Vertical low-temperature liquefied natural gas storage tank

An LNG tank, LNG technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problem of increasing the volume of the inner tank, narrow space, and inconvenient removal of welding burrs And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

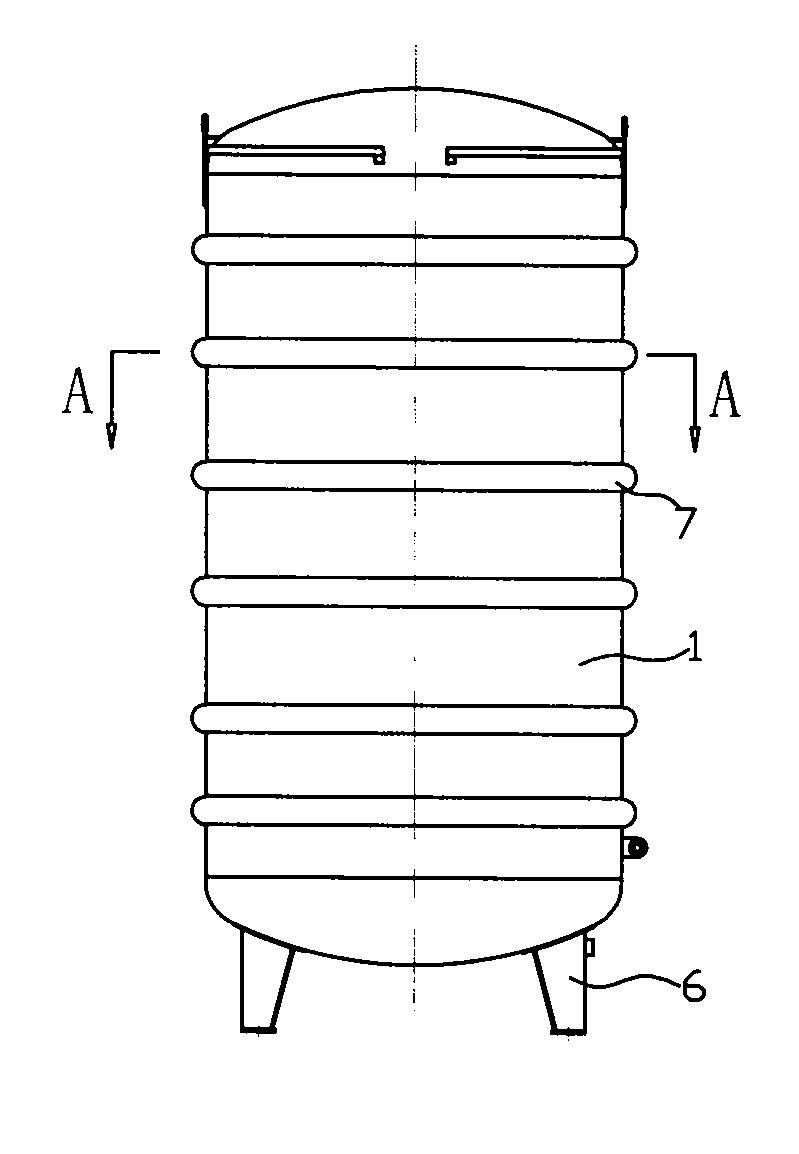

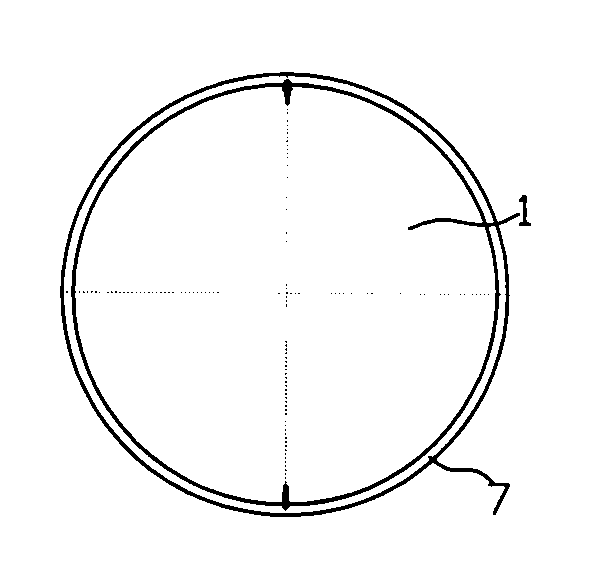

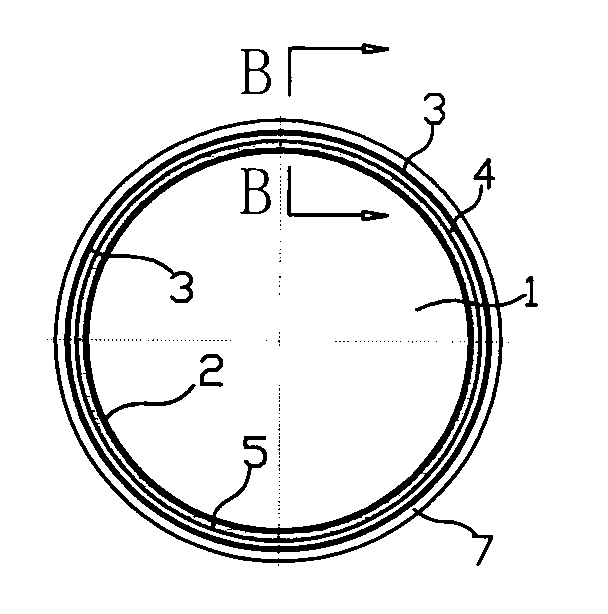

[0020] Figure 1~Figure 4 Among them, the vertical cryogenic liquefied natural gas storage tank has a cryogenic liquefied natural gas tank 1, and the cryogenic liquefied natural gas tank has an inner tank body 2 and an outer tank body 3 which are nested together, and both the inner tank body and the outer tank body have a cylindrical body Both ends of the cylinder have elliptical heads, there is a gap 4 between the inner tank and the outer tank, the outer side of the inner tank is covered with a flexible aluminum foil insulation quilt 5, and the outer tank is evenly distributed with circular Annular ribs, the axis of the cryogenic liquefied natural gas tank is perpendicular to the horizontal plane, the lower end surface of the cryogenic liquefied natural gas tank is evenly distributed with feet 6, and the reinforcing ribs on the outer tank body are circular rings that are evenly distributed and welded on the outer circumference of the outer tank body Shape profile 7.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com