Patents

Literature

50results about How to "Does not affect vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

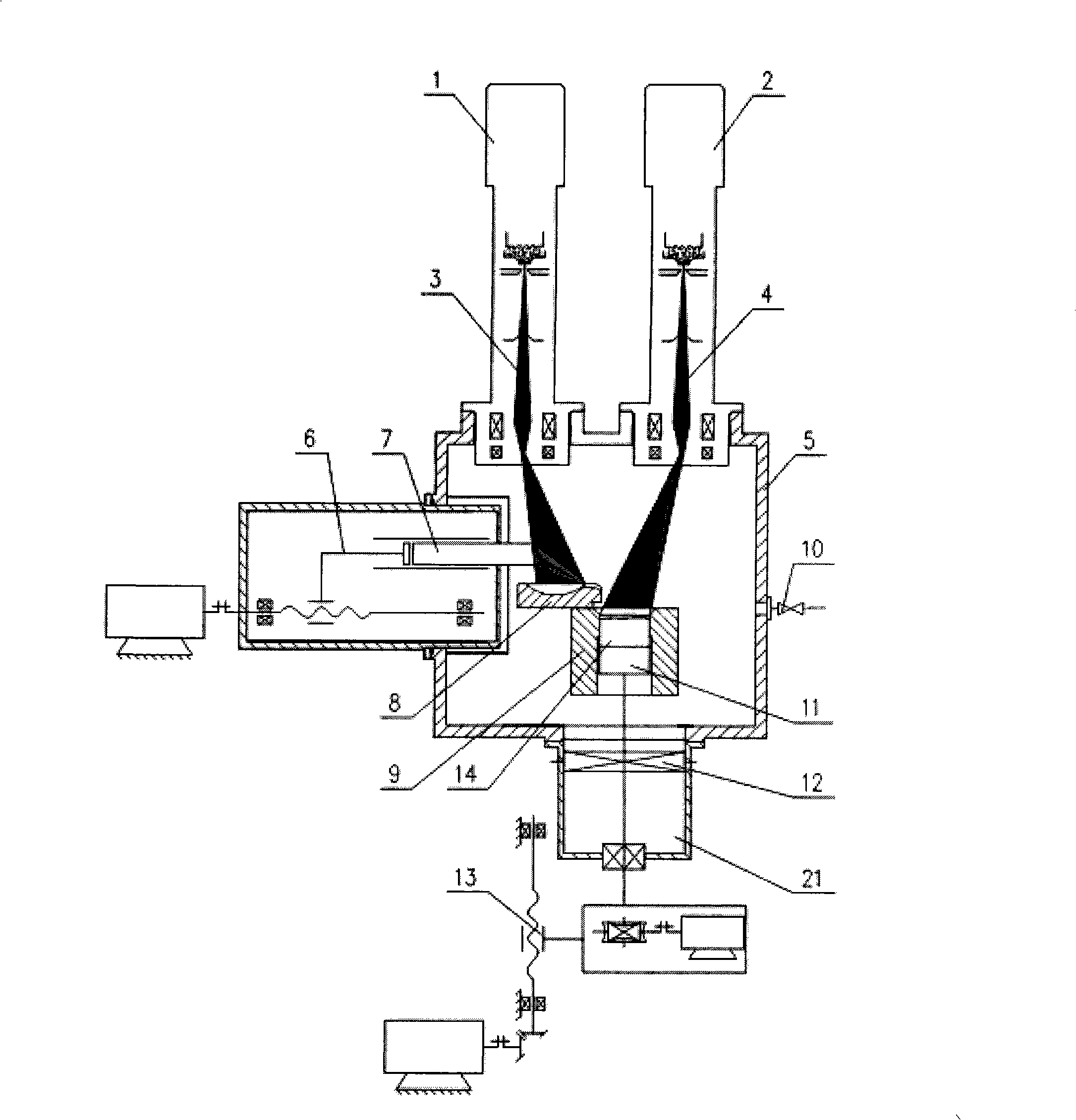

Vacuum electron beam melting furnace for polysilicon purification

ActiveCN101445957AIncrease productivityDoes not affect vacuumPolycrystalline material growthChemical industryIsolation valveTransformer

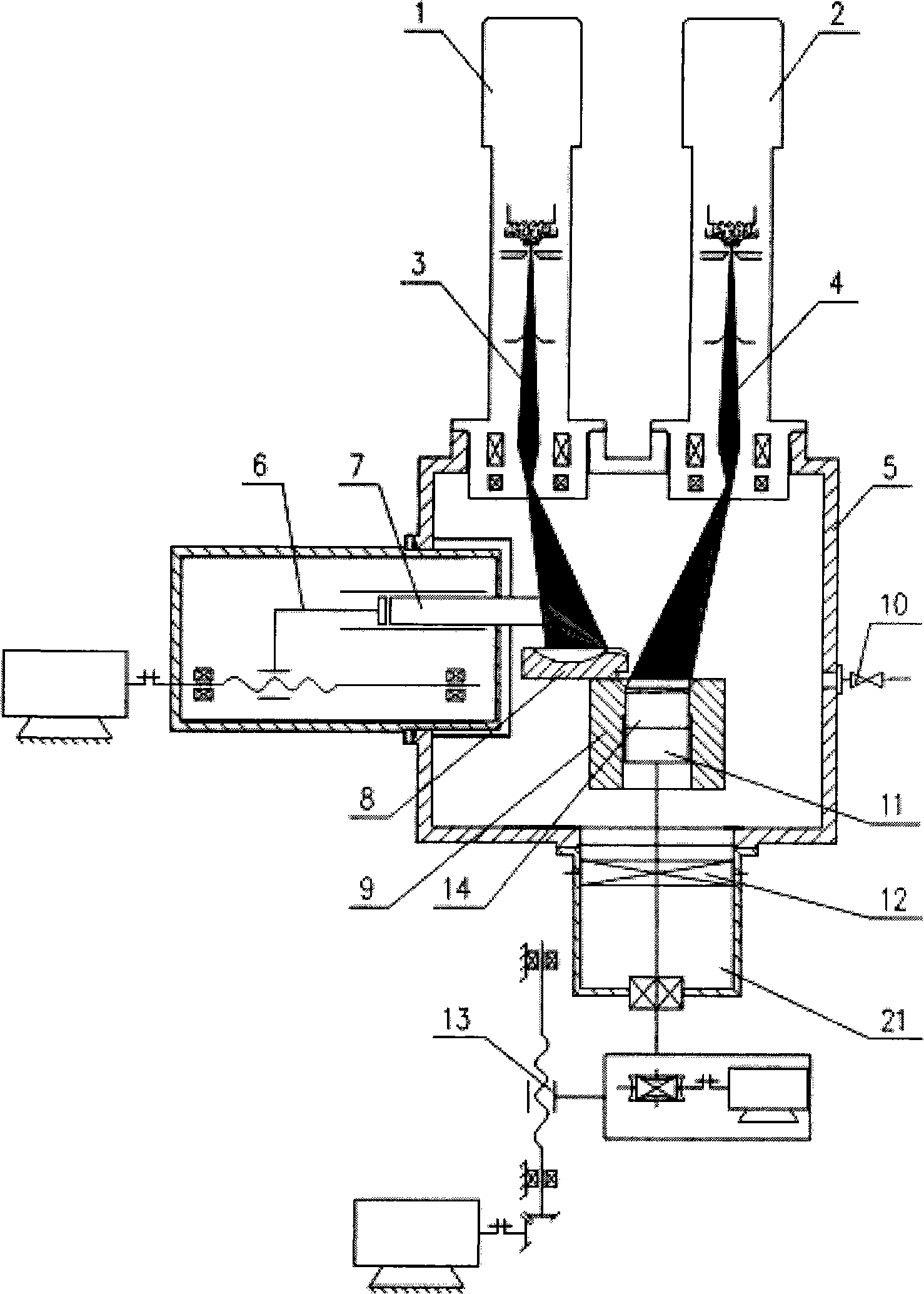

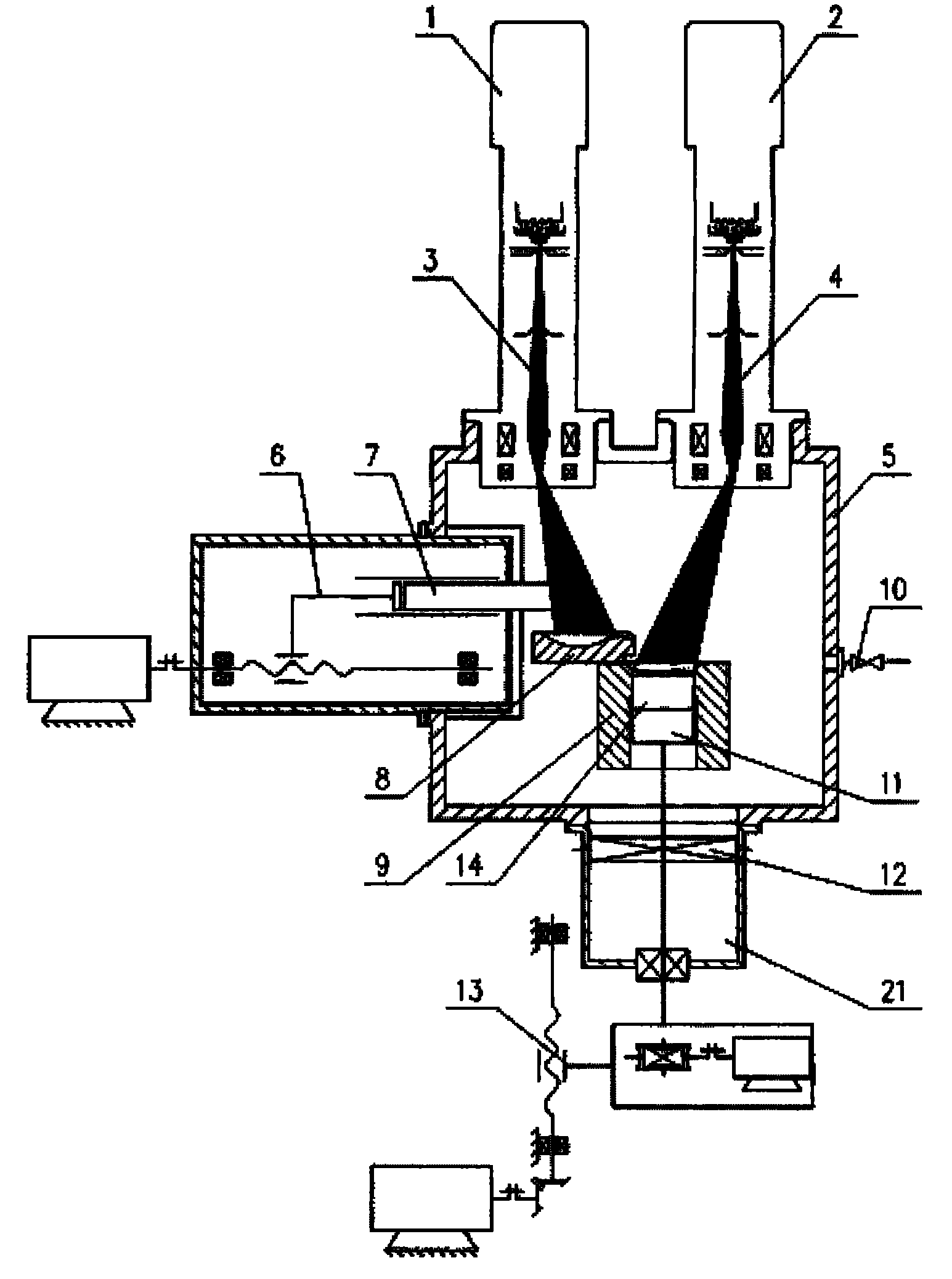

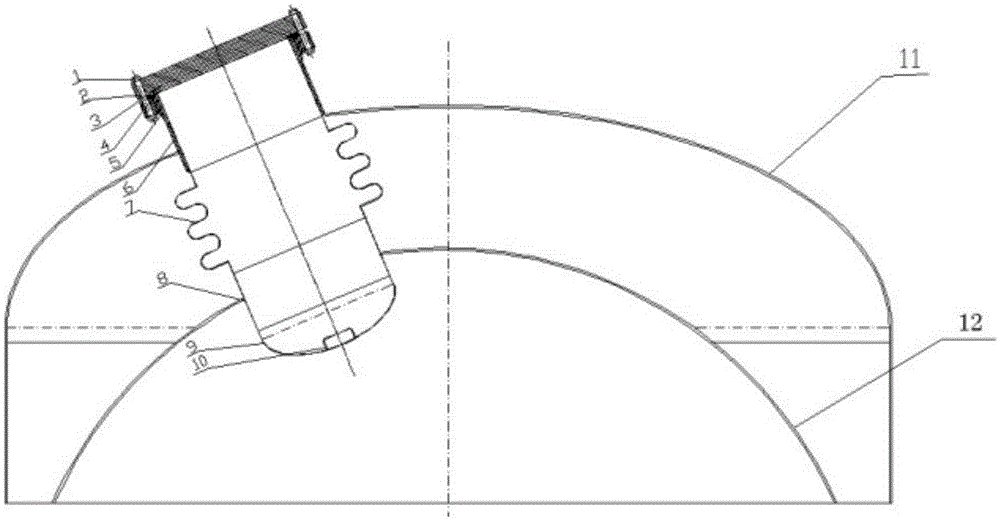

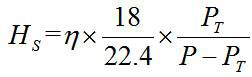

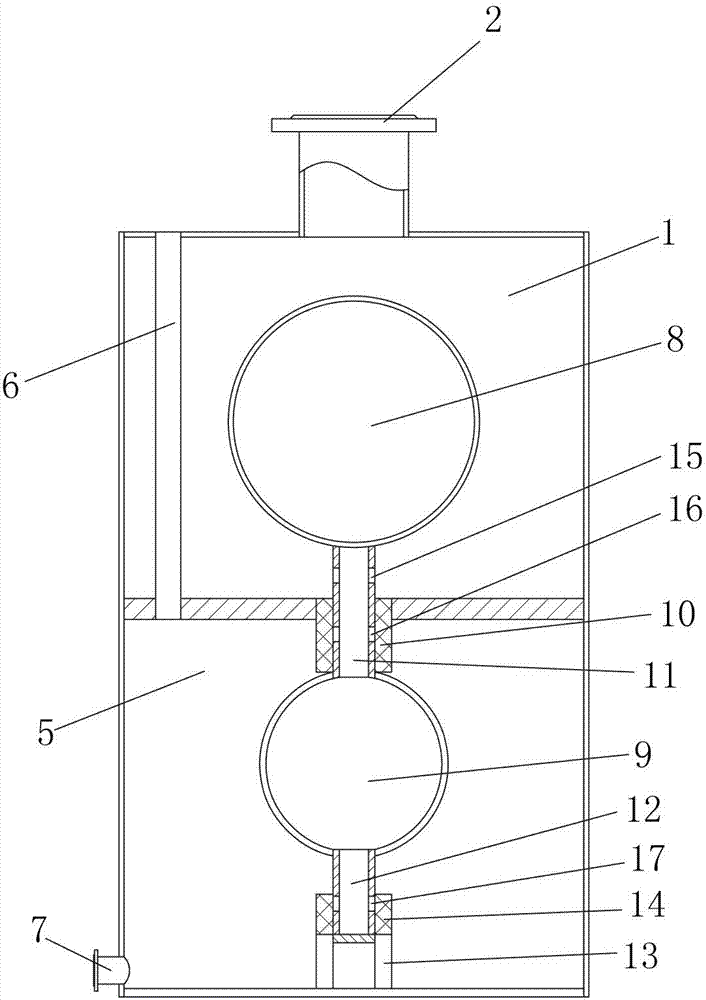

The invention provides a vacuum electron beam melting furnace for polysilicon purification. The melting furnace is characterized in that a melting chamber is square or cylindrical, a chamber wall is of a double water cooling structure or a coil water cooling structure; an electron gun is vertically and downwardly or horizontally arranged on the chamber wall of the melting chamber, a vacuum system is arranged at the rear of the melting chamber; an isolating valve is arranged between a feeding chamber and the melting chamber of a feed mechanism, and an inflation valve of an inflation system is arranged at the other side of the melting chamber; a discharge mechanism is arranged at the bottom of the melting chamber and connected with an ingot-pulling mechanism; the ingot-pulling isolating valve is arranged between discharge mechanism and the melting chamber; the melting chamber is internally provided with a water cooling crucible and a crystallizing crucible; all high-voltage devices of a high-voltage power supply of an electrical control system are arranged at a fuel tank filled with a transformer; and by adopting oil insulation of the transformer, the high-voltage power supply is connected with an electric cabinet which is connected with a console. The melting furnace has the advantages that a plurality of elements can be purified simultaneously, the production efficiency is high, energy consumption is low, energy-saving effect is excellent, and large-scale and automatic operation is easy to be implemented.

Owner:桂林实创真空数控设备有限公司

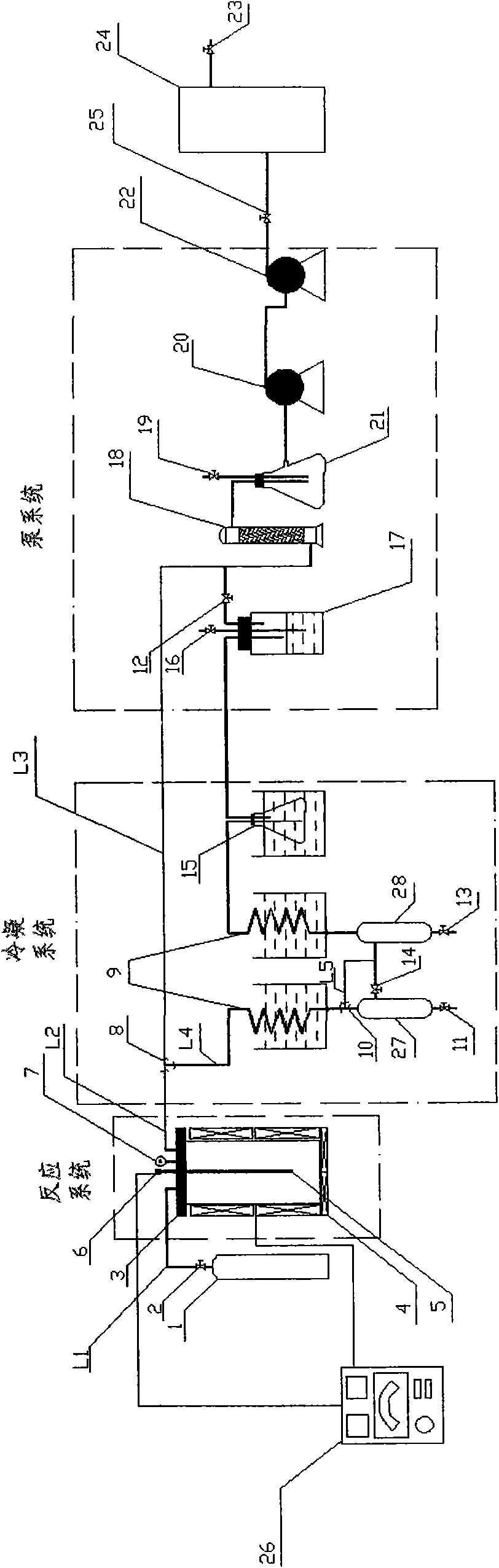

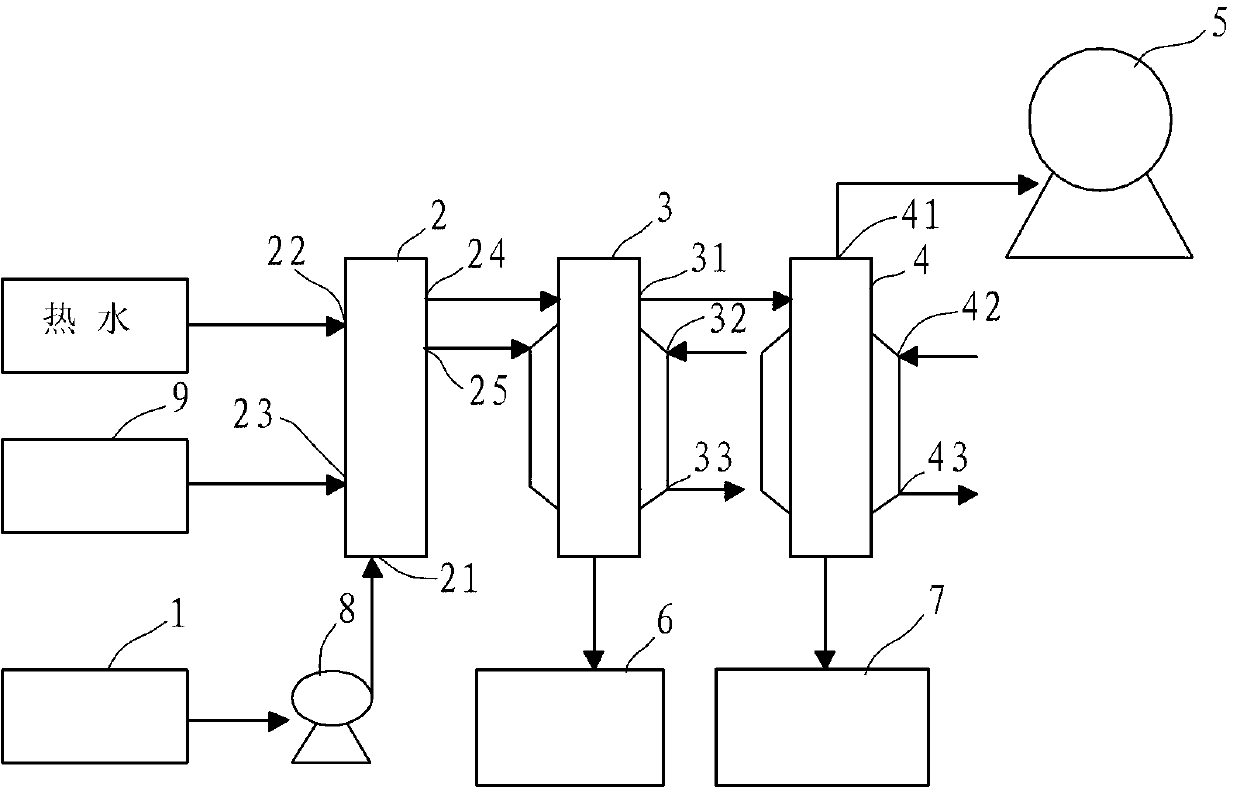

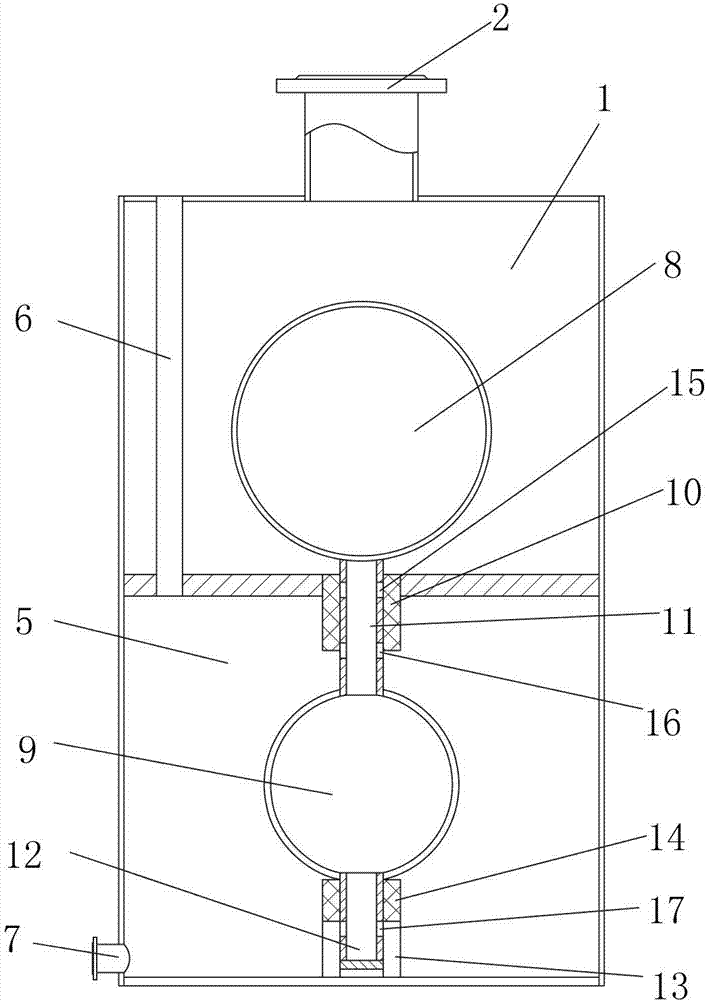

Method for preparing biological oil through vacuum pyrolysis of biomasses

InactiveCN101613617AImprove heat transfer efficiencyReduce consumptionBiofuelsLiquid hydrocarbon mixture productionHysteresisWater vapor

