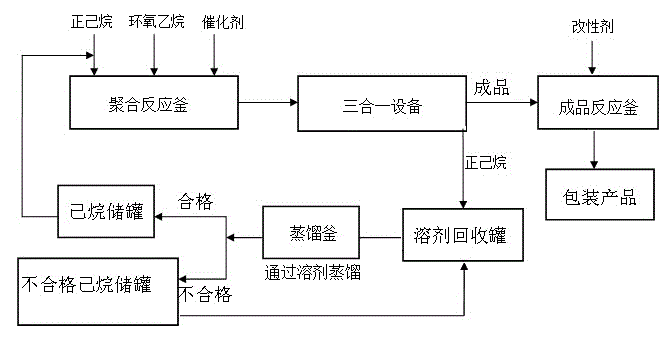

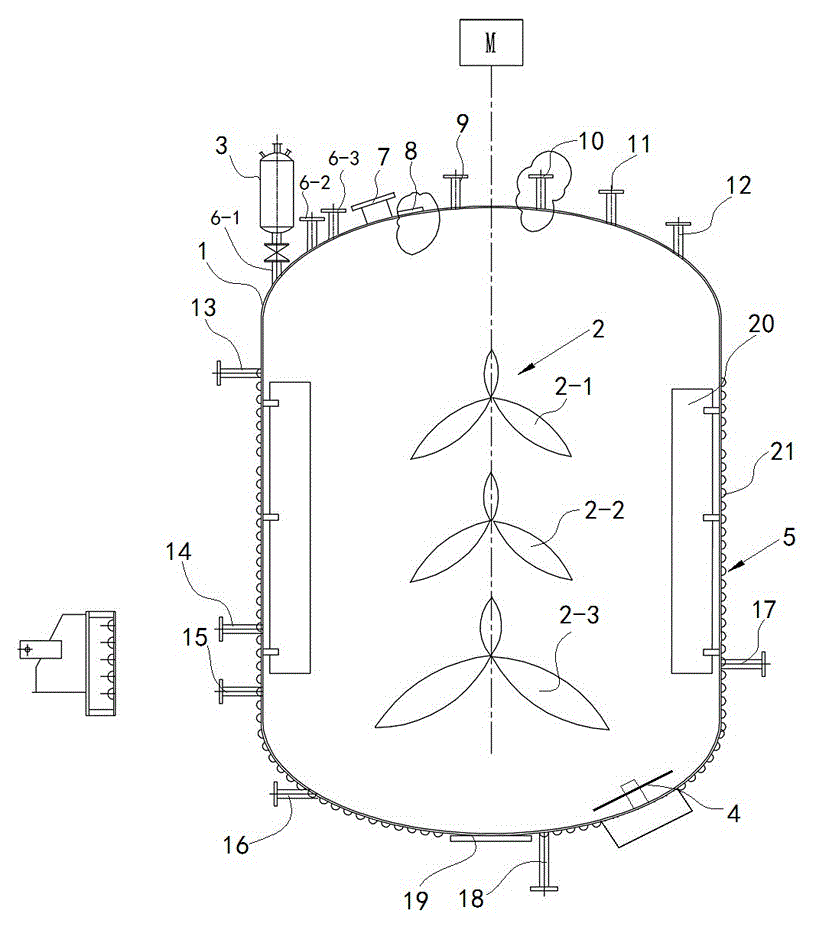

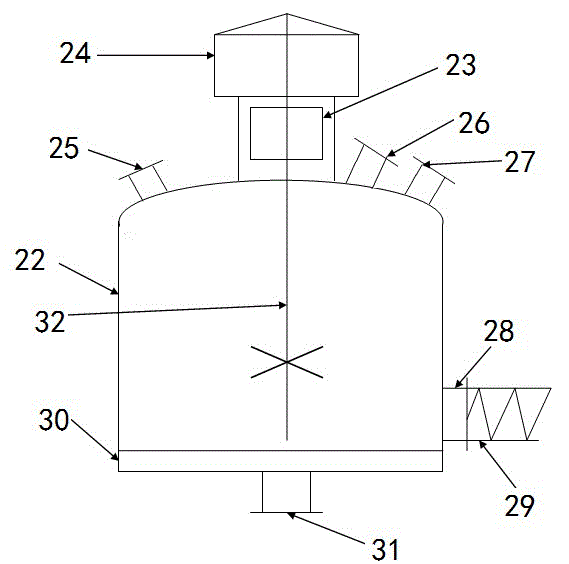

Production equipment for polyoxyethylene products and preparation method thereof

The invention relates to production equipment for polyoxyethylene products and a preparation method thereof. The equipment comprises a polymerization reaction kettle, integrated equipment, a finished product mixing kettle, a solvent recycling tank, a distillation kettle, a hexane storage tank and an unqualified hexane storage tank. The production process of the polyoxyethylene products comprises the steps that ring opening polymerization is performed on ethylene oxidein C6 or C7 solvent through the action of a catalyst, exothermic reaction is performed at a certain temperature and under certain pressure, and the requirements of product specifications are achieved through the growth of polymeric chains; after the reaction is finished, the products are processed through the integrated equipment with the functions of filtering, drying and washing, and then packaging is performed. According to the production equipment for the polyoxyethylene products and the preparation method thereof, the partial implosion phenomenon caused by the reaction is avoided, the volume of the reaction kettle is successfully enlarged to 6000 litres, the production scale of a PEO device is enlarged, and the stability of the product quality is improved; the method solves the problems of solvent dehydrating and solvent recycling and reusing.

Owner:吉化集团吉林市星云化工有限公司

Water-supply water-return dual-loop cooling circulation system

ActiveCN105704986AEasy maintenanceEasy to assembleCooling/ventilation/heating modificationsSoftware engineeringLoop design

The invention discloses a water-supply water-return dual-loop cooling circulation system. The circulation system comprises an inner circulation system containing a cooled unit, and an outer circulation system containing a cooling unit, wherein the inner circulation system and the outer circulation system are connected through a middle heat exchange unit to realize the heat exchange between the inner circulation system and the outer circulation system; and the inner circulation system and the outer circulation system adopt the loop design, so that a refrigerating medium can flow in the pipeline in a bidirectional manner. The water-supply water-return dual-loop cooling circulation system is capable of realizing accurate refrigerating, rapid and convenient to install and maintain, and capable of avoiding one-way leakage or avoiding a condition that the pipeline cut-off system cannot be operated normally in maintenance.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

High-Arsen gold ore pretreatment method

The invention relates to a high-Arsen gold ore pretreatment method which comprises the following steps of: crushing high-Arsen gold ore into power which is not more than 200 meshes; enriching to obtain high-Aresen gold concentrate fines; adding NaCl, NaOH and diethyldithiocarbamate in proportion; uniformly stirring and filling in an oxidizer; heating and pressurizing for a while under a closed condition; and recovering residual gas by using active carbon or an alkaline solution, wherein solid substances generated after oxidation contain native gold, limonite, ferric oxide, arsenic bloom and mixtures of other impurities. The method solves the problems of the prior art, such as under-burning, over-burning, environment pollution, difficult recovery of other useful components and the like. Through pretreatment experiments of several high-Arsen gold fine mines, after oxidization, Arsen, gold and other components are converted into native gold, ferric oxide, arsenic bloom, gypsum and other independent minerals or oxides; the method facilitates the recovery of other useful components, has no problems of under-burning and over-burning, and ensures that the pretreatment process has no environment pollution, simple process and convenient operation.

