PTC inorganic composite material and preparation method and application thereof

An inorganic composite material and carbon material coating technology, which is applied to heating element materials, non-adjustable metal resistors, electrical components, etc., can solve the problems of affecting the service life of materials, uneven conductivity, and increasing costs, and achieve extended use The effect of life, overheating and power runaway increase, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) In nano-ceramic materials composed of metal oxides, non-metal oxides, and metal borides, the molar ratio of each element is 5-15% for Ti, 20-50% for Si, 1-5% for Fe, and B 5-10% for O, 50-70% for O;

[0035] 2) 75kg of the above-mentioned nano-ceramic material, 20kg of nano-scale graphite with a thickness below 100nm, and then add 0.5kg of polyvinyl alcohol and an appropriate amount of ethanol to a solution state, use a cell pulverizer to mix and pulverize for 30min, and control the speed at 800rpm;

[0036] 3) After evaporating ethanol to dryness, heat-treat the obtained product to remove polyvinyl alcohol. 2 Protect;

[0037] 4) After the heat treatment product is ground and sieved, it is evenly compounded with the carbon paste, and the addition ratio is 2wt%, that is, the carbon paste with PTC properties and enhanced far-infrared performance is obtained.

Embodiment 2

[0039] 1) In nano-ceramic materials composed of metal oxides and non-metal oxides, the molar ratio of each element is 10-20% for Ba, 5-30% for Ti, 5-10% for Si, and 5-10% for Ag. %, O is 50-75%;

[0040] 2) 95 kg of the above-mentioned nano-ceramic material, 10 kg of graphene oxide with a thickness below 50 nm, then add 5 kg of polyethylene glycol and an appropriate amount of ethanol to a solution state, and use a vacuum ball mill to perform ball milling for 2 hours at a speed of 500 rpm;

[0041] 3) After evaporating ethanol to dryness, heat treatment was carried out on the obtained product to remove polyethylene glycol. The heat treatment temperature was 150° C. 2 Protect;

[0042] 4) After the heat treatment product is ground and sieved, it is uniformly compounded with the carbon paste, and the addition ratio is 5 wt%, that is, the carbon paste with PTC properties and enhanced far-infrared performance is obtained.

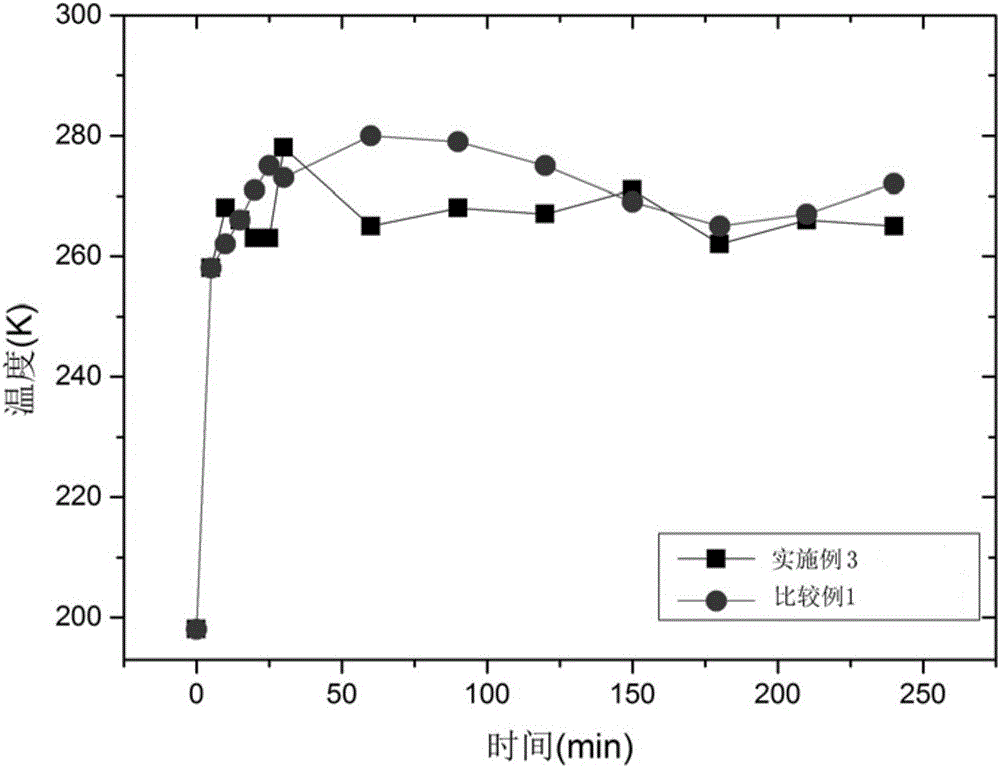

Embodiment 3

[0044] 1) In nano-ceramic materials composed of metal oxides, non-metal oxides, and metal borides, the molar ratio of each element is 10-30% for Ti, 5-10% for Fe, 10-20% for Si, and 10-20% for Cu. 5-10% for Sn, 1-5% for Sn, 50-70% for O;

[0045] 2) 80kg of the above-mentioned nano-ceramic material, 1kg of graphene with a thickness below 30nm, and then add 1kg of polyethylene glycol and an appropriate amount of ethanol to a solution state, and 700W ultrasonic for 60min;

[0046] 3) After evaporating ethanol to dryness, heat treatment was carried out on the obtained product to remove polyethylene glycol. The heat treatment temperature was 150° C. 2 Protect;

[0047] 4) After the heat treatment product is powdered and sieved, it is uniformly compounded with the carbon paste, and the addition ratio is 4wt%, that is, the carbon paste with PTC properties and enhanced far-infrared performance is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com