Patents

Literature

40results about How to "The water quality is clear and transparent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

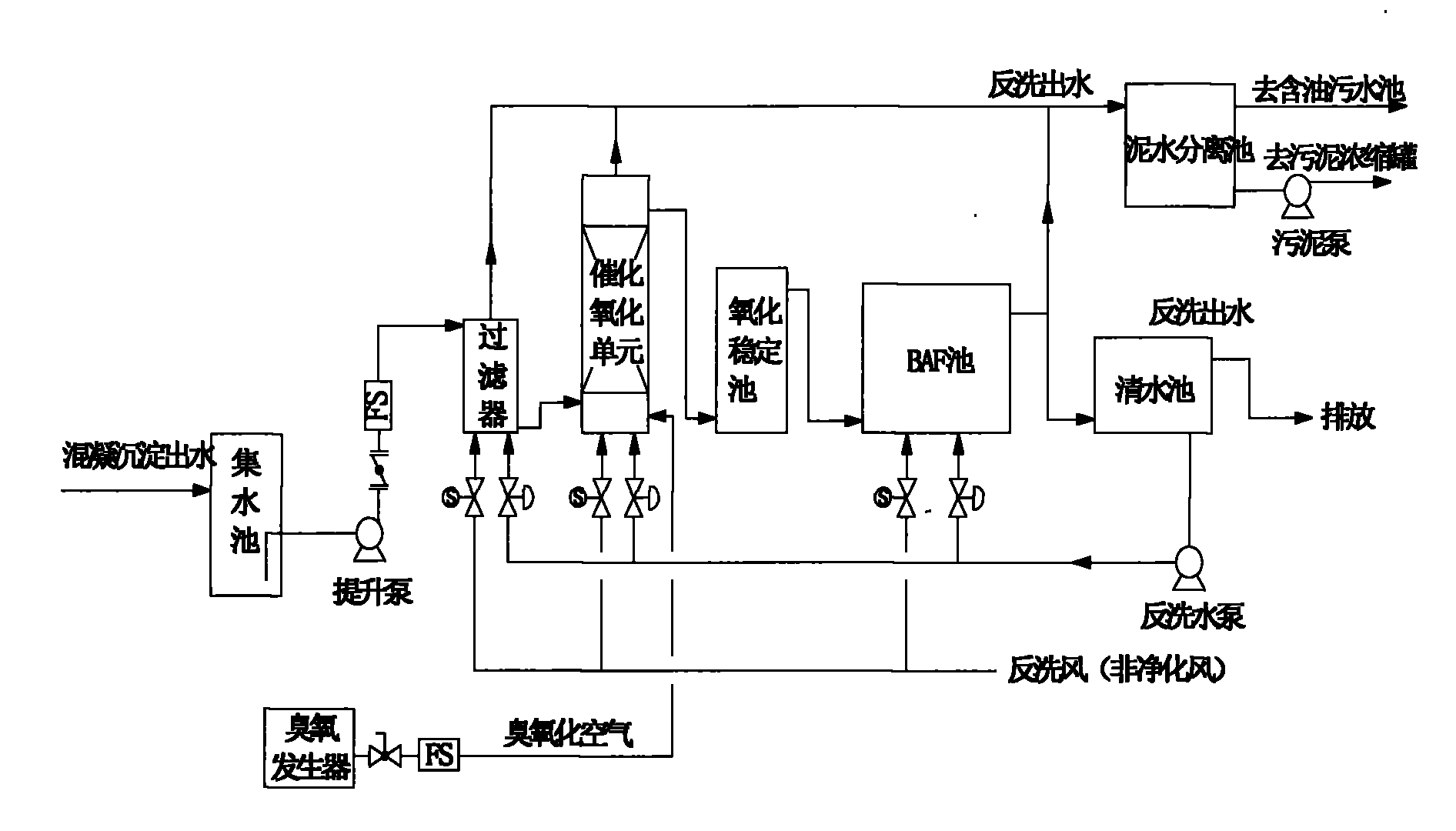

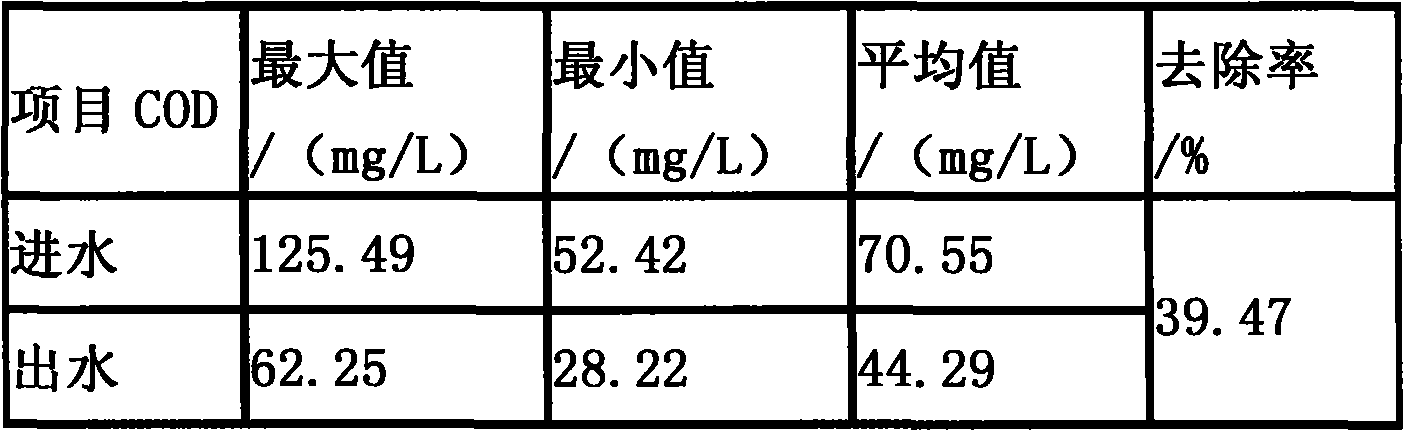

Method for advanced treatment of wastewater by using combination of catalytic ozonation and internal circulation biological filter

ActiveCN101863589ABreak through the biochemical limitImprove biodegradabilityMultistage water/sewage treatmentChemical industryBiological filter

