Method and device for supplying heat carrier gas to preset combustion chamber of oxygen-enriched combustion internal heating type coal low-temperature dry distillation furnace

An oxygen-enriched combustion and combustion chamber technology, applied in the direction of combustion methods, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems of unstable product quality of dry distillation, fluctuating furnace conditions, difficulty in going smoothly, etc., and achieve stable quality of dry distillation products, Uniform airflow and temperature distribution, stable furnace conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

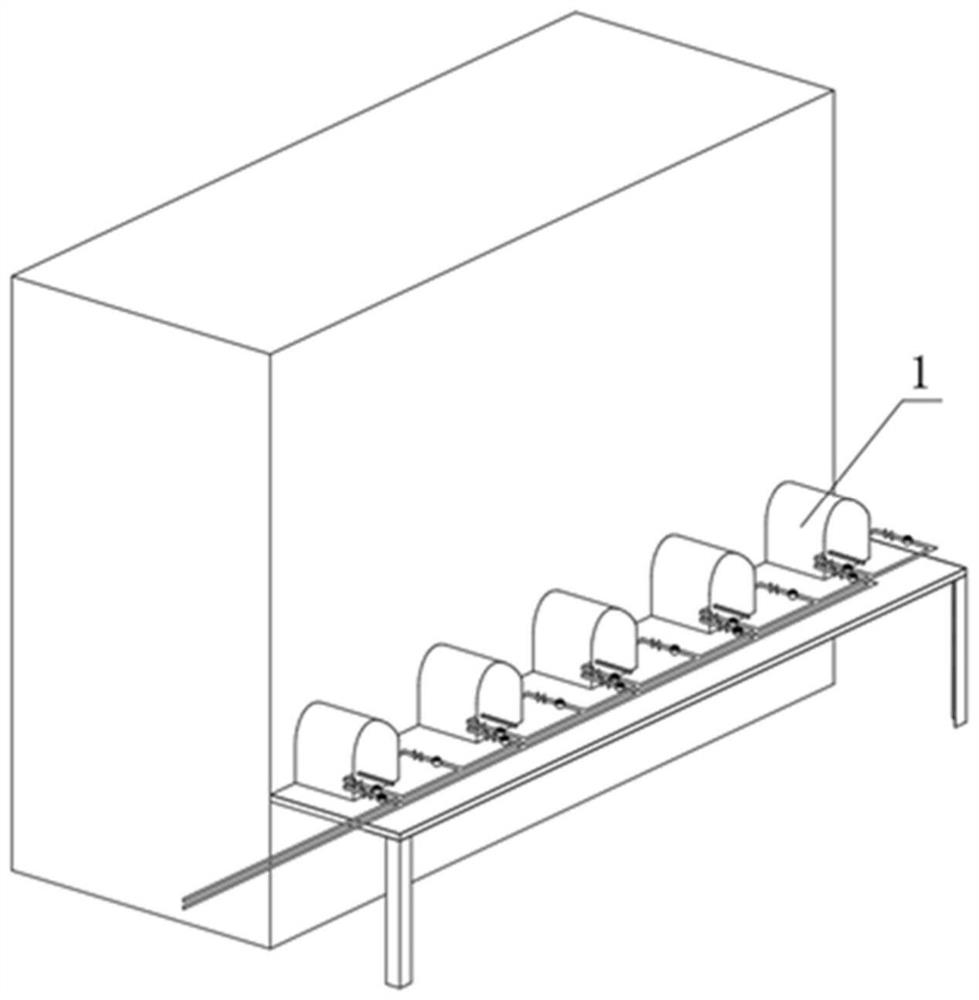

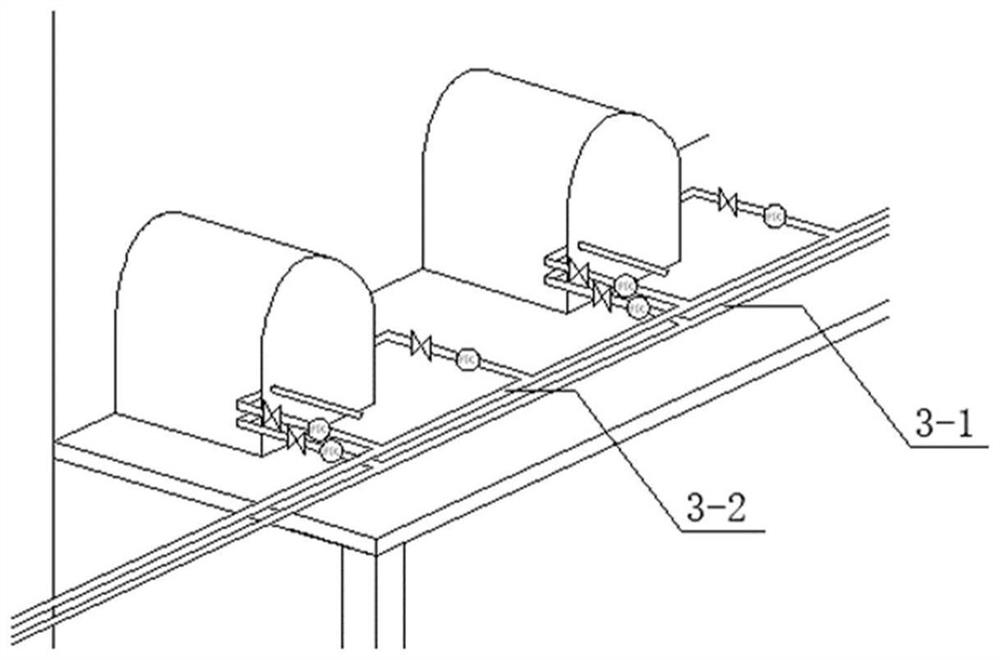

[0057] Embodiment 1 adopts distributed preset combustors, and is applied to an oxygen-enriched combustion internal heat low metamorphism coal carbonization furnace with an oxygen enrichment rate of 83% and an annual output of 75,000 tons