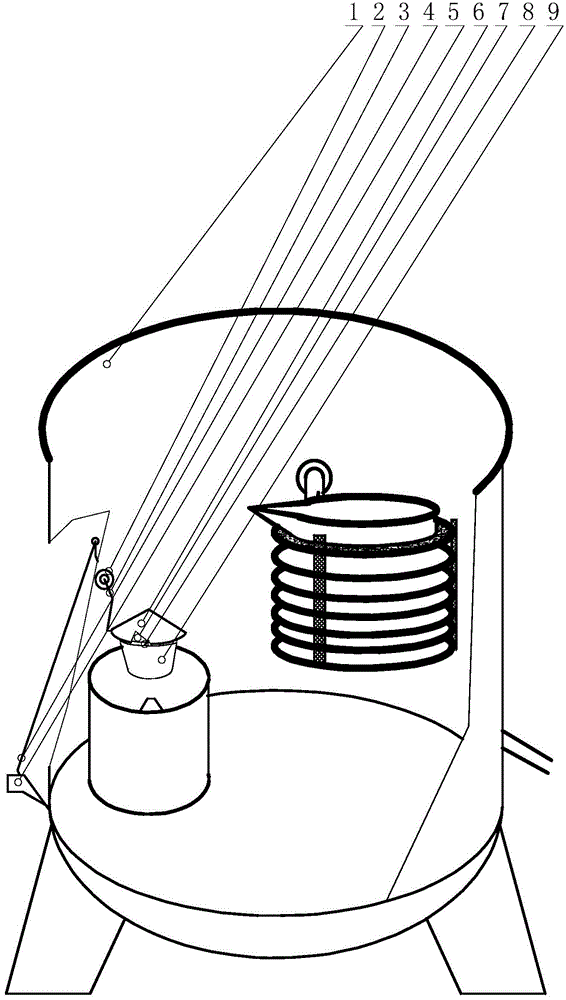

The invention relates to a method for preparing biological oil through vacuum pyrolysis of biomasses, which comprises the following technological processes: (1) vacuum pyrolysis: adding raw materials after pretreatment into a reaction kettle, and heating a peripheral pipe type furnace to raise the temperature for pyrolysis, wherein a heat conducting device is arranged in the reaction kettle; (2) condensation: introducing volatile components (mainly comprising water vapor) at a low temperature into a drying tower, and guiding the volatile components at a high temperature into a coil condenser for condensation, wherein the online sampling can be achieved in the process of the pyrolysis; and (3) absorption: absorbing the water vapor in incondensable gas by the drying tower and absorbing nitride and sulfide by a bubbling absorption bottle so as to effectively reduce the pollution caused by vacuum pump oil. The method partially solves the problem of temperature rise hysteresis caused by the low heat transfer efficiency of the biomasses in the process of the temperature rise and the problem of low condensation efficiency and the online sampling, and simultaneously the method preliminarily reduces the water content in the biological oil.

Owner:SOUTHEAST UNIV

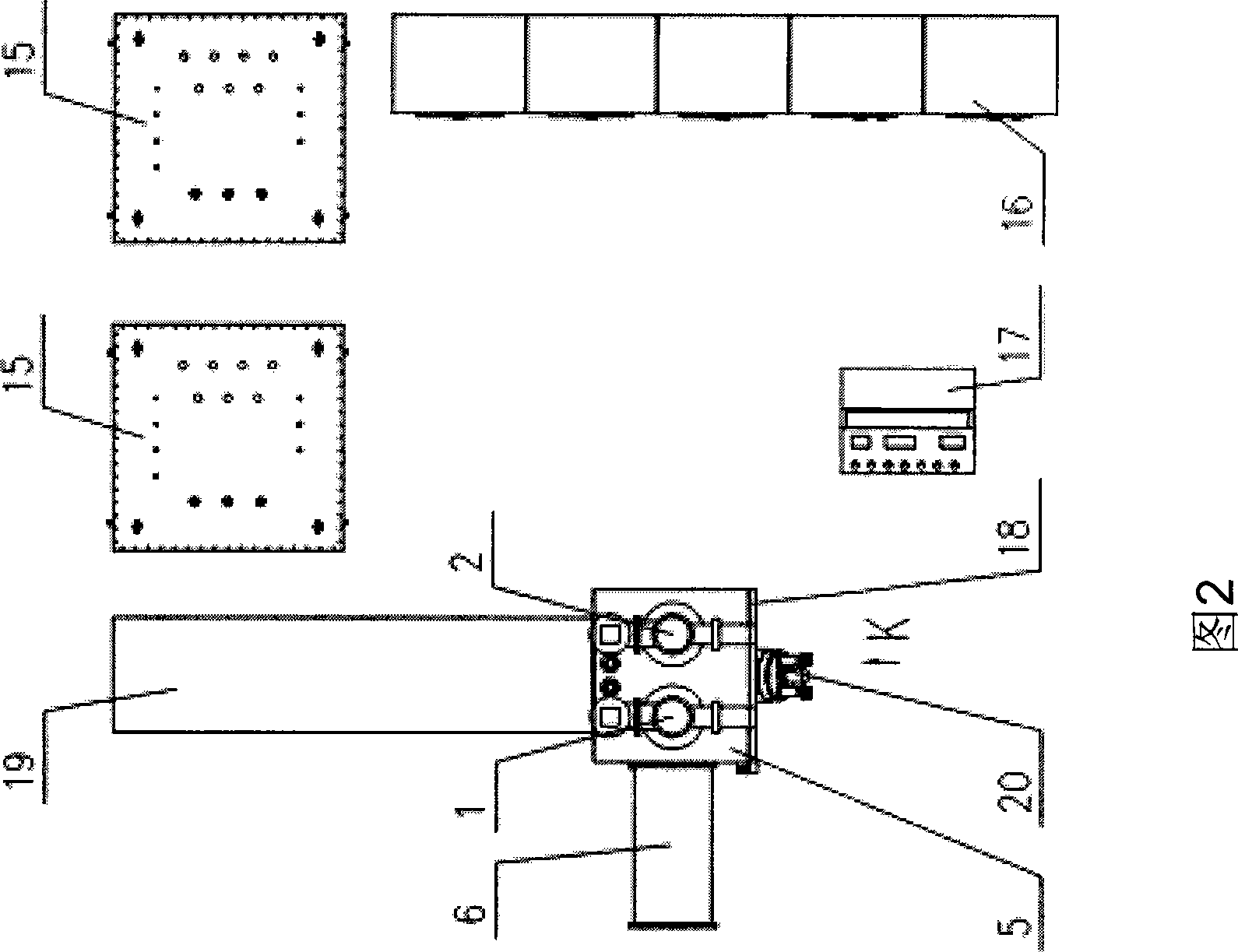

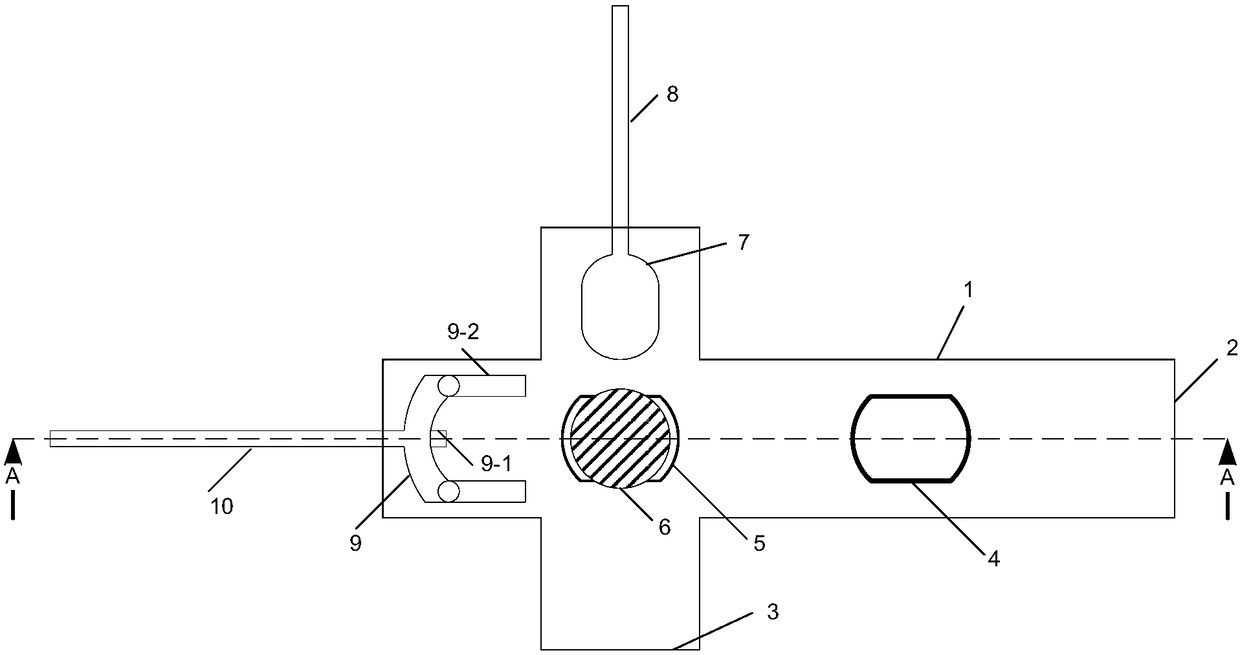

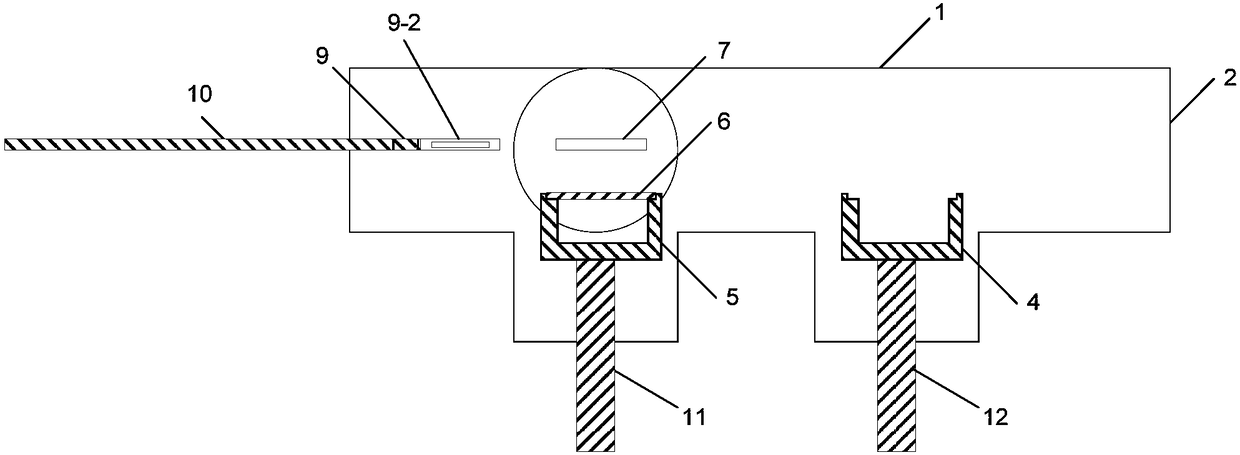

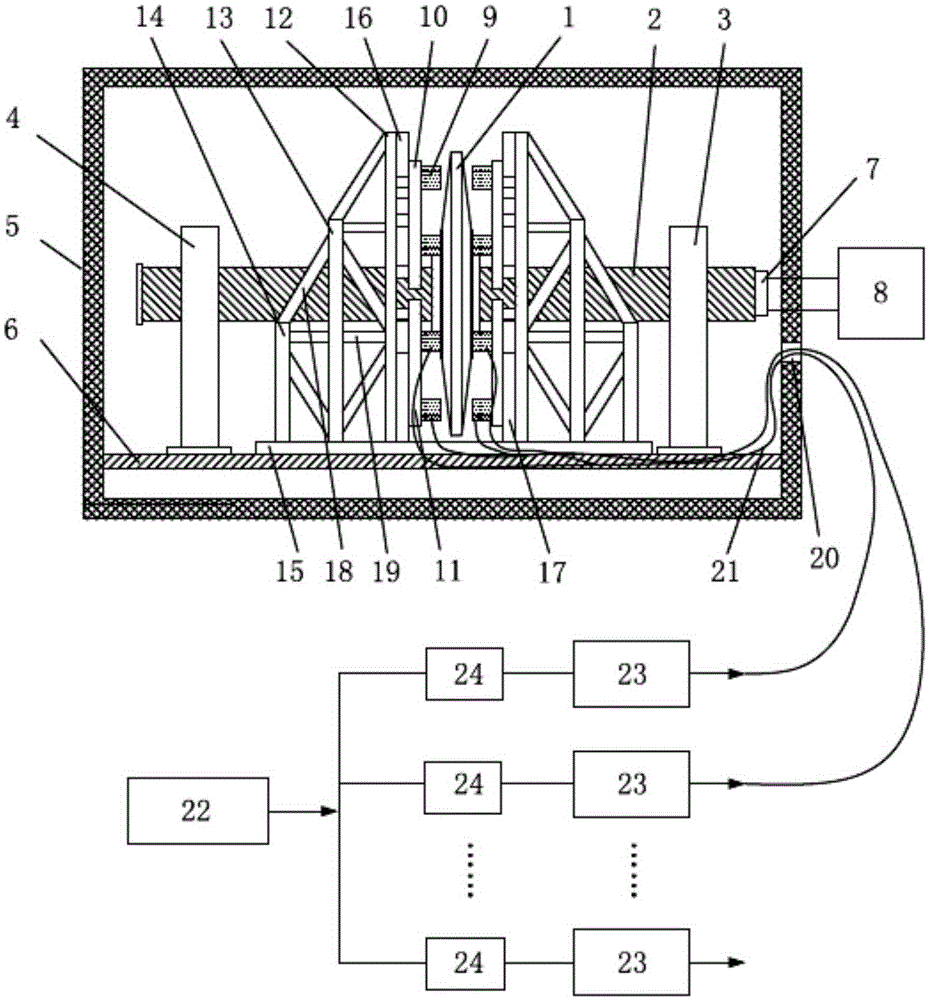

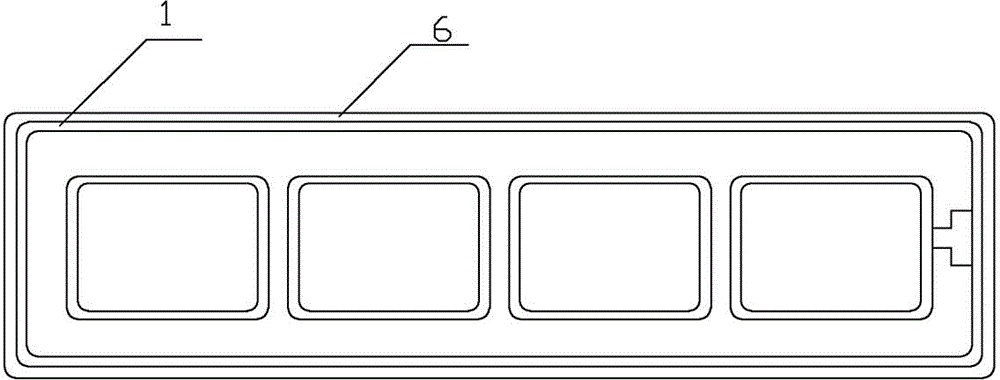

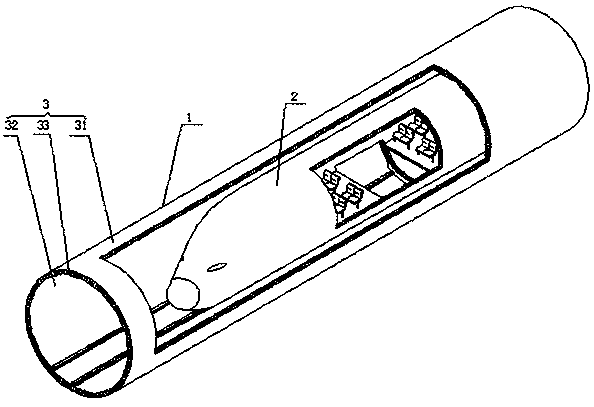

Sample conveying system applied to vacuum interconnection system

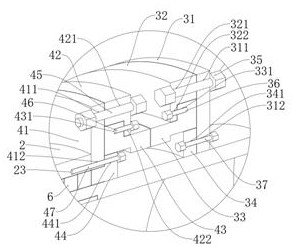

The invention discloses a sample conveying system applied to a vacuum interconnection system. The sample conveying system applied to the vacuum interconnection system comprises a vacuum pipeline, at least two sample supports, two vacuum lifting tables corresponding to the at least two sample supports, at least one full-mechanical drive manipulator, at least one sample manipulator, and at least twovacuum magnetic rods. The full-mechanical drive manipulator is at least used for conveying a sample between the sample supports and driving an upper surface and a lower surface of the sample to overturn; the sample manipulator is at least used for fetching and sending the sample in the sample support to a corresponding device; and the two vacuum magnetic rods are used for driving the full-mechanical drive manipulator and the spoon-shaped sample manipulator. By adopting full-mechanical movement in vacuum, the sample is conveyed from one sample support to the other sample support or the device,and the upper surface and the lower surface of the sample are overturned; and in vacuum, an electric or pneumatic servo drive sample conveying process is not adopted, so that a vacuum degree and thecleanliness of the whole system are not influenced, and the sample conveying system applied to the vacuum interconnection system can adapt to a local high temperature working condition and a space dimension in the vacuum interconnection system.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