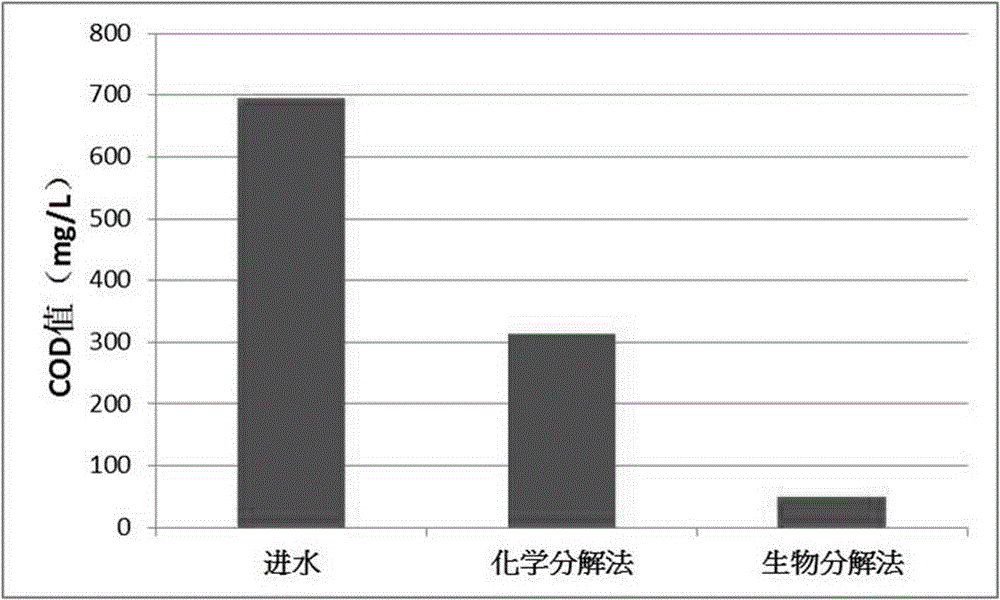

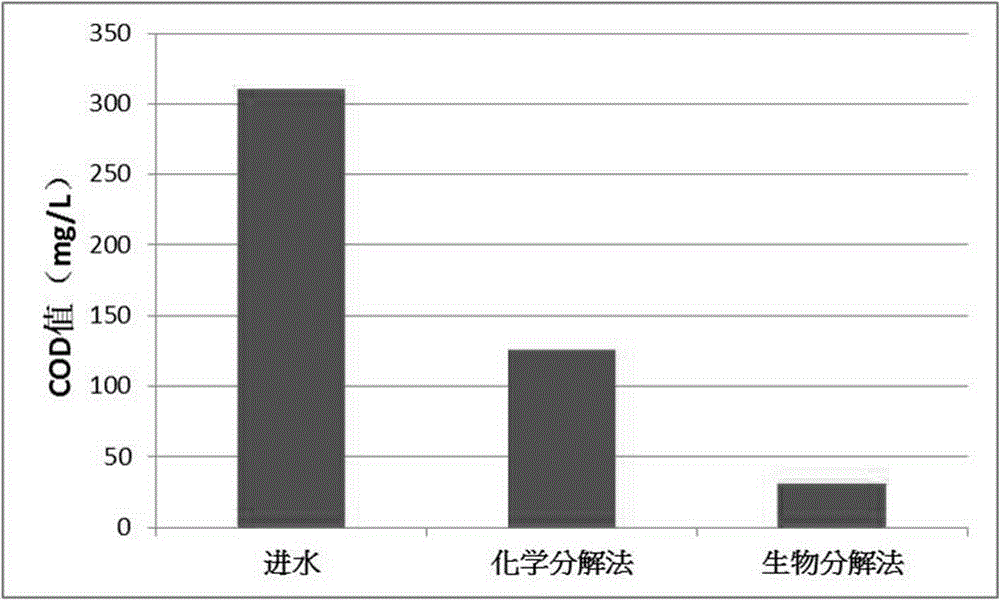

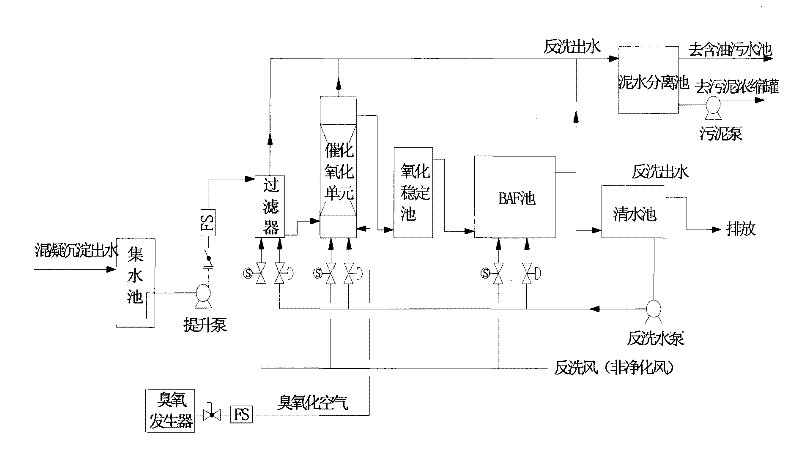

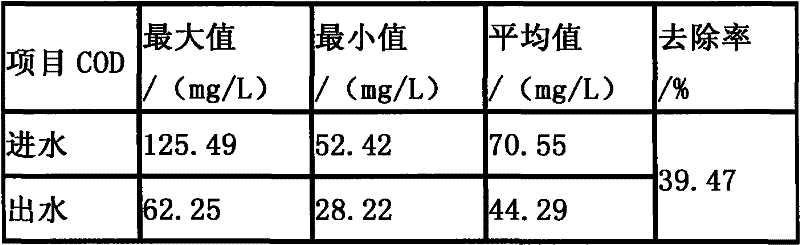

The invention discloses a method for the advanced treatment of wastewater. The method comprises the following steps of: 1) filtering off-standard wastewater, delivering the wastewater into a catalytic ozonation tower, and simultaneously adding ozone for contact oxidization reaction; 2) delivering the effluent of the catalytic ozonation tower into an oxidization buffer stabilization basin for stabilization; 3) and after the stabilization, delivering the effluent into a BAF basin for treatment, and delivering discharged water into a clean water basin. The method reduces the addition amount of the ozone, improves the utilization efficiency of the ozone, converts the ozone into hydroxyl radicals by using a metal catalyst, and reduces the activation energy of hydroxyl radical oxidation reaction to promote hardly biodegradable macromolecule organic substances in the wastewater to be oxidized into easily biodegradable micromolecule substances, so that the biochemical limit to refining the wastewater is broken through and the biodegradability of the wastewater is increased; and the water quality of the effluent can meet the provincial standard of Jiangsu province, namely Chemical Industry Main Water Pollutant Discharge Standard, completely by further treatment in the BAF basin.

Owner:CHINA NAT OFFSHORE OIL CORP +2

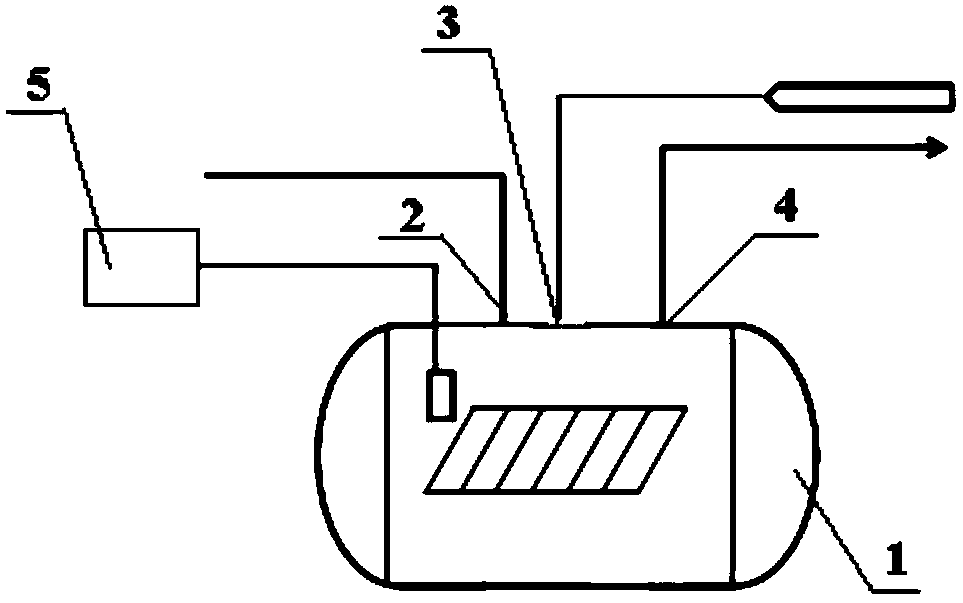

Integrated processing method of fracturing flow-back fluid

ActiveCN103539234AImprove processing efficiencySimple equipmentWater/sewage treatment with mechanical oscillationsWater/sewage treatment by oxidationPollutantPetroleum