[0058] (1) Basic information

[0059] A low-metamorphism coal retort furnace with an annual output of 75,000 tons of semi-coke has been built. Oxygen-enriched air and gas with an oxygen-enriched rate of 83% are used to generate high-temperature heat carrier gas in the arched combustion chamber. Coal dry distillation provides heat. A total of 48 groups of gas supply branches are arranged on both sides of the lower part of the furnace body to provide oxygen-enriched air and gas to 48 combustion chambers respectively. Relevant facilities are fully equipped, including dry distillation furnace body, combustion-supporting fan, gas fan, raw material preparation (crushing and screening system), feeding system, gas export system, coke discharge syst...

Embodiment 2

[0064] Embodiment 2 adopts distributed preset combustion chambers, and is applied to an oxygen-enriched combustion internal heat low-deterioration coal carbonization furnace with an oxygen enrichment rate of 100% and an annual output of 112,500 tons

[0065] (1) Basic information

[0066] A low-metamorphism coal retort furnace with an annual output of 112,500 tons of semi-coke has been built. Oxygen-enriched air and gas with an oxygen-enriched rate of 100% are used to generate high-temperature heat carrier gas in the arched combustion chamber. Coal dry distillation provides heat. A total of 72 groups of gas supply branches are set on both sides of the lower part of the furnace body to provide oxygen-enriched air and gas to 72 combustion chambers respectively. Relevant facilities are fully equipped, including dry distillation furnace body, combustion-supporting fan, gas fan, raw material preparation (crushing and screening system), feeding system, gas export system, coke disch...

Embodiment 3

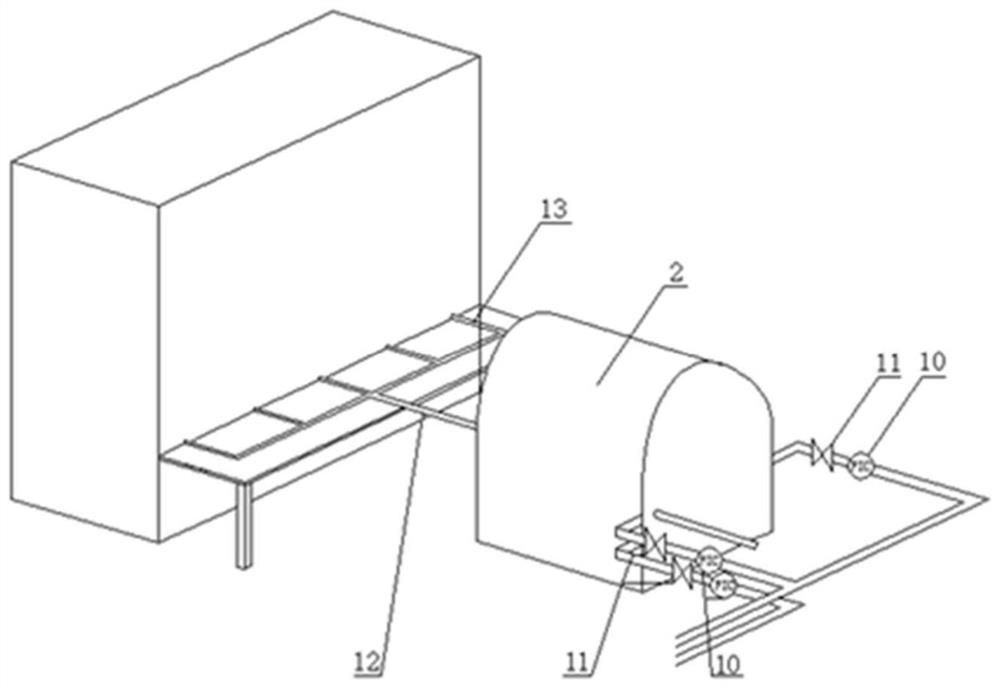

[0071] Embodiment 3 adopts a centralized preset combustion chamber, which is applied to an oxygen-enriched combustion internal heat type low-modification coal carbonization furnace with an oxygen enrichment rate of 83% and an annual output of 112,500 tons

[0072] (1) Basic information

[0073] A low-metamorphism coal retort furnace with an annual output of 112,500 tons of semi-coke has been built. Oxygen-enriched air and gas with an oxygen-enriched rate of 83% are used to generate high-temperature heat carrier gas in the arched combustion chamber, which passes through the fire channel in the retort furnace to achieve low-metamorphism Coal dry distillation provides heat. The lower part of the furnace body is equipped with a hot-carrier gas transmission main road, which is connected with 72 sets of hot-carrier gas transmission branches to provide hot-carrier gas to 72 fire channels. Relevant facilities are fully equipped, including dry distillation furnace body, combustion-sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com