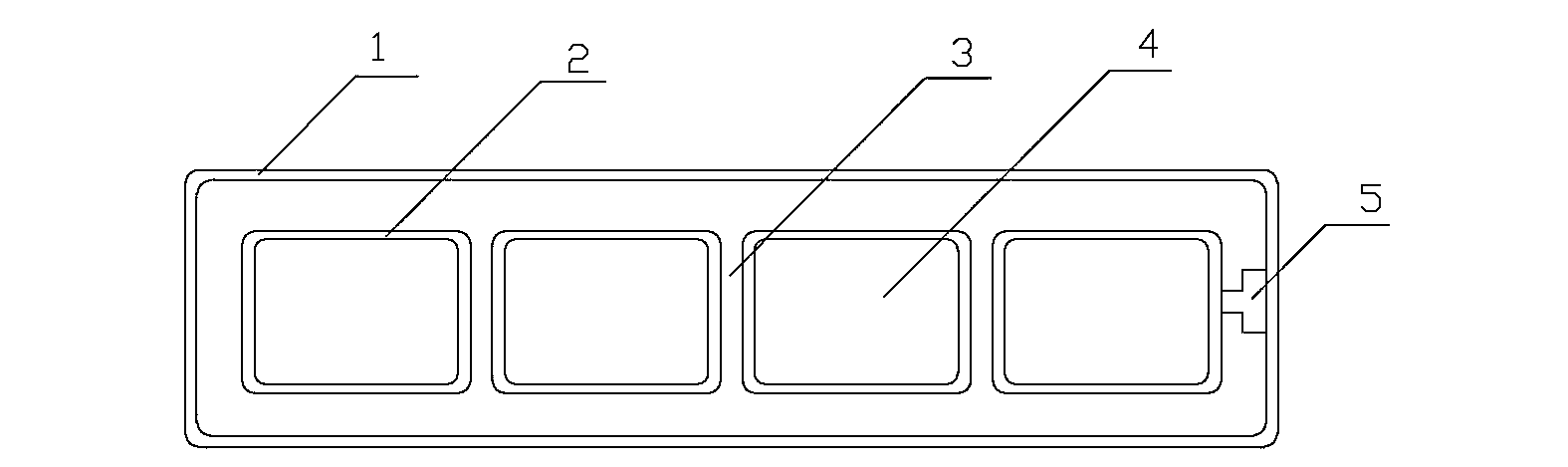

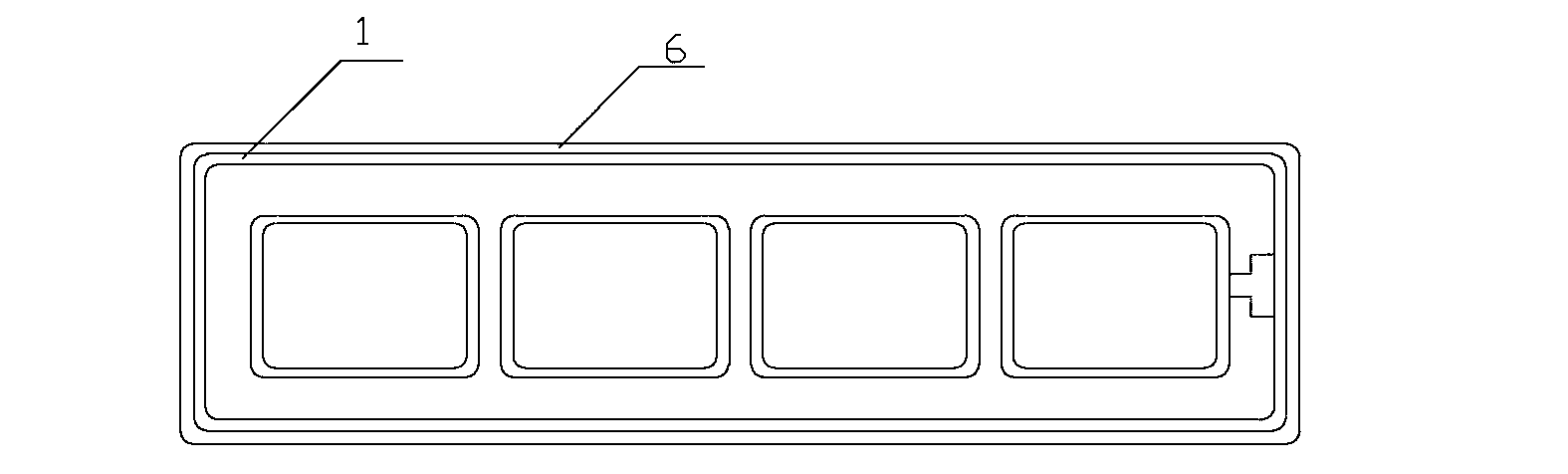

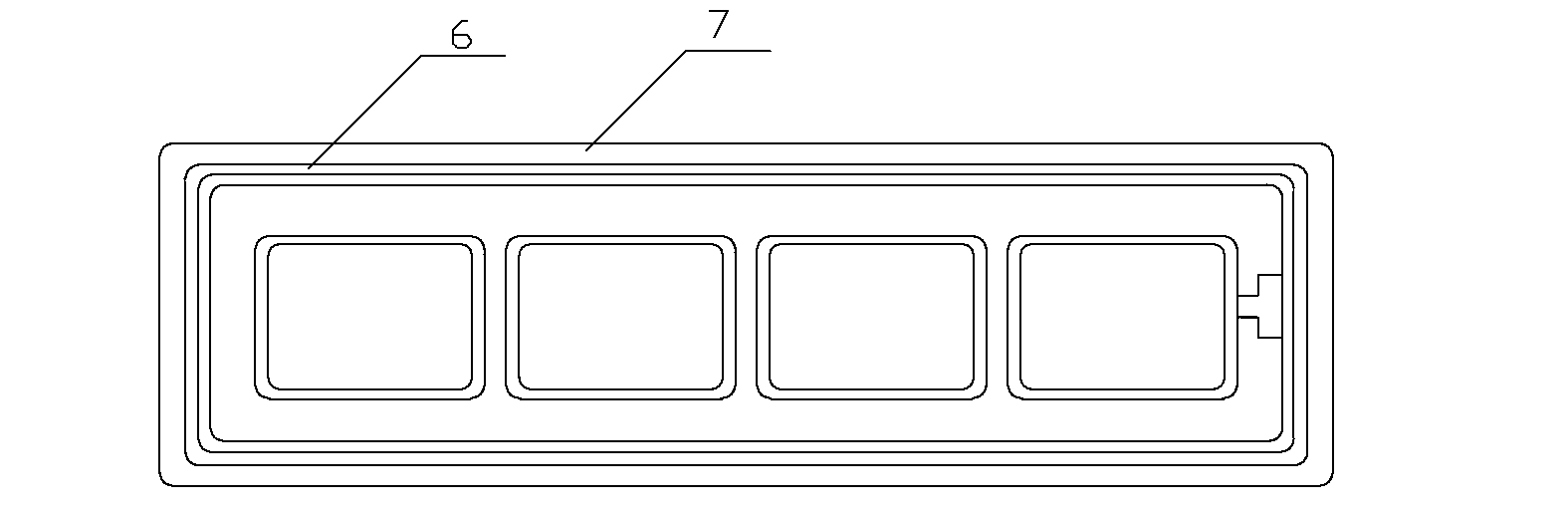

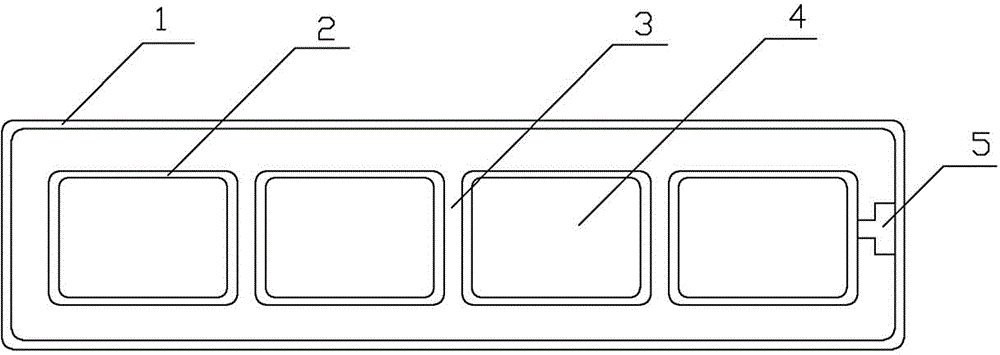

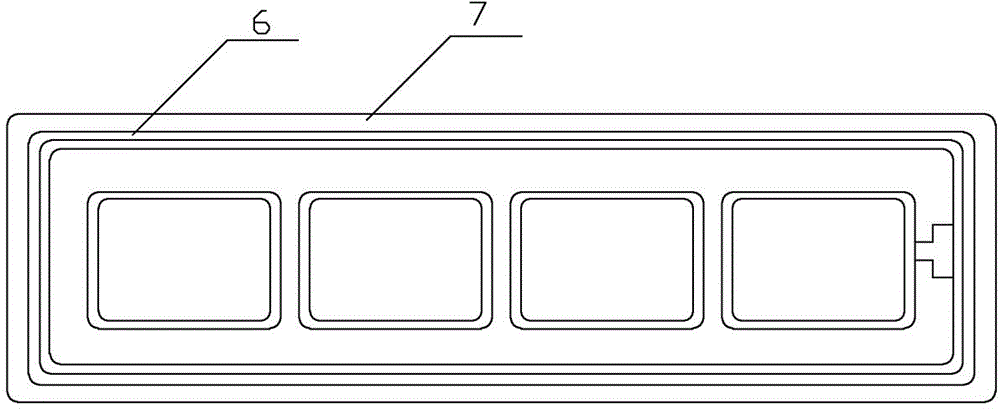

Vacuum insulation plate and manufacturing method thereof

InactiveCN103306388AGood insulation performanceExtended service lifeClimate change adaptationInsulation improvementVacuum pressureSelf weight

The invention discloses a vacuum insulation plate and a manufacturing method thereof. The vacuum insulation panel comprises a closed hollow cavity body which is formed by casting a material slurry, wherein the interior of the cavity body is hollow; an airtight layer is arranged on the inner wall or / and the outer wall of the cavity body. After the cavity body is vacuumized, convective heat transfer caused by air movement can be avoided, so that the thermal insulation is excellent; the vacuum insulation plate is formed by casting concrete or the material slurry, so that the vacuum insulation plate is firm and reliable; a basic material adopts the concrete or the material slurry with high strength, and the strength is high enough to bear long-term effects of a vacuum pressure, a wind load, self weight and a temperature deformation stress; more than 90% of the plate structure is made of cement and other inorganic materials, so that the long service life of the vacuum insulation plate can be ensured; the vacuum insulation plate mainly uses vacuum, the cement, pottery sand and other low-cost materials, so that the cost of the vacuum insulation plate disclosed by the invention is only 1 / 3 that of the conventional vacuum insulation plate; 90% of the plate structure is made of the cement and the pottery sand, so that the fire-proof performance is class A; the vacuum insulation plate is applicable to external wall insulation and roof insulation for buildings with a shear wall structure, a framework structure and a steel structure.

Owner:许浒

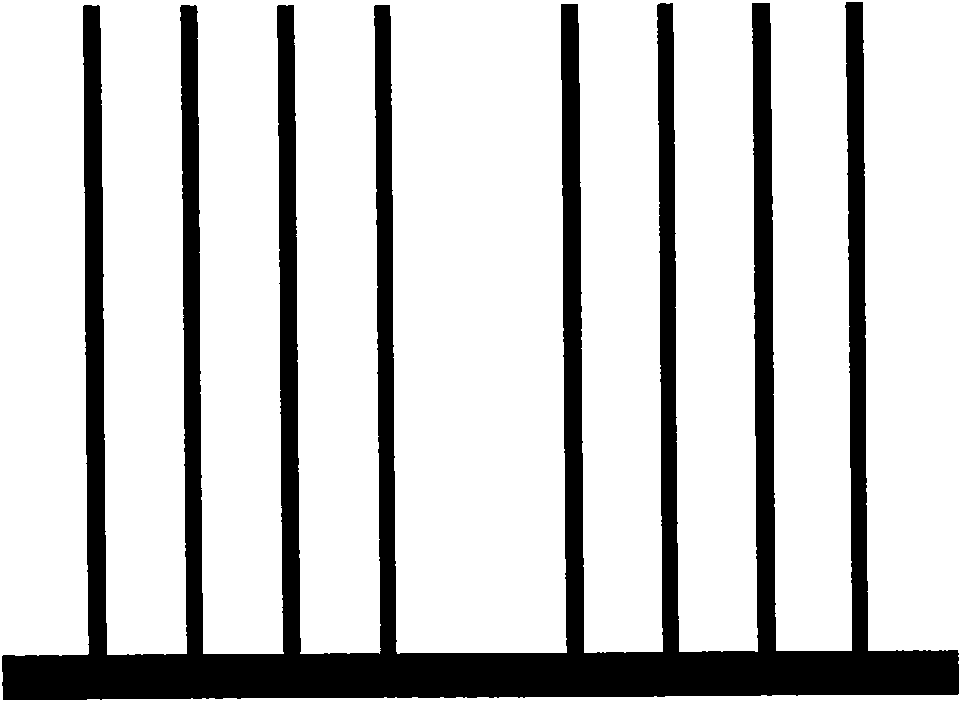

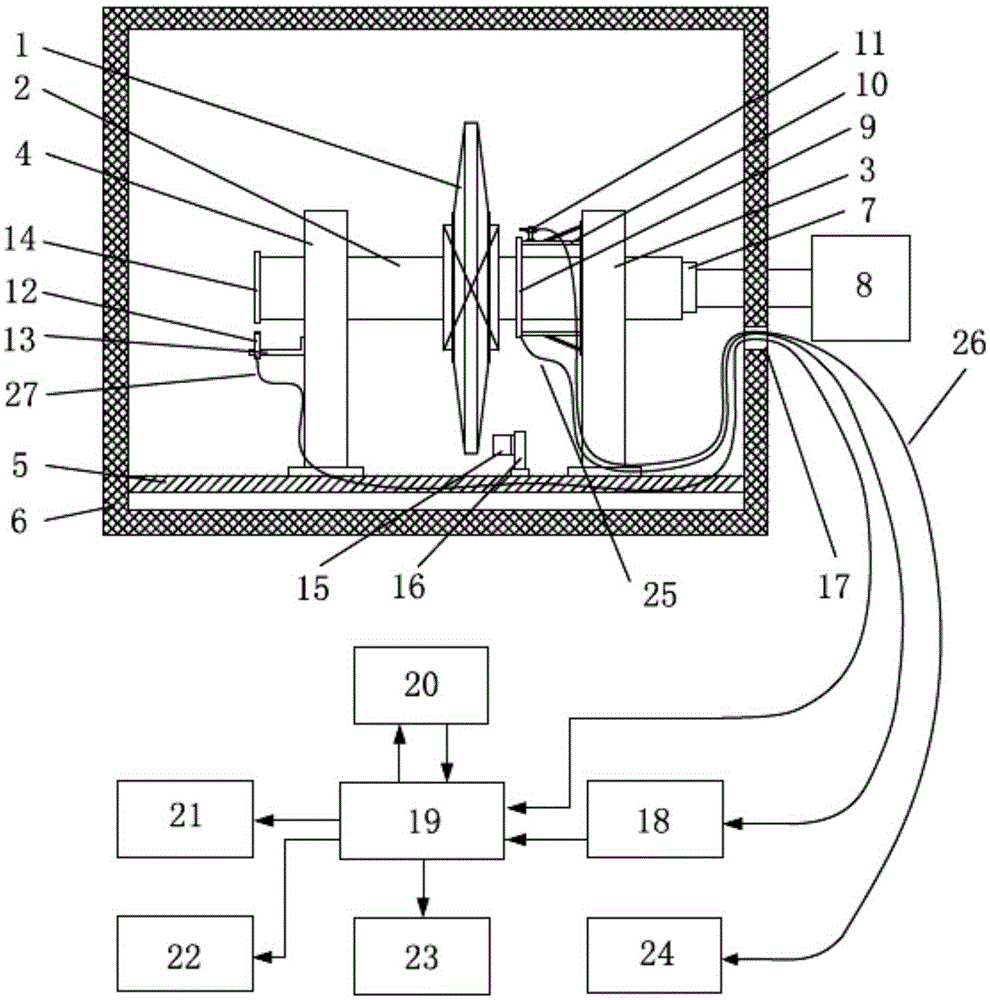

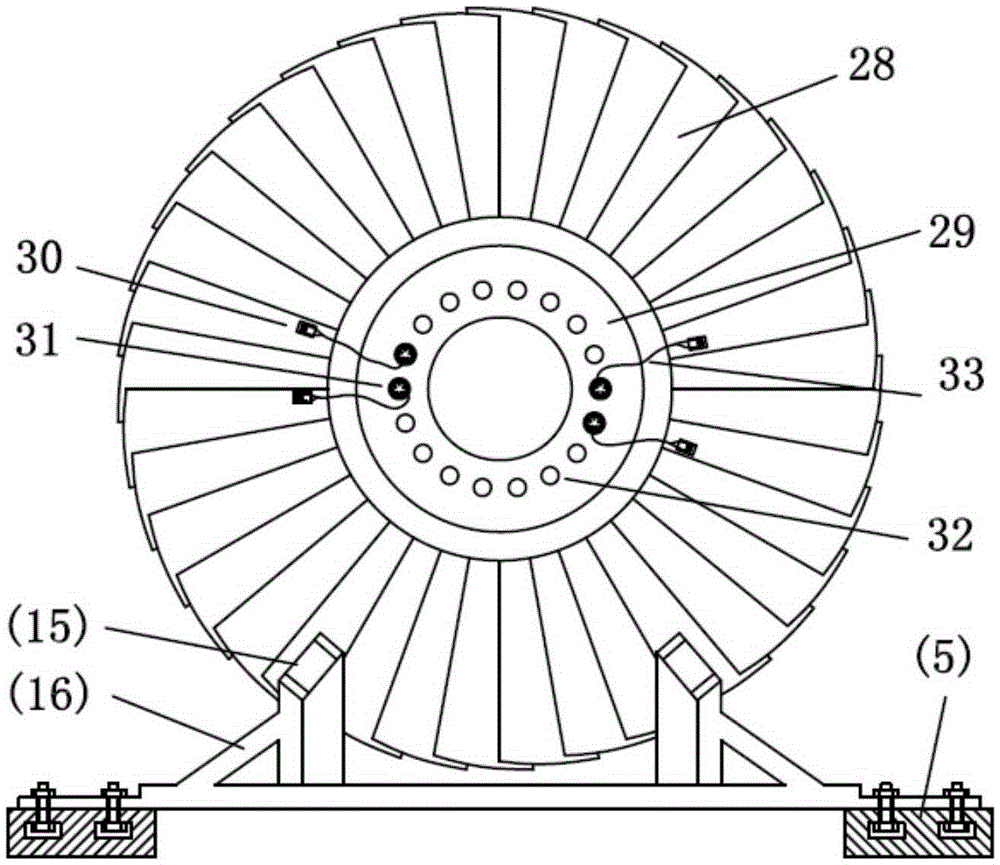

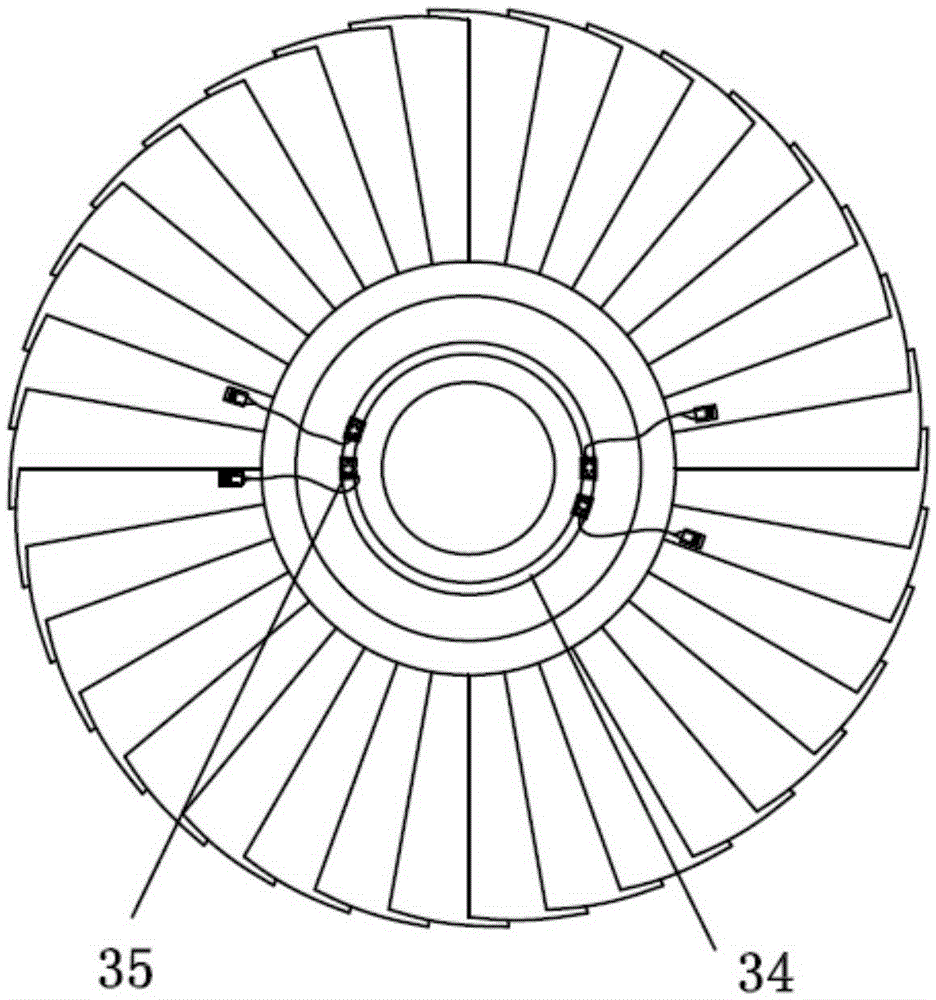

Blade dynamic frequency test apparatus using magnetic excitation

Disclosed is a blade dynamic frequency test apparatus using magnetic excitation. A magnetic exciter is used for applying an excitation force to a rotating blade, a strain gage is used for sensing blade vibration information, a signal transmitter transmits the blade vibration information sensed by the strain gage in real time via radio, and a signal receiver receives the collected blade vibration information in real time via a receiving antenna and transmits the blade vibration information to a multi-channel controller. Multiple input and output channels of a magnetic tape recorder are connected with the multi-channel signal controller and used for storing the blade vibration information of each channel. The multi-channel signal controller selects one- or multi-channel signals for a data analyzer for analyzing blade vibration characteristics. A thermometer, a tachometer and an oscilloscope are used for monitoring the temperature near the signal transmitter, the rotor velocity and signals of different channels in real time respectively. The invention solves the problem that a blade vibration frequency test using gas excitation would cause over temperature of equipment, and the invention is simple in structure, high in safety, low in cost, pollution-free, and capable of meeting blade vibration frequency test requirements.

