Electromagnetic harmonic wave exciting device for high-speed rotating impeller

A technology of excitation device and high-speed rotation, which is used in measurement devices, vibration testing, and testing of machine/structural components. , Improve the stability and ensure the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

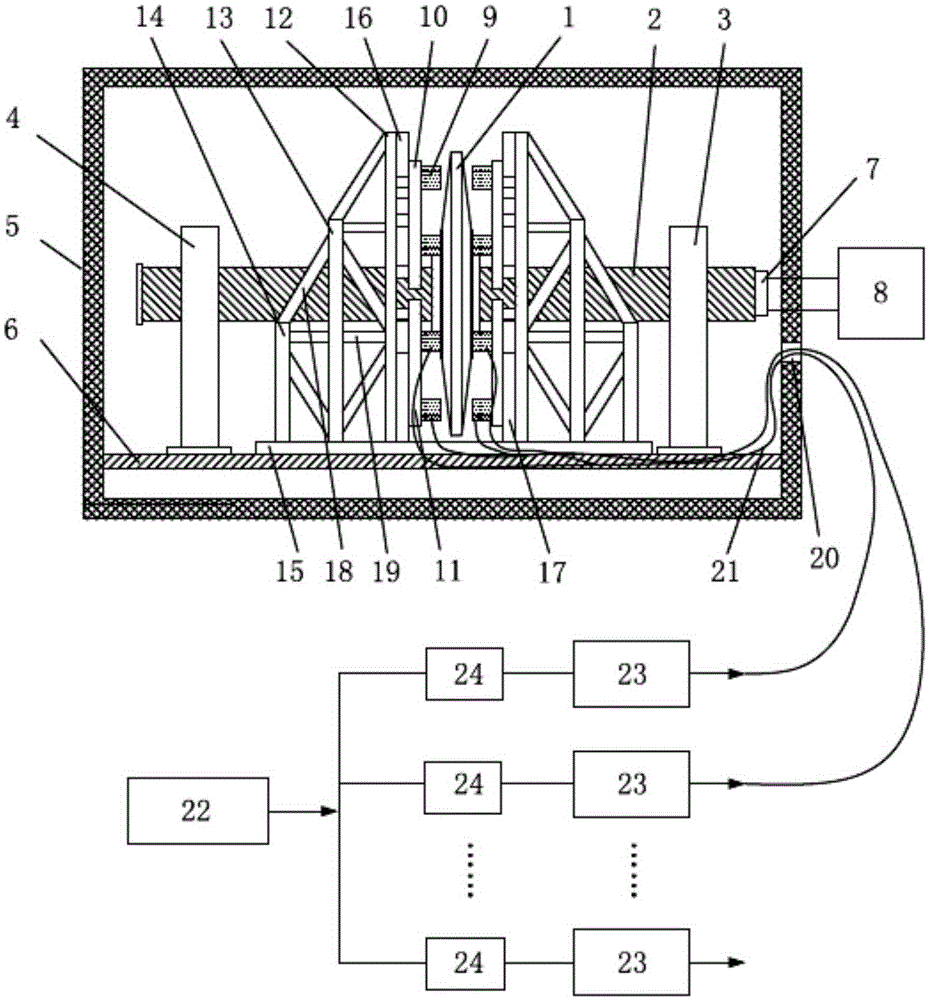

[0031] see figure 1 , an electromagnetic force excitation method for a high-speed rotating impeller of the present invention, including a vacuum cylinder 6, and a front swing frame 3 and a rear swing frame 4 installed in the vacuum cylinder 6, the impeller 1 to be tested together with the shaft 2 Installed on the front swing frame 3 and the rear swing frame 4, fixed on the swing frame track 5 in the vacuum cylinder 6, the front section of the shaft 2 is connected with the drive motor 8 outside the cylinder by a coupling 7.

