Preparation method of acrylamide crystals using acrylamide crystal continuous concentration device

A technology of acrylamide crystals and acrylamide, which is applied in sustainable manufacturing/processing, carboxylic acid amide separation/purification, organic chemistry, etc., can solve the problems of bulky concentration tower, long production cycle, energy-consuming waste water, etc., and achieve effective It is conducive to the large-scale equipment, the improvement of product quality, and the effect of reducing comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

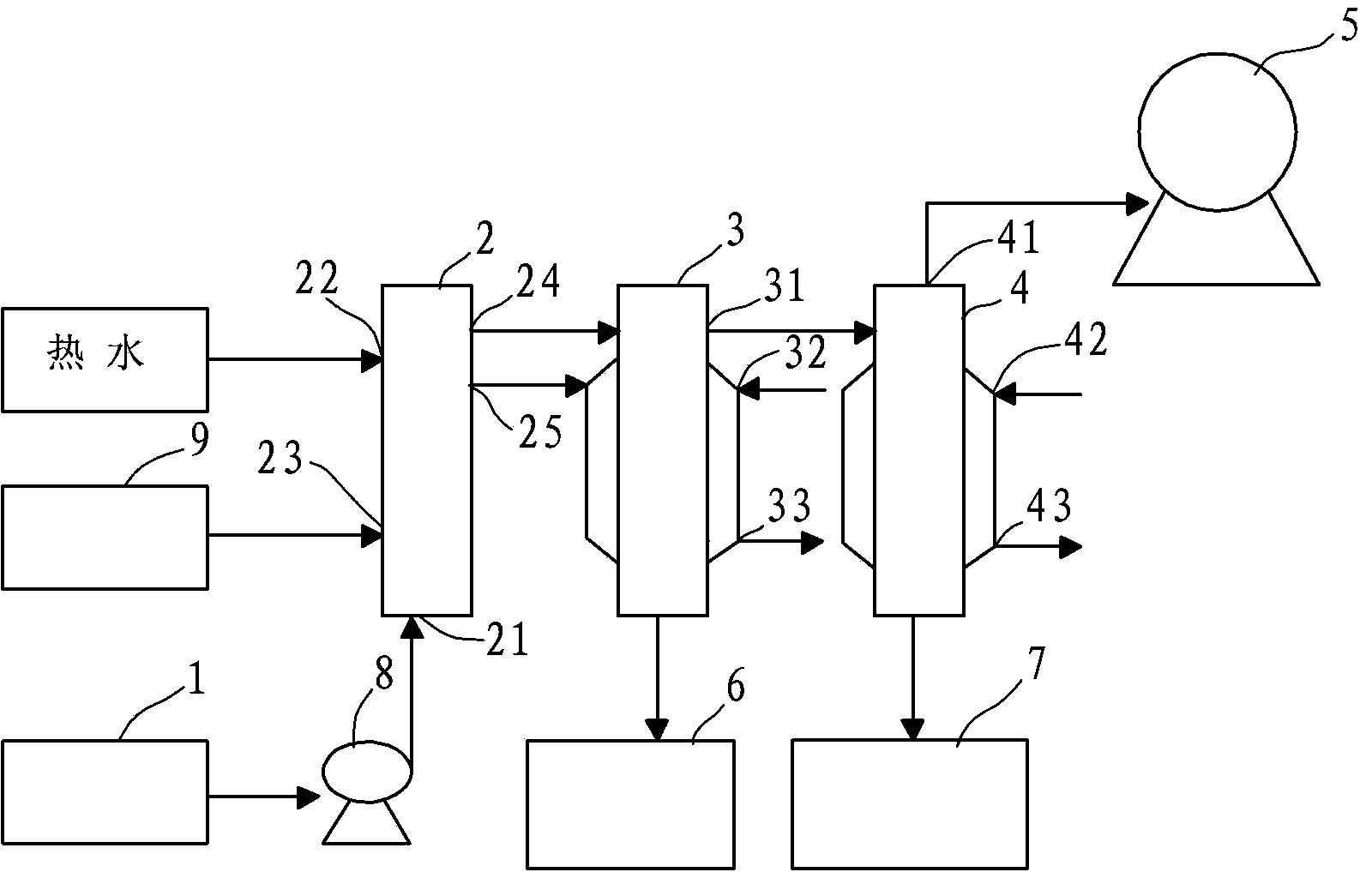

[0035] like figure 1 As shown, the acrylamide crystal continuous concentration device in this embodiment includes a feed tank 1, a film evaporator 2, a first condenser 3, a second condenser 4, a water ring vacuum pump 5, a first liquid storage tank 6 and The second liquid storage tank 7 .

[0036] The feed tank 1 is connected to the feed port of the film evaporator 2 through the metering pump 8. The film evaporator 2 has a feed port 21, a hot water inlet 22, an air inlet 23, a gas phase outlet 24 and a liquid phase outlet 25. The air inlet 23 of the type evaporator is provided with an air filter 9; the first condenser 3 is connected with the liquid phase outlet 25 and the gas phase outlet 24 of the film evaporator, and has a gas phase outlet 31, a first chilled water inlet 32 and a first chilled water inlet 32. A chilled water outlet 33; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com