Owner:XIAN THERMAL POWER RES INST CO LTD

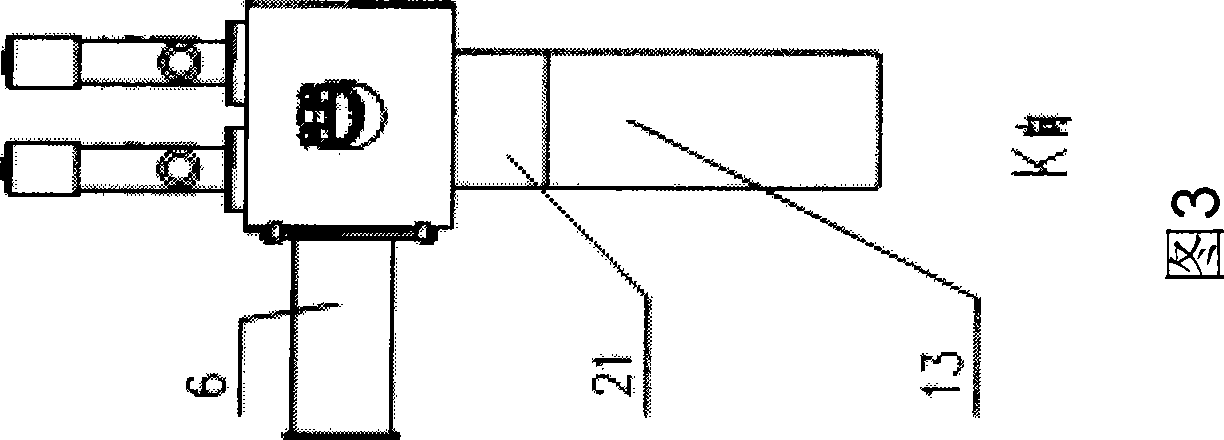

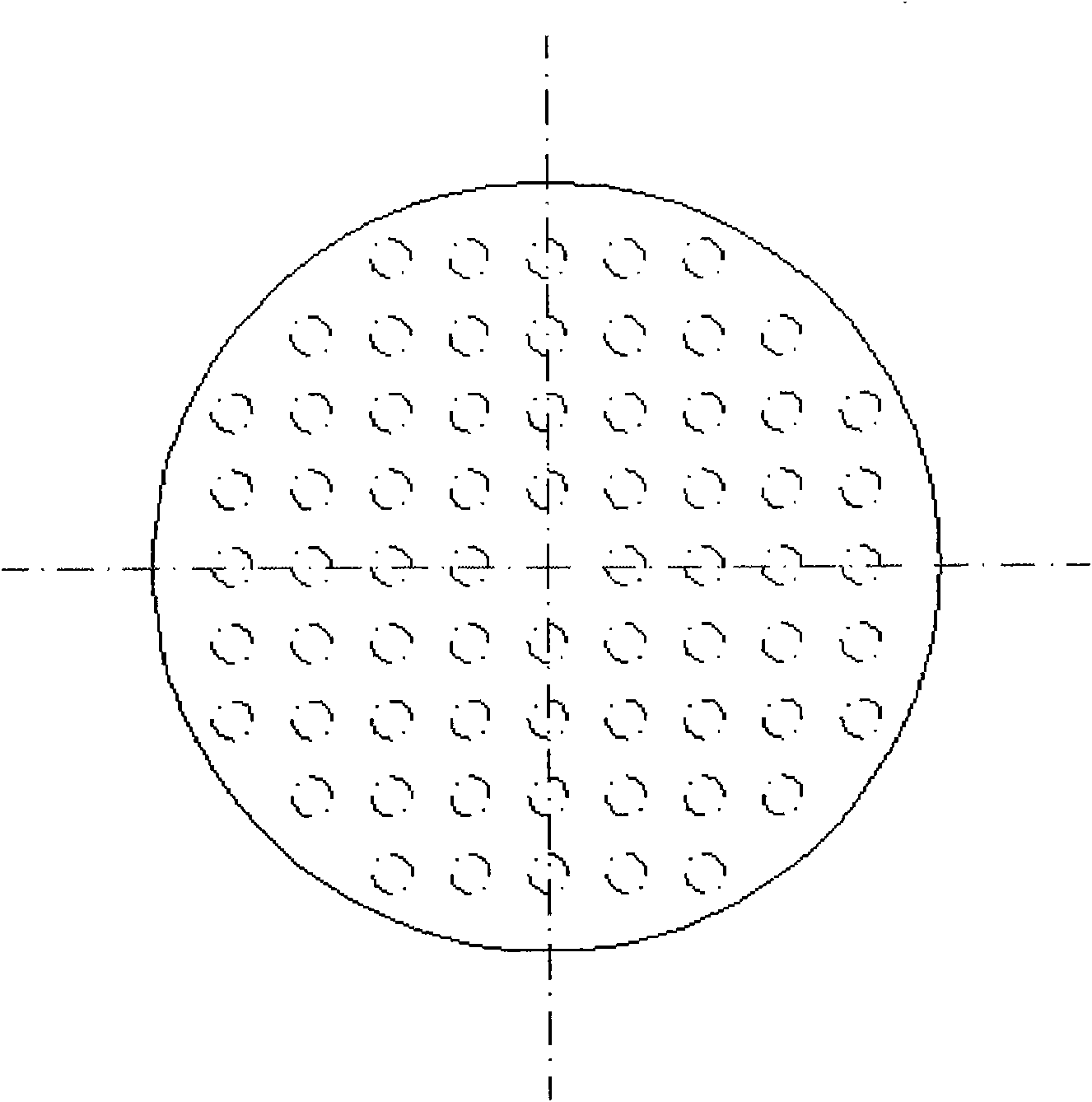

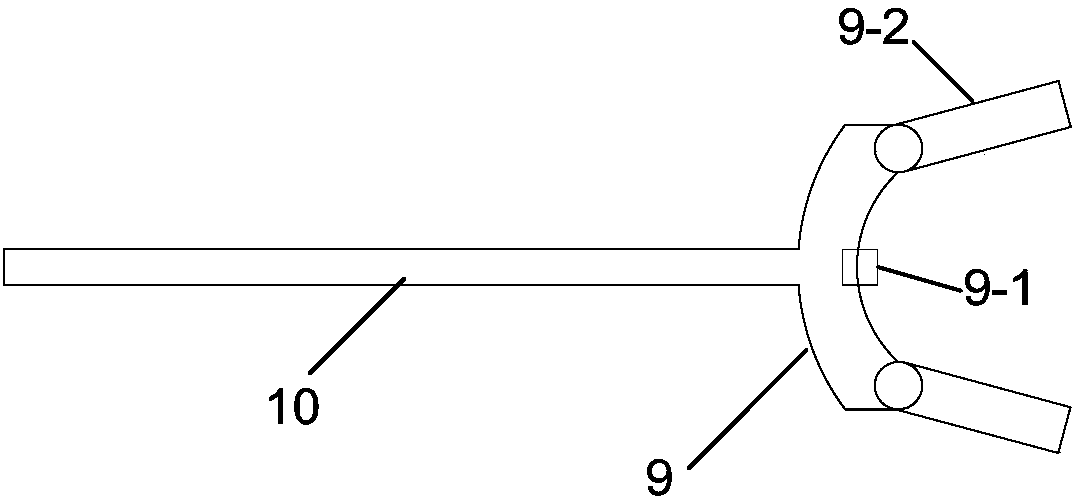

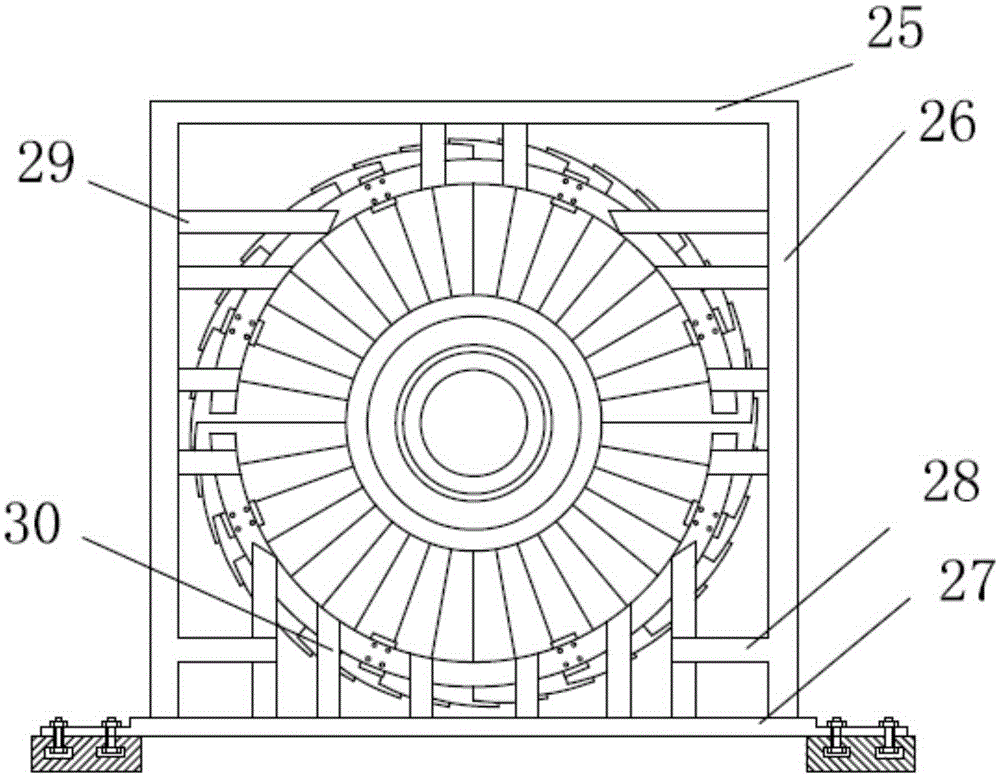

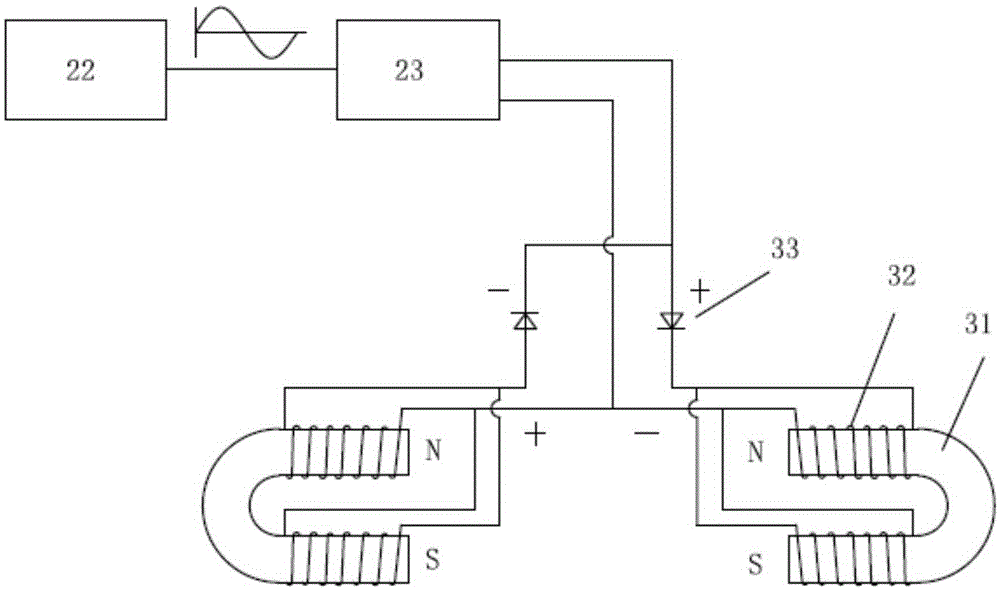

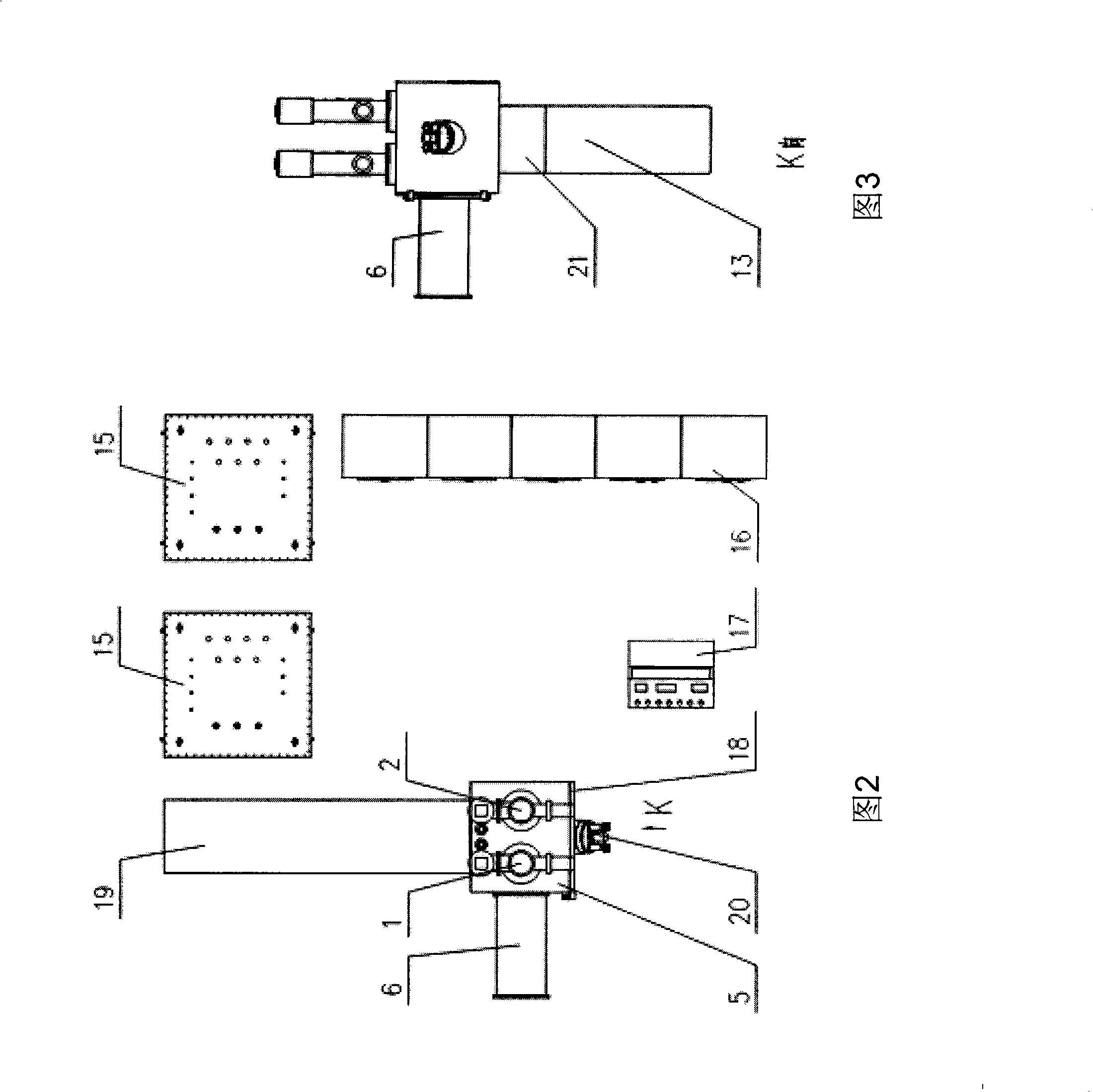

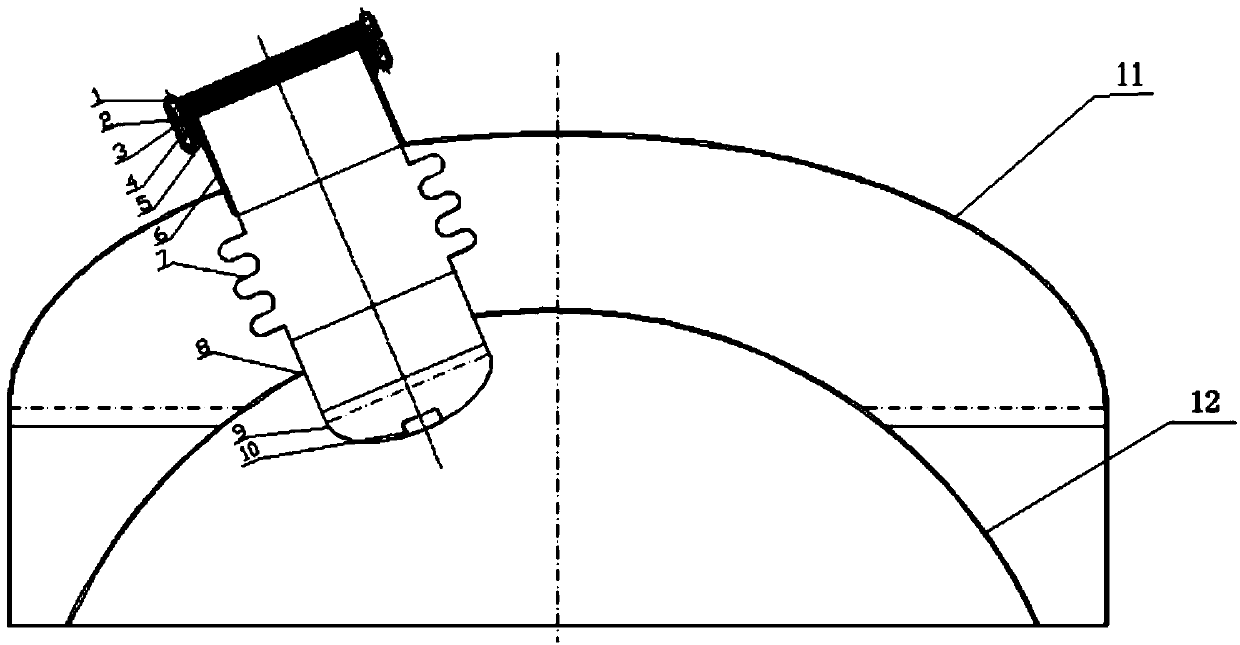

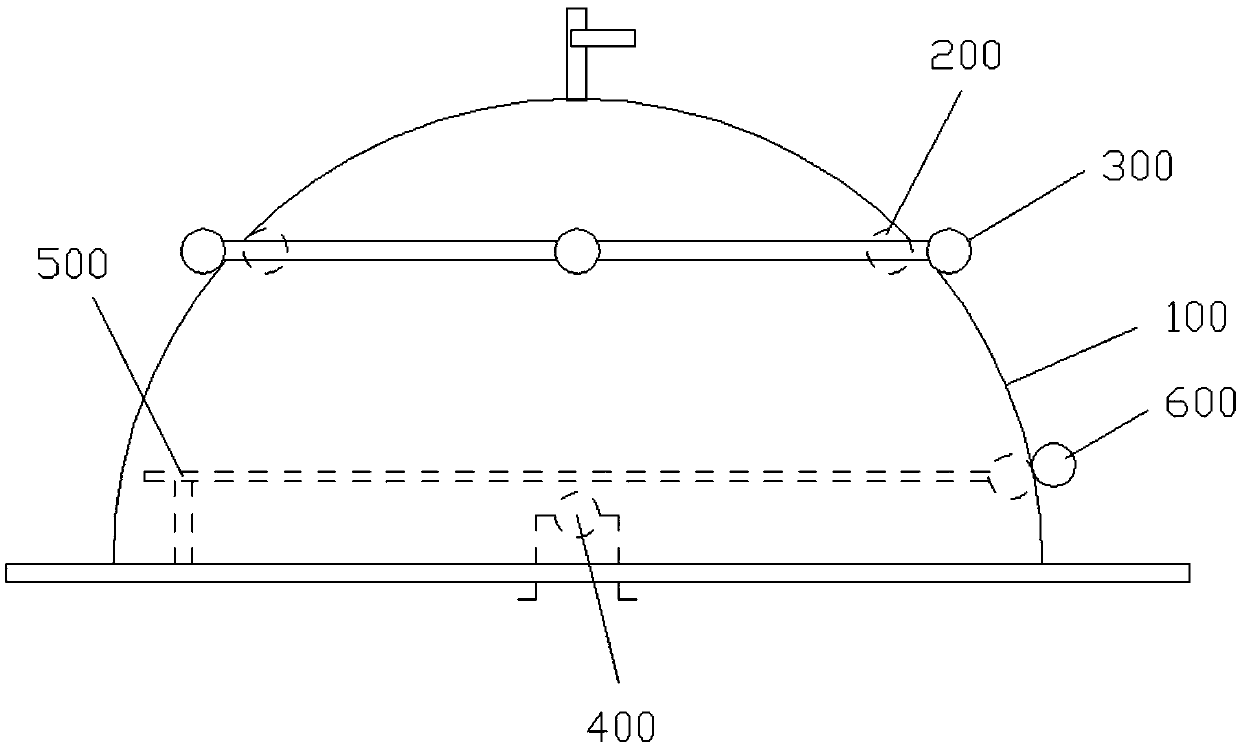

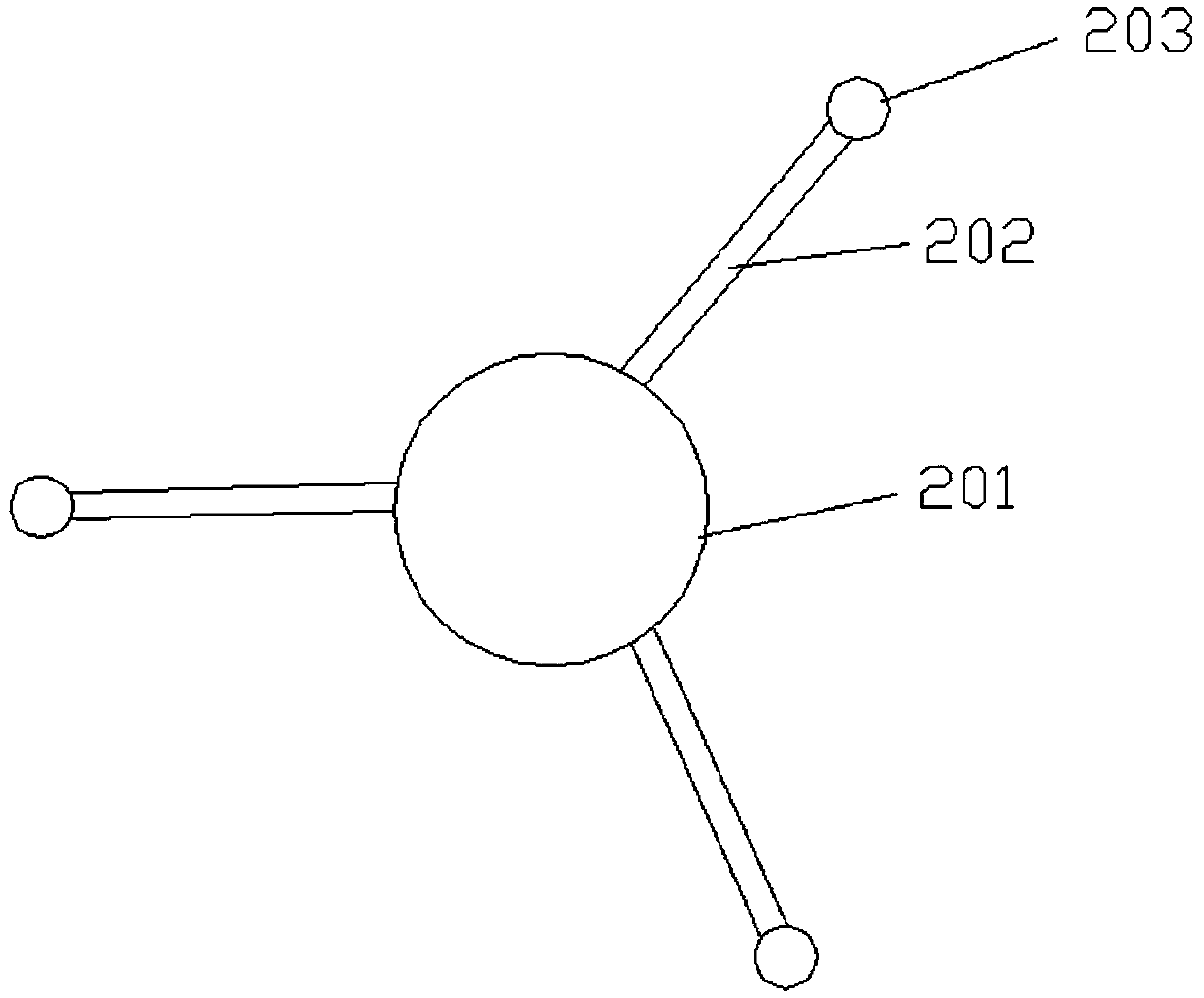

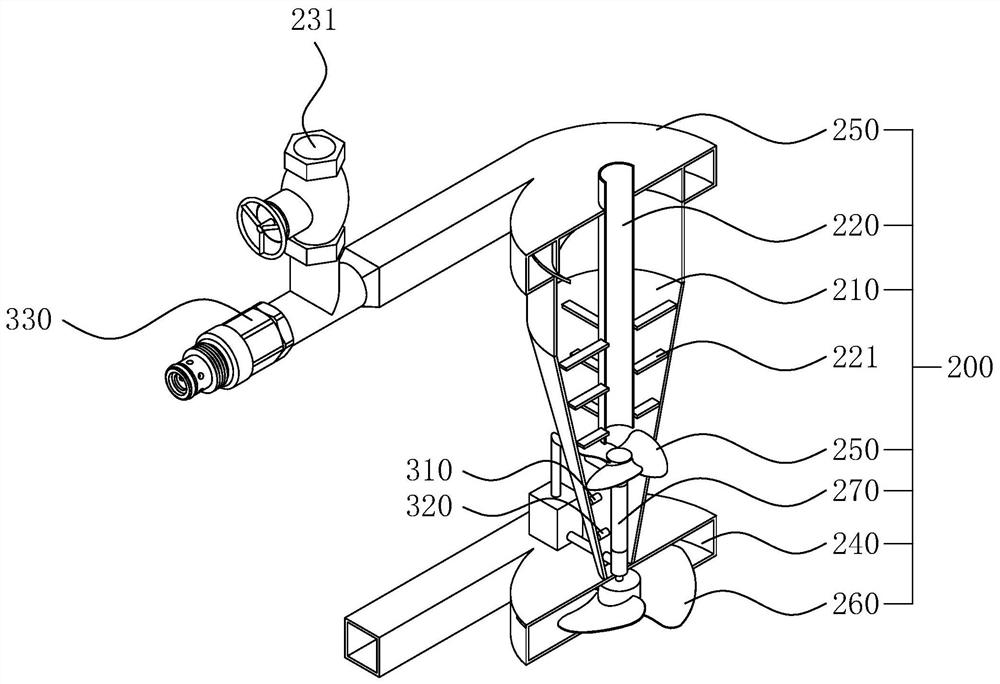

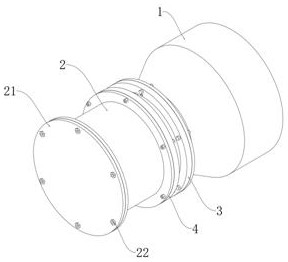

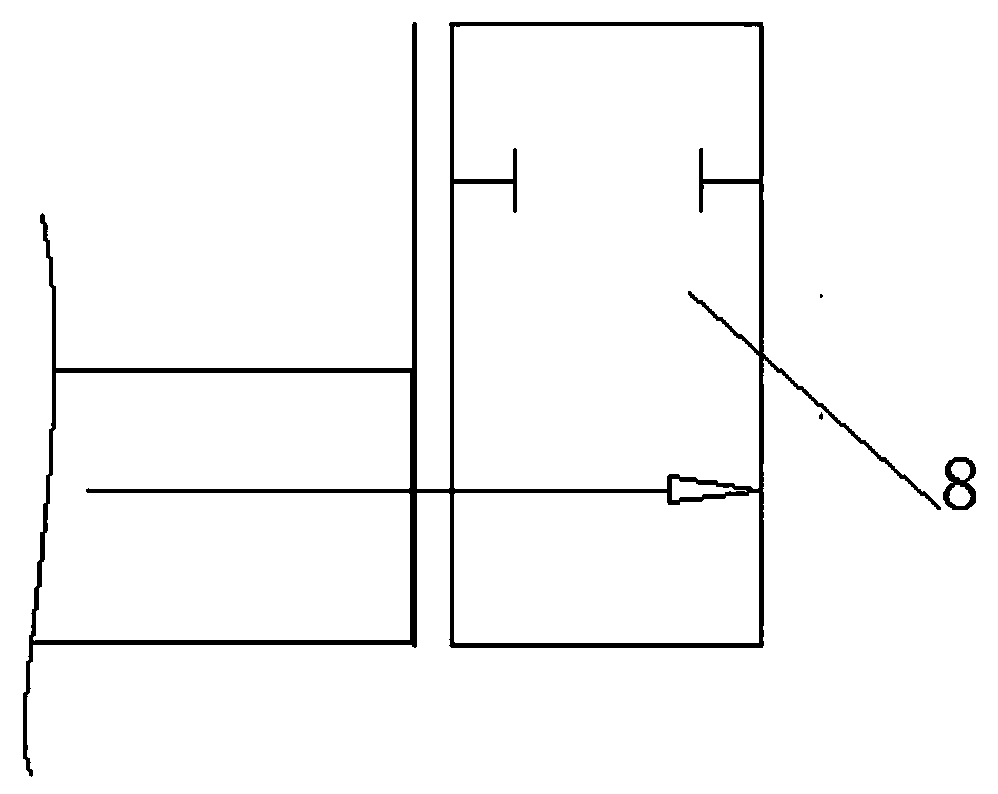

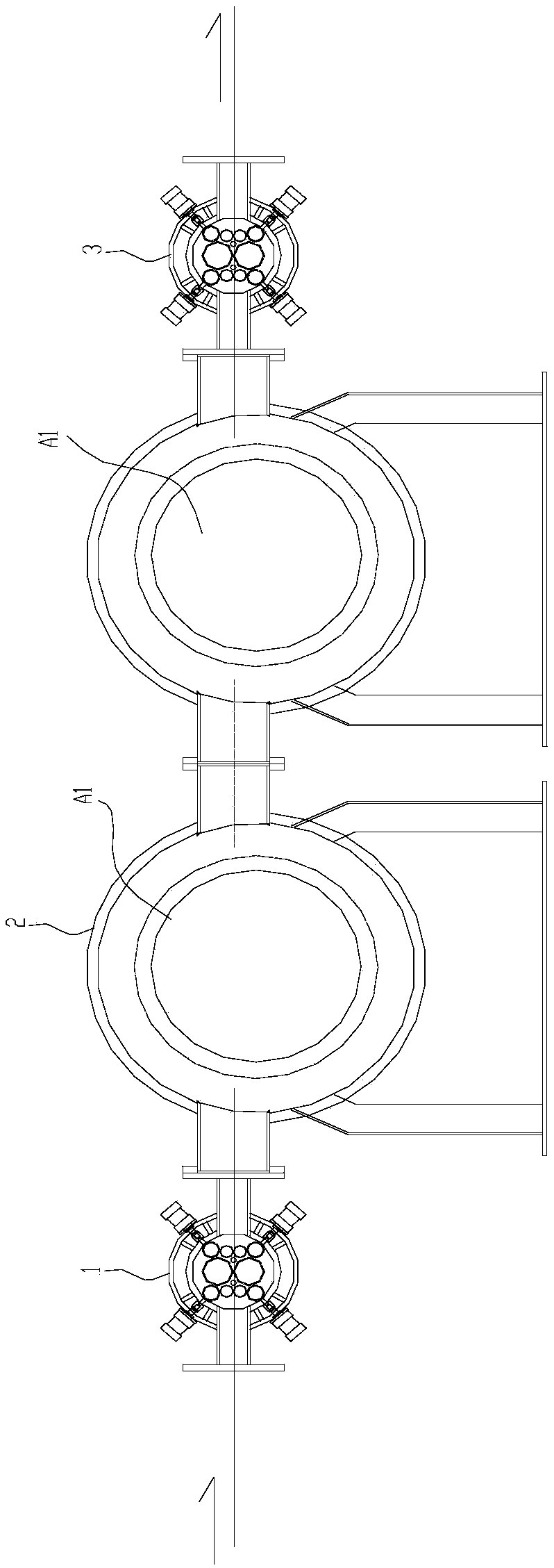

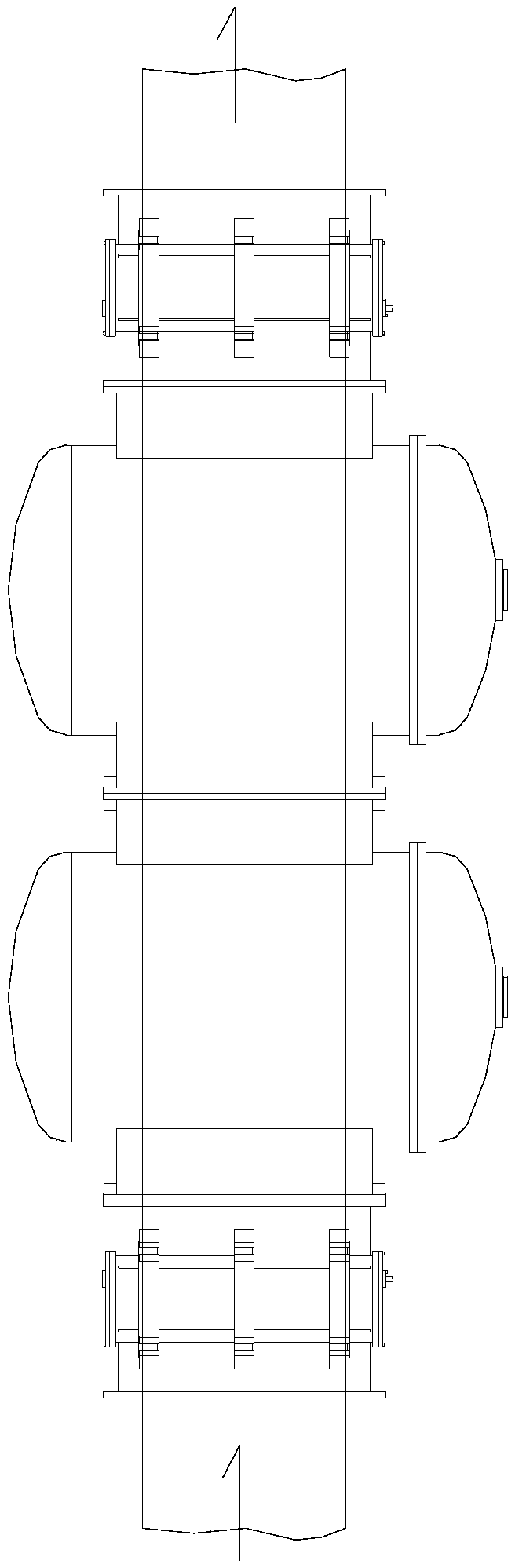

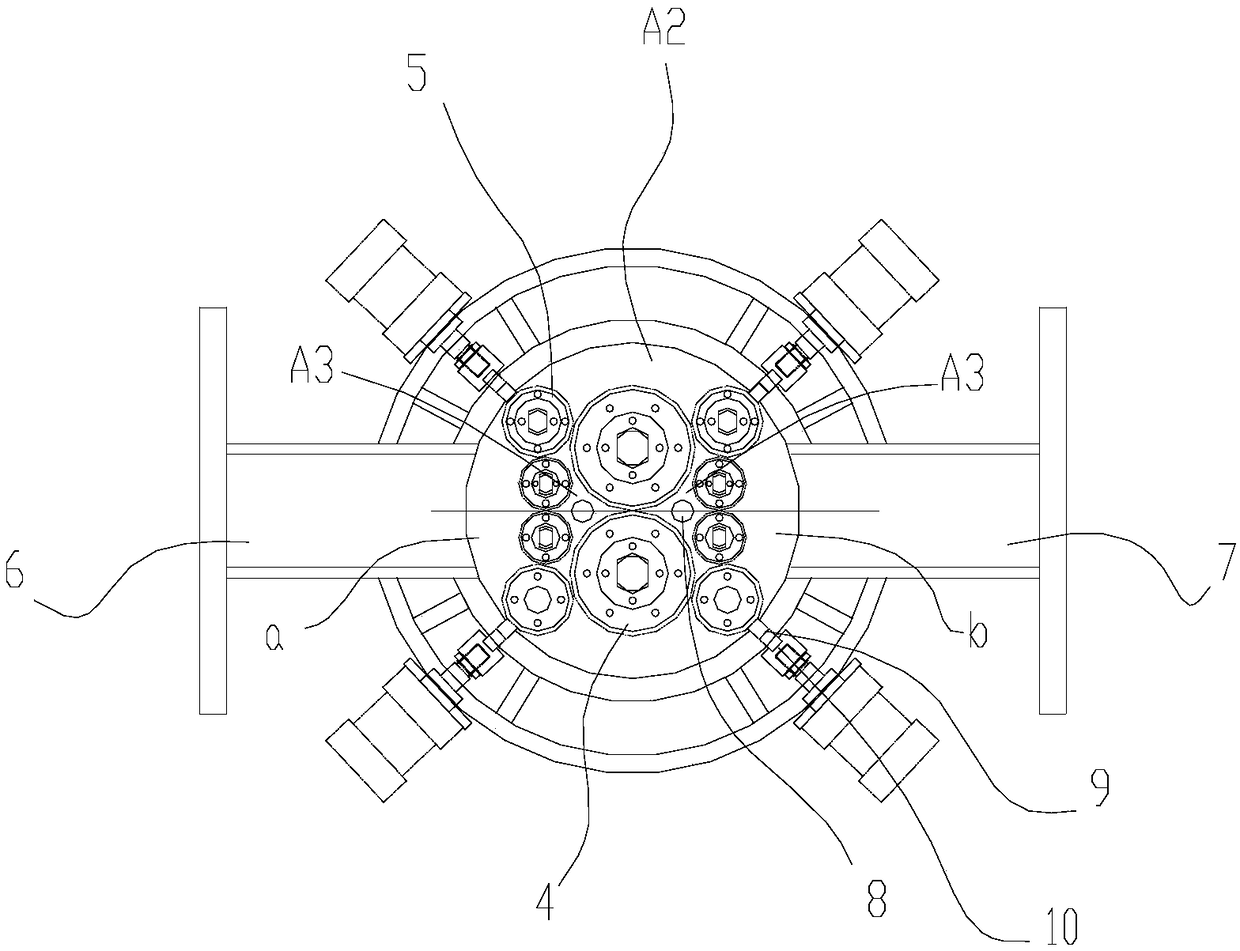

Electromagnetic harmonic wave exciting device for high-speed rotating impeller

ActiveCN105258886ADoes not affect vacuumImprove securityVibration testingImpellerAudio power amplifier

The invention discloses an electromagnetic harmonic wave exciting device for a high-speed rotating impeller. The electromagnetic harmonic wave exciting device comprises electromagnets, coils, installation boxes, electromagnetic exciter supports, power amplifiers and a signal generator. A sinusoidal signal is generated by use of the signal generator, passes through the power amplifiers and is then transmitted to electromagnetic exciters via a rectifier diode, and a sinusoidal excitation force is applied to the rotating impeller. A pair of electromagnetic exciters constitute a group and are symmetrically arranged at front and back of the impeller. A plurality of electromagnetic exciters are arranged along the circumference of the impeller and form circumferential sinusoidal excitation to the high-speed rotating impeller. The invention solves the problems of over temperature and insufficient excitation force due to that a conventional rotating impeller adopts a gas excitation manner, can meet sinusoidal excitation requirements of the impeller in a vibration test of the high-speed rotating impeller, and can adjust the amplitude of the sinusoidal excitation force.

Owner:XIAN THERMAL POWER RES INST CO LTD

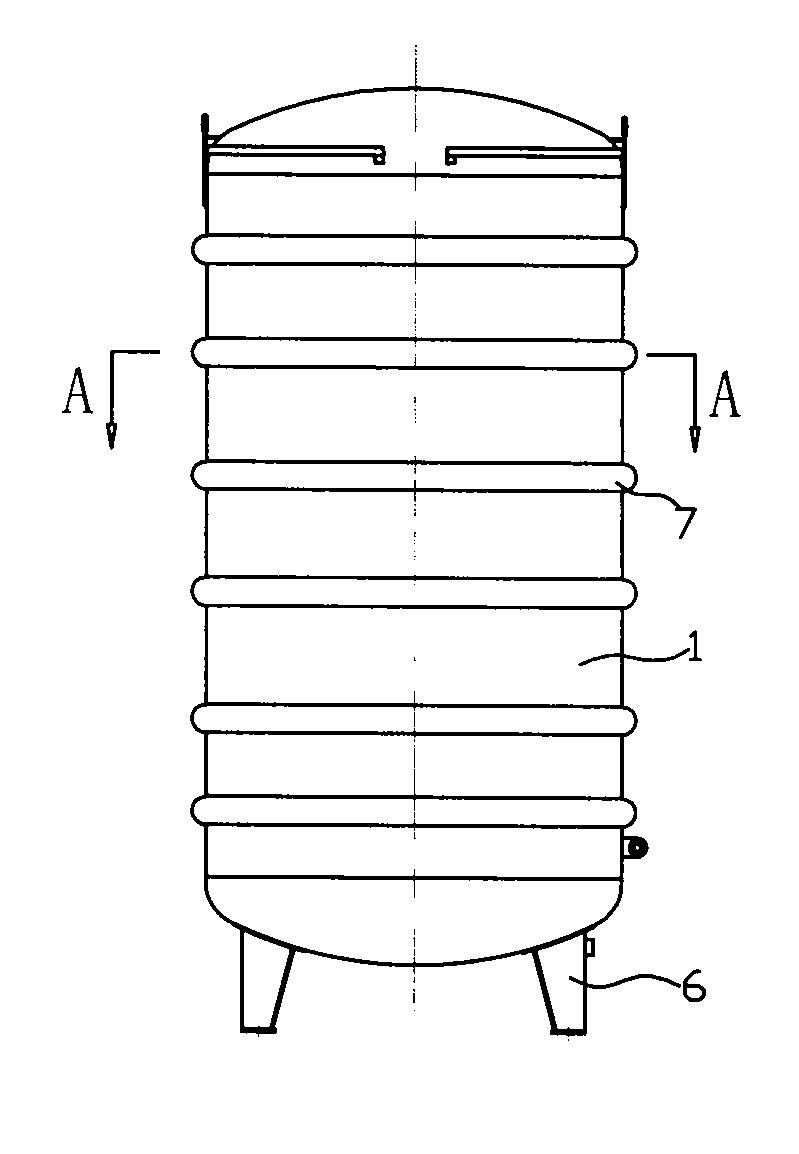

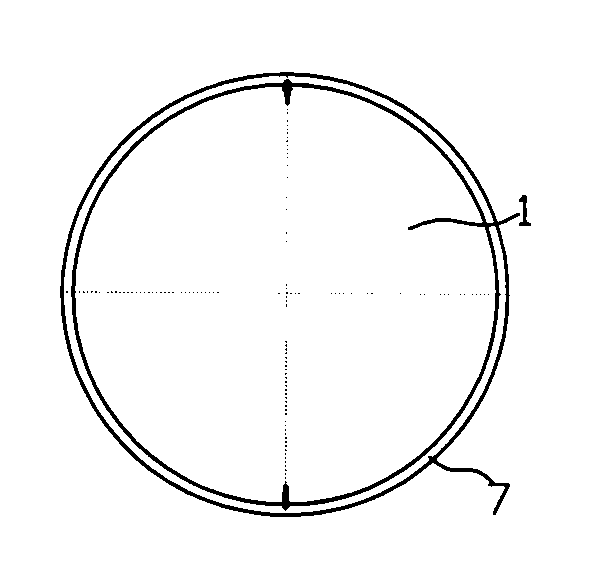

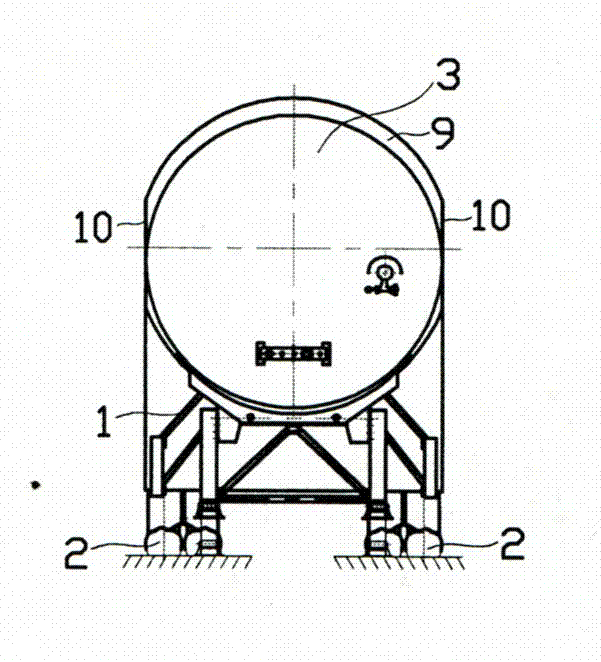

Vertical low-temperature liquefied natural gas storage tank

InactiveCN103075635AIncrease volumeGood removal effectContainer filling methodsPressure vesselsAluminum foilPetroleum engineering

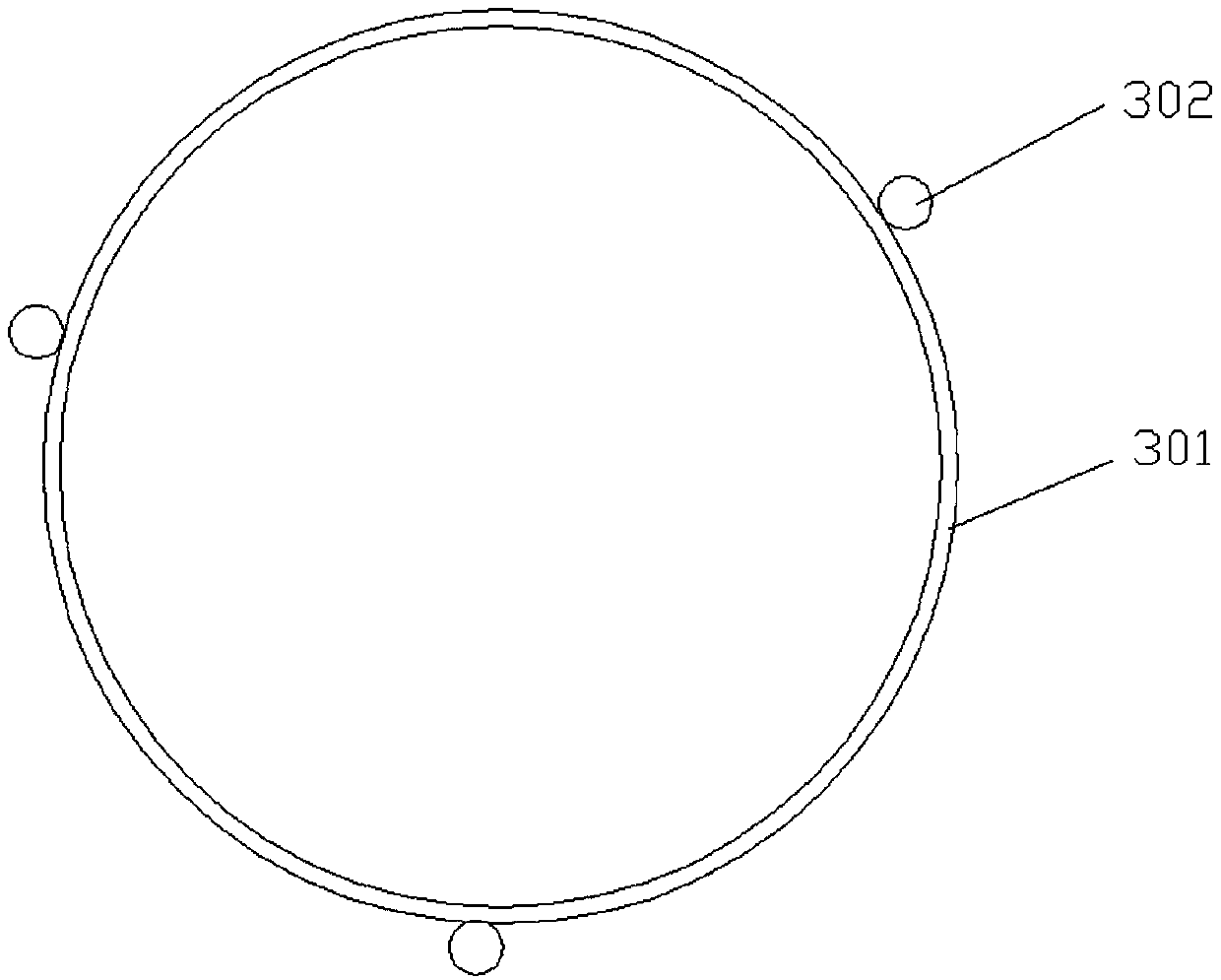

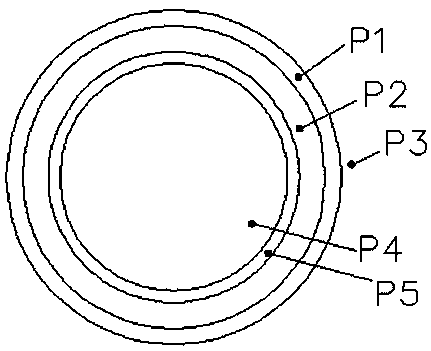

The invention provides a vertical low-temperature liquefied natural gas storage tank. The tank comprises an internal tank body and an external tank body which are sleeved together; a gap is formed between the internal tank and the external tank; the outside of the internal tank body is coated by a flexible aluminum foil heat preservation quilt; circular sectional material reinforcing ribs are uniformly welded at the external circumference of the external tank body; the axis of a low-temperature liquefied natural gas tank is vertical to the horizontal plane; and supporting legs are uniformly distributed at the lower end surface of the