Splash prevention device for vacuum melting

A vacuum smelting and splash-proof technology, applied in the field of precision casting, can solve the problems of affecting the qualified rate of products, uneconomical metal film covering method, lack of heat preservation and feeding effect, etc., to achieve convenient operation, reduce production costs, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

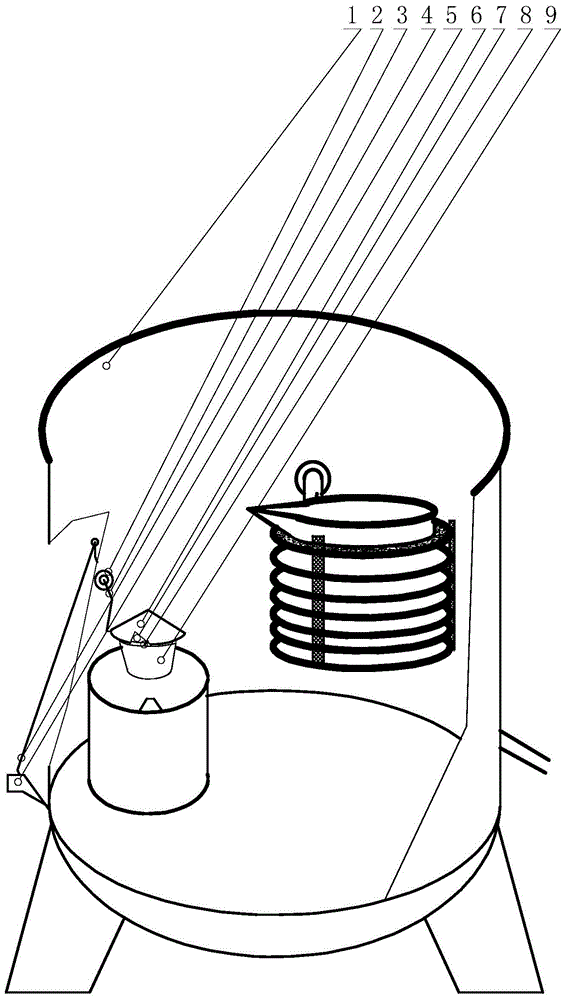

[0009] figure 1 As shown, the present invention is a splash-proof device for vacuum smelting, the sealing sleeve 2 is arranged on one side of the vacuum furnace wall 1, the curved rod 3 is arranged in the sealing sleeve 2, and the splash-proof cover 6 is arranged inside the curved rod 3 On the end, the bimetal claws 8 are connected under the splash-proof cover 6, the heat preservation cover 7 is arranged in the bimetal claws 8, the upper end of the connecting rod 4 is connected with the outer end of the curved rod 3, and the lower end of the connecting rod 4 is connected to the vacuum furnace. on the pedal 5 connection.

[0010] The invention adopts the pedal arranged on the vacuum furnace to be connected with the lower end of the connecting rod, so that the operation of the splash-proof cover is convenient; the bimetal claws arranged under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com