Continuous injection vacuum chamber

A vacuum chamber and sampling port technology, applied in the field of vacuum chambers, can solve problems such as inability to continuously inject samples, poor reliability, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

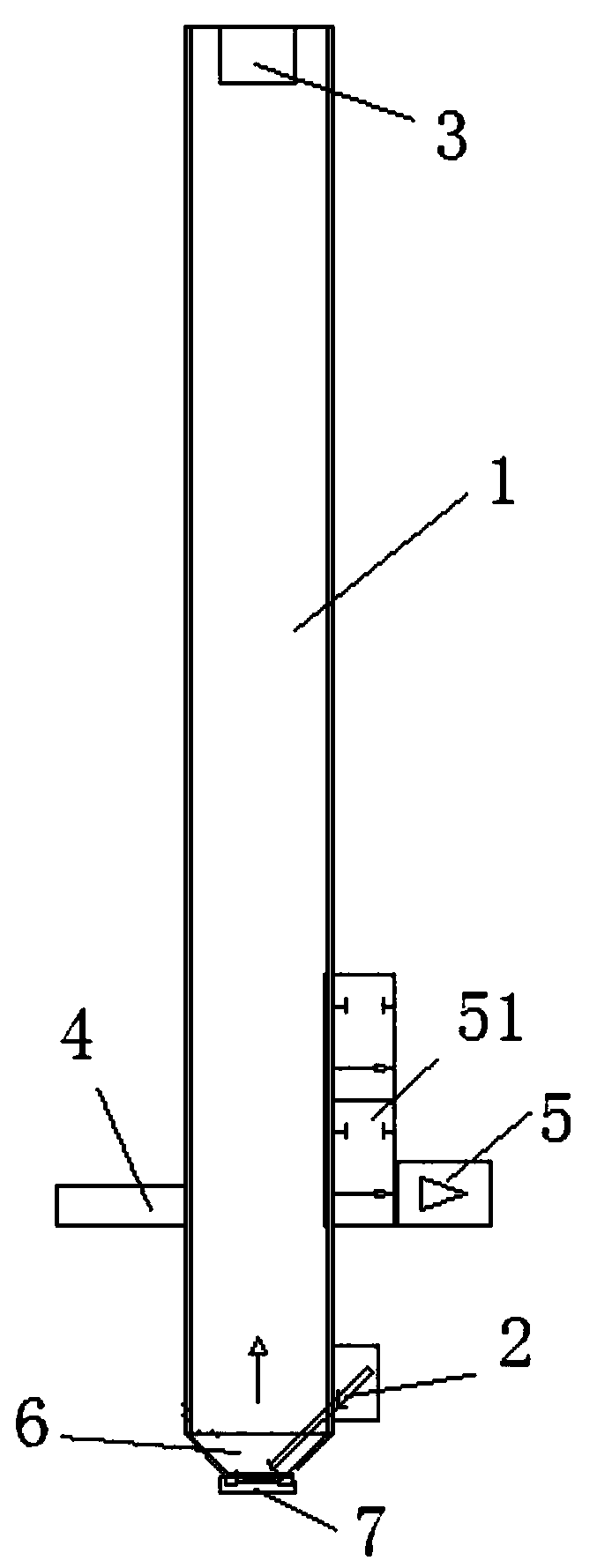

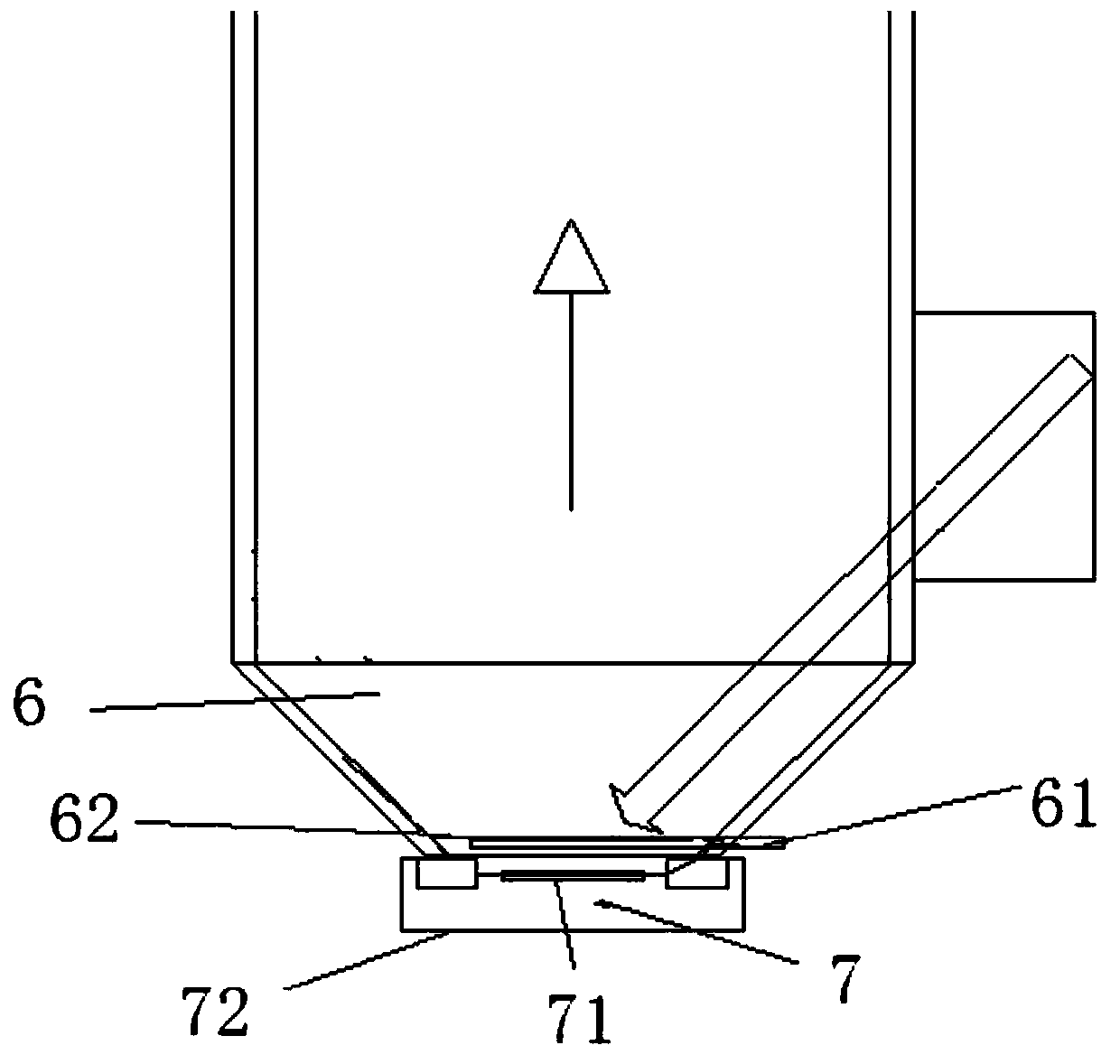

[0026] Such as Figure 1-3 Shown, a continuous sampling vacuum chamber, including

[0027] A vacuum chamber 1, the vacuum chamber 1 is provided with an ion exciter 2 and an ion detector 3. The vacuum chamber is a circular cavity with a length of 0.3M to 2M (the circular cavity is only a preferred method), and the top of the cavity is Closed, the bottom of the cavity