low-temperature liquefied natural gas tank. According to the invention, the reinforcing ribs on the external tank body are the circular sectional materials uniformly distributed and welded at the external circumference of the external tank body, the work of welding the circular sectional material reinforcing ribs at the external circumference of the external tank body is convenient; after welding, the welding burrs in the internal circumference of the external tank body can be conveniently removed; after the circular sectional material reinforcing ribs are welded at the external circumference of the external tank body, no welding junction is formed in the gap between the internal tank body and the external tank body; the vacuum degree of the gap between the internal tank body and the external tank body is not affected; and the circular sectional material reinforcing ribs are uniformly distributed and welded at the external circumference of the external tank body, so that the volume of the internal tank body can be increased.

Owner:铁岭黄海专用车制造有限公司

Mobile type final polycondensation spraying ethylene glycol nozzle

A movable type final polycondensation spray ethylene glycol nozzle is provided, which meets the spray ethylene glycol amount of the final polycondensation sprayer. The invention adopts the movable nozzle and changes the original rigid tube to the metal hose, and installs a ball valve additionally on the bottom end. Under the condition that the final polycondensation vacuum system is separated, the movable nozzle is used and is taken off from a spray system; after washing cleanly, the nozzle is installed again with convenient operation and complete washing and without effect on the vacuum degree of the final polycondensation system. Besides, the nozzle is widely applied in the actual operation of the polyester production.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

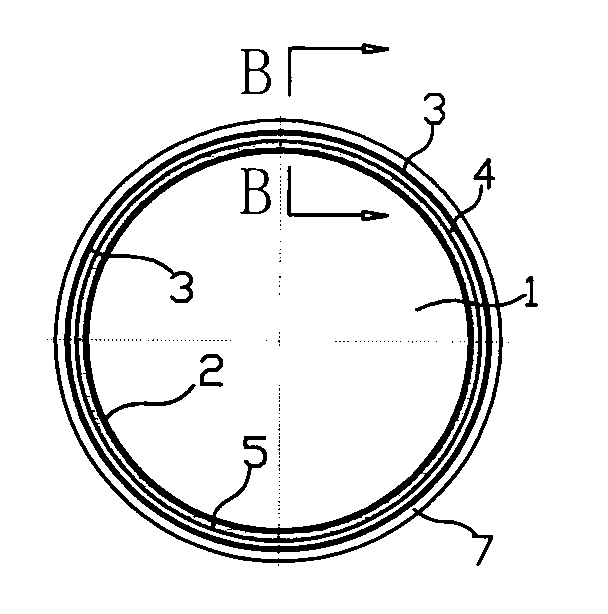

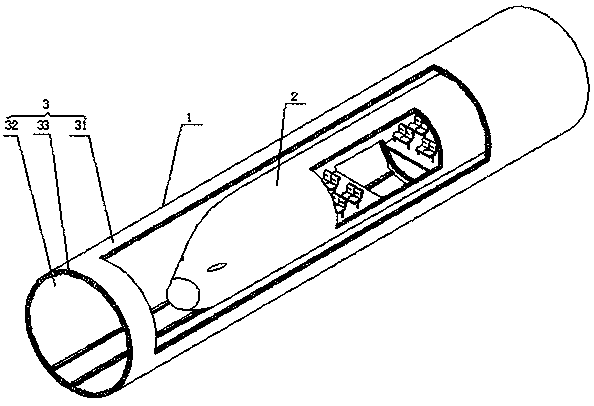

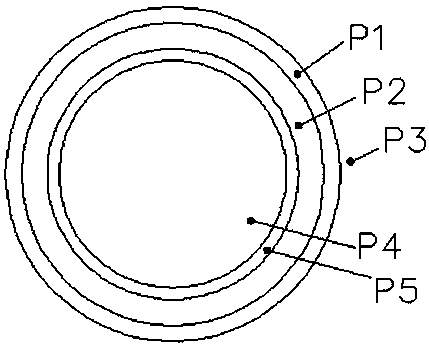

Leakage judging method for vacuum pipeline

ActiveCN107907281AImprove reliabilityWill not affect normal operationMeasurement of fluid loss/gain rateSandwich boardEngineering

The invention relates to a leakage judging method for a vacuum pipeline. The leakage judging method comprises a pipeline formed by a sandwich board, wherein the sandwich board comprises an inner layer, an outer layer and a sandwich layer arranged between the inner layer and the outer layer; the pressure strength of the sandwich layer is between the internal and external pressure strengths; if thedetected pressure strength of the sandwich layer is increased, the layer with relatively high pressure strength is leaked; and if the detected pressure strength of the sandwich layer is reduced, the layer with relatively low pressure strength is leaked. The invention further discloses another leakage judging method for the vacuum pipeline. According to the leakage judging method, the air leakage position can be accurately and rapidly judged, so that the security coefficient is greatly increased.

