Integrated double mechanical seal

A mechanical seal and double-end technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of increased sealing cost, large axial space, complex structure, etc., and achieve good sealing effect and simple assembly structure , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

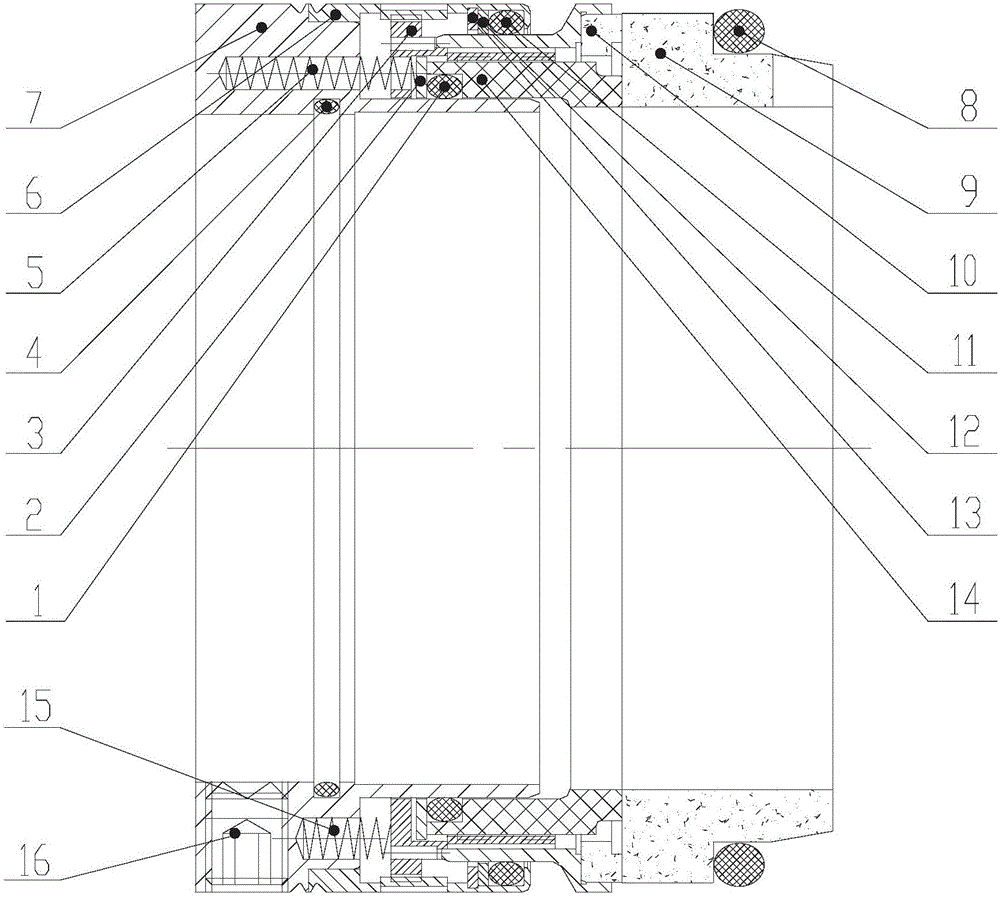

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the present invention includes a transmission seat 7, a static ring 9, a moving ring I10, a moving ring II14 and a floating transmission device, wherein the moving ring II14 and the moving ring I10 are sequentially sleeved on the outside of the transmission seat 7 from the inside to the outside, and move The inner wall of the ring II14 is sealingly connected with the transmission seat 7, and one end of the transmission ring I10 and the moving ring II14 is connected with the transmission seat 7 through a floating transmission device, and the other ends of the transmission ring I10 and the moving ring II14 are bonded to the static ring 9. The transmission seat 7 is radially provided with a set screw 16 for connecting with the rotating member, and the set screw 16 is a hexagon socket socket set screw with a concave end.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com