Owner:JILIN UNIV

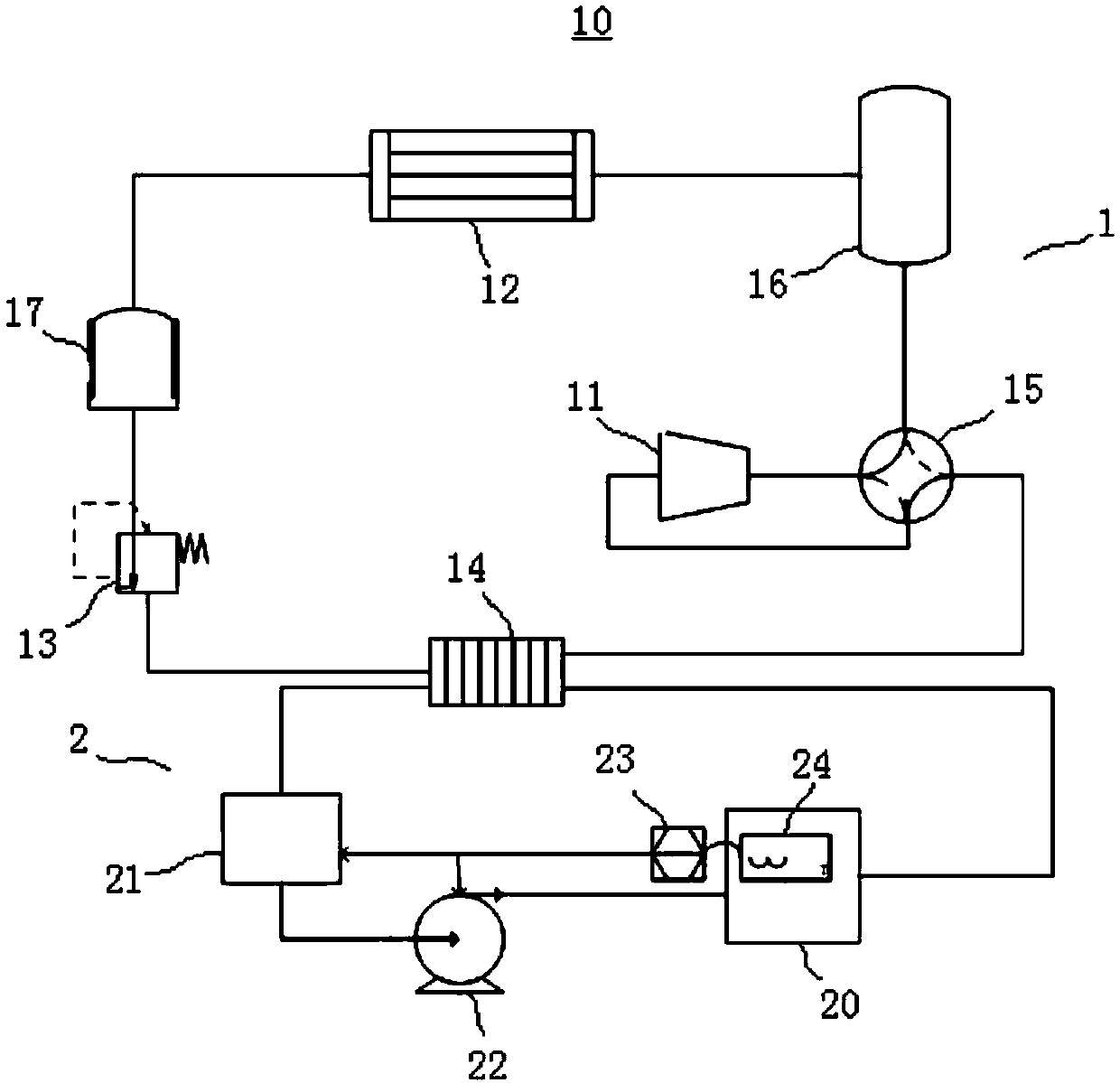

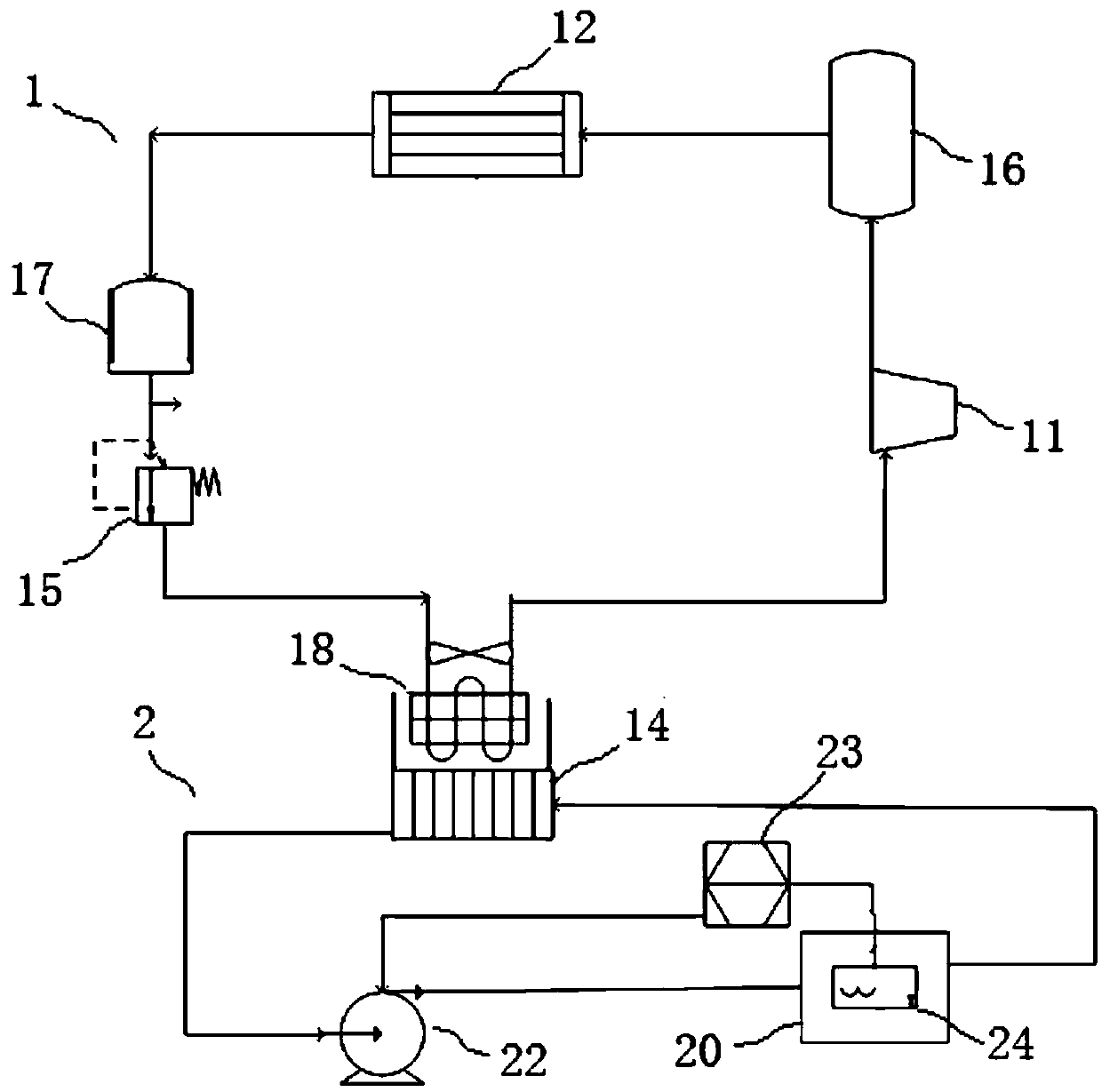

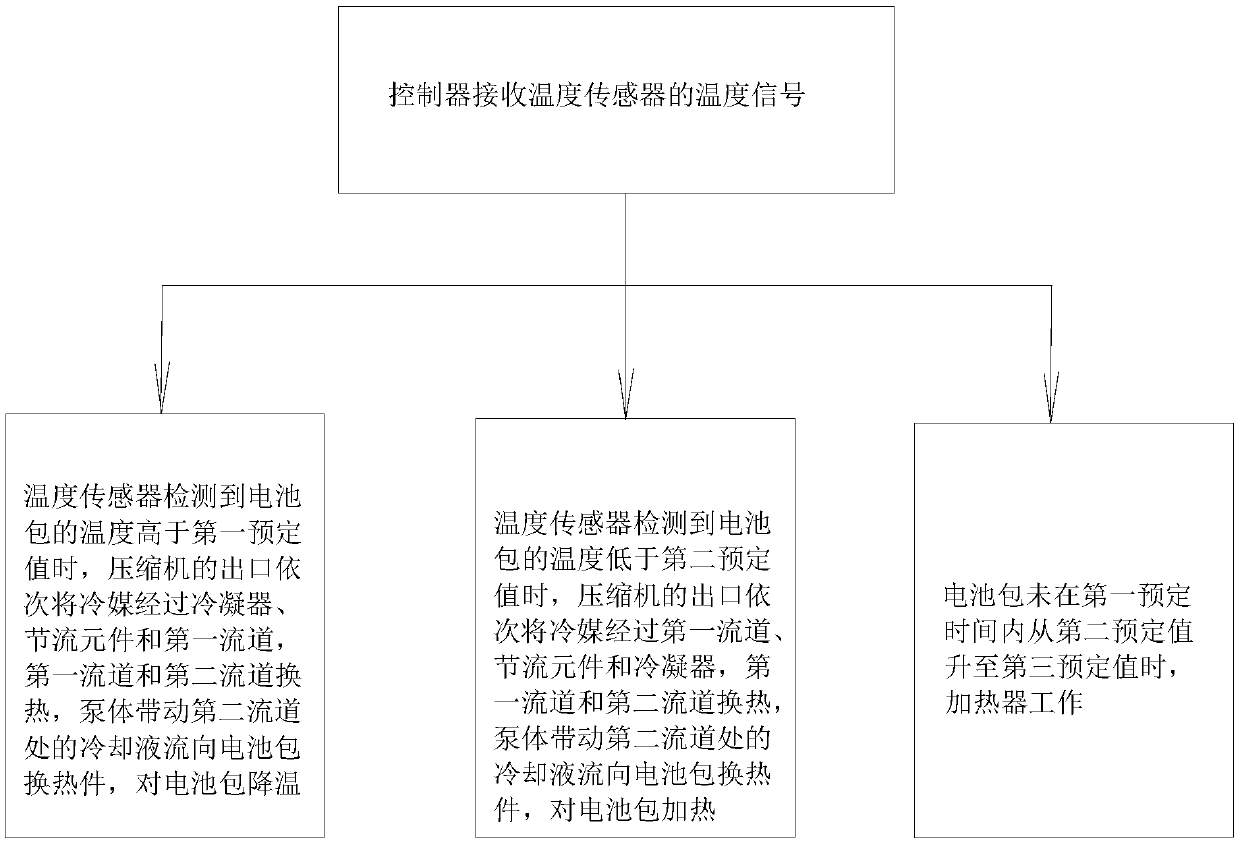

Battery thermal management system of vehicle and vehicle

ActiveCN110661056ASolve overheatingSolve the problem of overcoolingCell temperature controlBatteriesProcess engineeringMechanical engineering

The invention discloses a battery thermal management system of a vehicle and the vehicle. The battery thermal management system includes an air-conditioning circulating system and a battery pack heatexchange system. The battery pack heat exchange system comprises a heat exchanger, a heater, a pump body, a controller, a temperature sensor and a battery pack heat exchange part, wherein the air-conditioning circulating system selectively provides cold energy or heat energy for the heat exchanger. The heat exchanger, the heater, the pump body and the battery pack heat exchange part are communicated; the battery pack heat exchange part is arranged on the battery pack, the heater, the pump body and the temperature sensor are all electrically connected with the controller, and the controller selectively controls the heater to work according to the temperature detection result of the temperature sensor. Therefore, through the cooperation of the air-conditioning circulating system and the battery pack heat exchange system, the problems of overheating and supercooling of the battery pack can be effectively solved, and the battery pack can be ensured to work normally under any working condition.

