A method for judging the leakage of a vacuum pipeline

A technology of vacuum pipelines and pipelines, which is applied in liquid tightness measurement using liquid/vacuum degree, fluid tightness testing, machine/structural component testing, etc. It can solve poor sealing performance, affect passenger safety, and long pipeline and other issues to achieve the effect of improving reliability and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

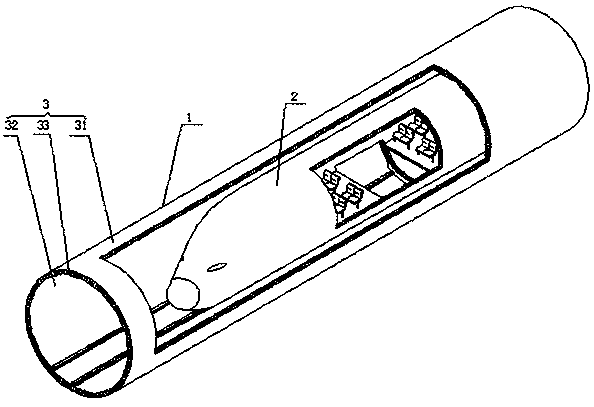

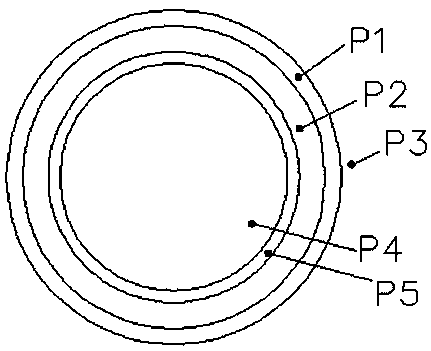

[0038] Such as figure 1 with figure 2 Shown: a method for judging the leakage of a vacuum pipeline, including a vacuum pipeline 1 composed of a sandwich panel 3, the sandwich panel 3 including an inner panel 32, an outer panel 31, and a sandwich layer 33 between the two ; The pressure of the sandwich layer is between the internal and external pressures. If the pressure sensor detects that the pressure of the sandwich layer 33 becomes larger, it indicates that the layer with strong pressure is leaking; if the pressure of the sandwich layer 33 becomes smaller, it indicates The layer with the lower pressure is leaking.

[0039] Specifically, the vacuum duct 1 is composed of a sandwich panel 3. The sandwich panel 3 is composed of an inner layer, an outer panel, and a sandwich layer 33 located between the two. The thickness of the outer layer and the inner panel of the sandwich panel are equal. The thickness is 300 mm, and the sandwich layer 33 includes a plurality of hollow tubes ar...

Embodiment 2

[0046] With the same structural signs, when the vacuum pipeline is placed 100m underwater, the underwater pressure is 980KPa at this time, and a pressure sensor is set on the vacuum pipeline 1. The inner cavity of the vacuum pipe 1 and the sandwich layer 33 are respectively sealed, and the inner cavity of the vacuum pipe 1 is evacuated first, so that the pressure inside the vacuum pipe 1 reaches P2=0 Pa and remains stable.

[0047] The leakage judgment method of the vacuum pipeline is the same as that in Example 1.

Embodiment 3

[0049] Such as figure 1 with figure 2 Shown: when vacuum pipe 1 contains train 2, vacuum pipe 1 and vacuum train 2 can be tested at the same time, that is, when vacuum pipe 1 is placed under atmospheric pressure, the pressure detection method of vacuum pipe 1 is the same as above. The shell of the train 2 is also composed of sandwich panels 3. When the train 2 is placed in the vacuum pipeline, the outside of the train is in a vacuum state, the external pressure value P2=0Pa, and the inside of the train is standard atmospheric pressure, that is, P4=101KPa. Detect the pressure value in the train sandwich layer. When the pressure value stabilizes at a certain value, such as 10KPa, the threshold range of the calibrated pressure value P is preset in the controller, such as 9.90~10.1 KPa.

[0050] The pressure sensor detects the pressure in the train sandwich layer in real time. If the pressure value in the train sandwich layer is detected P5 min (P min =9.90KPa), it means that ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com