Lubricating system for gear box of wind generating set

A technology for wind turbines and lubrication systems, applied in wind turbine components, wind turbines, gear lubrication/cooling, etc., can solve the problems of insignificant cooling effect of the lubrication system and imperfect system control, so as to improve the cooling effect and reduce the Maintenance cost, effect of avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

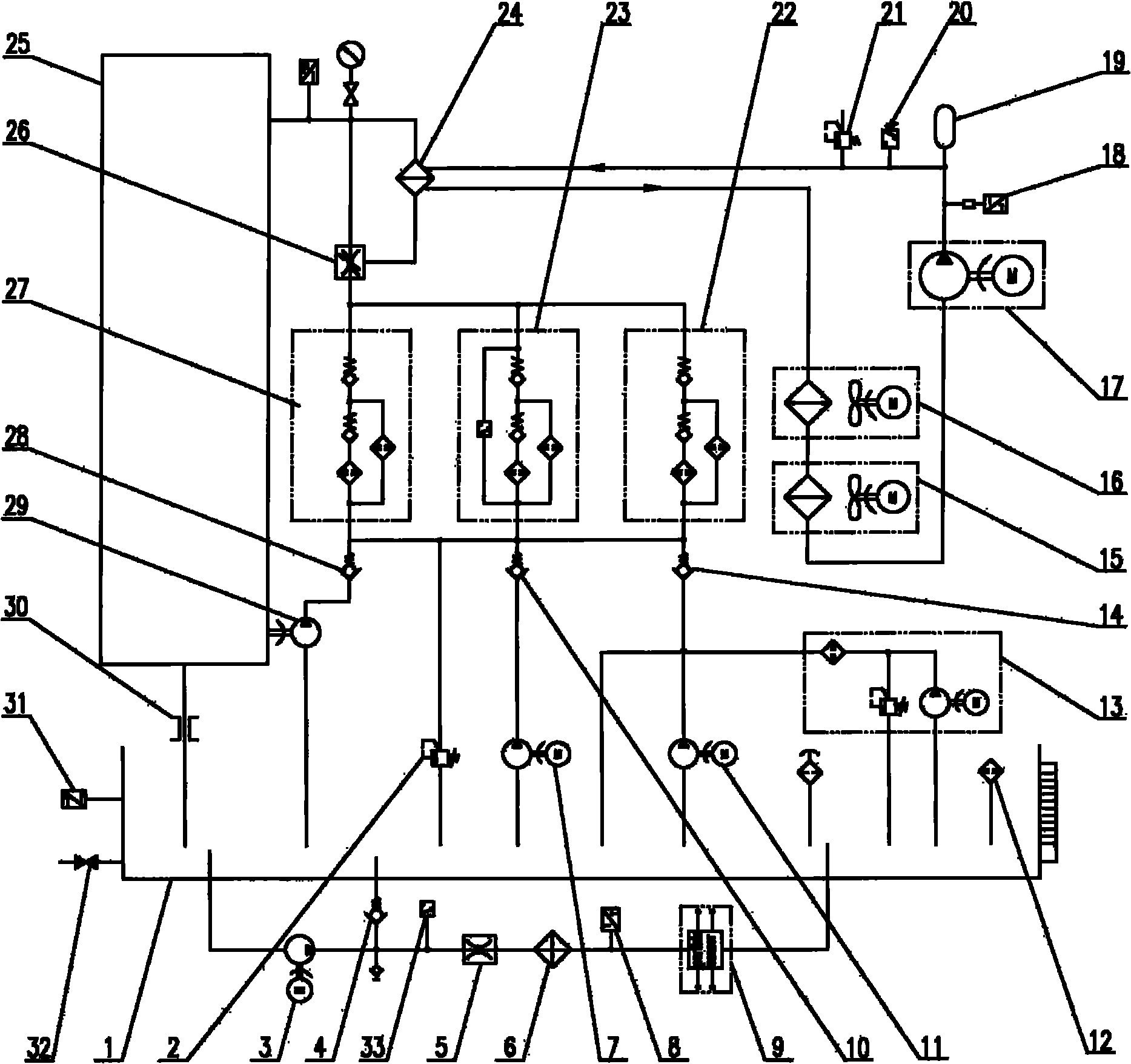

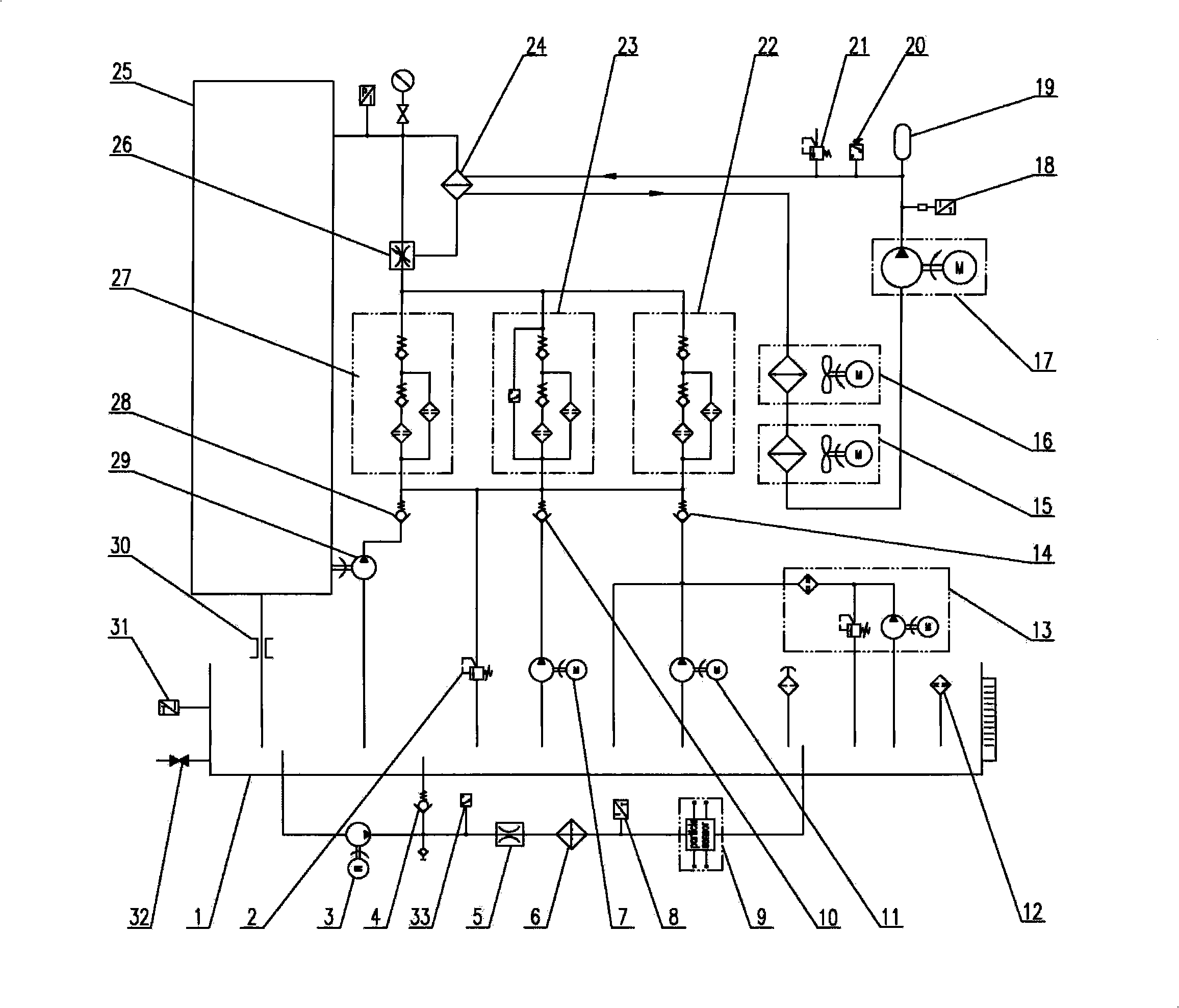

[0016] Such as figure 1 The gearbox lubricating system of a wind power generating set as shown includes an oil tank 1 and a gear box 25, and is characterized in that: the oil tank 1 is externally installed independently, has a circulation heating system on it, and is connected through a flexible rubber joint or a metal hose 30 communicates with the gear box 25, which effectively reduces the impact of the vibration of the gear box on the fuel tank device during operation. Lubricating oil is sucked from oil tank 1 through electric pumps 7, 11 and mechanical pump 29, then passes through check valves I10, II14, III28, and is distributed to filters I22, II23, III27, and then joins together and enters three-way temperature control valve 26, and Divided according to oil temperature. The oil temperature is usually set at 42°C to 45°C. When the temperature has not yet reached the set value, the lubricating oil directly enters the oil distributor of the gear box 25 after passing throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com