The invention discloses an integrated processing method of fracturing flow-back fluid. The integrated processing method comprises the following step of carrying out three-dimensional electrode electrochemical treatment on the fracturing flow-back fluid under the conditions of ultrasonic waves and an oxidant, thus realizing processing of the fracturing flow-back fluid, wherein the three-dimensional electrochemical treatment is carried out in an electrolytic tank. The integrated processing method can be integrally finished in one set of equipment, and the equipment is simplified and the cost is reduced while the processing efficiency is intensified. The processing method can be used for efficiently removing harmful ingredients, such as petroleum, suspended solids, organic pollutants and the like in the fracturing flow-back fluid, has the processing effect remarkably prior to that of a single technology, and has an industrial application prospect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

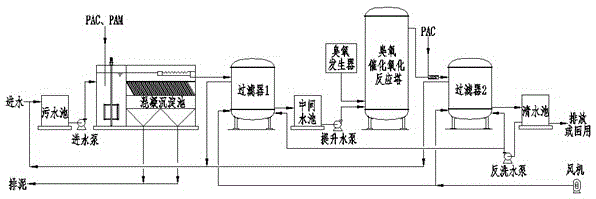

Petrochemical wastewater advanced treatment method

ActiveCN105060633AAvoid the problem of narrow adaptationIncrease profitMultistage water/sewage treatmentFlocculationFiltration

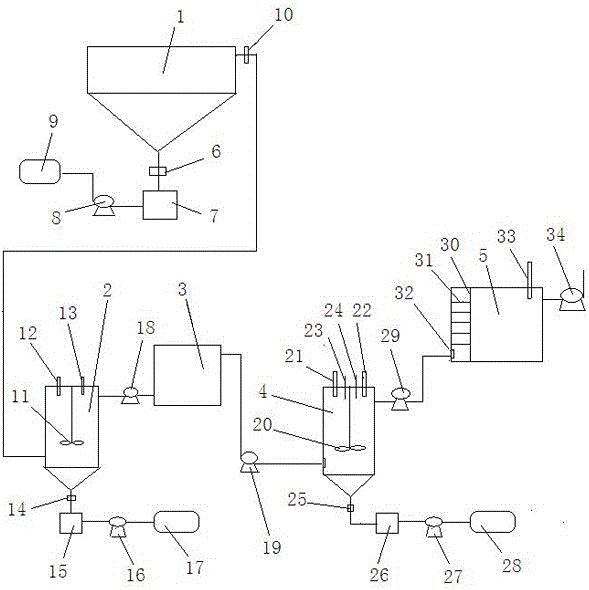

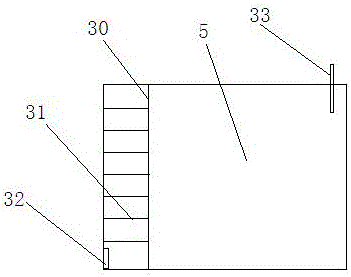

A petrochemical wastewater advanced treatment method includes the following steps: a, discharging secondary treatment effluent of petrochemical wastewater into a sewage pool, ascending the effluent into a coagulation sedimentation tank by a water inlet pump, at the same time, adding a flocculant PAC and a flocculant PAM to the coagulation reaction pool, determining the PAC adding quantity to be 10-30 mg / L and the PAM adding quantity to be 0.2-0.8 mg / L according to water quality conditions of the petrochemical wastewater, after sedimentation, allowing the effluent to enter a primary filter, filtering to remove residual suspended solids, and allowing the effluent after filtration to flow into a middle water pool; b, sending the wastewater in the middle water pool to a catalytic oxidation reactor by a lifting pump with the residence time of 0.5-1.5 h, feeding water and simultaneously adding ozone with the ozone adding quantity of 20-50 mg / L, and carrying out a catalytic oxidation reaction; and c, allowing the effluent of the catalytic oxidation reactor to self-flow through a pipeline mixer, adding the flocculant PAC in the pipeline mixer with the PAC adding quantity of 2-4 mg / L, allowing the wastewater after mixing to enter a secondary filter, carrying out micro-flocculation and filtration treatment, allowing clear water after filtration to enter a clear water pool, and meeting requirements of discharge or reuse.

