Efficient anti-scaling condensation pipe

A condensation tube and fouling technology, applied in evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of reducing condensation effect, increasing production cost, increasing copper tube wall thickness, etc., and achieves less chance of medium precipitation , increase the service life, reduce the effect of working stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

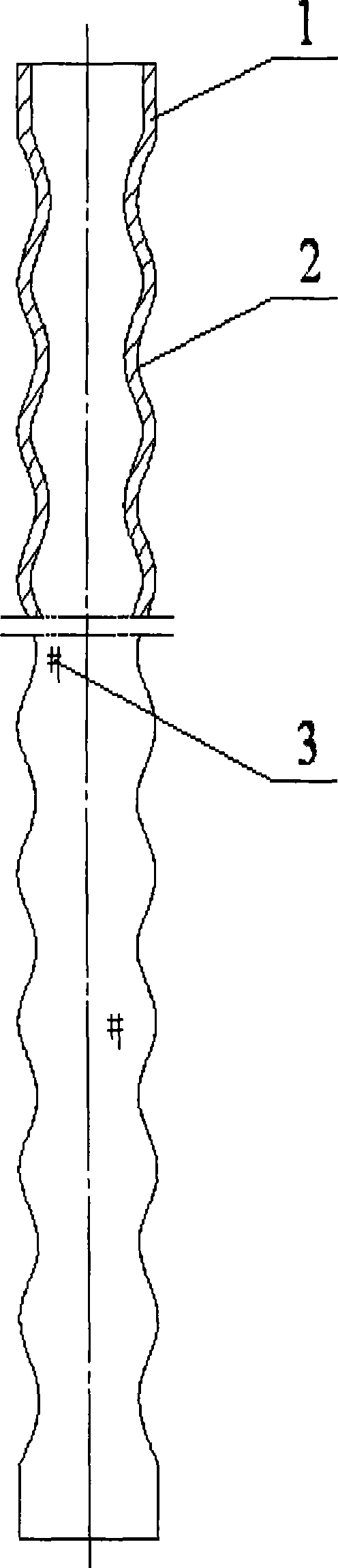

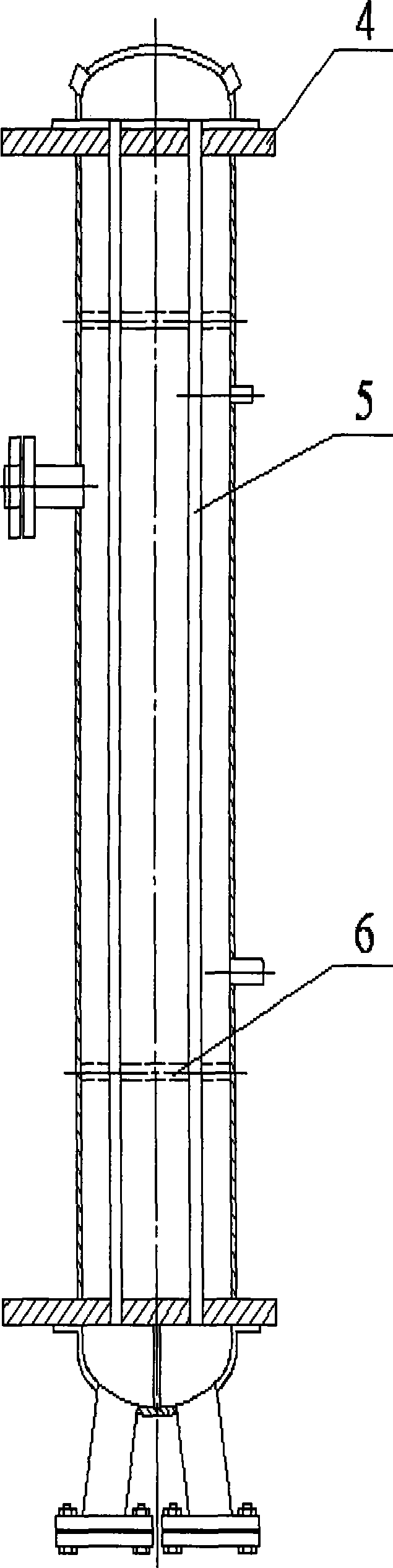

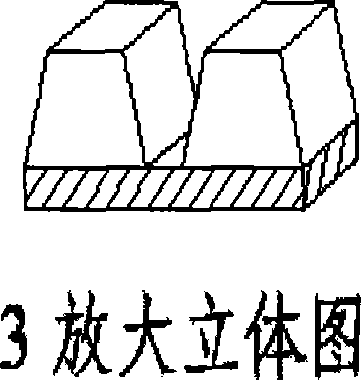

[0023] control figure 1 , the condenser pipe 5 of the present embodiment is made of thin-walled stainless steel, and its two ends are equal-diameter straight pipes 1, and the middle part is a corrugated pipe 2, and the straight pipe 1 and figure 2 The tube sheets 4 in the condenser 5 are connected by welding or expansion. The diameter of the straight pipe 1 is greater than or equal to the outer diameter of the wave crest of the corrugated pipe 2; because the condenser pipe is long, the condenser 5 is supported by a baffle plate 6, and its span is generally 200-400 mm. The corrugated pipe 2 has a full arc structure, and the corrugation is formed by arc-shaped crests and troughs tangentially and evenly transitioned without any processing stress, avoiding stress corrosion. Protruding quadrangular pyramid bosses 3 are evenly distributed on the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com