Manhole device of low temperature liquid storing and transporting container

A cryogenic liquid and container technology, applied in the field of cryogenic liquid storage and transportation equipment, can solve the problems of increased maintenance cost, reduced shell life, internal gas leakage, etc., and achieves obvious sealing effect, reduced maintenance cost, and convenient opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

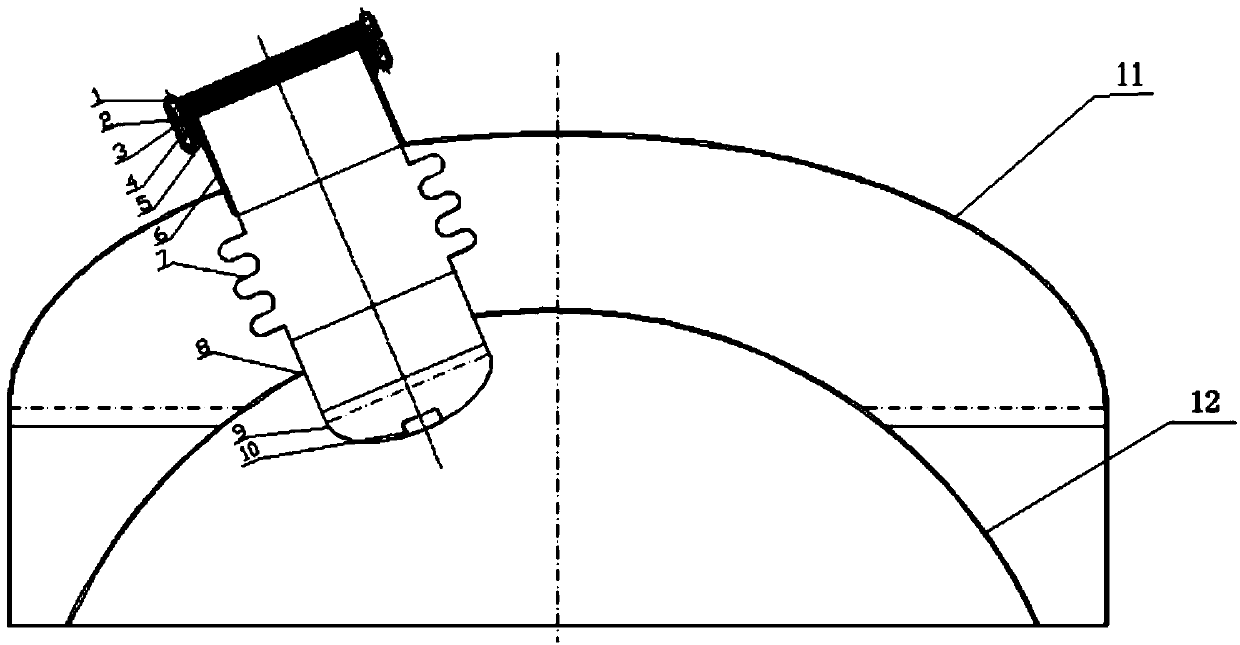

[0018] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention provides a manhole device for a cryogenic liquid storage and transportation container. The stud 2 and the nut 1 are used to fixedly connect the manhole flange 5 and the manhole flange cover 3; the manhole flange 5 is a long neck butt welding flange of DN400, One end is fixedly connected with the manhole sub-joint, and the other end is covered with a manhole cover 3 for closing the manhole device; the gasket 4 added between the manhole flange and the manhole flange cover is a metal wound gasket; the sealing surface of the manhole flange is in the form of a tongue and groove surface Sealing further strengthens the sealing effect. The manhole nipple 6 is welded to the shell head 11 of the cryogenic vessel with full penetration. One end of the expansion joint 7 is fixedly connected to the manhole nipple, and the other end is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com