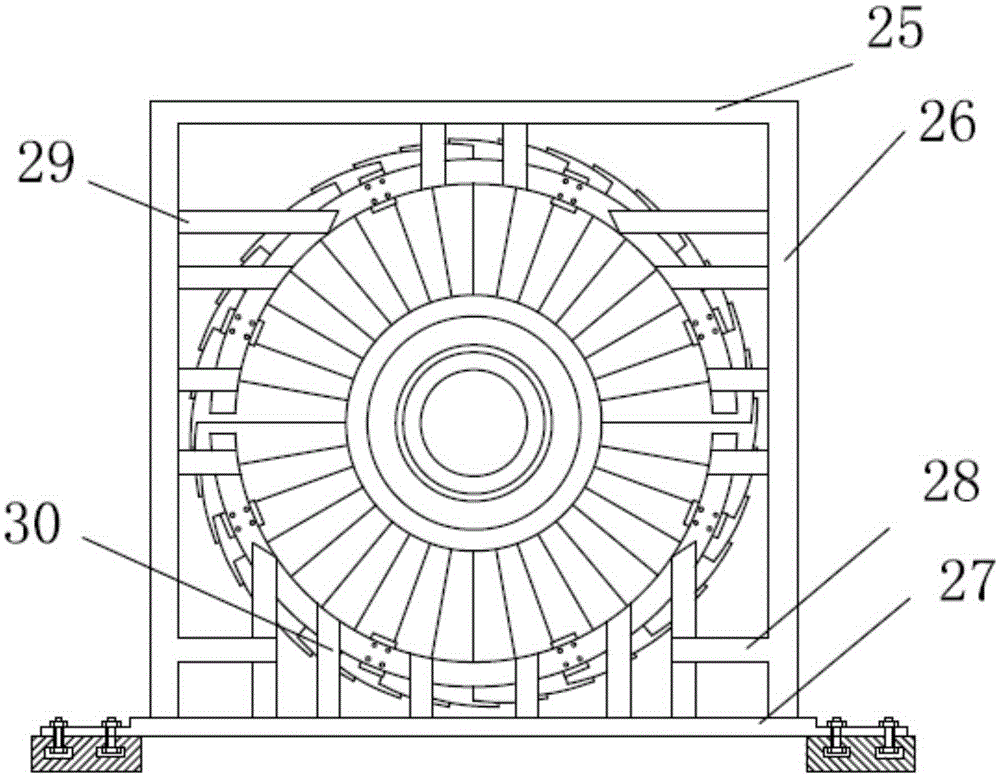

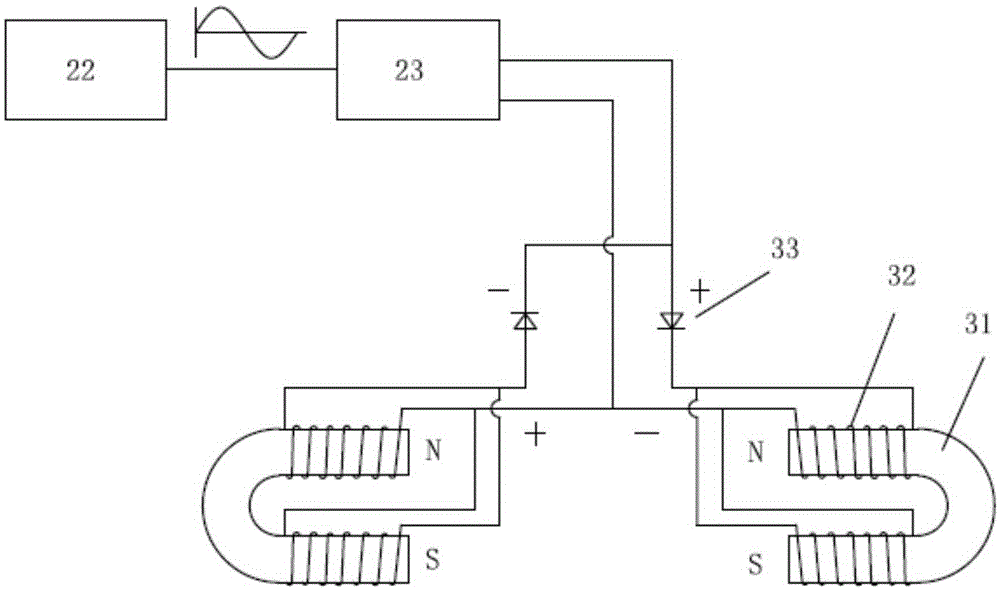

[0032] One or more sets of electromagnetic exciters 9 are selected and arranged along the circumference of the impeller 1, and the brackets of the electromagnetic exciters are fixed on the track 5 of the pendulum frame inside the cylinder. A pair of electromagnetic exciters 9 are symmetrically arranged on the front and rear sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com