Owner:BYD CO LTD

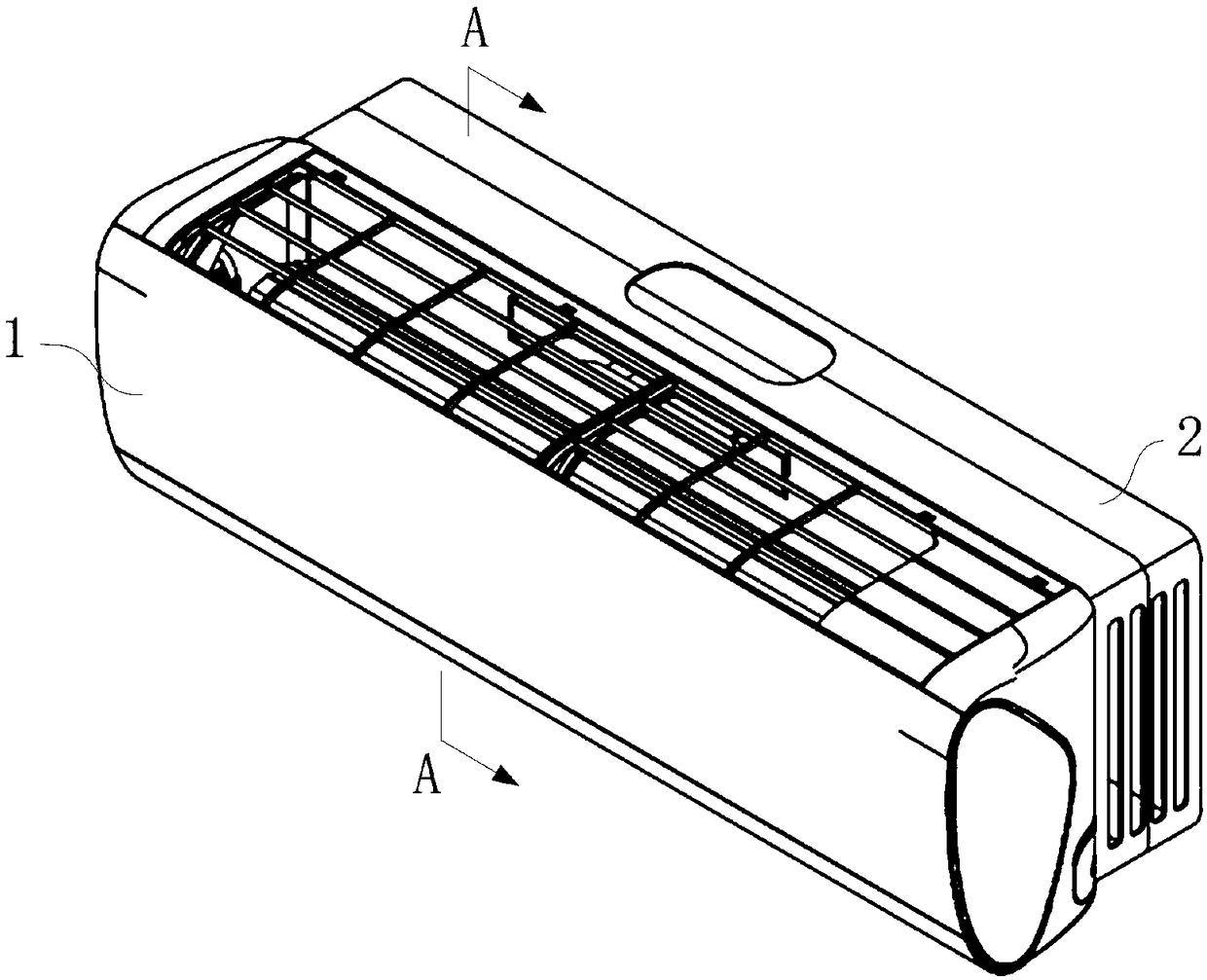

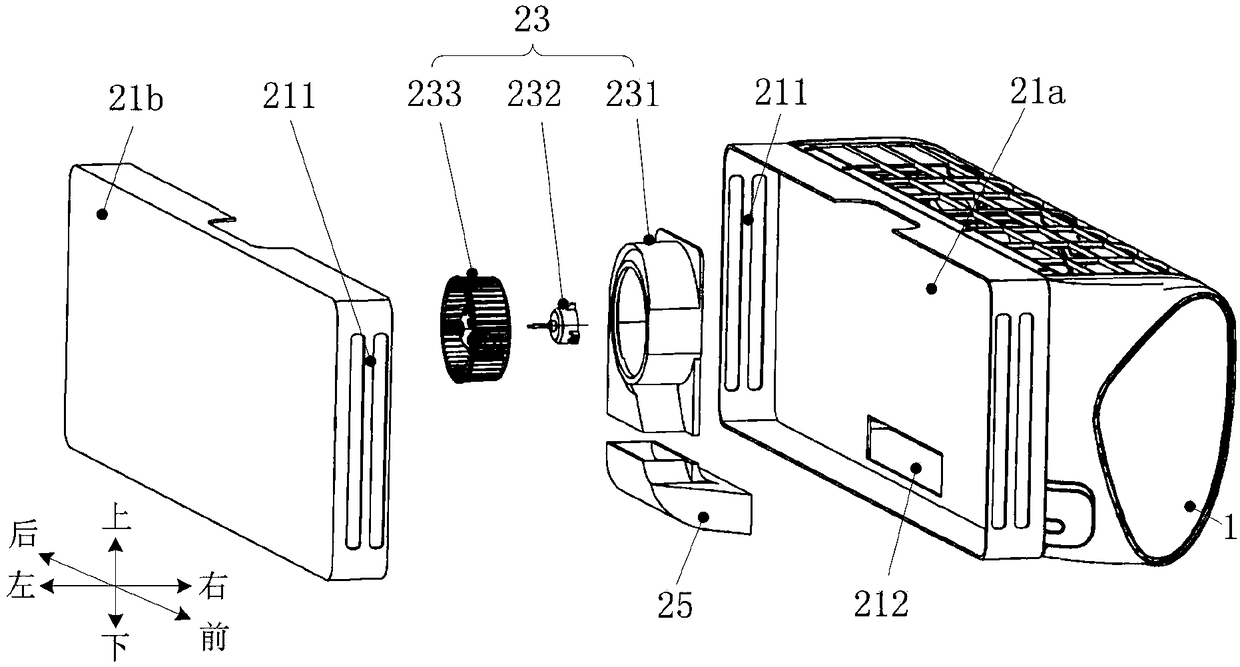

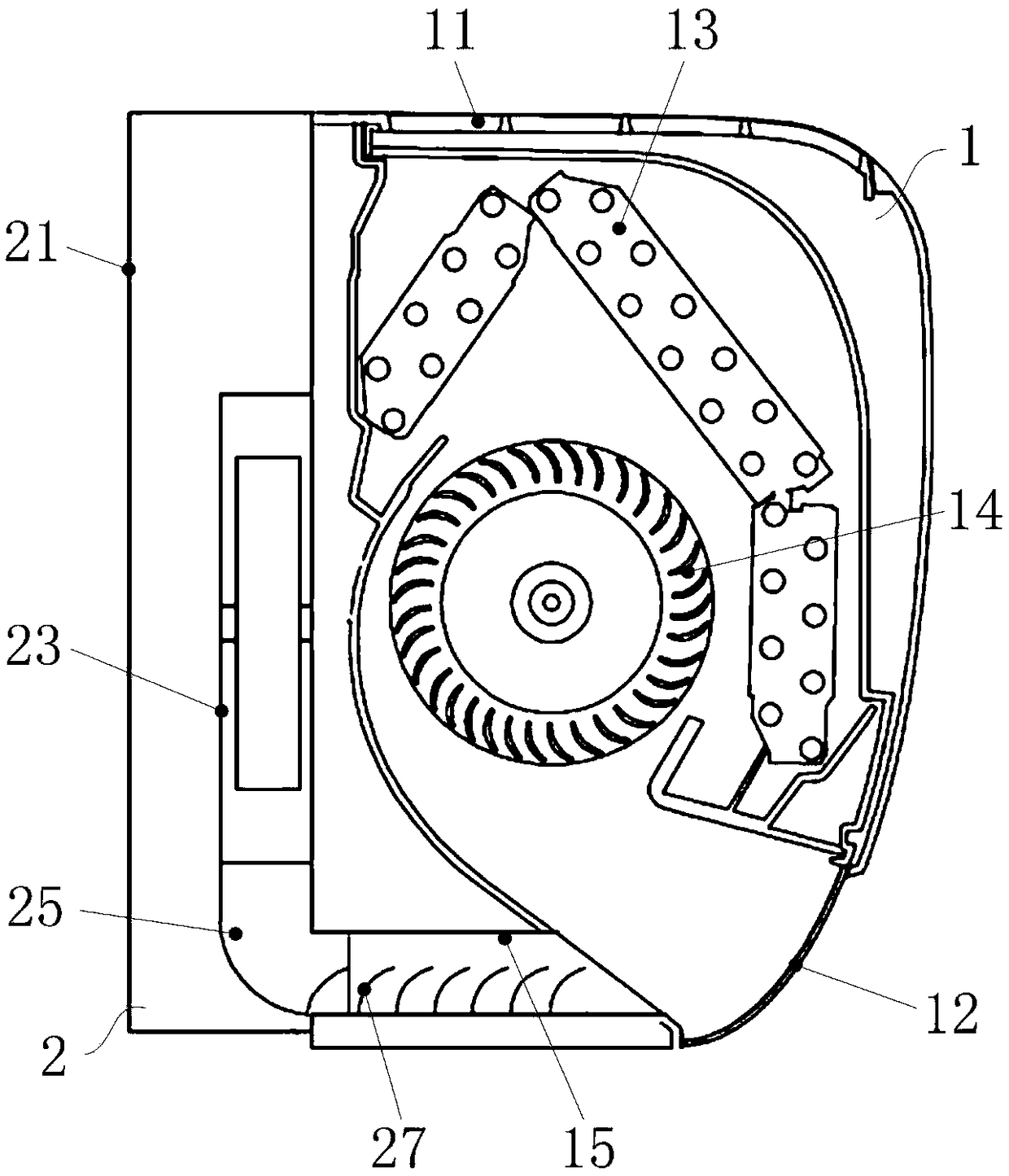

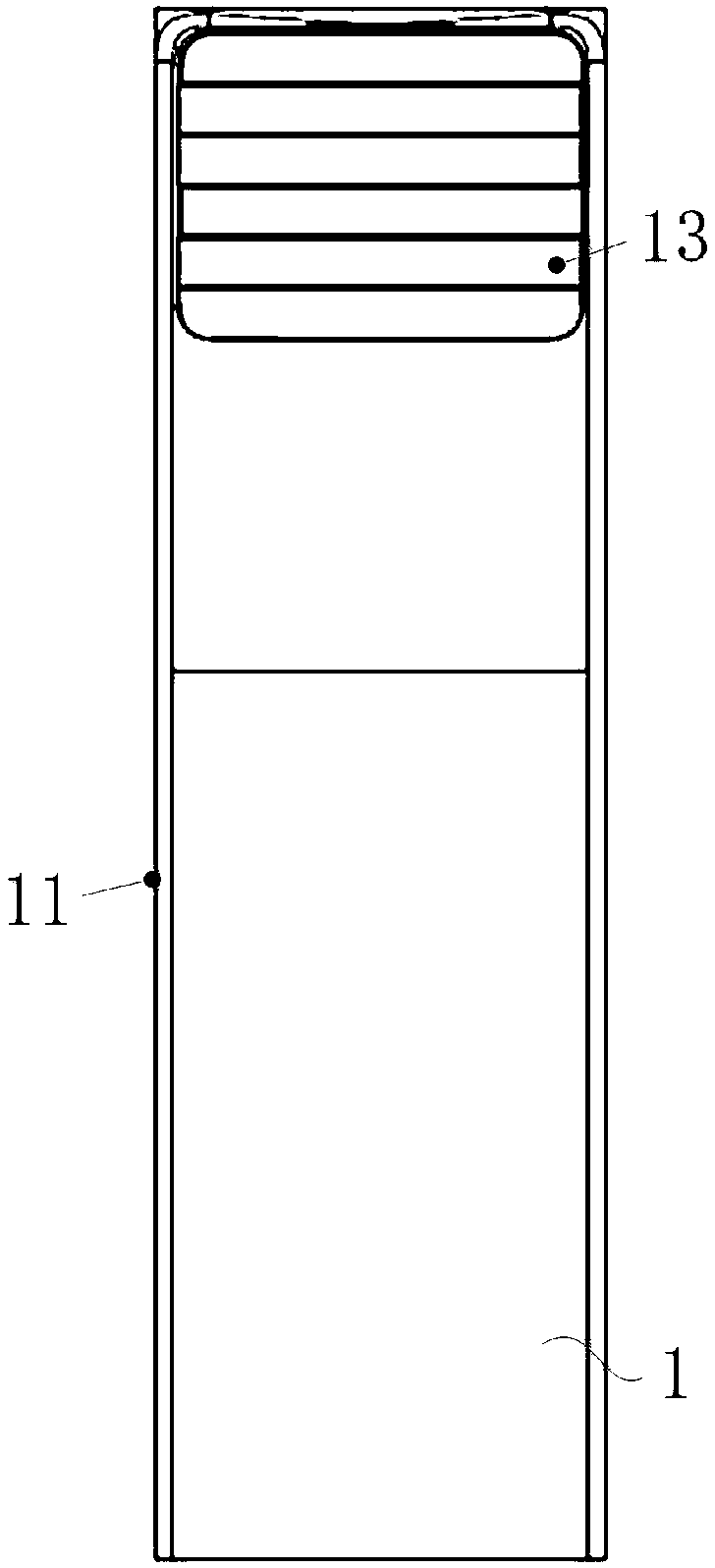

Air conditioning indoor unit and control method thereof

PendingCN108759018AImprove the phenomenon of overcooling/overheating of air supplySame or even improved performanceMechanical apparatusEfficient regulation technologiesEngineeringAir conditioning

The invention relates to the technical field of air conditioning, in particular to an air conditioning indoor unit and a control method thereof. The air conditioning indoor unit and the control methodthereof aim to solve the problems that for an existing air conditioner, when the air supply amount is large, the supplied air is overcooled / overheated, and the noise is large. The air conditioning indoor unit comprises a body, an air return port and an air supply port are formed in the body, an air supply fan is arranged in the body, the air conditioning indoor unit further comprises an air supplement module, the air supplement module comprises a shell, a first air inlet is formed in the shell, the shell is internally provided with an induced draft fan, the air supplement module is arranged to be capable of being driven by the induced draft fan to introduce indoor air into the shell through the first air inlet, and the air is discharged to the air supply port through an air discharge portof the induced draft fan and is mixed with air discharged from the air supply port. According to the air conditioning indoor unit and the control method thereof, the phenomenon that the supplied airof the air conditioning indoor unit is overcooled / overheated is avoided, and the operation noise of the air conditioning indoor unit is reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Environment-friendly production process of reclaimed rubber from tire

InactiveCN108178841ARealize desulfurization treatmentEliminate the grinding processPlastic recyclingMicrowaveFiltration

The invention provides an environment-friendly production process of reclaimed rubber from a tire. The process comprises the following steps: (1) waste rubber is smashed into waste rubber powder; (2)the waste rubber powder and reclaiming auxiliary materials are jointly conveyed to a microwave reclaimer, are subjected to microwave desulfurization and reclaiming treatment in a pipe of the microwavereclaimer and move from a feed port of the pipe to a discharge port under the conveying and mixing actions of a conveying screw in the pipe, wherein the reclaiming auxiliary materials comprise a reclaiming activator, a reclaiming softener and lemon essential oil, the reclaiming activator accounts for 0.2%-1.1% of the mass of the waste rubber powder, the reclaiming softener accounts for 2%-30% ofthe mass of the waste rubber powder, and the lemon essential oil accounts for 2%-3% of the mass of the waste rubber powder; (3) the rubber powder subjected to desulfurization treatment is refined andformed by a refiner, extrusion and filtration are performed, and the reclaimed rubber from the tire is obtained. The novel production process of the reclaimed rubber from the tire is energy-saving andenvironmentally friendly, and the produced reclaimed rubber has the advantages of high strength, stable quality and the like.

