Efficient vortex blade-type gas-liquid separator core

A technology of vortex blades and liquid separators, applied in the field of mechanical products, can solve problems such as failure, short service life, and rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

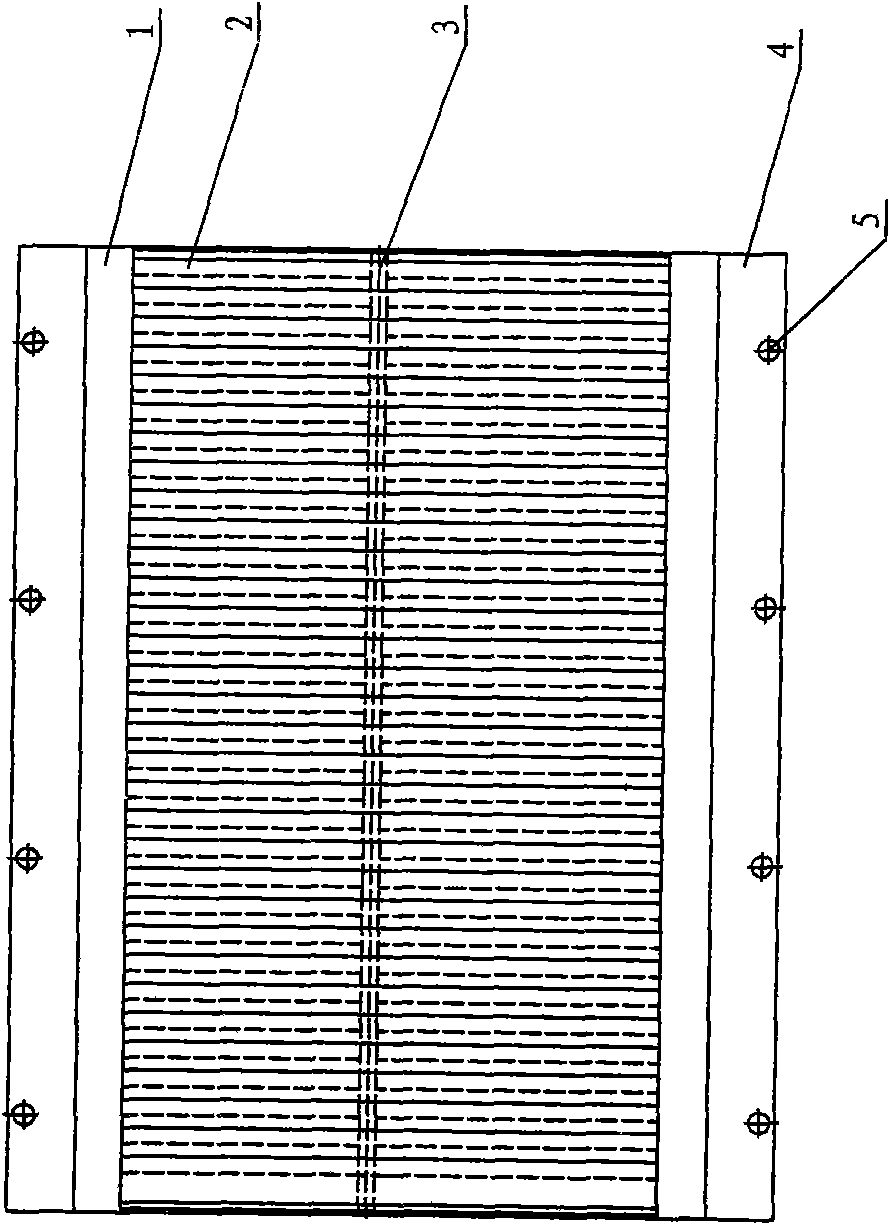

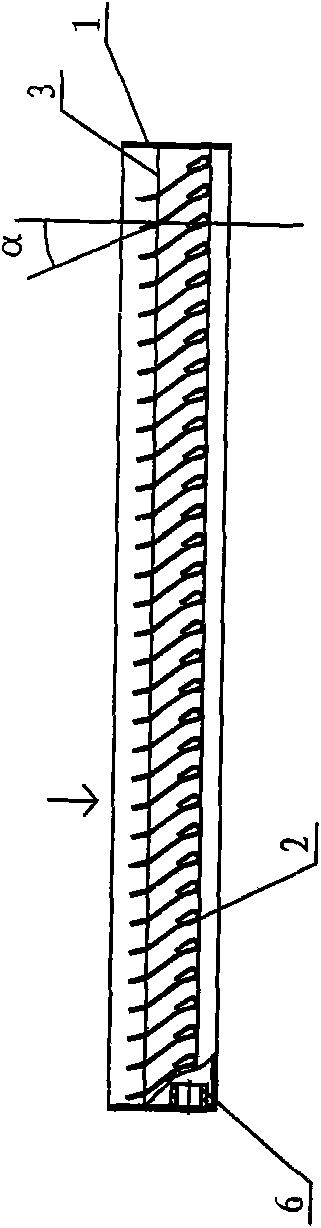

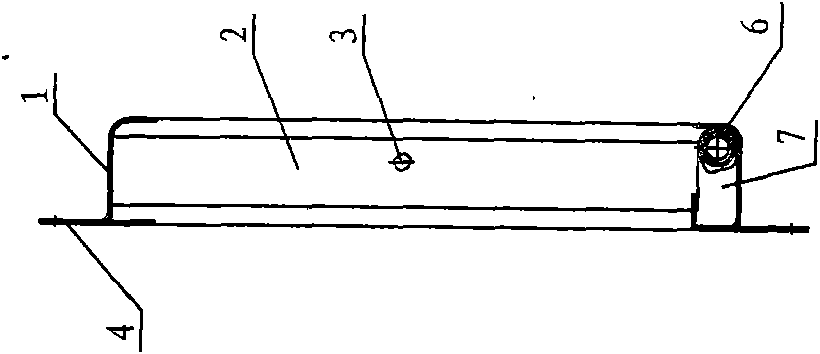

[0015] see figure 1 , 2 3. The present invention adopts a stainless steel plate to make a rectangular frame 1. The upper and lower frames of the frame 1 extend outwards with skirts 4, on which four screw holes 5 are respectively drilled, so that the present invention is installed in application. A drain groove 7 is also designed on the lower frame of the frame 1 and a drain port 6 is provided at the left end. Especially in the framework 1 of the present invention, 32 hooked vortex separation blades 2 are vertically arranged side by side, and a gap of 25 mm is maintained between the blades (the value can be taken between 20-30 mm). Each hooked vortex separation blade 2 described in the present invention is arranged at an angle of 20° with the vertical axis as the axis (generally, the rotation angle α is 10-30°), forming an overlapping arrangement, so as to ensure the gas-liquid flow direction , The head end of the previous hooked vortex separation blade blocks the tail end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com