High-temperature alloy cold material pulling two-segment type electric quenching softening annealing technology

A softening annealing, two-stage technology, which is applied in the softening annealing of large-size round rods and hexagonal superalloy cold-drawn materials, and the softening annealing process of two-stage power electric heating, which can solve the problems of reduced yield, tip breakage, and softening. Problems such as poor annealing effect, to achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

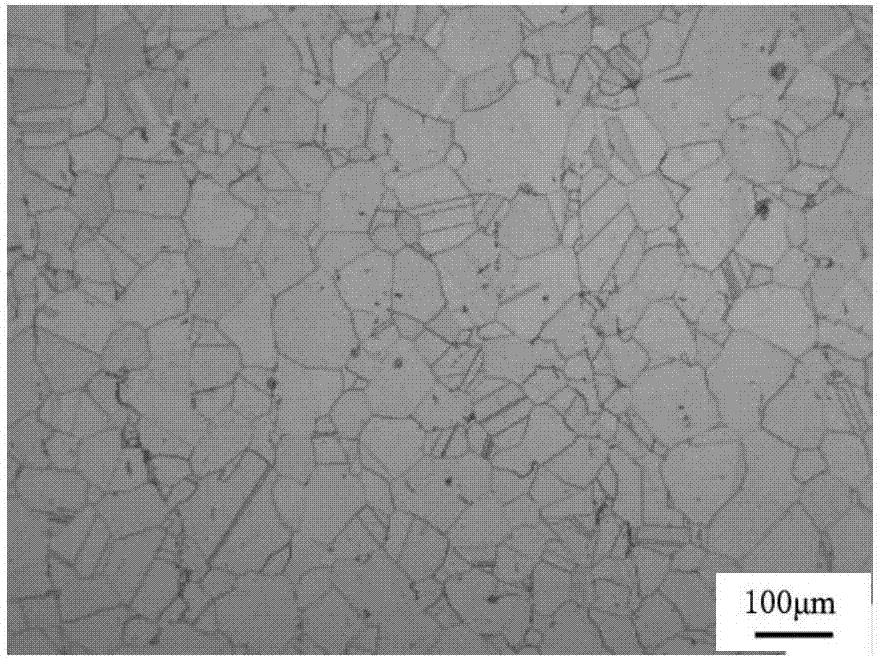

[0018] The hexagonal finished product size of nickel base hard-to-deform GH4738 alloy is S9mm, the billet diameter is Φ14mm, and the length is 3.2m~3.5m; The heating power is increased to 230kW, and after the billet is heated to 1100°C, the billet is quickly quenched in water (the time to stop heating until it enters the water is shorter than 5s). damage, grain structure such as figure 1 As shown, the grain size is grade 4, without over-burning and overheating.

Embodiment 2

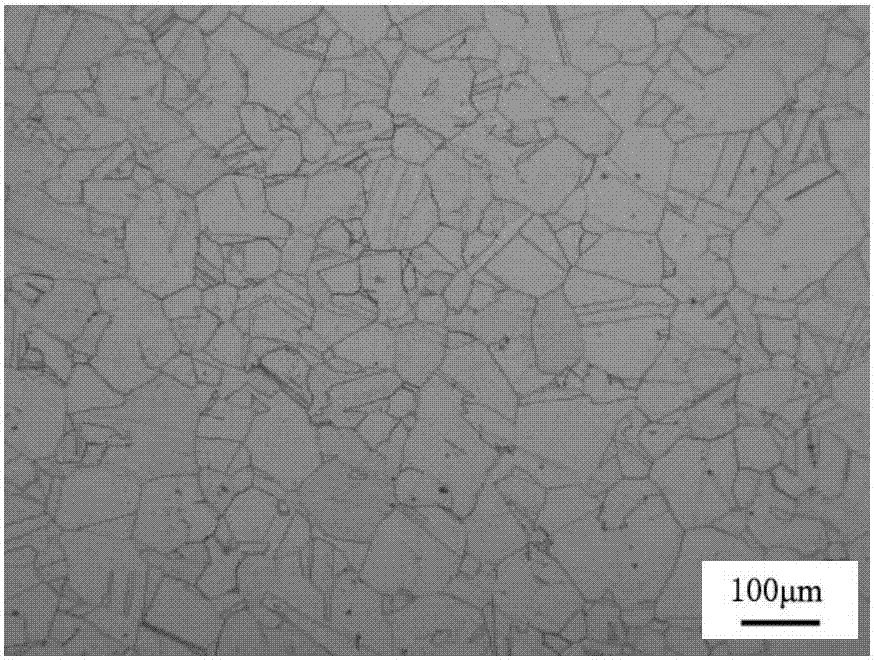

[0020] Nickel-based GH4033 alloy hexagonal finished product size S19mm, billet diameter Φ25mm, length 2.0m~2.5m, the heating power of the first stage of the billet is 180kW. Raise to 300kW, after the billet is heated to 1080°C, the billet is quickly quenched in water (stop heating until it enters the water for less than 5s). figure 2 As shown, the grain size is 4.5, without overheating and overheating.

Embodiment 3

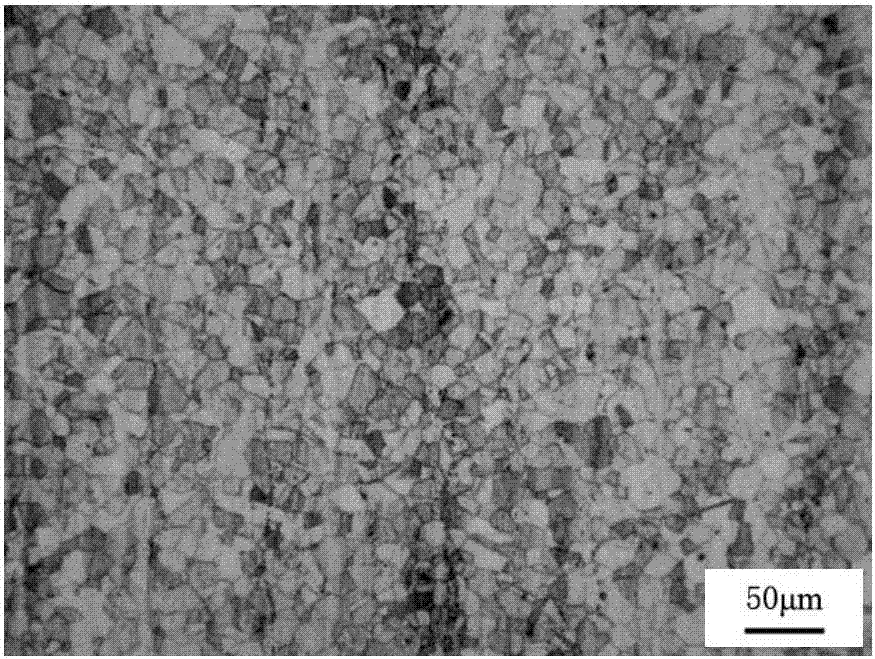

[0022] The iron-based GH2696 alloy hexagonal finished product size is S32mm, the billet diameter is Φ42mm, and the length is 3.2m~3.6m. The heating power of the first stage of the billet is 350kW. Raise to 450kW, after the billet is heated to 1060°C, the billet is quickly quenched in water (stop heating until it enters the water for less than 5s), the hardness (HBW) of the billet after annealing is 176, and the softening rate is 22.1%. image 3 As shown, the grain size is 8 grades, without over-burning and overheating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com