Owner:江苏华兴橡胶科技有限公司

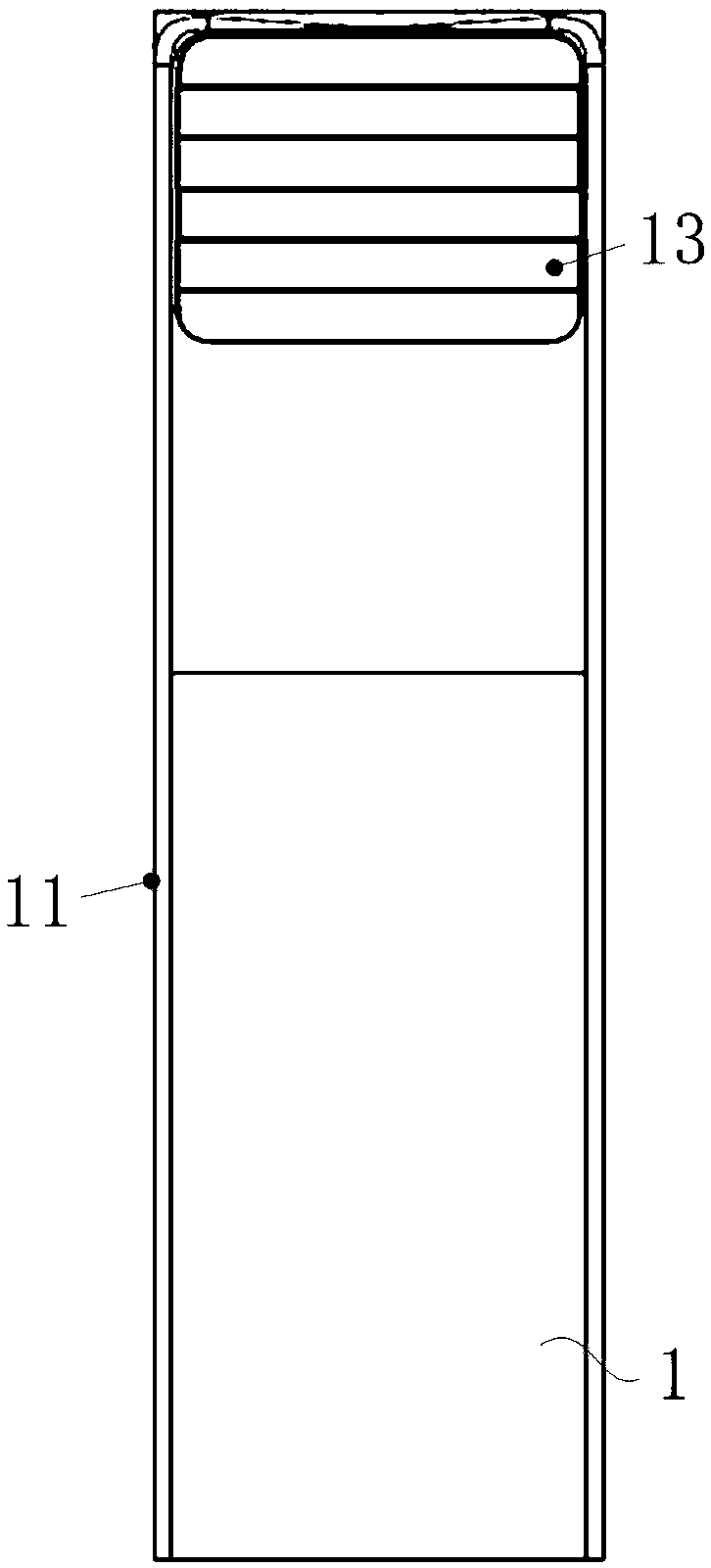

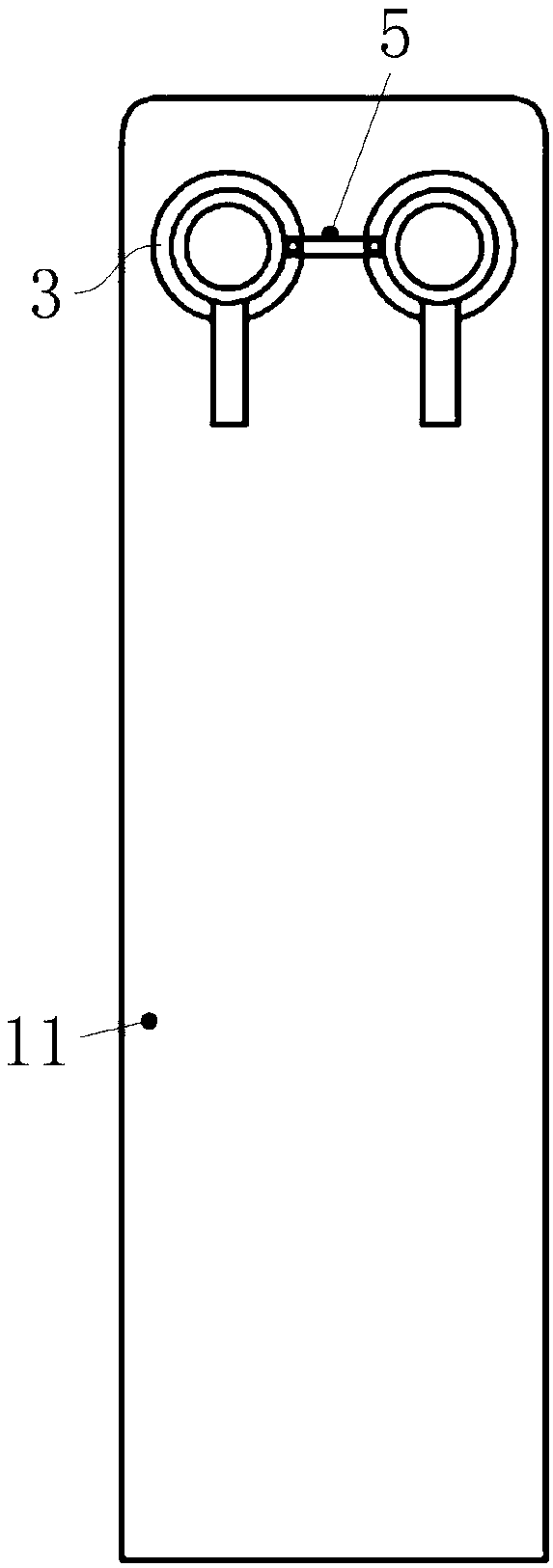

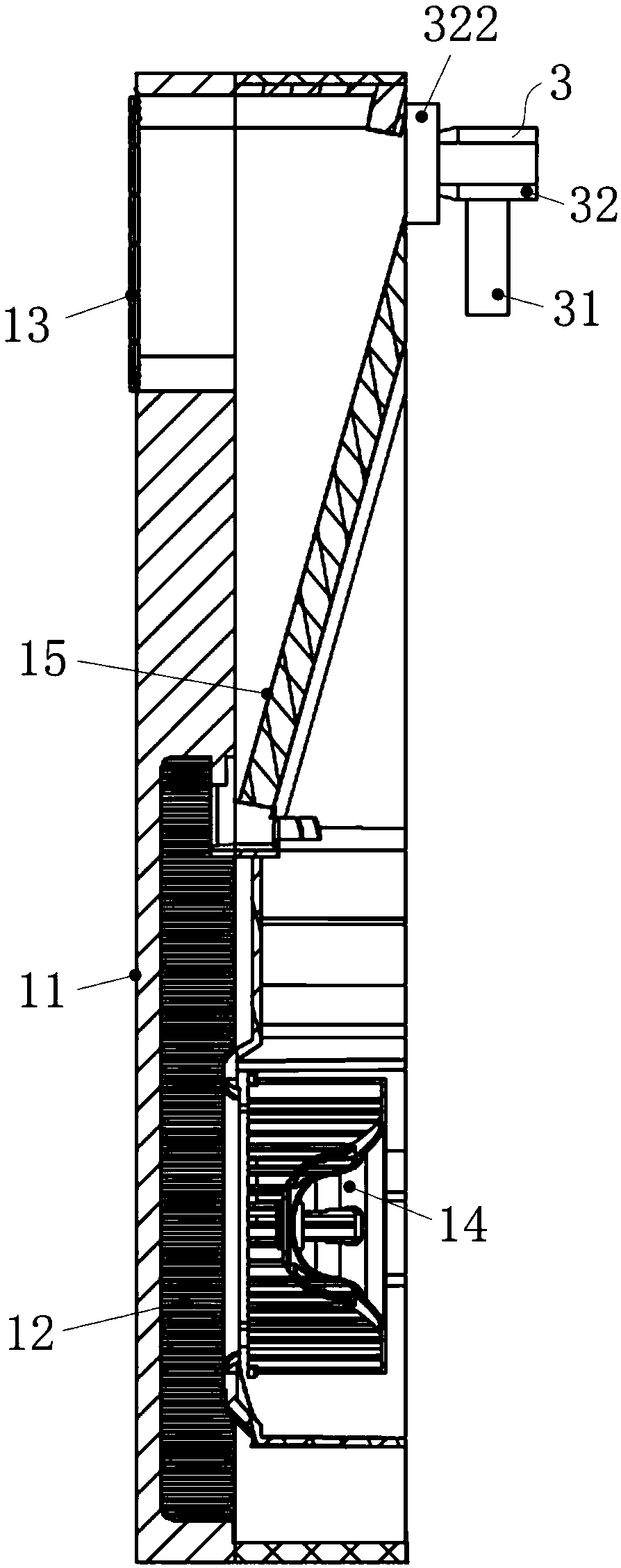

Cabinet type air conditioner and control method thereof

PendingCN110906444AImprove the phenomenon of overcooling/overheating of air supplyReduce noiseDucting arrangementsMechanical apparatusJet flowEngineering

The invention relates to the technical field of air conditioners and particularly relates to a cabinet air conditioner and a control method thereof. The invention aims to solve the problem that an existing air conditioner has too cold or too hot air supply and large noise when the air supply volume is large. For the above purpose, the cabinet type air conditioner of the present invention includesa cabinet, and a fan and a heat exchanger are set in the cabinet. The cabinet type air conditioner further includes an air mixing device, and the air mixing device includes an air guide unit and a jetunit. The air guide unit includes a pipe body, the pipe body has a first air inlet and a first air outlet, and an induced draft fan is arranged in the pipe body. The jet unit includes a cylinder, thecylinder has a second air inlet and a second air outlet, the second air inlet is connected to the first air outlet, and a jet channel is formed between the second air inlet and the second air outlet.The present invention can improve the phenomenon that the air supply of the air conditioner is too cold or too hot, and the operating noise of the air conditioner can be reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Production process of environment-friendly high-strength regenerated rubber

InactiveCN108047489ABreak through limitationsEliminate the grinding processPlastic recyclingMicrowavePolymer science

The invention provides a production process of environment-friendly high-strength regenerated rubber. The production process comprises the following steps that (1) waste rubber is pulverized into rubber powder; (2) the pulverized rubber powder in the first step enters a microwave desulfurization device for primary regeneration treatment firstly and then enters an ultrasonic desulfurization devicefor secondary regeneration to achieve complete desulfurization; (3) the completely-desulfurized rubber powder is subjected to refining formation through a refiner, extruded and filtered to obtain an available recyclable rubber raw material. By means of the production process of the novel energy-saving environment-friendly regenerated rubber, the produced regenerated rubber has the advantages of being high in strength, stable in quality and the like.

