Self-locking type vacuumizing feeding and discharging device

A vacuum-pumping and self-locking technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems that the production efficiency cannot be improved to the ideal level, and the operation cannot be adapted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

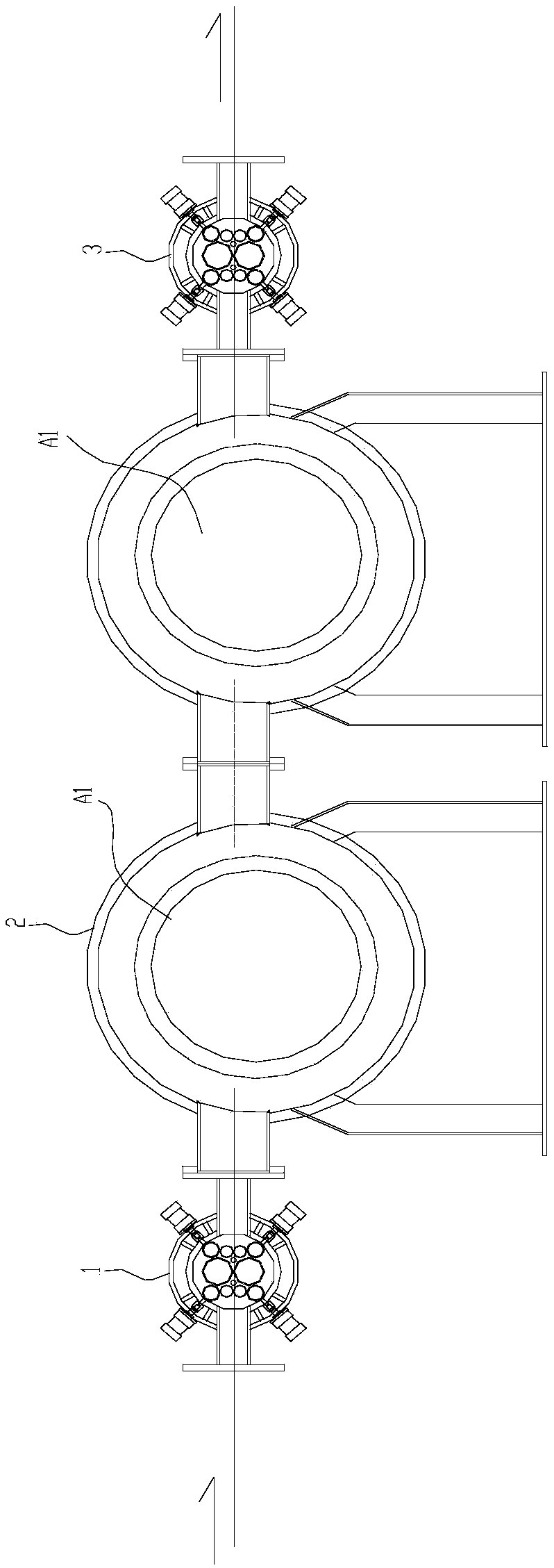

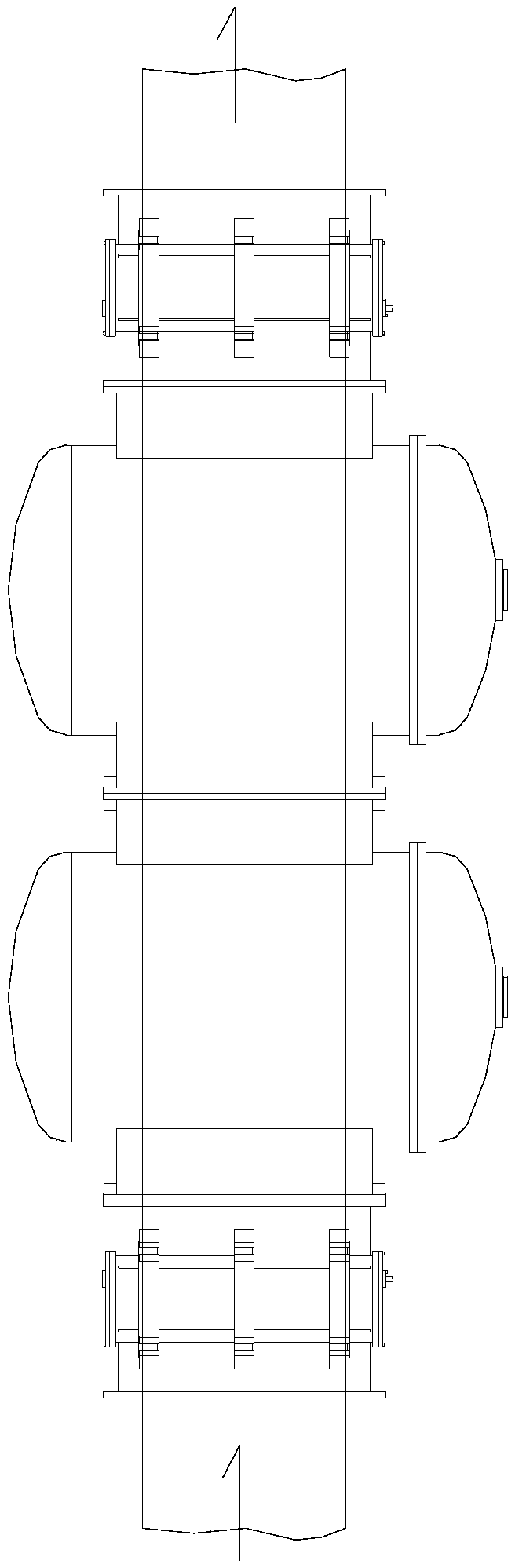

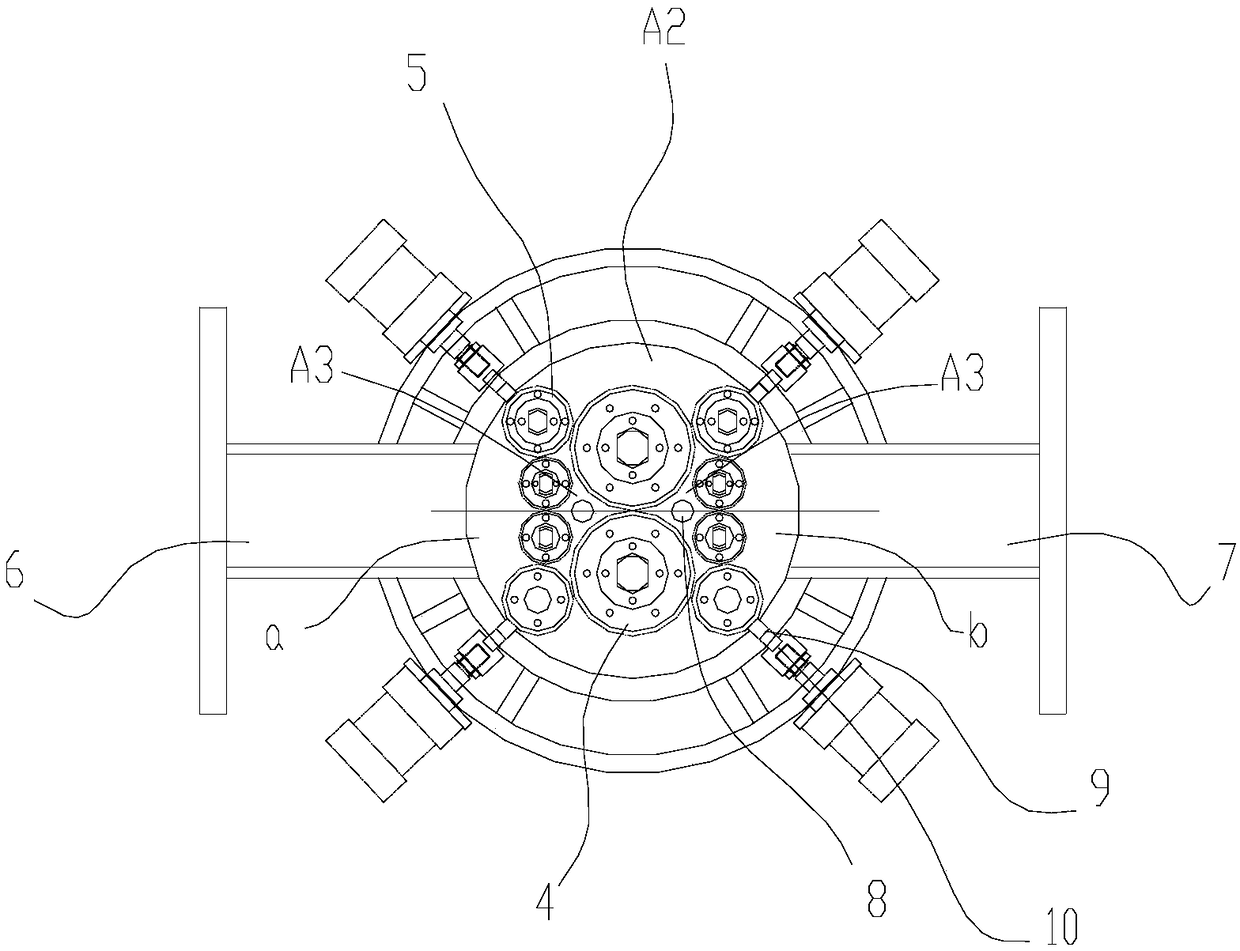

[0017] This embodiment relates to a plasma cleaning device for a strip, which can realize continuous plasma cleaning of the strip. According to the feeding direction of the strip, it includes a self-locking vacuum feeder 1, two (or more) plasma cleaning mechanisms 2, a self-locking vacuum discharge machine 3, and a self-locking vacuum feeder 1 A vacuum seal is formed for the feeding of the tape, and the self-locking vacuum discharge machine 3 constitutes a vacuum seal for the discharge of the tape, and the tape is sequentially cleaned twice (or multiple times) in two (or more) plasma cleaning mechanisms. Plasma cleaning works.

[0018] The vacuuming of this application is realized by a vacuum pump, and the vacuum pump has no special design in this application, and is not shown in detail in the drawings of the description. Those of ordinary sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com