Owner:张跃

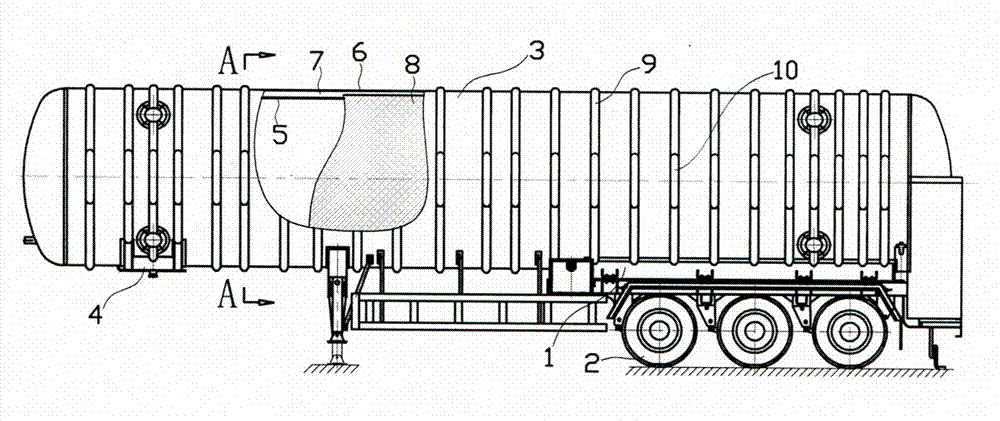

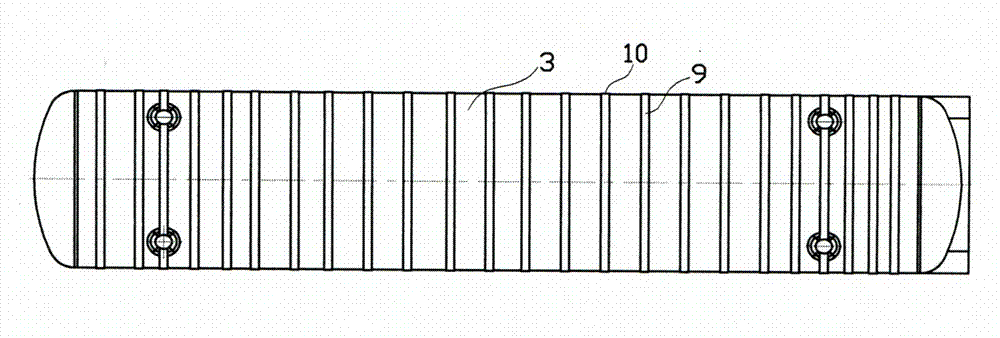

Low-temperature liquefied natural gas semitrailer tank truck

InactiveCN103090177AIncrease volumeGood removal effectContainer filling methodsPressure vesselsTank truckPetroleum engineering

The invention relates to a low-temperature liquefied natural gas semitrailer tank truck, wherein a low-temperature liquefied natural gas tank is arranged on a trailer frame; a traction seat is arranged below before the low-temperature liquefied natural gas tank; the low-temperature liquefied natural gas tank is provided with an inner tank body and an outer tank body which are sleeved into each other; a gap is formed between the inner tank body and the outer tank body; the inner tank body is covered with a flexible alumium-foil heat preservation quilt; and circular ring-shaped profile reinforcing ribs are evenly distributed on the outer circumference of the barrel of the outer tank body. The reinforcing ribs on the barrel of the outer tank body of the low-temperature liquefied natural gas tank are circular ring-shaped profile reinforcing ribs which are evenly distributed and welded on the outer circumference of the barrel of the outer tank body; the operation of welding the circular ring-shaped profile reinforcing ribs on the outer circumference of the barrel of the outer tank body is convenient, and after welding, removing of welding burr at the inner outer circumference of the barrel of the outer tank body is convenient; after the circular ring-shaped profile reinforcing ribs are welded on the outer circumference of the barrel of the outer tank body, no welded junction is formed in the gap between the inner tank body and the outer tank body without influence on the vacuum degree of the gap between the inner tank body and the outer tank body; and the circular ring-shaped profile reinforcing ribs are evenly distributed and welded on the outer circumference of the barrel of the outer tank body, so that the capacity of the inner tank body can be increased.

Owner:铁岭黄海专用车制造有限公司

Vacuum electron beam melting furnace for polysilicon purification

ActiveCN101445957BIncrease productivityDoes not affect vacuumPolycrystalline material growthChemical industryFuel tankHigh pressure

The invention provides a vacuum electron beam melting furnace for polysilicon purification. The melting furnace is characterized in that a melting chamber is square or cylindrical, a chamber wall is of a double water cooling structure or a coil water cooling structure; an electron gun is vertically and downwardly or horizontally arranged on the chamber wall of the melting chamber, a vacuum systemis arranged at the rear of the melting chamber; an isolating valve is arranged between a feeding chamber and the melting chamber of a feed mechanism, and an inflation valve of an inflation system is arranged at the other side of the melting chamber; a discharge mechanism is arranged at the bottom of the melting chamber and connected with an ingot-pulling mechanism; the ingot-pulling isolating valve is arranged between discharge mechanism and the melting chamber; the melting chamber is internally provided with a water cooling crucible and a crystallizing crucible; all high-voltage devices of ahigh-voltage power supply of an electrical control system are arranged at a fuel tank filled with a transformer; and by adopting oil insulation of the transformer, the high-voltage power supply is connected with an electric cabinet which is connected with a console. The melting furnace has the advantages that a plurality of elements can be purified simultaneously, the production efficiency is high, energy consumption is low, energy-saving effect is excellent, and large-scale and automatic operation is easy to be implemented.

Owner:桂林实创真空数控设备有限公司

Manhole device of low temperature liquid storing and transporting container

InactiveCN103470950AEasy to openReduce maintenance costsContainer filling methodsContainer discharging methodsTongue and grooveEngineering

The invention relates to a manhole device of a low temperature liquid storing and transporting container, comprising a manhole flange, a DN400 end socket and an expansion joint, wherein a long welding neck flange is adopted, one end of the flange is welded with the outer layer shell of the lower temperature container, the other end of the flange is covered by a manhole cover for sealing the manhole device, and a tongue and groove face is adopted as the sealing surface for sealing; the DN400 end socket is used for being welded with the inner layer shell of the low temperature container, so that the inner layer shell is in a heat insulation closed environment; the expansion joint is connected between the short joint of the manhole and a barrel joint connected with the end socket, so as to solve the problem of deformation caused by chilling shrink of the low temperature container. The invention provides the manhole device which is convenient to overhaul, obvious in sealing effect and convenient to install.

Owner:天津万广科技有限公司

Magnetic control device of vacuum system and vacuum equipment

ActiveCN109609921ADoes not affect vacuumVacuum evaporation coatingSputtering coatingMagnetic tension forceSample rotation

The invention provides a magnetic control device of a vacuum system and vacuum equipment, and relates to the technical field of vacuum control systems. The magnetic control device of the vacuum systemcomprises a cover body, a sample supporting magnetic suction assembly and a first magnetic suction assembly, and the first magnetic suction assembly is arranged at the exterior of the cover body andabsorbs the sample supporting magnetic suction assembly; and the first magnetic suction assembly drives the sample supporting magnetic suction assembly to rotate. The problem that the rotation of thesample needs to enter a vacuum cover through a connecting rod, and the vacuum degree in the cover body and the material deposition of the sample surface are affected is solved; and the sample supporting magnetic suction assembly is arranged in the cover body, the first magnetic suction assembly is arranged outside the cover body, the first magnetic suction assembly fixes the position of the samplesupporting magnetic suction assembly, the sample rotation is completed, and the purity and uniformity of the material deposition on the sample surface are ensured.

Owner:CHENZHOU TEIKYO CHEM TECH

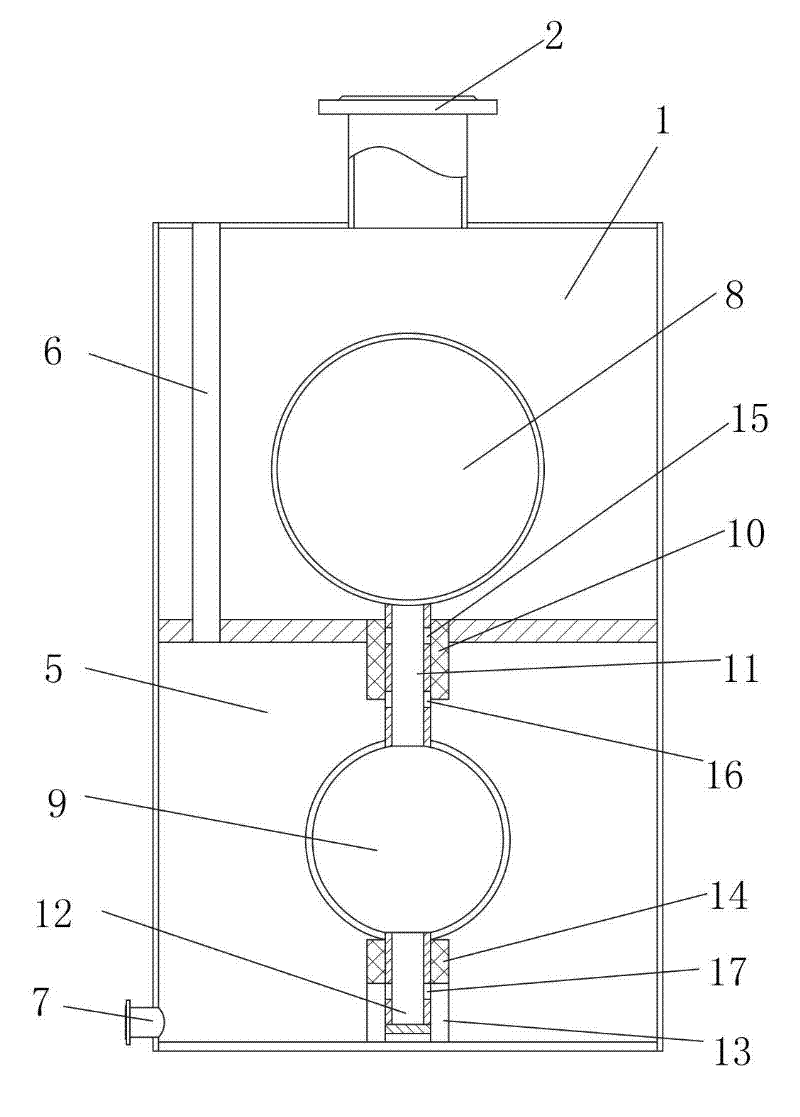

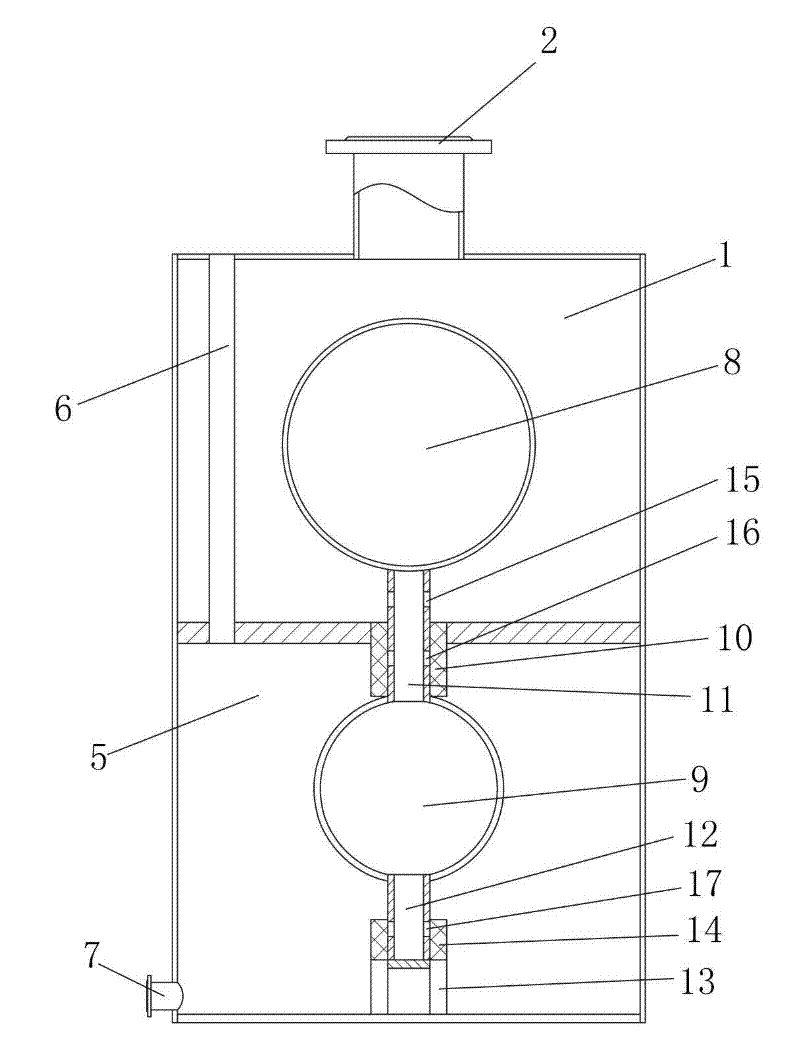

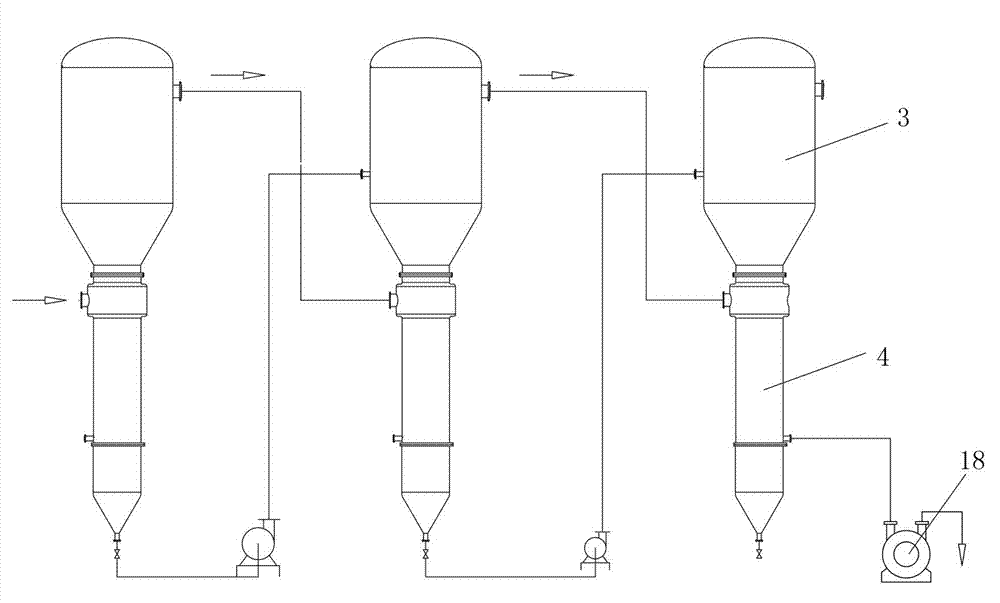

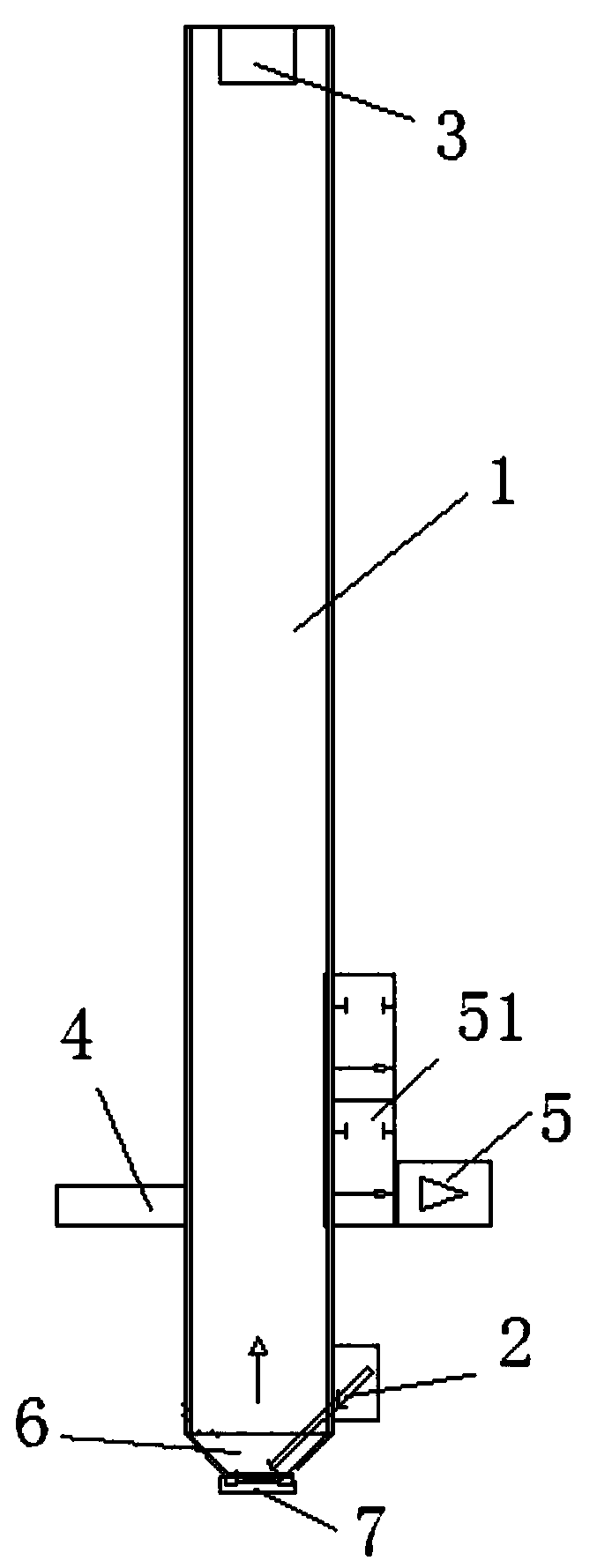

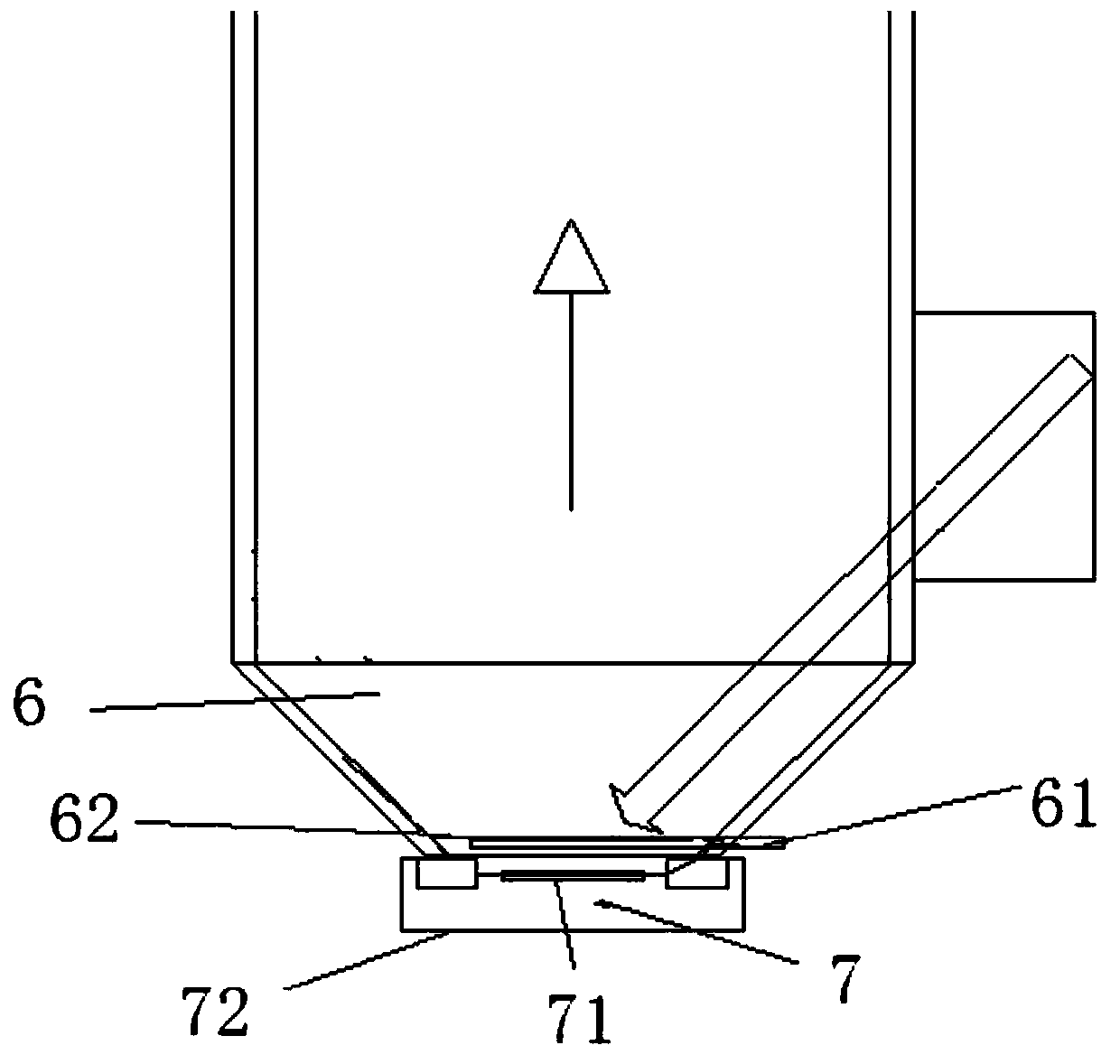

Evaporative vacuum drainer

InactiveCN102225241ASmooth dischargeDischarge resistanceEvaporator accessoriesMultiple-effect evaporationExternal energyEngineering

The invention relates to an evaporative vacuum drainer, which comprises a vacuum chamber, a balance chamber, a hollow sink-and-float device, a vacuum valve set and a balance valve set, wherein an evaporator heating chamber connector is formed on the vacuum chamber; the balance chamber is positioned under the vacuum chamber; an air inlet pipe and a water outlet are arranged on the balance chamber;the upper half part of the sink-and-float device is positioned in the vacuum chamber; the lower half part of the sink-and-float device is positioned in the balance chamber; the vacuum valve set is arranged at the upper half part of the sink-and-float device; the balance valve set is arranged at the lower half part of the sink-and-float device; when the sink-and-float device floats upwards, the vacuum valve set is opened and the balance valve set is closed; and when the sink-and-float device sinks, the vacuum valve set is closed and the balance valve set is opened. The evaporative vacuum drainer has the advantages that the evaporated condensate water can be drained out of a system at vacuum state without the help of an external energy resource.