Owner:PENYAO ENVIRONMENTAL PROTECTION

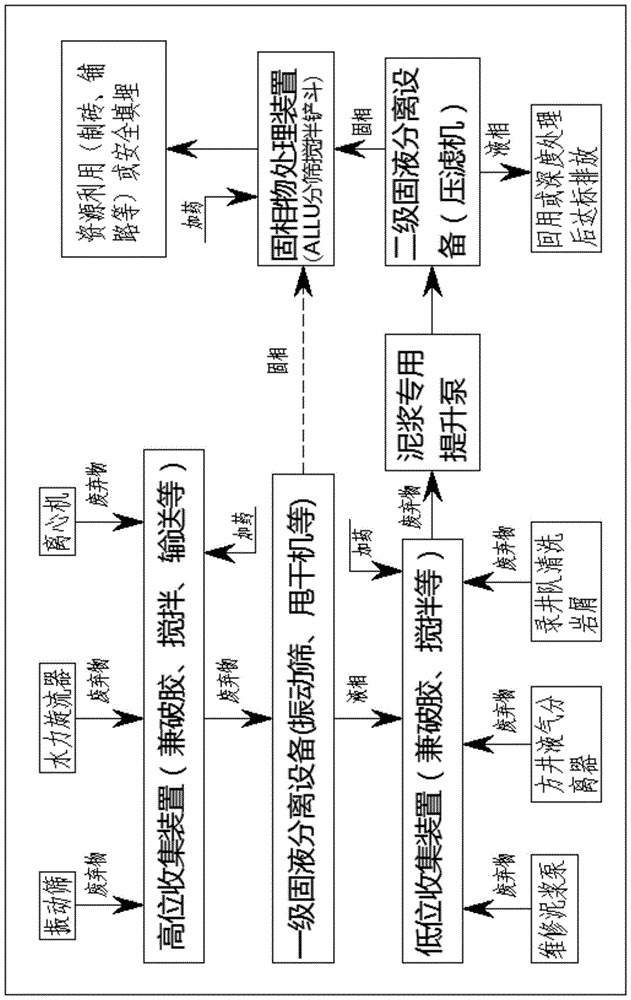

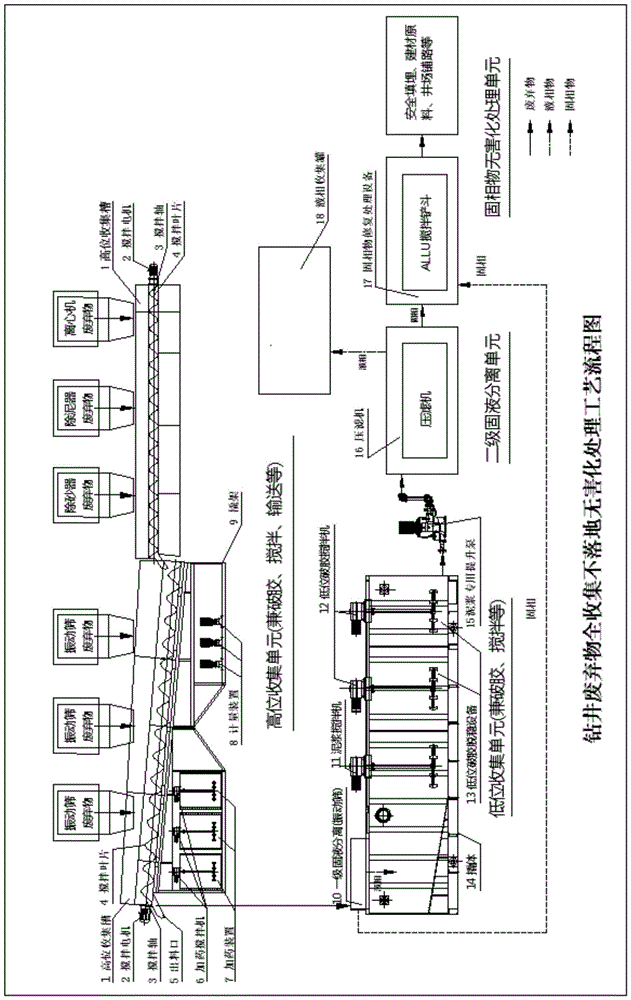

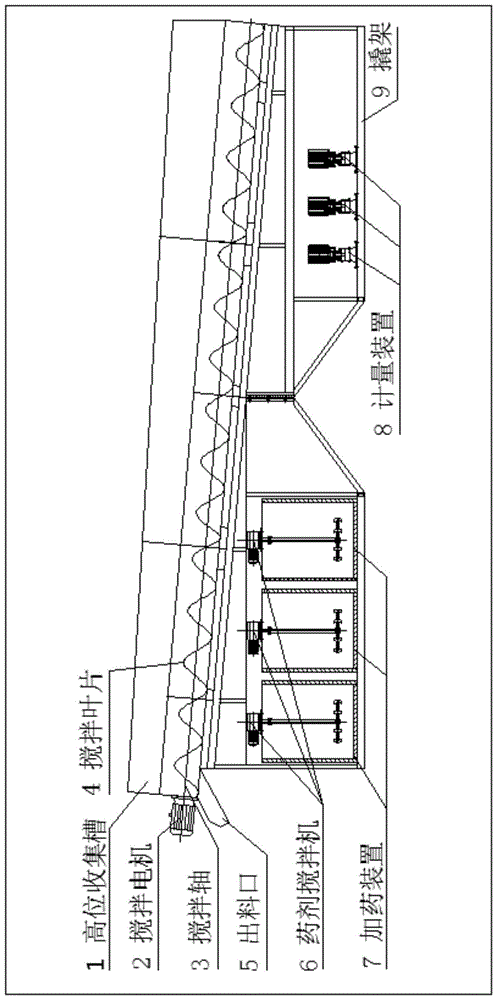

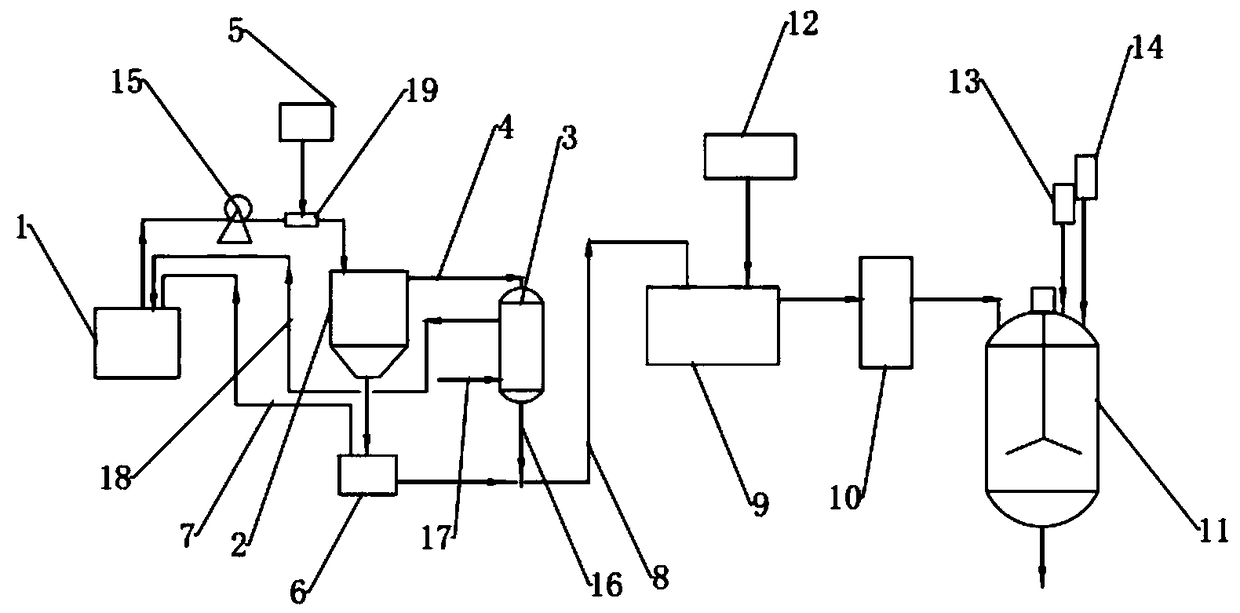

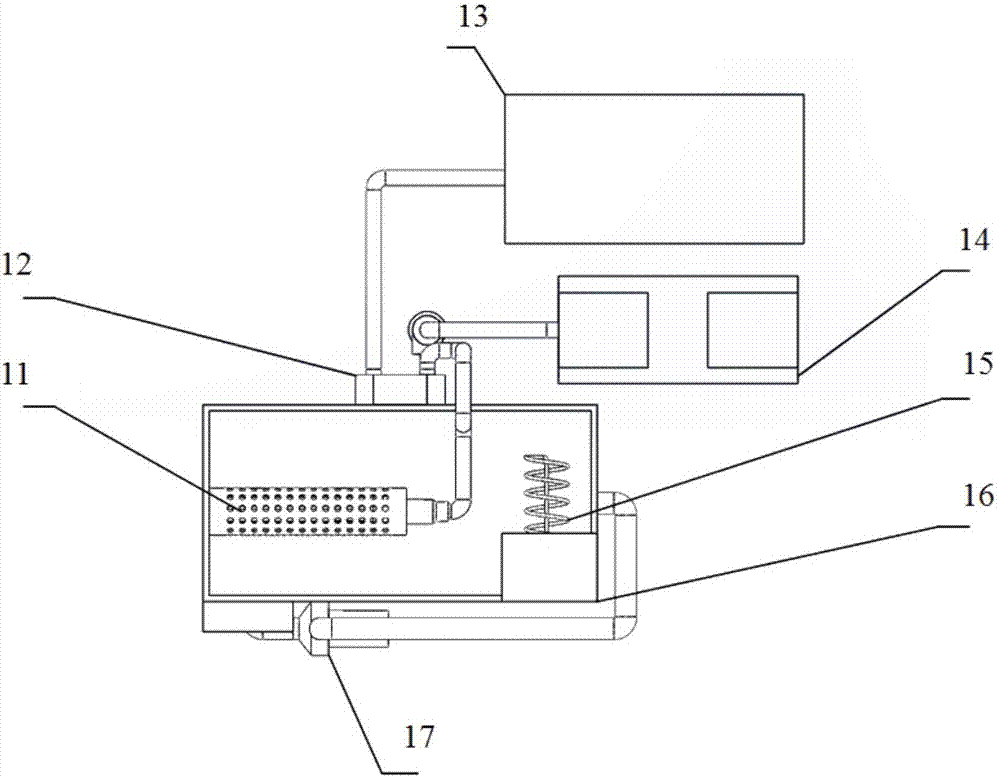

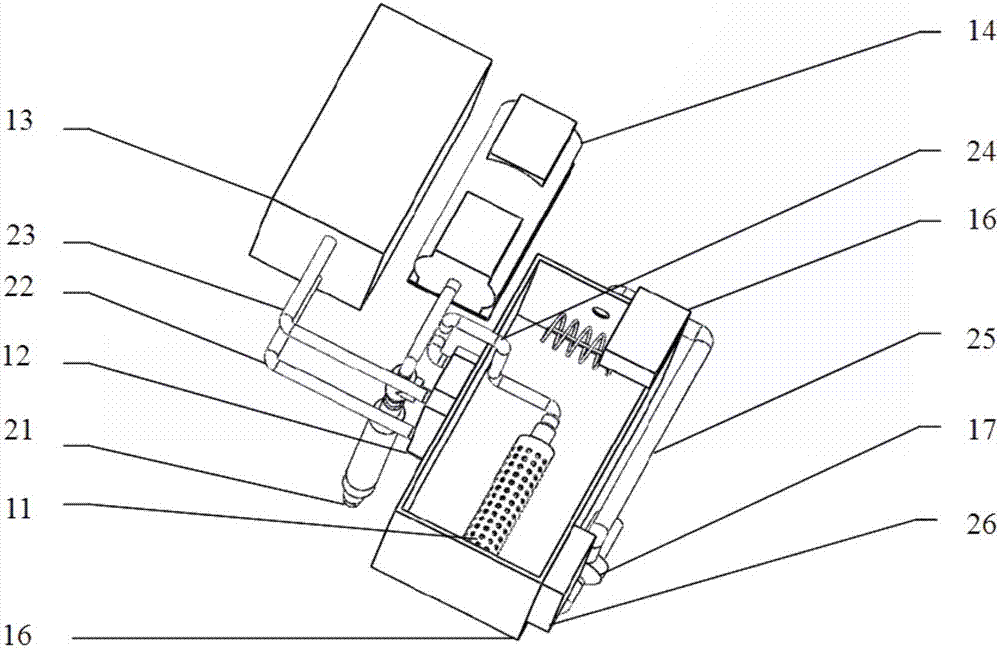

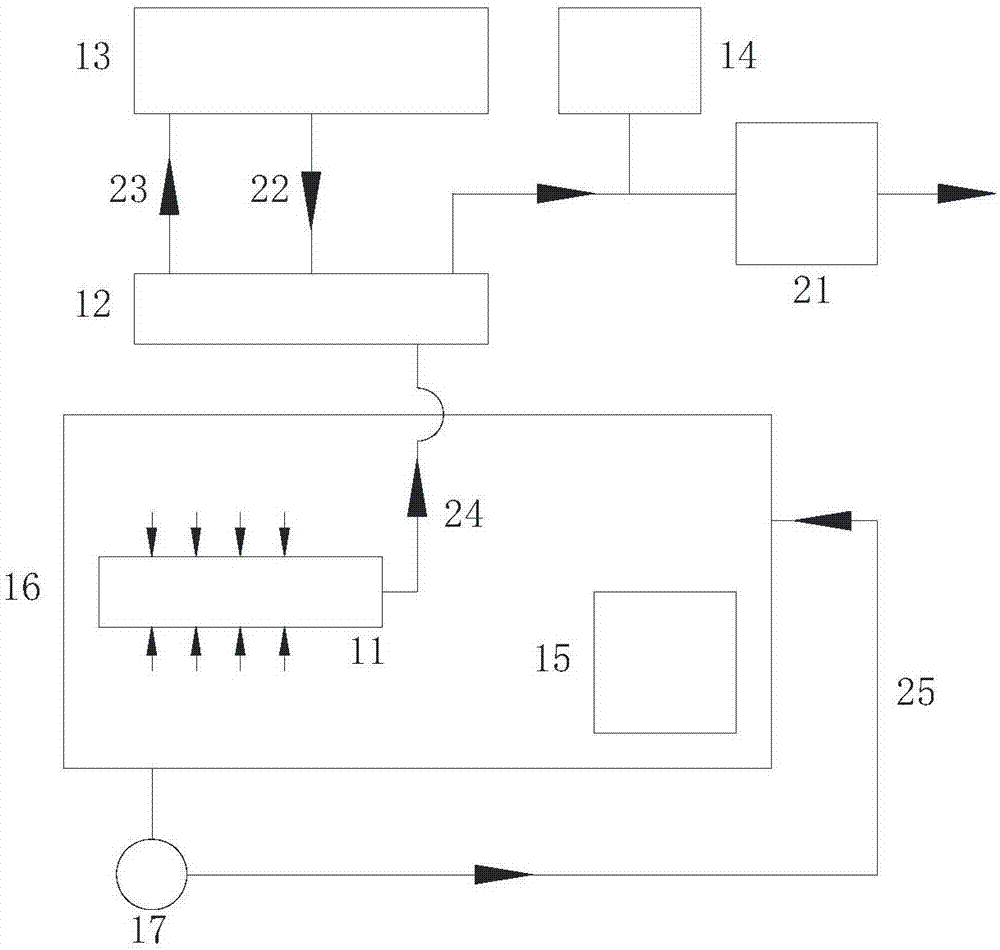

Process and device for complete-collection anti-falling harmless treatment on well drilling waste

ActiveCN105672948APrevent inflowThe water quality is clear and transparentBorehole/well accessoriesSolid phasesPollution

The invention discloses a process and a device for complete-collection anti-falling harmless treatment on well drilling wastes. The process comprises three steps of complete-collection and gel breaking treatment on well drilling wastes, solid-liquid separation treatment and efficient and harmless solid-phase treatment. Due to complete-collection anti-falling harmless treatment on the well driving wastes of an oil-gas field, the defects that wastes cannot be completely collected, solids and liquids cannot be thoroughly separated, and treated well drilling wastes are hard to meet the requirements of minimization, harmlessness and cleaner production when other while-drilling anti-falling treatment processes and techniques in China and other countries are adopted can be overcome, the purpose of preventing a well site and a surrounding environment from pollution caused by the well drilling wastes can be achieved, and moreover due to skid-mounted modulation design, the device is simple in equipment structure, flexible and convenient to operate, small in space occupation and low in investment, the efficacy, the normalization and the convenience of complete-collection anti-falling harmless treatment on the well drilling wastes of the oil-gas field can be greatly improved, and popularization and application of an anti-falling harmless treatment technique for well drilling wastes can be facilitated.