Owner:江苏华兴橡胶科技有限公司

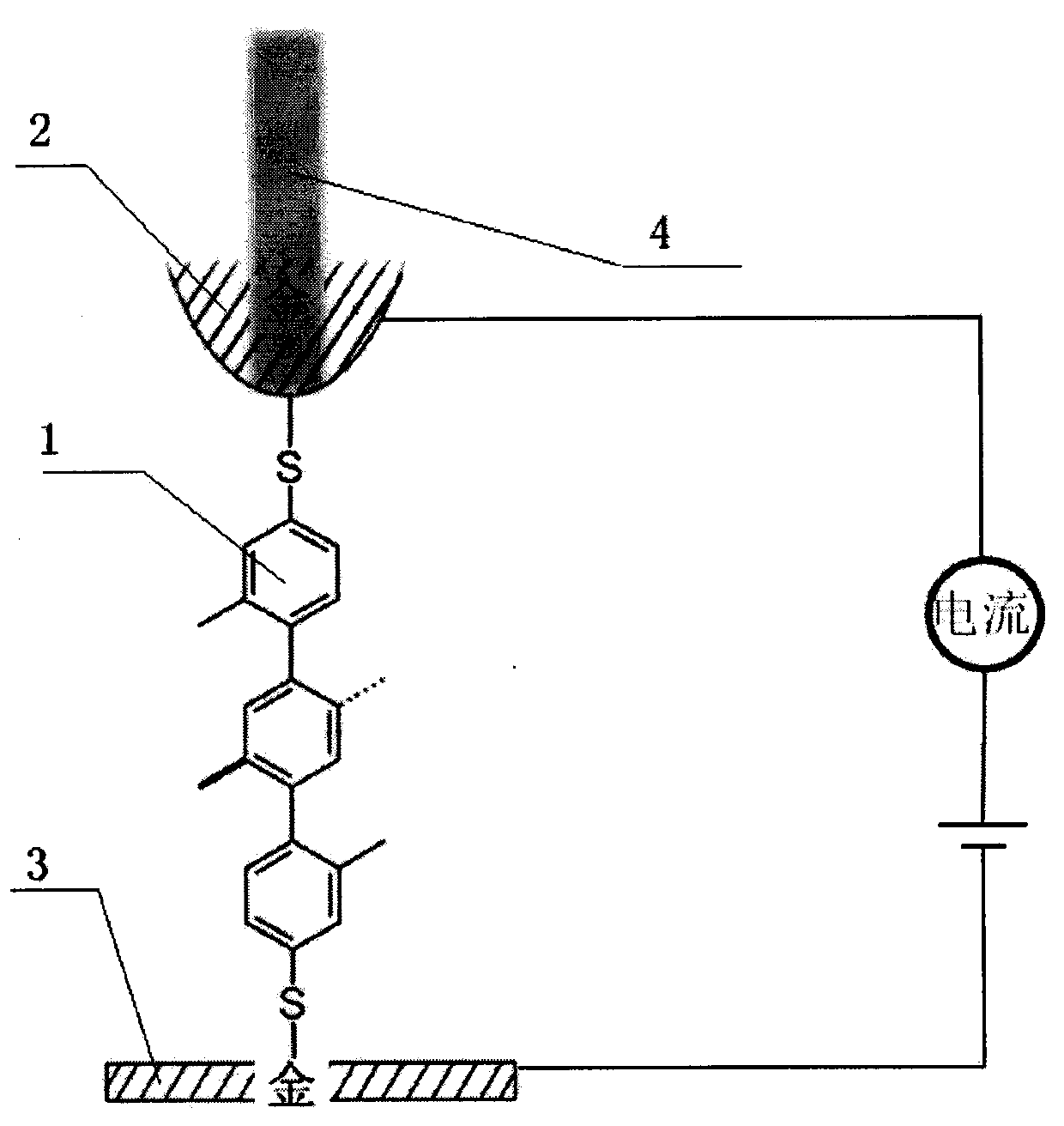

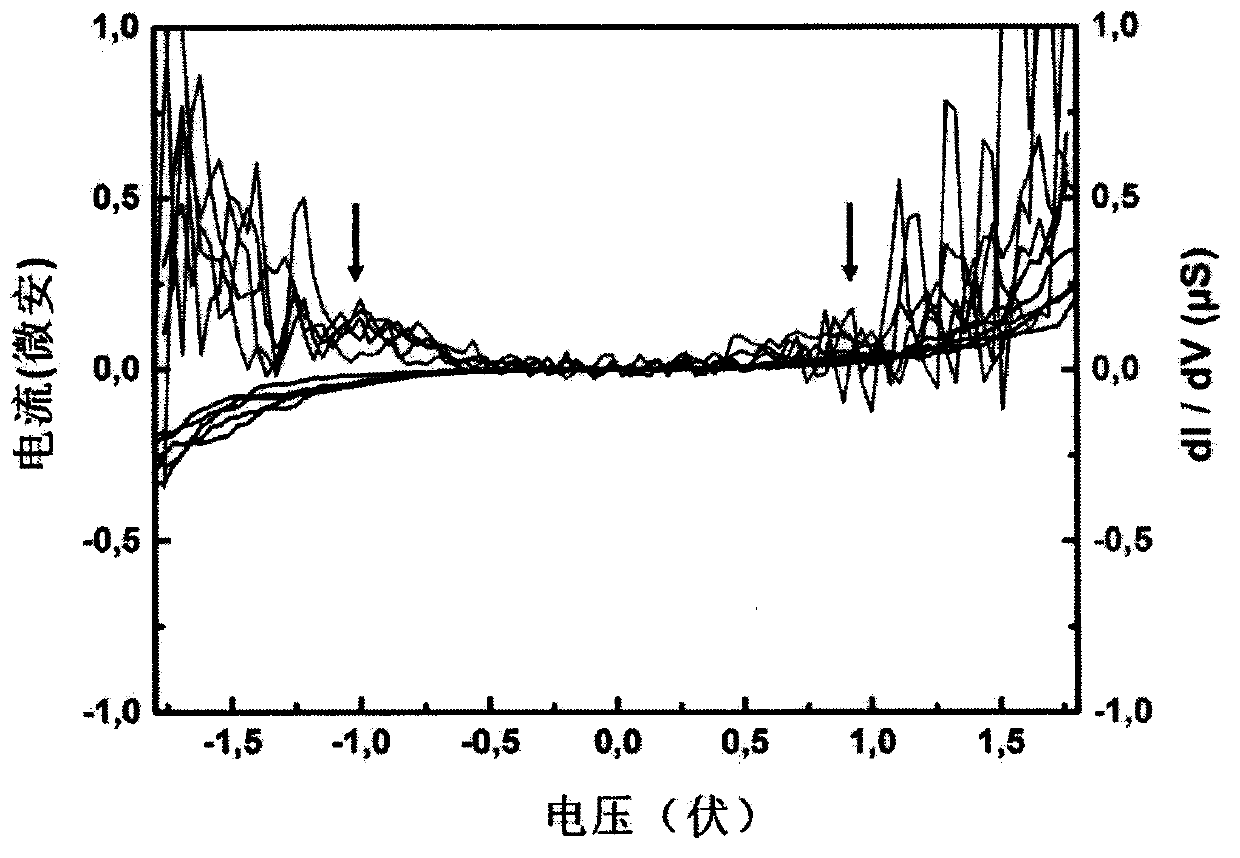

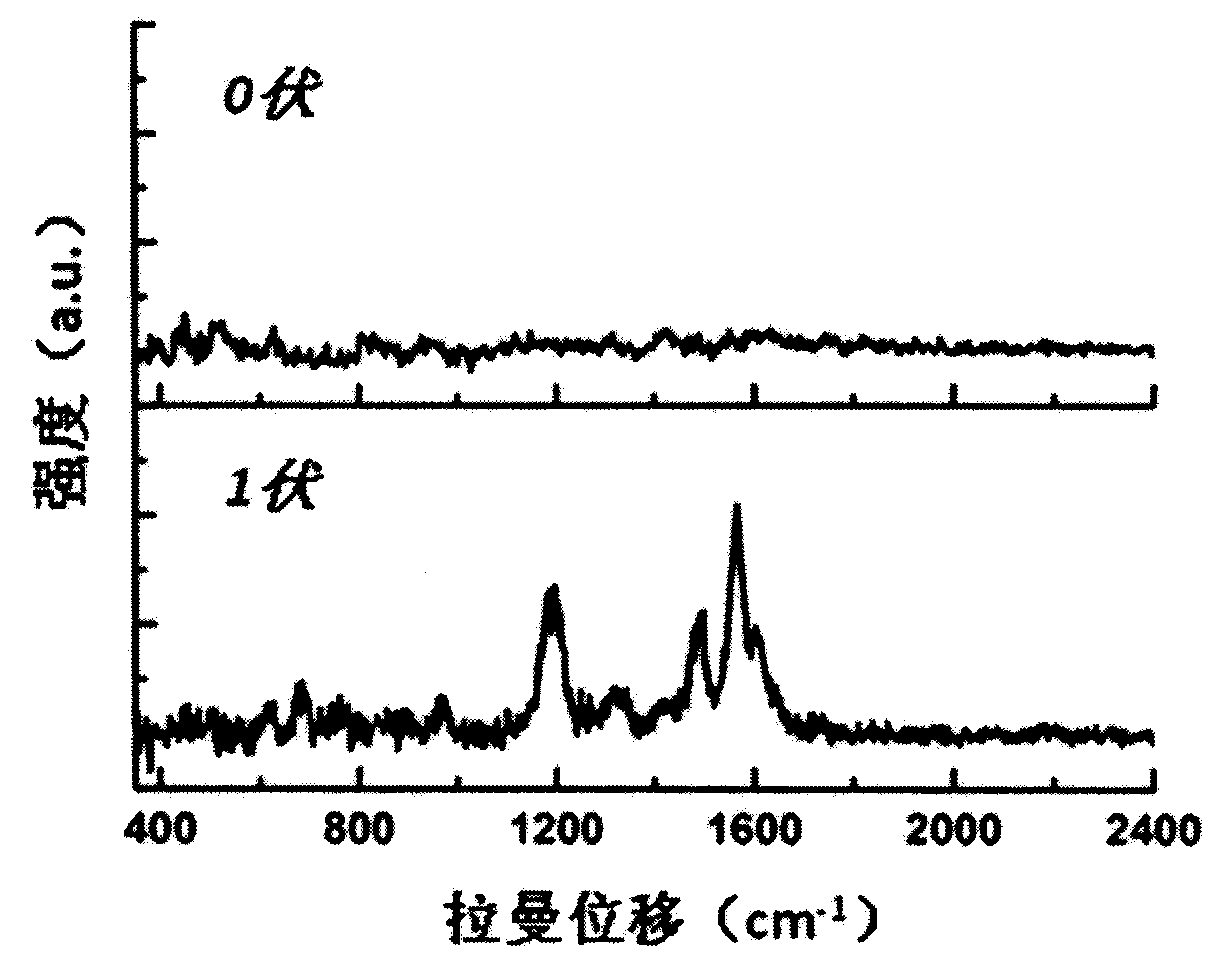

Single-molecular-junction logic gate

InactiveCN104202039AIncrease speedImprove responsivenessLogic circuits using elementary logic circuit componentsElectrical controlLaser light

The invention discloses a single-molecular-junction logic gate. The single-molecular-junction logic gate comprises a logic gate single molecular junction, a positive electrode, a negative electrode, a laser device and a molecular junction logic gate readout device, wherein the two ends of the logic gate single molecular junction are electrically connected with the positive electrode and the negative electrode respectively; the laser device is arranged over the electrodes; the molecular junction logic gate readout device is arranged on one side of the logic gate single molecular junction, and is arranged close to the logic gate single molecular junction; the emitting end of the laser device points to the logic gate single molecular junction; and laser light emitted by the laser device is laser light of 633 nanometers. Logic operation of the micro-scale logic gate single molecular junction under an electrical control condition is realized, and the logic gate single molecular junction has extremely high logic operating rate and response capability; and meanwhile, real single molecular operation capability is provided by the logic gate single molecular junction, so that an important foundation is laid for the replacement of a silicon semiconductor technology.

