Sample conveying system applied to vacuum interconnection system

A sample transmission and interconnection system technology, applied in the field of sample transmission system, can solve problems such as simple mechanical movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

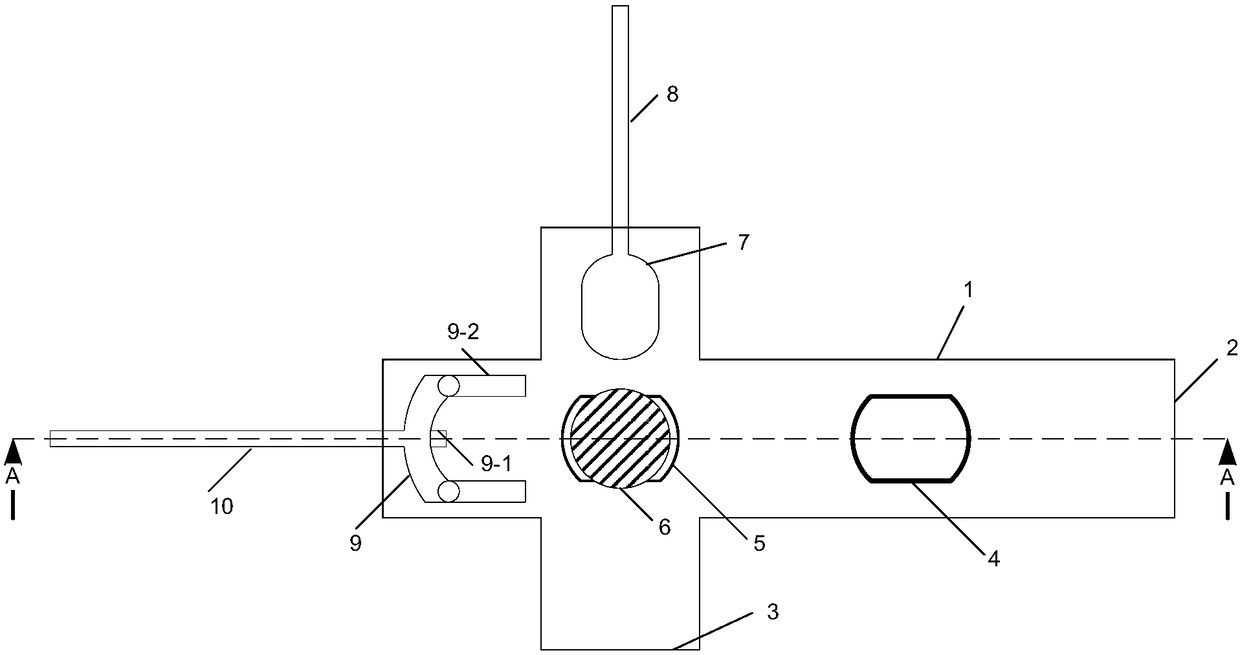

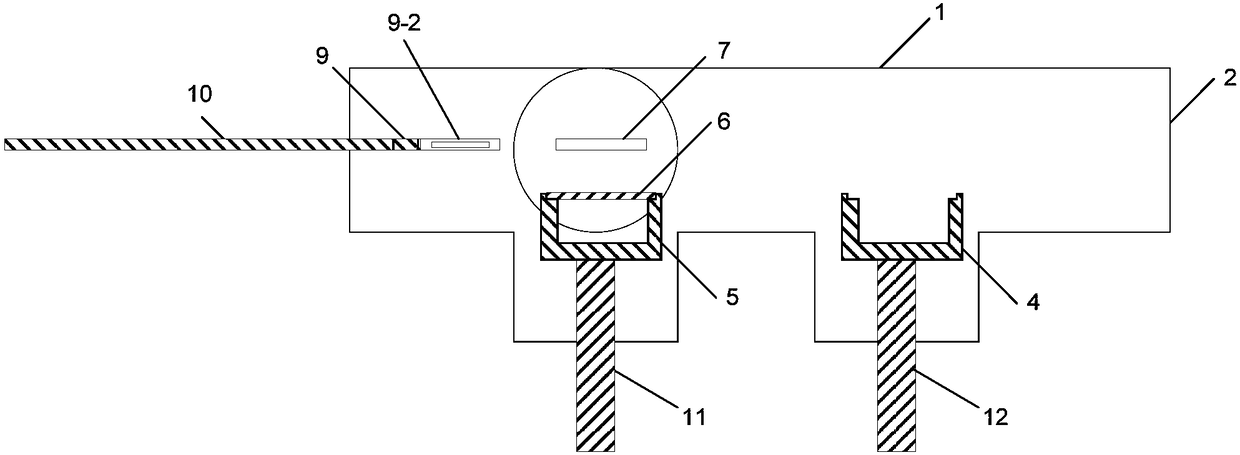

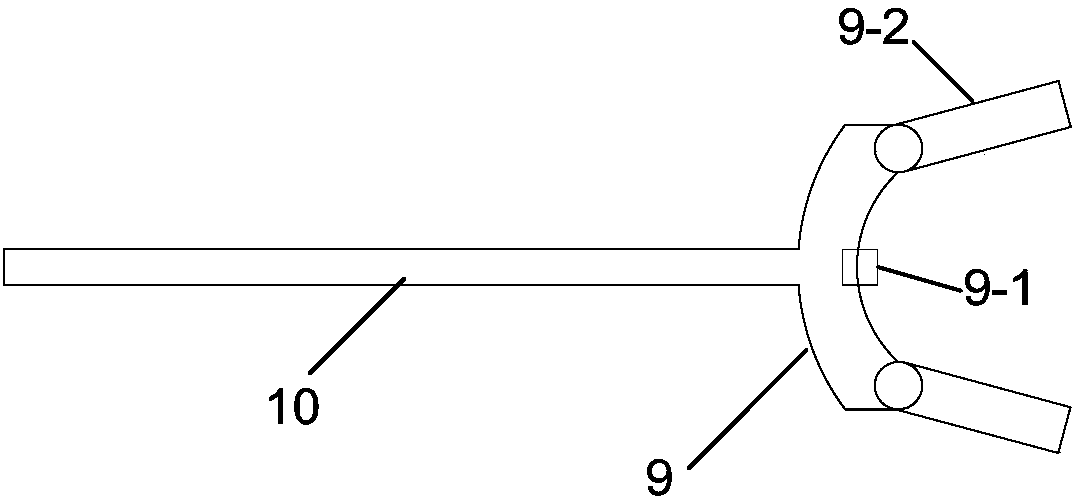

[0021] ginseng figure 1 and figure 2 , a sample transfer system applied to a vacuum interconnection system, the sample transfer system includes a vacuum pipeline 1; at least two sample holders 5, 4 and two vacuum lifting platforms 11 corresponding to the at least two sample holders 5, 4 , 12; at least one fully mechanically driven manipulator 9, which is at least used for transferring the sample 6 between the sample holder 5 and the sample holder 4, and driving the upper and lower sides of the sample 6; at least one sample manipulator 7, The sample manipulator 7 is at least used to take the sample 6 in the sample holder 5 to the corresponding equipment; at least two vacuum magnetic rods 10 and 8 are used to drive the fully mechanically driven manipulator 9 and the sample manipulator 7 respectively.

[0022] Further, the sample mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com