Owner:高翔

Manhole device of low-temperature liquid storing and transporting container

InactiveCN105270780AGuaranteed tightnessGuaranteed insulation performanceLarge containersUnderwater structuresEngineeringExpansion joint

The invention relates to a manhole device of a low-temperature liquid storing and transporting container. The manhole device of the low-temperature liquid storing and transporting container comprises a manhole flange, a DN400 sealing head and an expansion joint, wherein the manhole flange is a long-neck butt-welded flange; one end of the manhole flange is welded with an outer layer housing of a low-temperature container; one end of the manhole flange is covered by a manhole cover used for sealing the manhole device; the sealing surface of the manhole flange is sealed by a tenon slot; the DN400 sealing head is welded with an inner layer housing of the low-temperature container, so that the inner layer housing is in a heat insulation sealed environment; the expansion joint is connected between a manhole short segment and a tube section which is connected with the sealing head. Through the manhole device of the low-temperature liquid storing and transporting container, the problem of deformation caused by cold shrinkage of the inner housing of the low-temperature container is solved; and the manhole device is convenient to maintain, obvious in sealing effect and convenient to mount.

Owner:天津万广科技有限公司

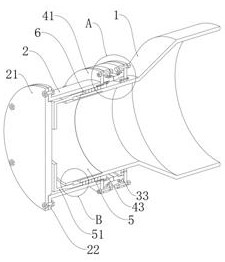

Splash-proof device for vacuum melting

ActiveCN104930851ADoes not affect vacuumEasy to operateFurnace componentsFoundry mouldsDual actionPulp and paper industry

A splash-proof device for vacuum melting is characterized in that a sealing sleeve is arranged on a vacuum furnace wall, a bent lever is arranged in the sealing sleeve, a splash-proof cover is arranged at the inner end of the bent lever, double metal claws are arranged on the lower portion of the splash-proof cover, a heat insulation cover with double functions is arranged in the double metal claws, a connecting rod is arranged at the outer end of the bent lever, and the lower end of the connecting rod is connected with a pedal arranged on a vacuum furnace. By the aid of the double metal claws arranged on the lower portion of the splash-proof cover, the double metal claws can be pressed into the heat insulation cover when the double metal claws are in the cold state. When vacuum melting is performed, the splash-proof cover is closed, so that impurities are prevented from splashing into a melt die orifice. When the splash-proof cover is opened, melt metal liquid is filled, then the splash-proof cover is closed, the heat insulation cover and the splash-proof cover can loosen through the double metal claws under the action of rise of the temperature of the melt die orifice, the heat insulation cover timely covers the melt die orifice and can effectively function in preventing spatter and timely keeping warm and feeding, the quality of products is improved from perfection of the device, and production cost is reduced.

Owner:WUXI LIHU PRESSURIZE TECH CO LTD

Vacuum water ring combined pump

ActiveCN112145426AReduce fouling rateSmall flow resistanceRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsAir pumpEngineering

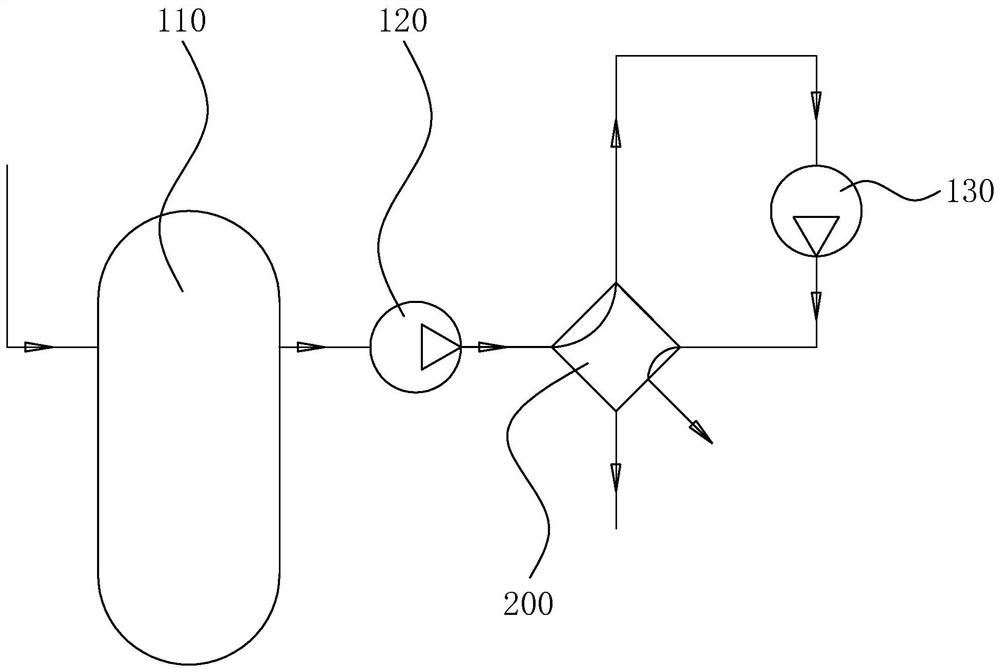

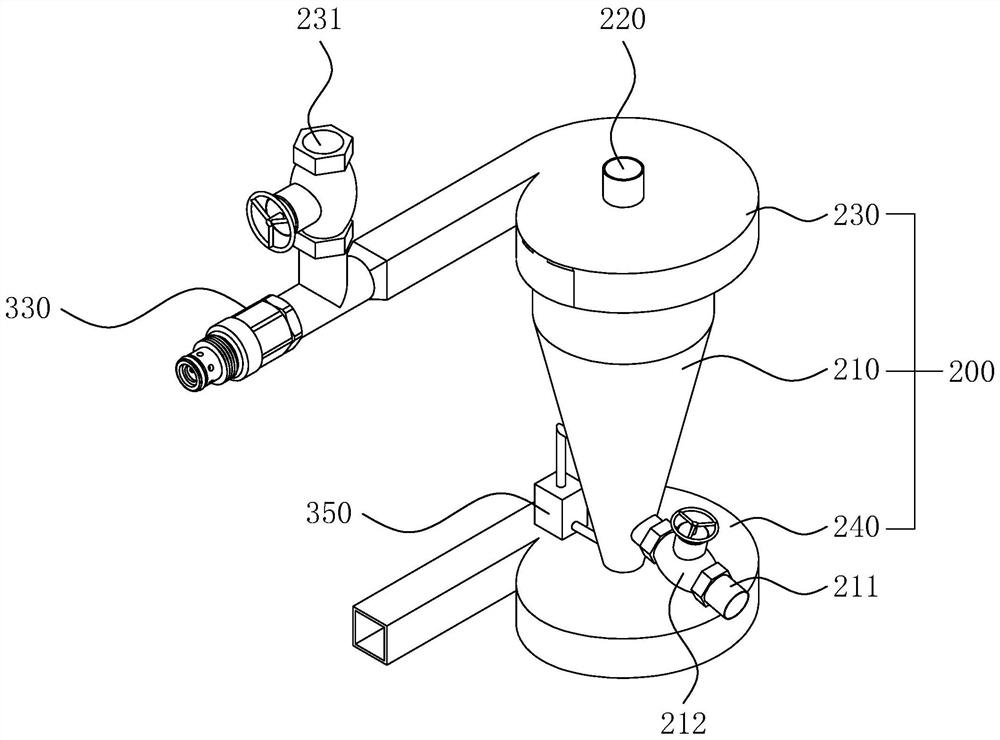

The invention relates to the technical field of air pumps, in particular to a vacuum water ring combined pump. The vacuum water ring combined pump comprises a storage tank, a roots vacuum pump, a filtering device and a water ring vacuum pump, the storage tank, the roots vacuum pump, the filtering device and the water ring vacuum pump sequentially communicate with one another through air pipes, andthe filtering device comprises a centrifugal shell, an exhaust pipe and a first volute; the centrifugal shell is vertically arranged, the first volute is fixedly connected to the axial upper end of the centrifugal shell, the first volute and the centrifugal shell are coaxially arranged, one end of the first volute communicates with the air outlet end of the roots vacuum pump, the other end of thefirst volute communicates with the interior of the centrifugal shell, the lower end of the centrifugal shell communicates with a blow-off pipe, and the blow-off pipe communicates with a blow-off valve; and the exhaust pipe and the centrifugal shell are coaxially arranged, one end of the exhaust pipe penetrates into the centrifugal shell from the upper end of the centrifugal shell, and the other end of the exhaust pipe communicates with the air inlet end of the water ring vacuum pump. According to the vacuum water ring combined pump, the probability of scaling in the water ring vacuum pump canbe reduced, and the vacuumizing effect of the combined pump is not prone to being affected.

Owner:淄博双环真空泵厂

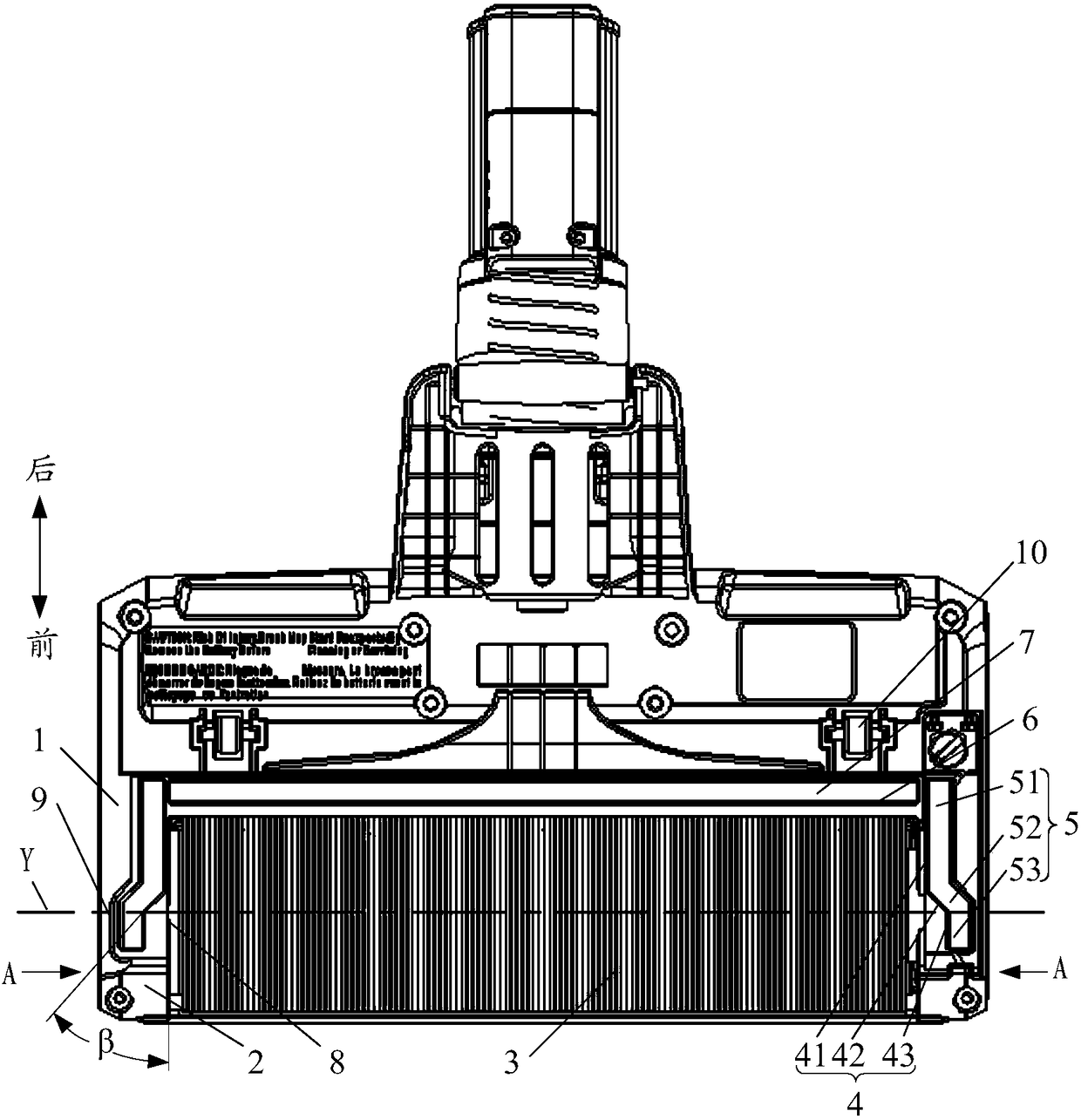

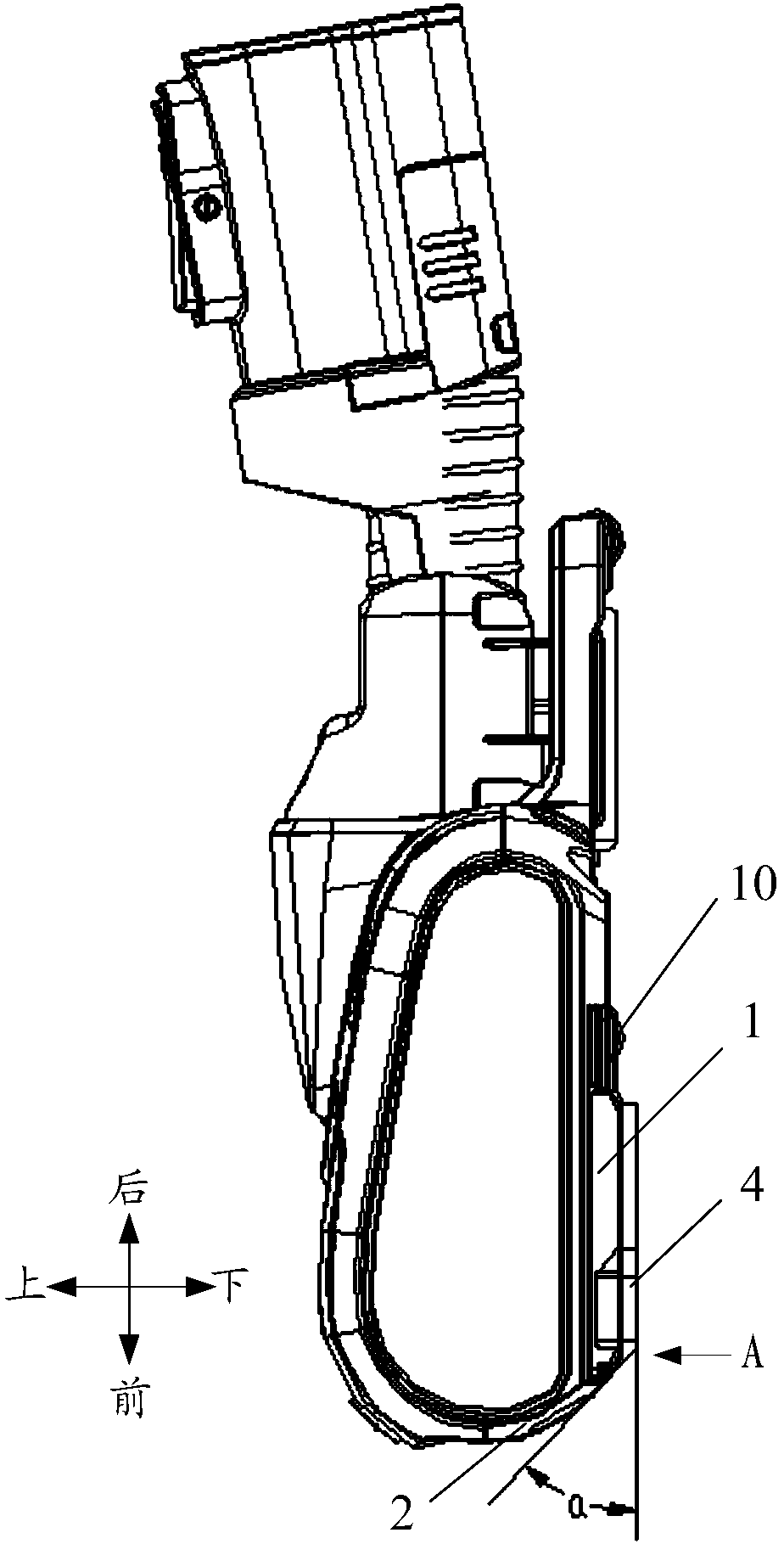

Floor brush and dust collector

The invention provides a floor brush. The floor brush comprises a shell body, a dust collection port arranged on the shell body and a sealing structure, wherein the sealing structure comprises a horizontal sealing strip and two vertical sealing strips, the horizontal sealing strip is horizontally arranged at the rear side of the dust collection port, and the two vertical sealing strips are respectively symmetrically arranged at the two sides of the dust collection port; the horizontal sealing strip and the two vertical sealing strips form dust collection space of which the front is wide and the rear is narrow. The invention further provides a dust collector, the dust collector comprises the floor brush as described above. The sealing structure of the dust collector adopts a structure modethat the vertical sealing strips at the two sides of the dust collection port is set to be that the front is wide and the rear is narrow, the dust collection space is enlarged, the collected dust canalso be directly guided to the floor brush to avoid dust accumulation at the two sides of a rolling brush, the vacuum degree of a vacuum area can not be affected, and the efficiency of dust collectionis greatly improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

Method for smelting TA2 casting ingot by using hot cathode electron beam cold bed furnace

InactiveCN109868389AImprove market competitive advantageReduced smelting processSmelting processIngot

The invention provides a method for smelting a TA2 casting ingot by using a hot cathode electron beam cold bed furnace. The method comprises the steps that after scattered titanium sponge and titaniumdioxide powder are evenly mixed according to the ratio, a mixture is added into the hot cathode electron beam cold bed furnace to be cast, and the TA2 casting ingot is obtained. A melting process ofthe hot cathode electron beam cold bed furnace includes a gun starting stage, a casting ingot bottom making stage and a stable smelting stage; the hot cathode electron beam cold bed furnace comprisesa smelting zone, a refining zone and a crystallization zone which are adjacent in sequence; and in the stable smelting stage, the power of the smelting zone is controlled to be 1200 Kw to 1800 Kw, thepower of the refining zone is controlled to be 600 Kw to 800 Kw, and the power of the crystallization zone is controlled to be 600 Kw to 1000 Kw. The method has the beneficial effects that compared with a traditional production method, the smelting method for producing the TA2 casting ingot significantly reduces the smelting process, the whole smelting process is simple, operation is simple, theproduction efficiency is greatly improved, the produced TA2 casting ingot product effectively meets the market demand, the economic efficiency of enterprises is improved, and the market competitive advantage of the enterprises is improved.

Owner:QINGHAI JUNENG TITANIUM IND CO LTD

Vacuum insulation plate and manufacturing method thereof

InactiveCN103306388BDoes not affect vacuumExtended service lifeClimate change adaptationInsulation improvementSlurryExternal wall insulation

The invention discloses a vacuum insulation plate and a manufacturing method thereof. The vacuum insulation panel comprises a closed hollow cavity body which is formed by casting a material slurry, wherein the interior of the cavity body is hollow; an airtight layer is arranged on the inner wall or / and the outer wall of the cavity body. After the cavity body is vacuumized, convective heat transfer caused by air movement can be avoided, so that the thermal insulation is excellent; the vacuum insulation plate is formed by casting concrete or the material slurry, so that the vacuum insulation plate is firm and reliable; a basic material adopts the concrete or the material slurry with high strength, and the strength is high enough to bear long-term effects of a vacuum pressure, a wind load, self weight and a temperature deformation stress; more than 90% of the plate structure is made of cement and other inorganic materials, so that the long service life of the vacuum insulation plate can be ensured; the vacuum insulation plate mainly uses vacuum, the cement, pottery sand and other low-cost materials, so that the cost of the vacuum insulation plate disclosed by the invention is only 1 / 3 that of the conventional vacuum insulation plate; 90% of the plate structure is made of the cement and the pottery sand, so that the fire-proof performance is class A; the vacuum insulation plate is applicable to external wall insulation and roof insulation for buildings with a shear wall structure, a framework structure and a steel structure.

Owner:许浒

Vacuum sealing assembly structure of calcining kiln

ActiveCN114518027ADoes not affect vacuumAchieving a sealed rotary connectionMuffle furnacesRetort furnacesPumping vacuumSliding contact

The vacuum sealing assembly structure comprises a furnace body conical barrel, the furnace body conical barrel is rotationally sleeved with a sealing barrel, the end, away from the furnace body conical barrel, of the sealing barrel is covered with a sealing cover, and the end face of the sealing barrel and the sealing cover are jointly annularly provided with sealing bolts at equal intervals; a first sealing ring is fixedly installed on the outer side wall of the end, close to the sealing barrel, of the furnace body conical barrel, the end, close to the furnace body conical barrel, of the sealing barrel is fixedly sleeved with a second sealing ring, and the first sealing ring and the second sealing ring are in sliding contact with each other. By means of negative pressure generated by vacuumizing in the furnace body, sealed rotating connection between the furnace body taper pipe and the sealing cylinder is achieved, the pressure of the furnace body is restored to normal pressure during disassembly, disassembly and assembly operation is more convenient, furnace ash is prevented from entering a rotating gap in a screw-in sealing mode, the sealing performance of rotating connection is improved, and the vacuum degree in the furnace is not affected.

Owner:靖江市峰力干燥成套设备有限公司

Preparation method of acrylamide crystals using acrylamide crystal continuous concentration device

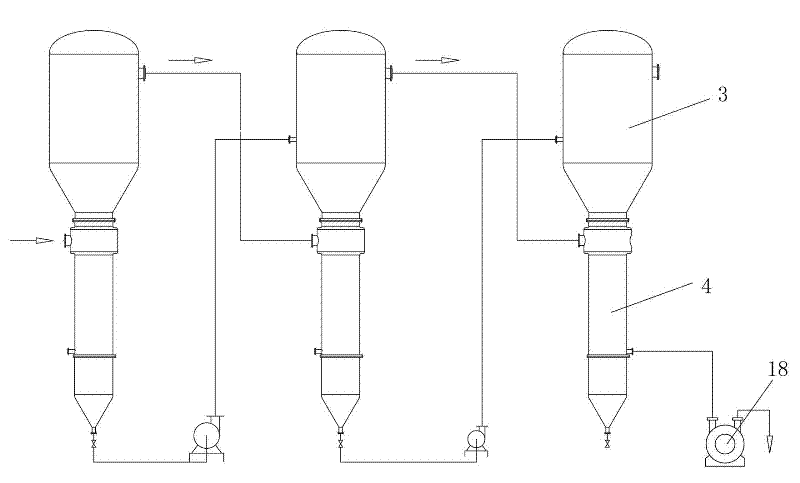

InactiveCN103274960BHigh activityAvoid uniformityChemical industryCarboxylic acid amide separation/purificationLiquid storage tankEngineering

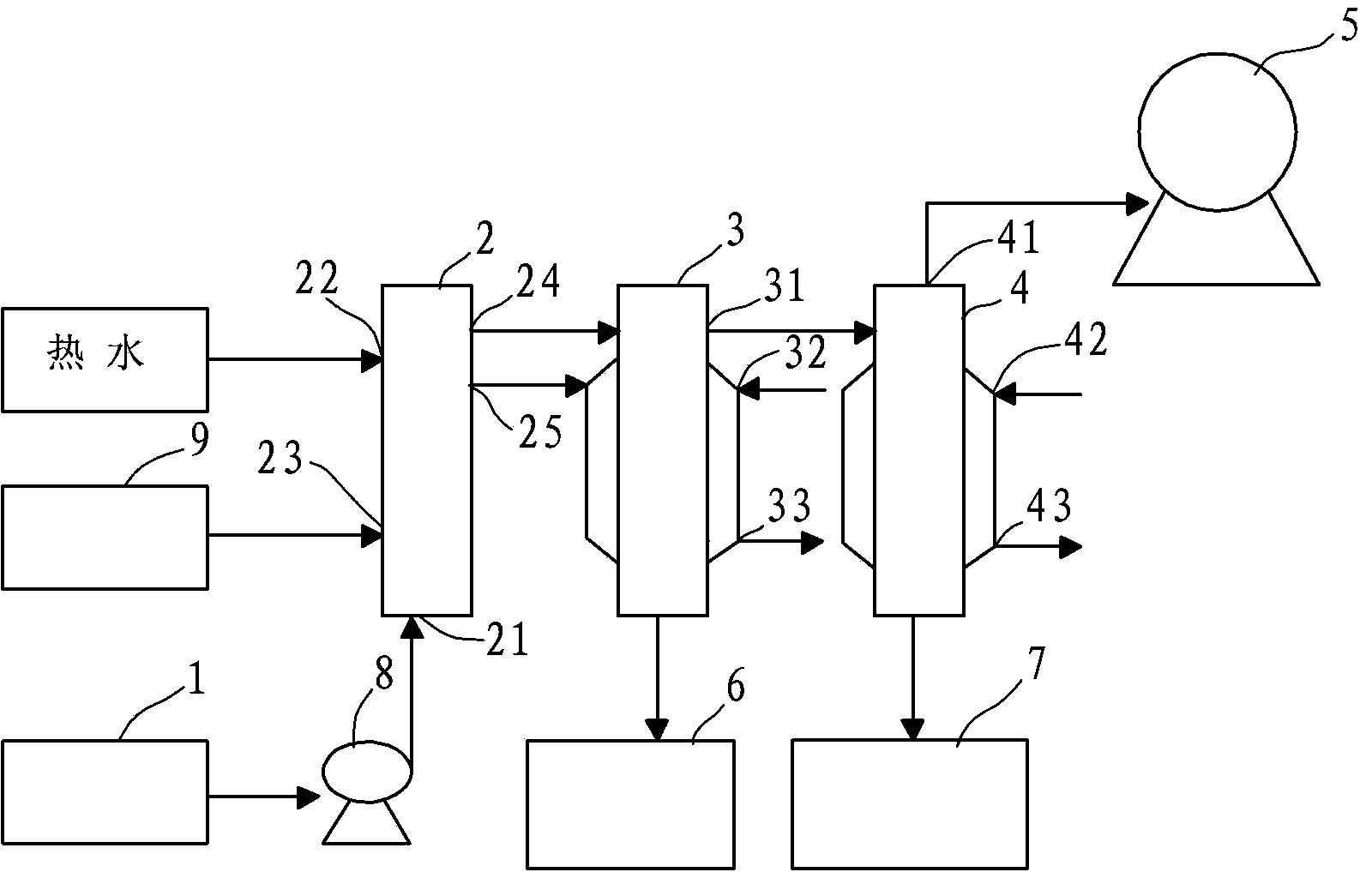

The invention discloses an acrylamide crystal continuous concentration device which is characterized by comprising a feed tank, a membrane type evaporator, a first condenser, a second condenser, a water ring vacuum pump, a first liquid storage tank and a second liquid storage tank, wherein the first liquid storage tank is connected with a liquid outlet of the first condenser; and the second liquid storage tank is connected with a liquid outlet of the second condenser. The invention also discloses a preparation method of an acrylamide crystal. Compared with the prior art, the device and method disclosed by the invention have the advantages of high efficiency, low energy consumption and stable operation.