Owner:SUZHOU HUALAIDE ELECTRONICS TECH

Solar thermal collector and heat supplying system

PendingCN109539373AEnsure safe workSolve crackingSolar heating energyFluid circuit connectionsEngineeringPlate fin heat exchanger

The invention relates to the technical field of solar energy application, and provides a solar thermal collector and a heat supplying system. The solar thermal collector comprises a header, vacuum tubes and a flow guiding device, wherein an air medium is arranged in the header, the vacuum tubes are arranged on the side face of the header and is used for heating the air medium in the header, the flow guiding device is arranged on the top side of the header, and the two ends of the header are communicated with the flow guiding device so as to circulate the air medium. The heat supplying system comprises the solar thermal collector, the solar thermal collector is connected with a gas-water heat exchanger through circulating pipelines, the gas-water heat exchanger is connected with a heat collecting water tank through the circulating pipelines, and the heat collecting water tank is connected with the heating tail end through the circulating pipelines.

Owner:北京中安信能科技有限公司

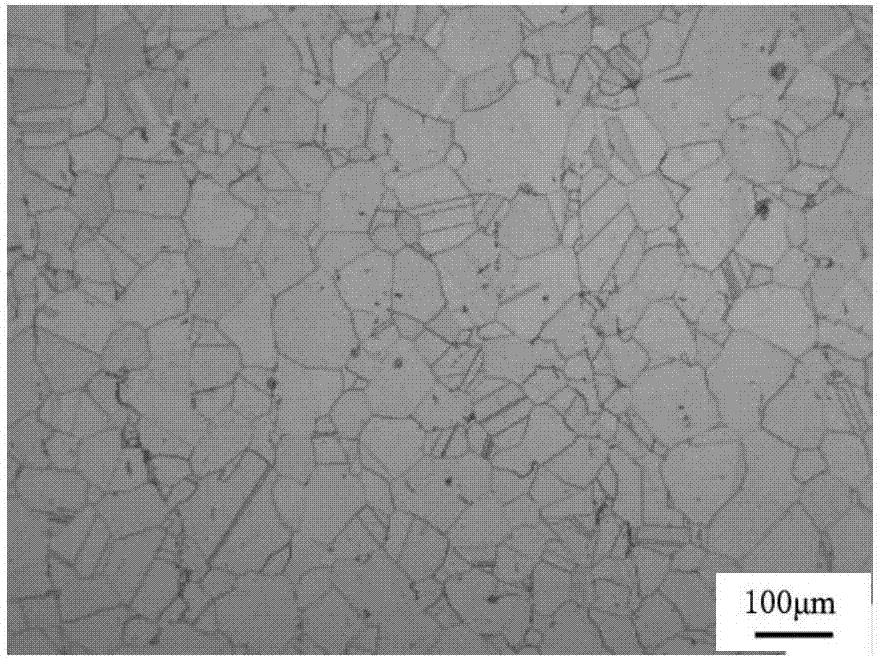

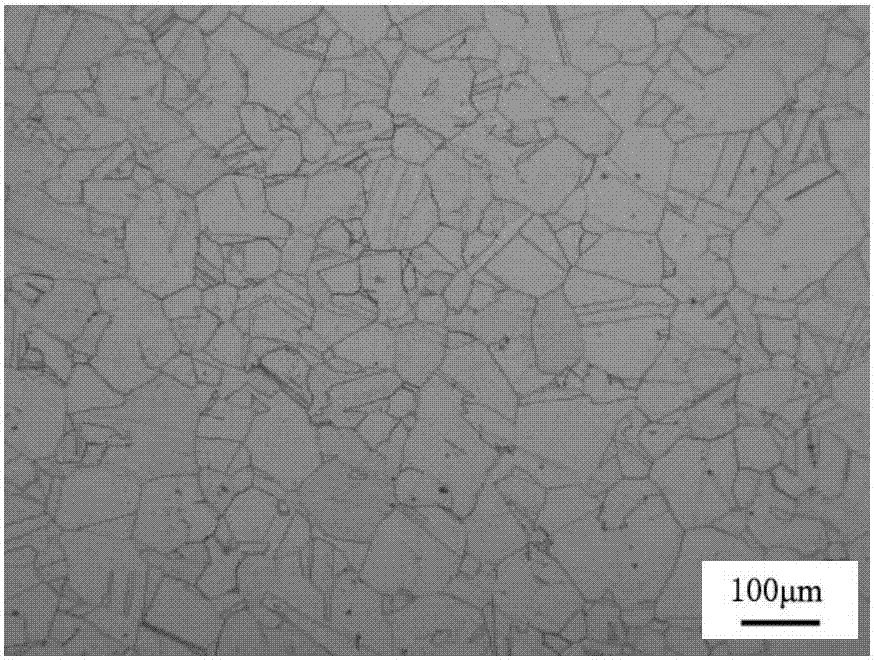

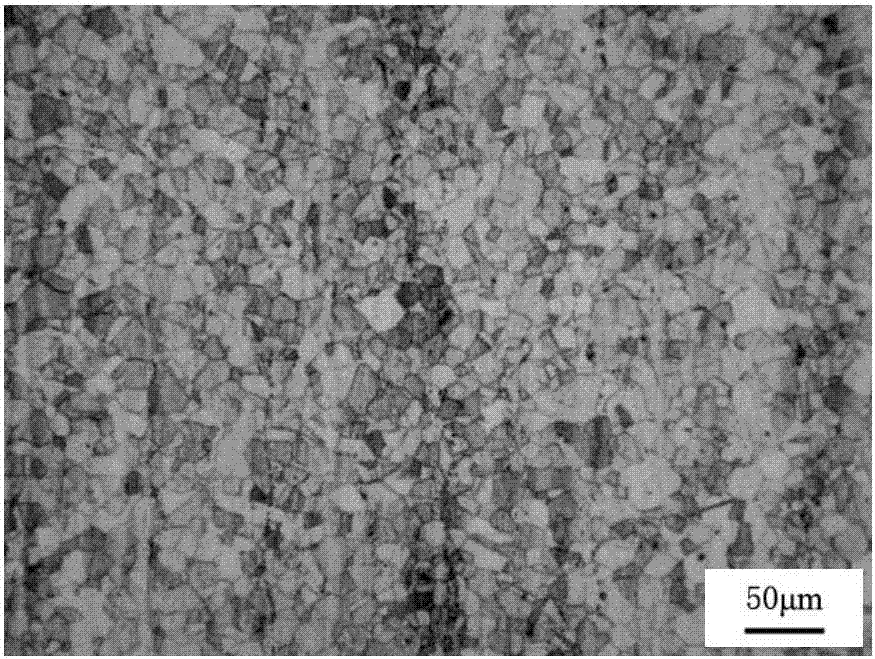

High-temperature alloy cold material pulling two-segment type electric quenching softening annealing technology

ActiveCN106884077ASolve overheatingSolve the problem of broken tipElectrical resistance and conductanceElectricity

The invention discloses a two-segment type power electric heating softening annealing technology. An electric quenching device is used for replacing a continuous type roller bottom annealing furnace to carry out softening annealing on a high-temperature alloy cold drawing billet; after the cold drawing billet is subject to tip twisting, the section size of the tip is small, the resistance is large, the temperature rise of the portion is higher than that of the other portions, and overburning or tip breaking of the billet is caused. In order to solve the overburning and tip breaking problems, and avoid the yield decreasing generated by repeated tip cutting, a two-segment type power electric heating technology is adopted, low-power preheating is carried out, the twisted tip portion and the other portions of the billet are subject to temperature synchronous constant treatment, high-power electric heating is carried out, after the billet reaches the temperature, rapid water quenching is carried out, through the technology, the overburning or tip breaking problem of the tip twisting portion of the billet is effectively solved, and the yield of a large-specification high-temperature alloy cold drawing material is improved.

Owner:FUSHUN SPECIAL STEEL SHARES

Descaling cleaning agent for automotive cooling system

InactiveCN102911801AGood cooling effectSolve overheatingCationic surface-active compoundsDetergent compounding agentsAutomotive engineeringBenzotriazole

The invention relates to a descaling cleaning agent for an automotive cooling system, belonging to the technical field of traffic industry. The cleaning agent is prepared by the following raw materials in parts by weight: 10-30 parts of hexamine, 5-15 parts of calcium oxide, 15-35 parts of glycolic acid, 1.0-3.0 parts of benzotriazole, 20-40 parts of dibutyl phthalate, 1.0-15 parts of urotropine and 40-60 parts of pure water. According to the invention, accumulation of dirt in the cooling system, such as water scale, incrustation, gel and the like, and blockage of a water passage can be completely solved, so that the cooling system has a better radiating effect. According to the invention, the problem of overheating of an engine is solved, the cooling system has no any damage, the service life of the engine and the cooling system can be effectively prolonged, and requirements of users are greatly achieved.

Owner:吴峥辰

Method and device for supplying heat carrier gas to preset combustion chamber of oxygen-enriched combustion internal heating type coal low-temperature dry distillation furnace

ActiveCN114322304AStable high equivalence ratio combustionSolve for uniformityDirect heating destructive distillationAir heatersCombustion chamberHeat carrier

The invention discloses a heat carrier gas supplying method and device for a preset combustion chamber of an oxygen-enriched combustion internal heating type coal low-temperature dry distillation furnace, and belongs to the field of low-temperature dry distillation in the coal chemical industry. A furnace body is additionally arranged outside the dry distillation furnace to serve as a preset combustion chamber, oxygen-enriched air and low-temperature dry distillation gas are combusted in the combustion chamber, a certain amount of adjusting gas is added to enter the combustion chamber to be mixed with combustion products, the temperature of the combustion products is adjusted to a target value needed by dry distillation, and hot carrier gas is formed to enter the dry distillation furnace to provide heat for the low-temperature dry distillation process of coal. Wherein the form of the furnace body can be a distributed preset combustion chamber or a centralized preset combustion chamber. According to the invention, stable large-equivalence-ratio combustion of low-temperature dry distillation gas and oxygen-enriched air can be realized on the basis of an original dry distillation furnace, hot carrier gas with uniform temperature and components is provided for the dry distillation furnace, and the technical problems of non-uniform temperature at each fire hole, over-temperature and slag bonding at the fire hole are solved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Cabinet type air conditioner and control method thereof

PendingCN110906439AImprove the phenomenon of overcooling/overheating of air supplyReduce noiseDucting arrangementsMechanical apparatusJet flowProcess engineering