Owner:CHENGDU GUOSHENG ENVIRONMENTAL PROTECTION TECH

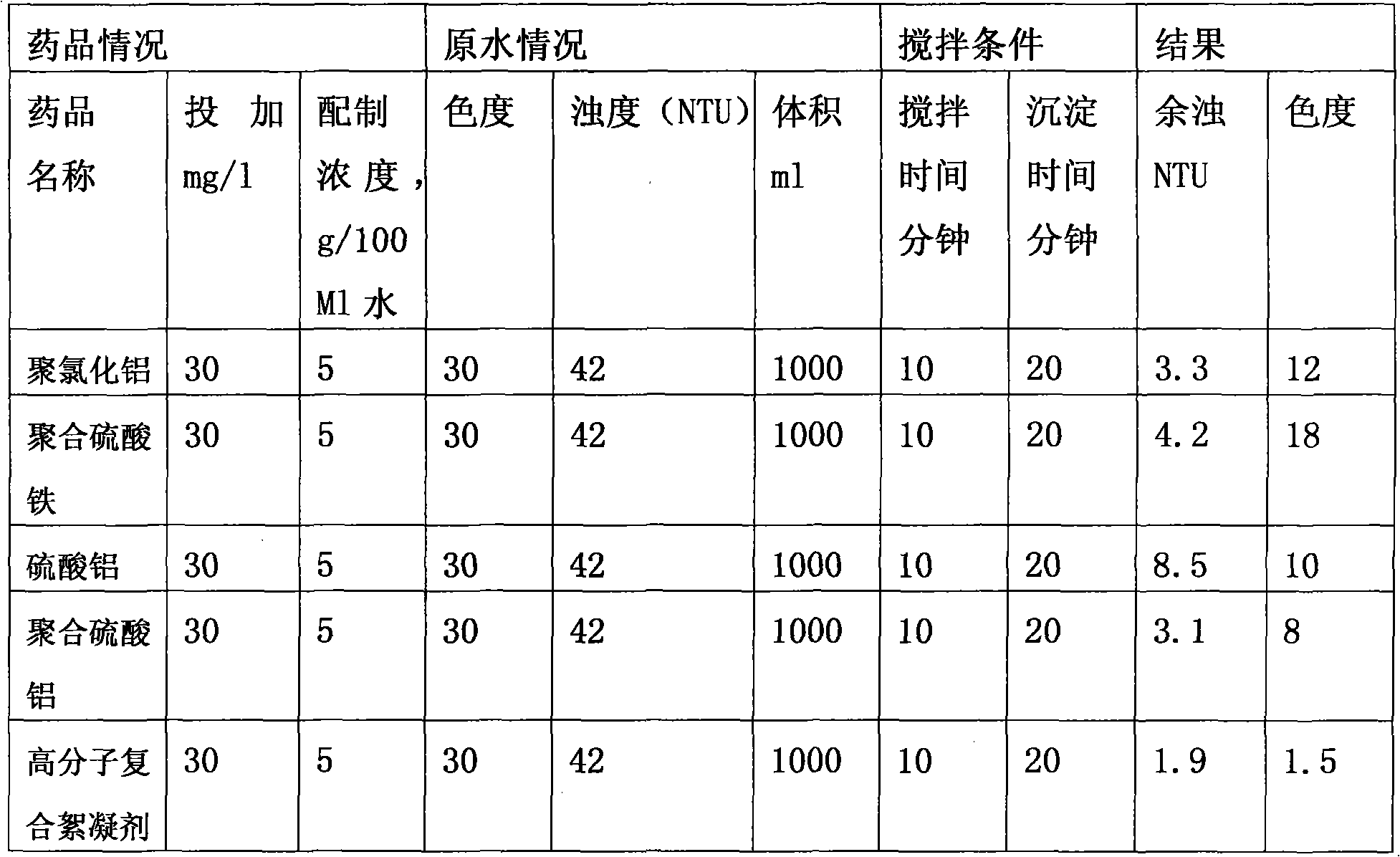

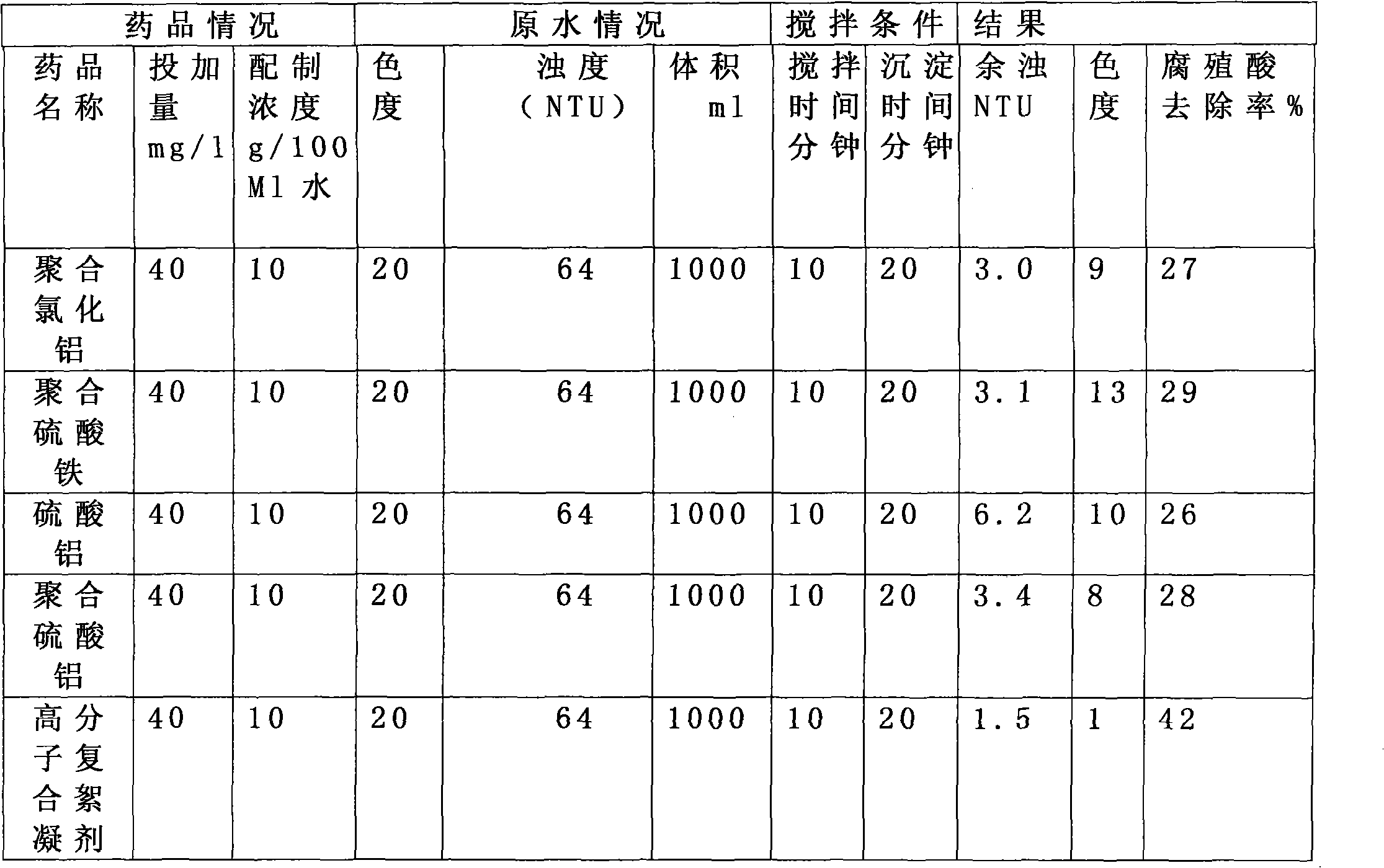

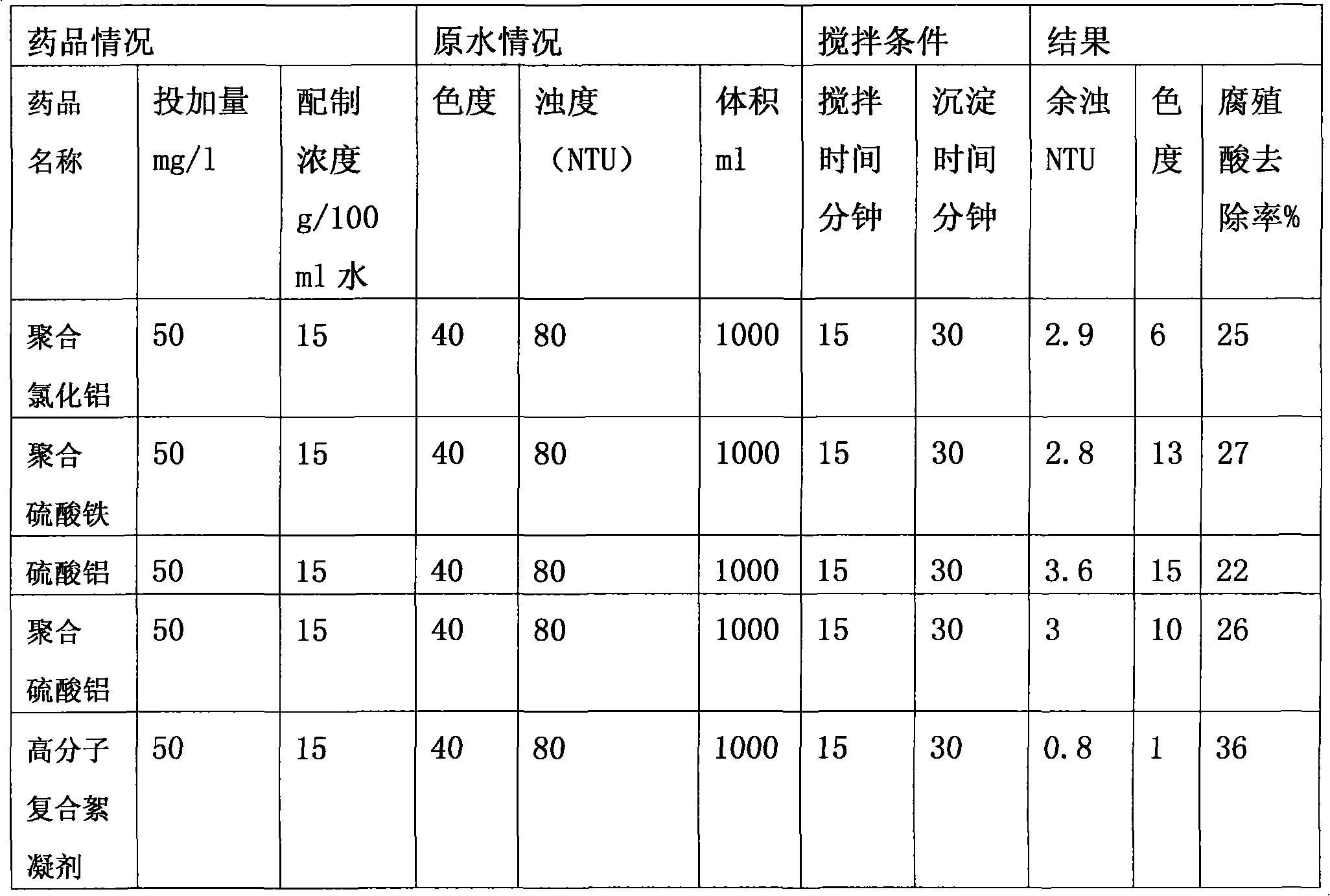

Macromolecular composite flocculant and preparation method and application thereof

InactiveCN101628749ASignificant progressWide variety of sourcesWater/sewage treatment by flocculation/precipitationIndustrial waste waterWater quality

The invention relates to a macromolecular composite flocculant and a preparation method and an application thereof, belonging to the water treatment technical field, in particular to a macromolecular composite flocculant prepared by combining polymeric aluminum sulfate and polydimethyldiallylammonium chloride and a preparation method and an application thereof. The composite flocculant comprises the following raw materials: 85-95% of polymeric aluminum sulfate water solution and 5-15% of polydimethyldiallylammonium chloride water solution. The invention provides the ideal macromolecular composite flocculant and the preparation method and the application thereof which have the advantage of simple preparation method, low production cost, wide sources of the raw materials, good decoloration effect to raw water with high chromaticity color and high humic acid, less dosage, clean and transparent treated water, safe and reliable drinking water and good deoiling effect to oily sewage. The composite flocculant can be widely used in the flocculation and defecation treatment and decoloration and deoiling treatment for drinking water, industrial circulating water, industrial wastewater and domestic wastewater.

Owner:ZIBO LUJING CHEM

Method of purifying immersed liquid in extraction process of algin, iodine and mannitol

InactiveCN101058530AReduce usageThe water quality is clear and transparentOrganic chemistryHalogen/halogen-acidsMANNITOL/SORBITOLIodine

The invention discloses a new purifying method of immersing liquid in the extracting course of algin, iodine and mannitol, which is characterized by the following: adopting tap water to soak sea-tangle for many times; merging the soaking liquid; adding flocculant; removing carbohydrate gum; making the mannitol density in the soaked liquid of sea-tangle to 1. 9-2. 5%.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