is open, the ion exciter 2 is set at the bottom of the vacuum chamber, the ion detector 3 is set at the top of the vacuum chamber, the cavity is formed as an ion flight channel, the ion exciter is introduced from the non-axis of the vacuum chamber, and the introduction angle is 10°~170°;

[0028] A vacuum gauge 4, the vacuum gauge 4 communicates with the vacuum chamber 1;

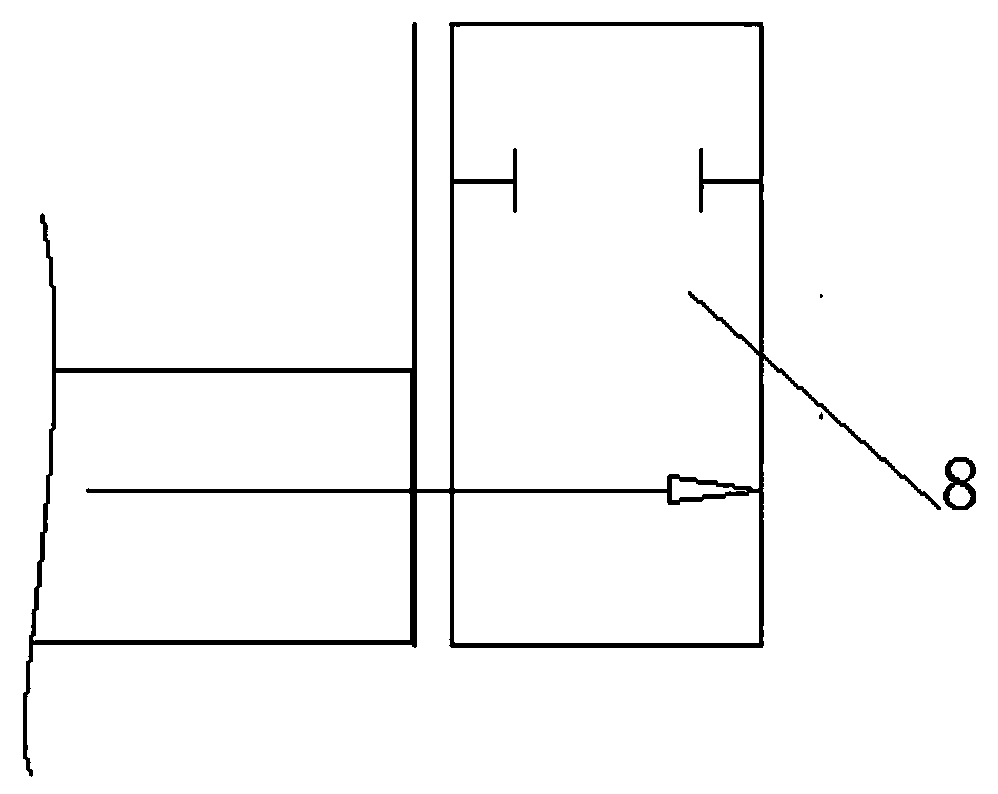

[0029] Vacuum pump 5, described vacuum pump 5 is connected with vacuum chamber 1 by vacuum valve 51, and vacuum chamber is disconnected with vacuum pump when closing vacuum valve, and vacuum degree is better than 10 6 mBar;

[0030] The samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com