The invention relates to the technical field of air conditioners and particularly relates to a cabinet air conditioner and a control method thereof. The invention aims to solve the problem that an existing air conditioner has too cold or too hot air supply and large noise. For the above purpose, the cabinet type air conditioner of the present invention includes a cabinet, and a fan and a heat exchanger are set in the cabinet. The cabinet type air conditioner further includes an air mixing device, and the air mixing device includes a purification unit, an air guide unit and a jet unit. The purification unit includes a box body and a purification component. The box body is provided with a first air inlet and a first air outlet. The air guide unit includes a pipe body, the pipe body has a second air inlet and a second air outlet connected to the first air outlet, and an induced draft fan is arranged in the pipe body. The jet unit includes a cylinder, the cylinder has a third air inlet anda third air outlet connected to the second air inlet, and a jet channel is formed between the third air inlet and the third air outlet. The present invention can improve the phenomenon that the air supply of the air conditioner is too cold or too hot, and the operating noise of the air conditioner can be reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

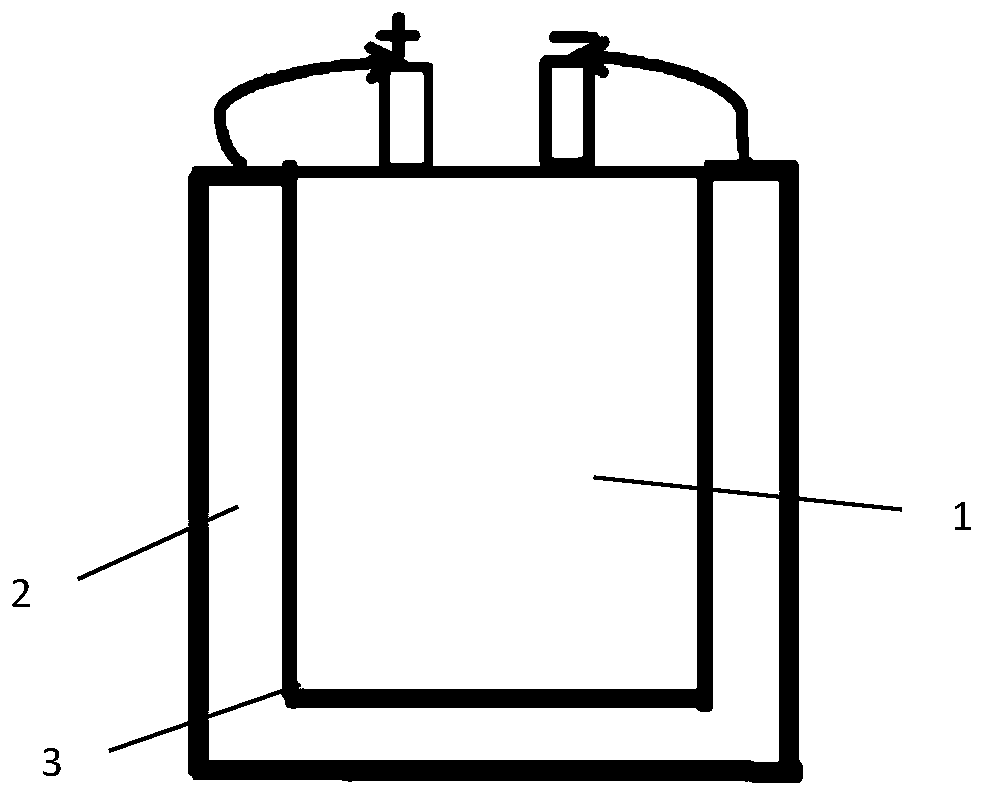

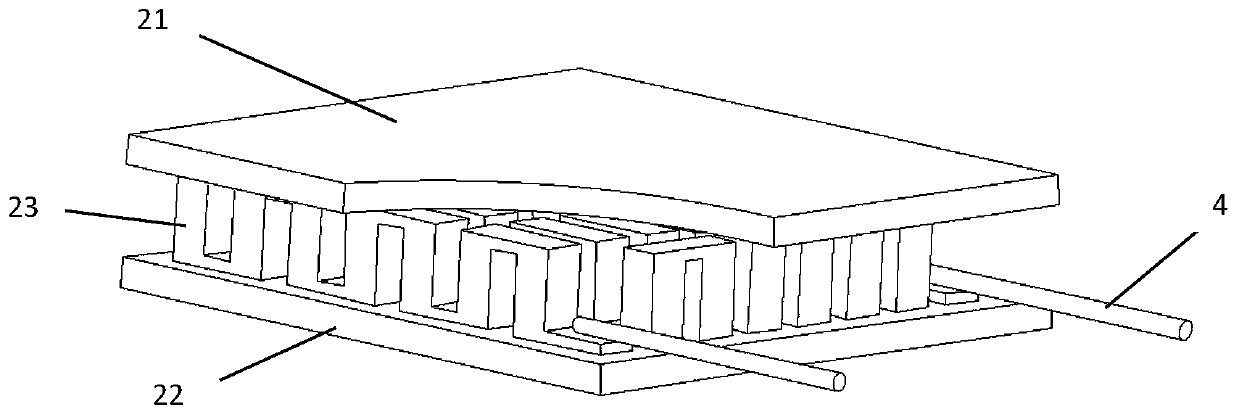

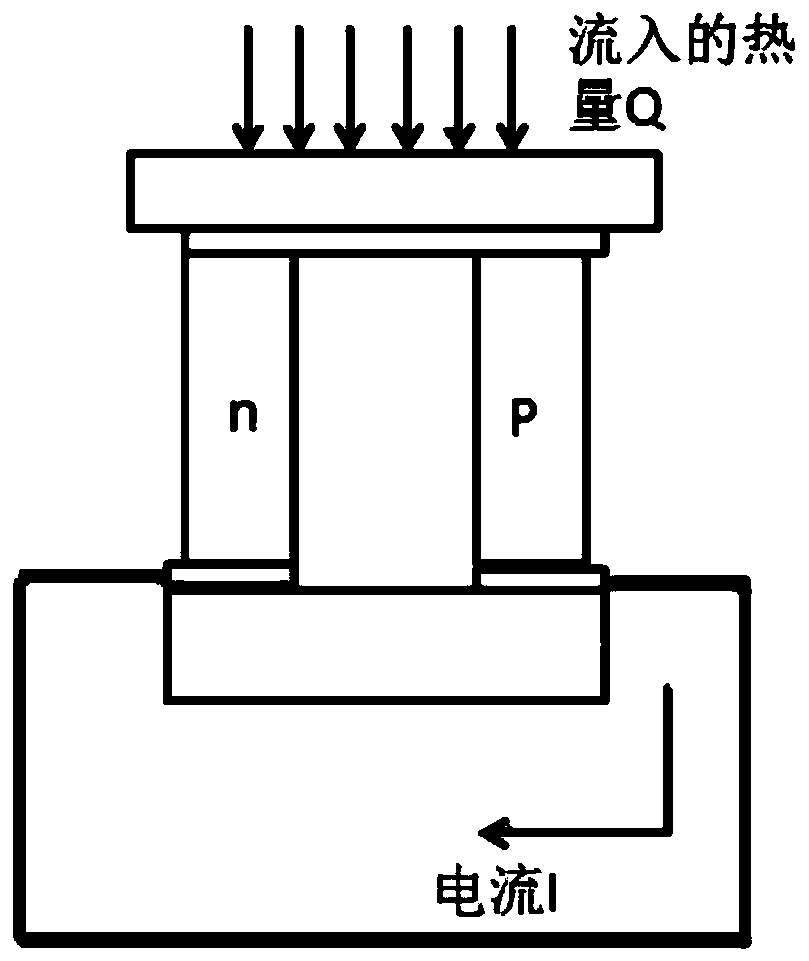

Anti-overheating circulation energy storage device

InactiveCN111211708ASolve overheatingSolve the problem of overheatingBatteries circuit arrangementsSecondary cellsProcess engineeringElectric energy

The invention discloses an anti-overheating circulation energy storage device. The device comprises an energy storage apparatus and a thermoelectric power generation apparatus; The thermoelectric power generation apparatus is of a concave structure; the energy storage apparatus is arranged in the groove of the thermoelectric power generation apparatus; the bottom surface and the side surface of the energy storage apparatus are in contact with the thermoelectric power generation apparatus; the thermoelectric power generation apparatus is electrically connected with the energy storage apparatus.With the anti-overheating circulation energy storage device of the invention adopted, the problem of the overheating of electronic products is effectively solved; and waste heat can be converted intoelectric energy to be stored, so that the repeated cyclic utilization of the heat energy and electric energy is achieved. The anti-overheating cyclic energy storage device is high in quality.

Owner:GUANGDONG UNIV OF TECH

Control system and control method for pumping and metering of easy-to-vaporize medium

InactiveCN102767526APrevent leakageReduce energy consumptionPump controlNon-positive displacement fluid enginesElectric machineControl system

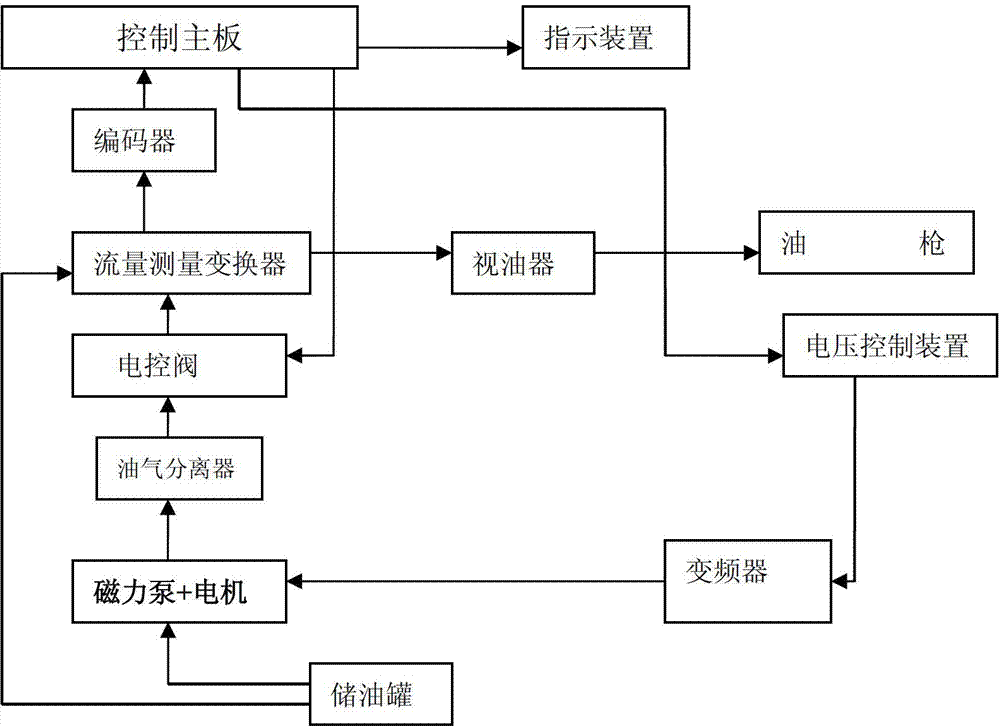

The invention provides a control system for the pumping and metering of an easy-to-vaporize medium. The control system is characterized by comprising a control mainboard, a coder, a flow measurement converter, an electric control valve, an oil-gas separator, a frequency converter, a voltage control device, an oil monitor, an indication device, a magnetic pump and a magnetic pump motor, wherein the voltage control device, the frequency converter, the magnetic pump, the magnetic pump motor, the oil-gas separator, the electric control valve, the flow measurement converter, the coder, the control mainboard and the indication device are in signal connection in sequence; the control mainboard is also in signal connection with the voltage control device and the electric control valve respectively; the oil monitor is also connected with an easy-to-vaporize medium outlet; and an easy-to-vaporize medium storage device is also connected with the flow measuremen converter, the magnetic pump and the magnetic pump motor respectively. The invention also discloses a control method for the control system. By the control system and the control method, heat produced by the magnetic pump can be effectively reduced, the reliability of the magnetic pump can be improved, and the magnetic pump can be widely applied to the pumping and metering of the easy-to-vaporize medium.