Owner:NINGBO XIANAN CHEM

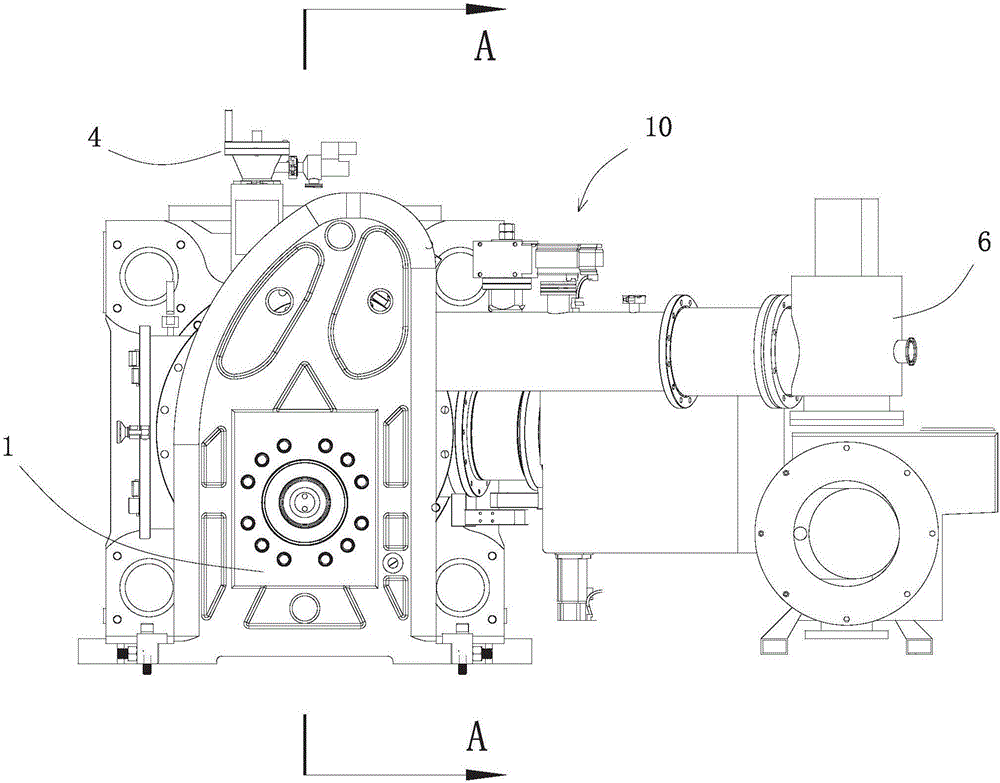

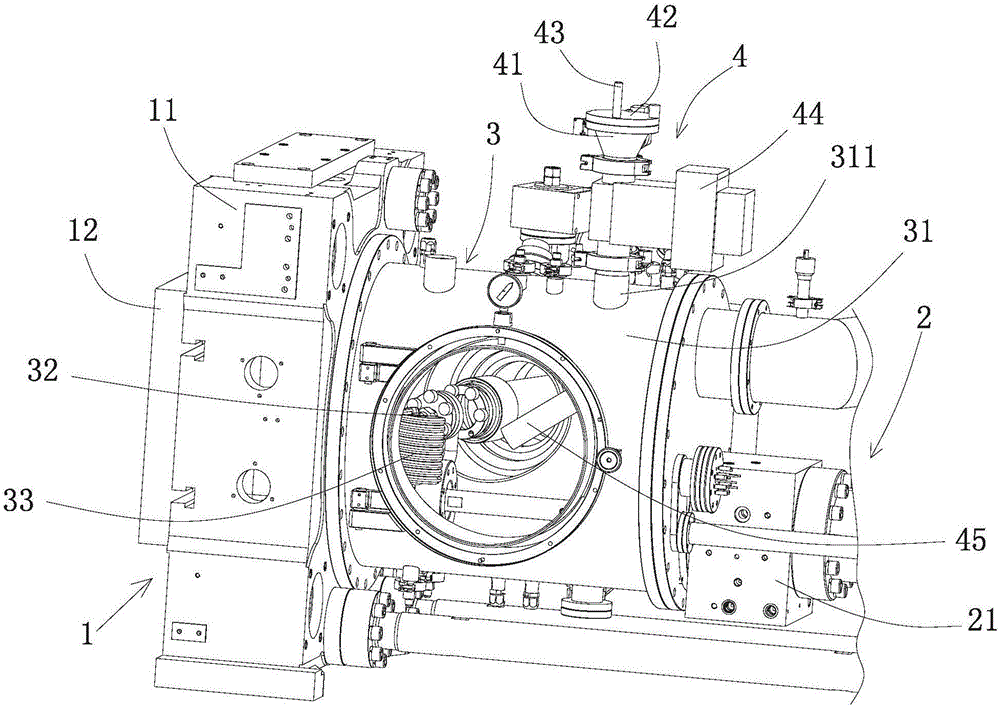

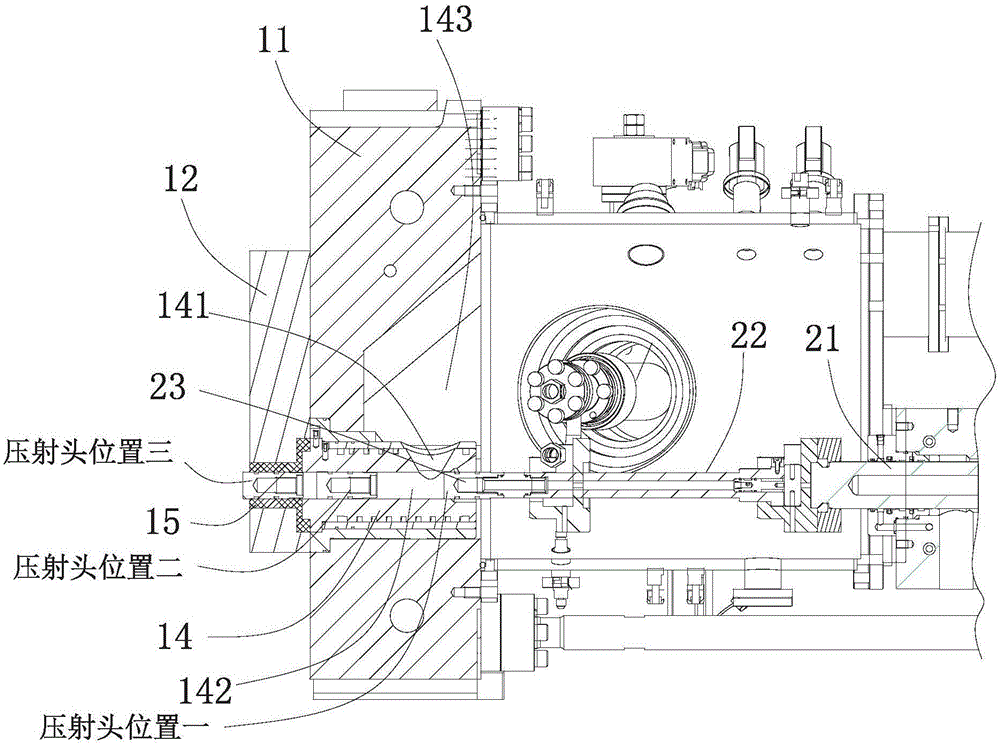

Metal die-casting molding equipment and metal die-casting molding method

The invention discloses metal die-casting molding equipment and a metal die-casting molding method. The metal die-casting molding equipment comprises a vacuum melting device, a feeding device, a press-shoot device and a die device, wherein the vacuum melting device is provided with a vacuum chamber and a heating vessel, the heating vessel is arranged in the vacuum chamber and is used for melting a material from the feeding device, and the feeding device is installed on a feeding hole of the vacuum chamber; the press-shoot device is composed of a driver, a press-shoot rod and a press-shoot head, wherein one end of the press-shoot rod is connected with the driver, and the other end of the press-shoot rod is connected with the press-shoot head; and the feeding device is arranged to keep the vacuum atmosphere of the vacuum chamber when the material is added in the heating vessel, and in addition, the press-shoot head is arranged to keep the vacuum atmosphere of the vacuum chamber both in the die opening and closing processes of the die device. The metal die-casting molding equipment can realize continuous die casting under the condition without destroying the vacuum atmosphere.

Owner:张斌

Acrylamide crystal continuous concentration device and preparation method thereof

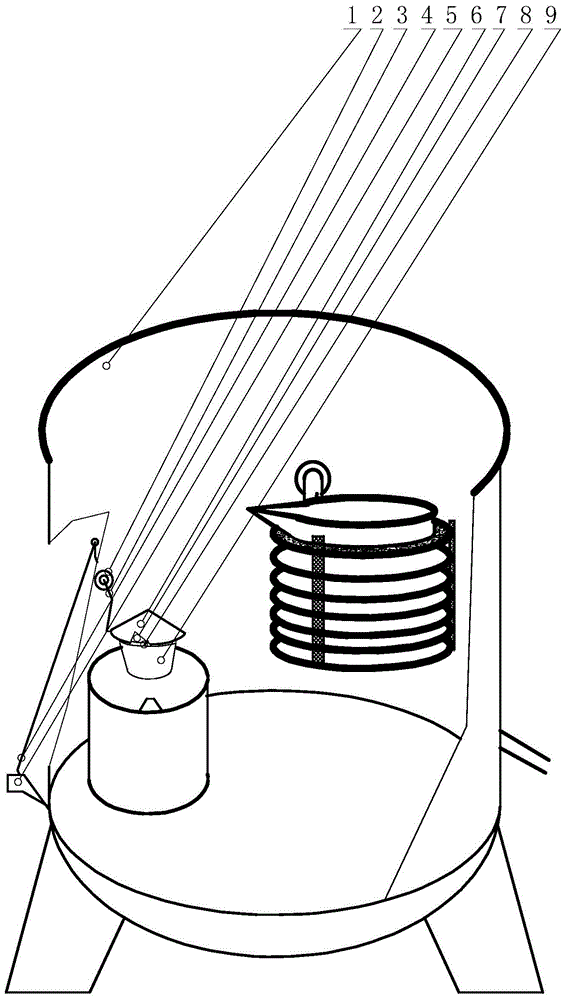

InactiveCN103274960AImprove efficiencyShort heating timeChemical industryCarboxylic acid amide separation/purificationLiquid storage tankEngineering

The invention discloses an acrylamide crystal continuous concentration device which is characterized by comprising a feed tank, a membrane type evaporator, a first condenser, a second condenser, a water ring vacuum pump, a first liquid storage tank and a second liquid storage tank, wherein the first liquid storage tank is connected with a liquid outlet of the first condenser; and the second liquid storage tank is connected with a liquid outlet of the second condenser. The invention also discloses a preparation method of an acrylamide crystal. Compared with the prior art, the device and method disclosed by the invention have the advantages of high efficiency, low energy consumption and stable operation.

Owner:NINGBO XIANAN CHEM

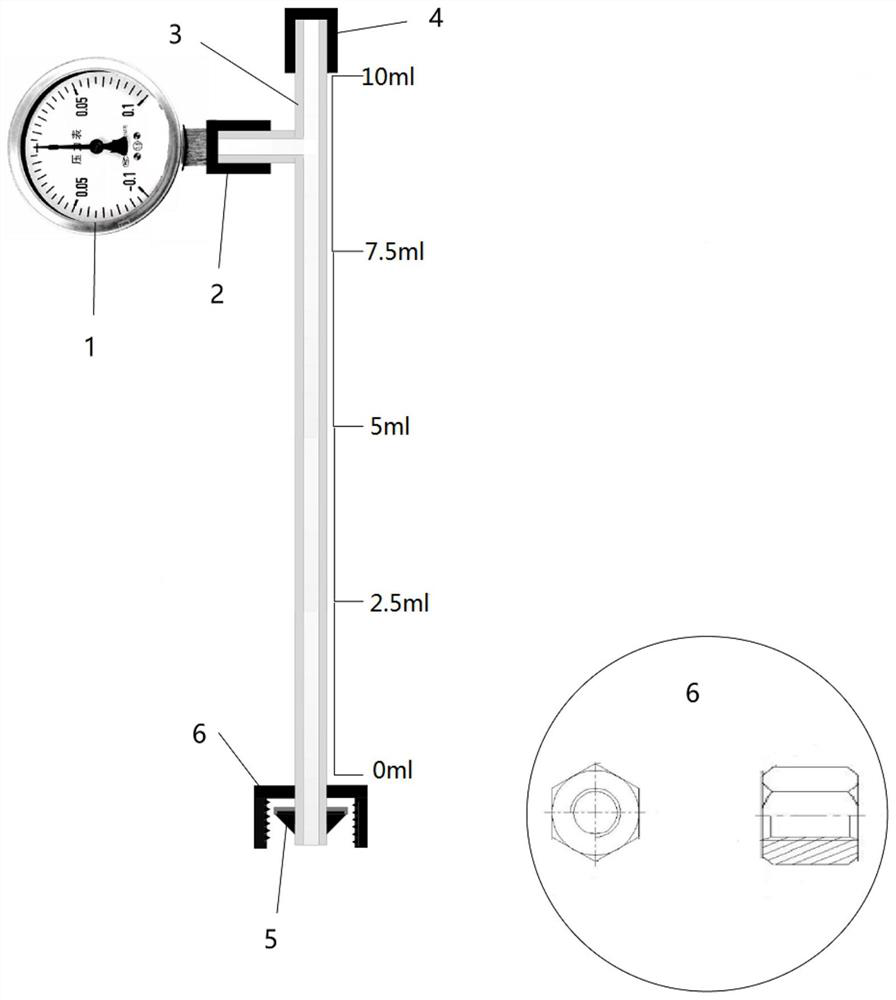

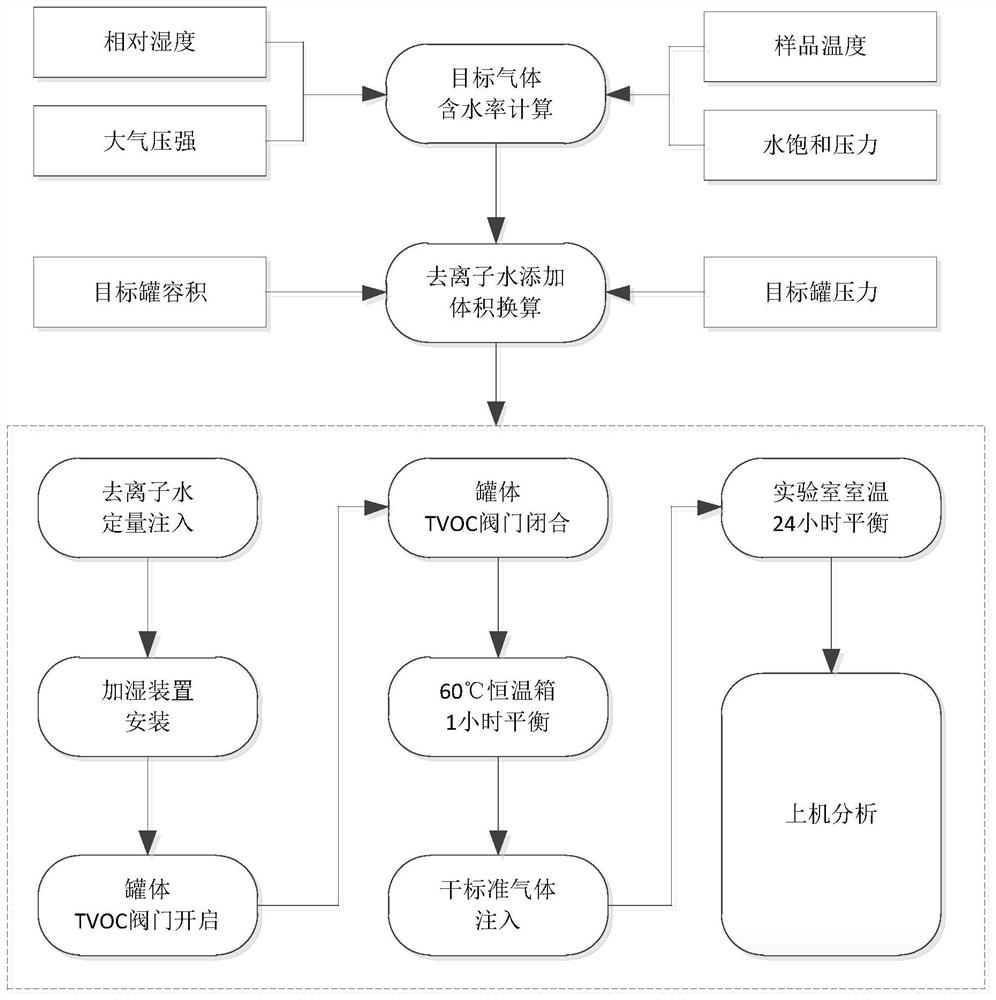

Device and method for accurate negative pressure humidification of atmospheric vocs sampling tank

ActiveCN109211641BSimple structureEasy to usePreparing sample for investigationAir monitoringAtmospheric sciences

The invention discloses a device and method for accurate negative pressure humidification of atmospheric VOCs sampling tanks, which can conveniently and quickly perform the humidification process without destroying the vacuum degree in the sampling tank, and solve the dry standard in the process of ambient air VOCs monitoring and analysis. The gas humidity does not match the actual situation, which causes the problem of deviation in the analysis of VOCs components that are easily soluble in water such as aldehydes and ketones, and also solves the problem of humidification expansion of dry standard gases by traditional dynamic diluters.

Owner:CHENGDU ACADEMY OF ENVIRONMENTAL SCI

Splash prevention device for vacuum melting

ActiveCN104930851BDoes not affect vacuumEasy to operateFurnace componentsFoundry mouldsPulp and paper industryVacuum furnace

A splash-proof device for vacuum melting is characterized in that a sealing sleeve is arranged on a vacuum furnace wall, a bent lever is arranged in the sealing sleeve, a splash-proof cover is arranged at the inner end of the bent lever, double metal claws are arranged on the lower portion of the splash-proof cover, a heat insulation cover with double functions is arranged in the double metal claws, a connecting rod is arranged at the outer end of the bent lever, and the lower end of the connecting rod is connected with a pedal arranged on a vacuum furnace. By the aid of the double metal claws arranged on the lower portion of the splash-proof cover, the double metal claws can be pressed into the heat insulation cover when the double metal claws are in the cold state. When vacuum melting is performed, the splash-proof cover is closed, so that impurities are prevented from splashing into a melt die orifice. When the splash-proof cover is opened, melt metal liquid is filled, then the splash-proof cover is closed, the heat insulation cover and the splash-proof cover can loosen through the double metal claws under the action of rise of the temperature of the melt die orifice, the heat insulation cover timely covers the melt die orifice and can effectively function in preventing spatter and timely keeping warm and feeding, the quality of products is improved from perfection of the device, and production cost is reduced.

Owner:WUXI LIHU PRESSURIZE TECH CO LTD

Evaporative vacuum drainer

InactiveCN102225241BSmooth dischargeDischarge resistanceEvaporator accessoriesMultiple-effect evaporationExternal energyEngineering

The invention relates to an evaporative vacuum drainer, which comprises a vacuum chamber, a balance chamber, a hollow sink-and-float device, a vacuum valve set and a balance valve set, wherein an evaporator heating chamber connector is formed on the vacuum chamber; the balance chamber is positioned under the vacuum chamber; an air inlet pipe and a water outlet are arranged on the balance chamber;the upper half part of the sink-and-float device is positioned in the vacuum chamber; the lower half part of the sink-and-float device is positioned in the balance chamber; the vacuum valve set is arranged at the upper half part of the sink-and-float device; the balance valve set is arranged at the lower half part of the sink-and-float device; when the sink-and-float device floats upwards, the vacuum valve set is opened and the balance valve set is closed; and when the sink-and-float device sinks, the vacuum valve set is closed and the balance valve set is opened. The evaporative vacuum drainer has the advantages that the evaporated condensate water can be drained out of a system at vacuum state without the help of an external energy resource.

Owner:高翔

Continuous injection vacuum chamber

PendingCN110310880ADoes not affect vacuumSmall vacuum volumeSamples introduction/extractionMaterial analysis by electric/magnetic meansVacuum pumpVacuum chamber

The invention discloses a continuous injection vacuum chamber. The continuous injection vacuum chamber includes a vacuum chamber provided with an ion exciter and an ion detector, a vacuum gauge communicated with the vacuum chamber, and a vacuum pump. The continuous injection vacuum chamber is advantaged in that continuous injection can be achieved, work efficiency is improved, and service life isimproved.

Owner:ZHEJIANG DIGENA DIAGNOSTIC TECH CO LTD

Self-locking type vacuumizing feeding and discharging device

The invention relates to a vacuumizing feeding and discharging device. The vacuumizing feeding and discharging device is characterized by comprising a self-locking type vacuumizing feeding machine anda self-locking type vacuumizing discharging machine which are arranged at the head end and the tail end of a vacuum operation line respectively, wherein the self-locking type vacuumizing feeding machine is used for forming a feeding vacuum seal on strips, the self-locking type vacuumizing discharging machine is used for forming a discharging vacuum seal on the strips, the strips continuously passby the self-locking type vacuumizing feeding machine and enter the vacuum operation line, and then are continuously discharged from the self-locking type vacuumizing discharging machine, so that a guarantee for the continuous operation under the vacuum condition is provided, continuous feeding under the vacuum condition is realized, and the increasing of the production speed is facilitated.

Owner:JIANGYIN RUIXING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com