Owner:FOSHAN HAIZHUORUI FLUID CONTROL ENG

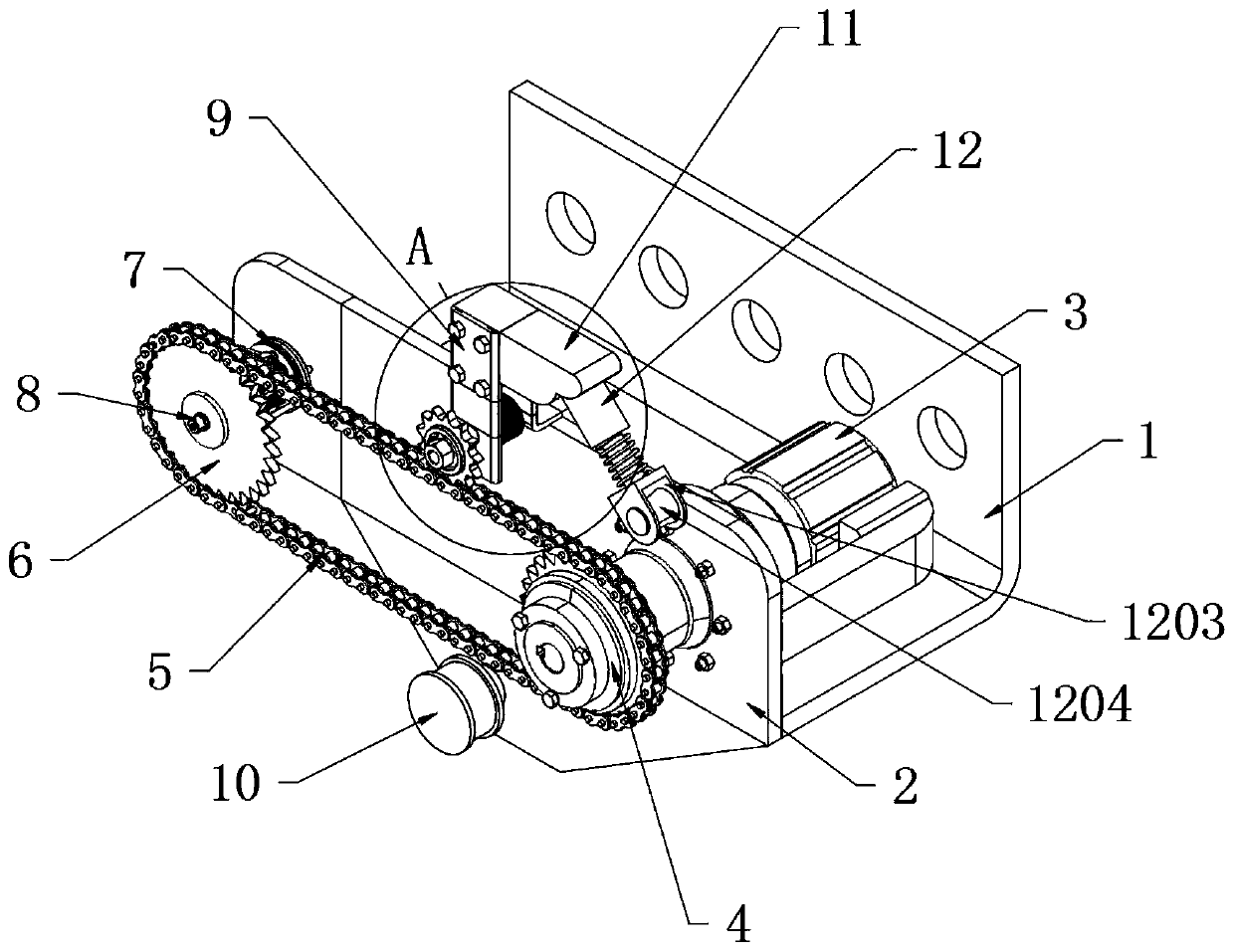

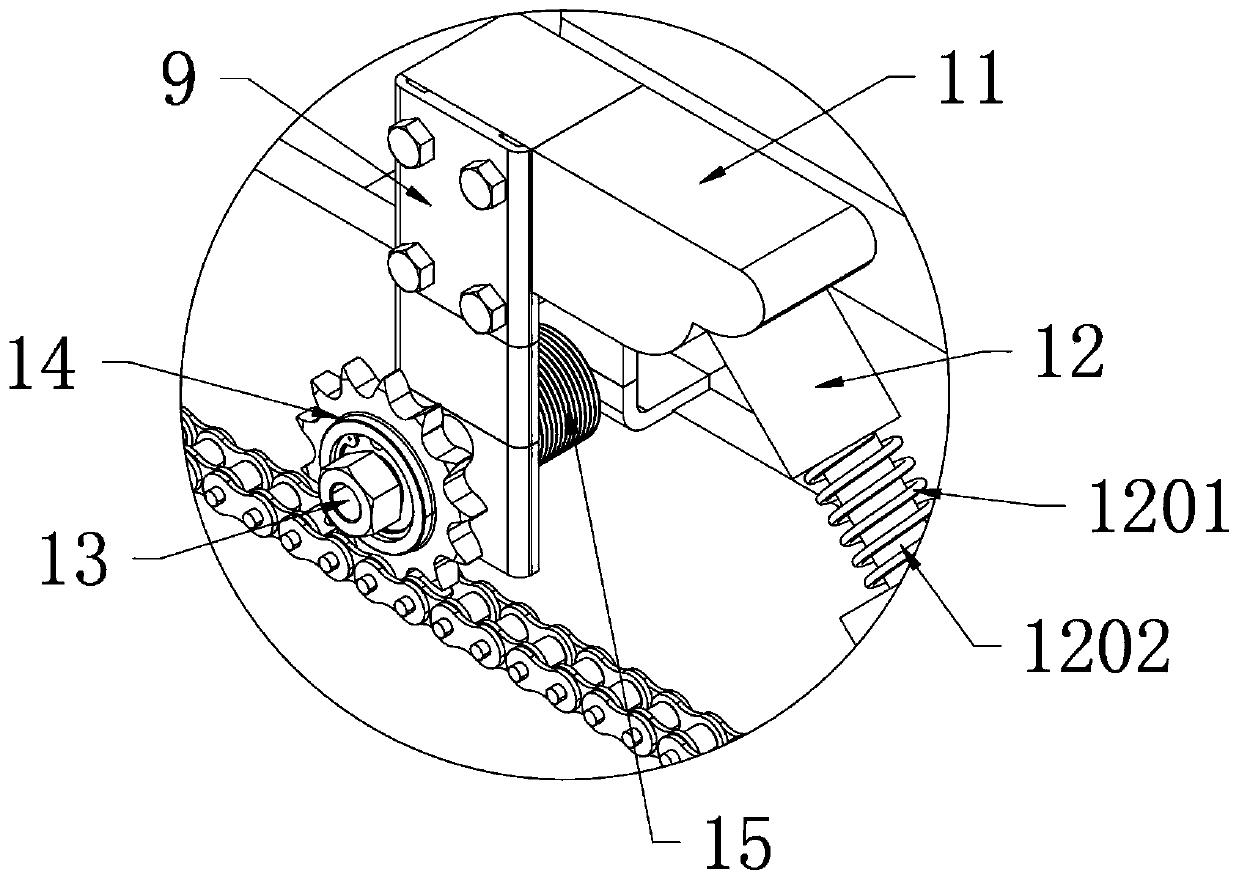

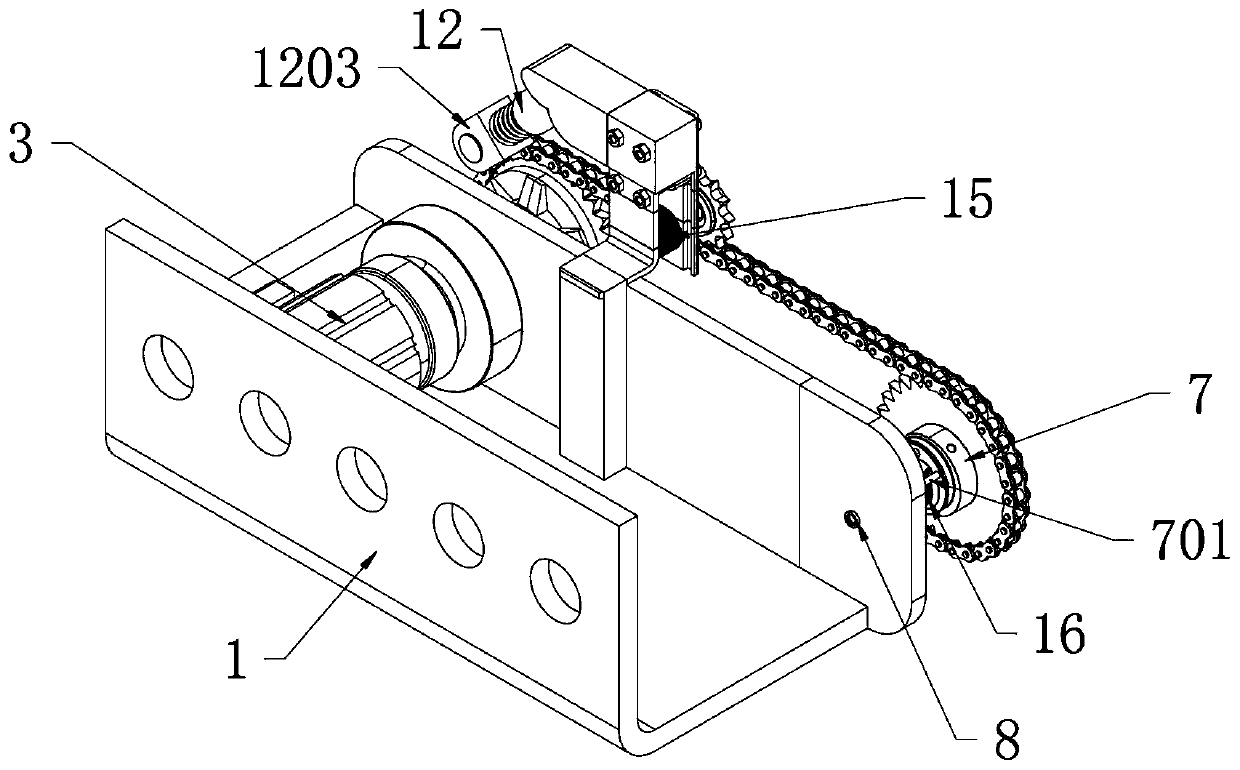

Improved yarn guide device of computerized flat knitting machine

The invention provides an improved yarn guide device of a computerized flat knitting machine. The improved yarn guide device comprises a hanging plate, yarn guide ring groups and snap rings, wherein the whole hanging plate is of a right-angle plate structure, and hanging holes allowing the hanging plate to be hung on the lower edge of the outer wall of an operating table of the computerized flat knitting machine are formed in the vertical wall of the hanging plate; a vertical plate is vertically connected with the side wall of the front end of the hanging plate. According to the improved yarnguide device of the computerized flat knitting machine, a yarn feeding wheel and a shaft sleeve are arranged, the middle part of the shaft sleeve is of a hollow-out structure, the two ends of the shaft sleeve are connected through six connecting rods to form a hub-shaped structure, on one hand, stable strength can be provided for the shaft sleeve, on the other hand, the yarn can conveniently penetrate out, the yarn feeding wheel is fixedly mounted on a universal driving shaft in the shaft sleeve, and the lower ends of the snap rings are parallel to the outer arc surface of the yarn feeding wheel, so that the yarn can be tensioned and is prevented from winding when penetrating out of the yarn feeding wheel to be sent to a yarn carding wheel.

Owner:嘉兴明德机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com