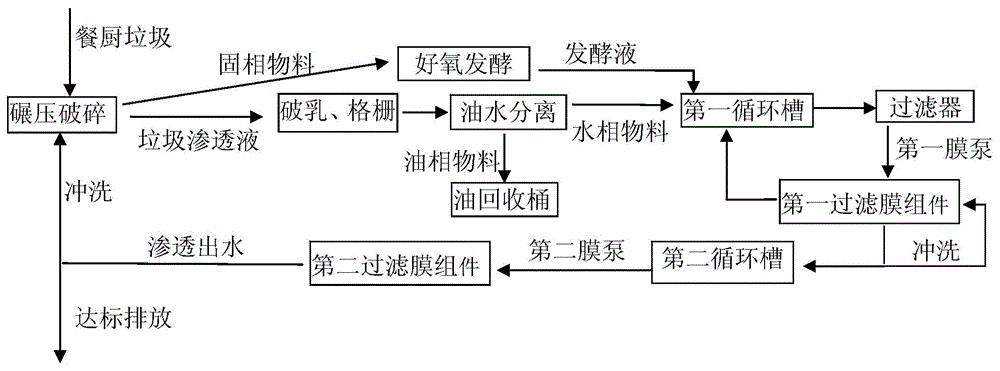

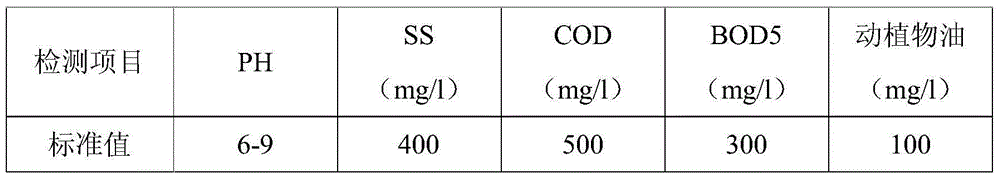

Kitchen waste treatment process

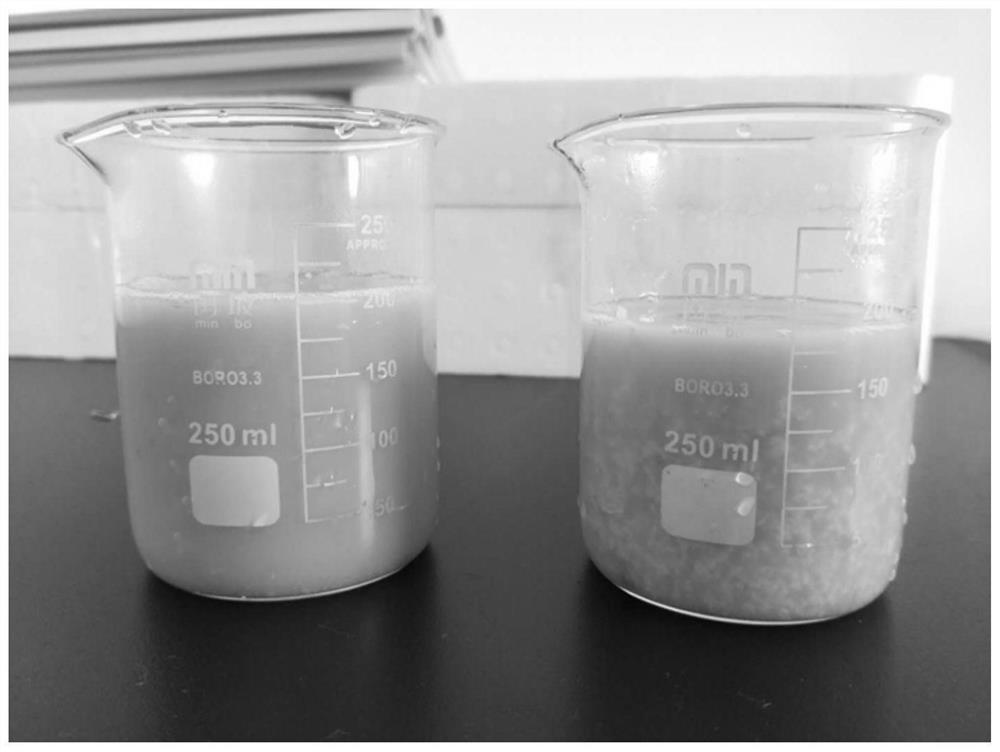

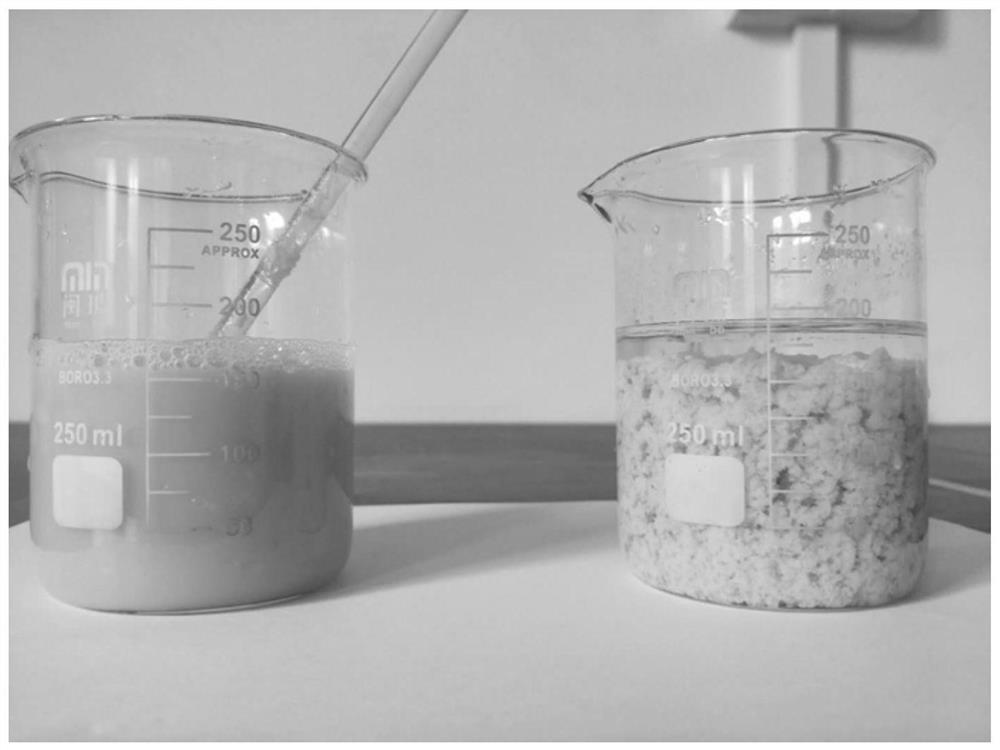

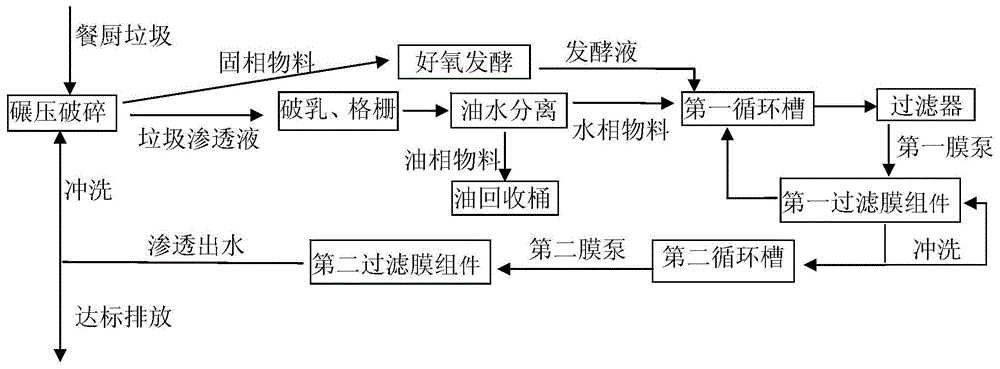

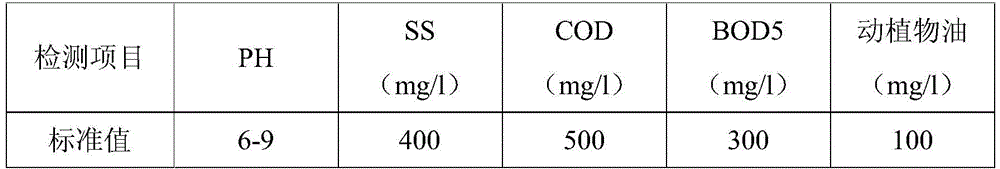

ActiveCN104959367AReduce CODEasy to handleSolid waste disposalClimate change adaptationCross-flow filtrationWater quality

The invention relates to a kitchen waste treatment process. The kitchen waste treatment process comprises the following steps: (1) carrying out pretreatment for dividing the kitchen waste into a solid-phase material, an oil-phase material and a water-phase material through a pretreatment system; (2) carrying out primary filtering treatment for introducing the water-phase material into a first filtering system, wherein the first filtering system comprises a first filtering film component, the water-phase material is filtered by a cross flow filtration manner through the first filtering film component, the obtained filtrate is primary treatment water, and the trapped molecular weight of the first filtering film is 250000; and (3) carrying out secondary filtering treatment for introducing the primary treatment water into a second filtering system, wherein the second filtering system comprises a second filtering film component, the primary treatment water is filtered by a roll type filtering manner through the second filtering film component, the obtained filtrate is dischargeable water, and the trapped molecular weight of the second filtering film is 100. The treatment process is capable of effectively removing pollutants in the kitchen waste; the obtained water is clear and transparent and meets the discharge standard; in addition, the water production rate of the treatment process reaches over 85 percent.

Owner:SHENZHEN LONGJISHUN IND DEV

Phosphorus thiochloride production waste water emission reduction and purification treatment method

InactiveCN106007048AHigh removal rateSimple processWater contaminantsWaste water treatment from gaseous effluentsFiltrationWastewater

The invention provides a phosphorus thiochloride production waste water emission reduction and purification treatment method. The method is characterized in that phosphorus thiochloride storage tank absorption water is cyclically used as reaction kettle pot washing water and reaction kettle tail gas alkali absorption water; the reaction kettle pot washing water and the reaction kettle tail gas alkali absorption water are mixed to produce waste water; oxidizing agents are added into production waste water to perform oxidation reaction; filtration is performed to obtain production waste water filter liquid; a phosphorus removing agent is added into obtained production waste water filter liquid to perform deep dephosphorization; the obtained purification standard reaching production waste water is discharged. The method provided by the invention has the advantages that the technical flow process is simple; the speed is high; the operation is convenient; the cost is lower; the contaminant removal rate is high; therefore the method provided by the invention has good popularization values. The contaminants in the waste water can be effectively removed by the method; the treated waste water does not contain S<2-> ions; the mass concentration of the phosphorus, Al<3+> and COD is reduced; the water quality is clear and transparent; the national discharge standard is reached.

Owner:荆州沙隆达控股有限公司

Harmless treatment device and process for steel pickling waste liquid

InactiveCN109368857ARealize harmless and clean productionLess investmentTreatment involving filtrationWaste water treatment from metallurgical processLiquid wasteLiquid storage tank

The invention discloses a harmless treatment device and process for steel pickling waste liquid, and belongs to the technical field of waste liquid recovery and treatment. The device comprises a wasteliquid storage tank, a sedimentation tank and a sand filter tank which are sequentially connected by a pipeline, the sedimentation tank is communicated with the sand filter tank through a drainage pipe, and a venturi mixer is disposed between the sedimentation tank and the waste liquid storage tank and communicated with a lye tank through a pipeline. The bottom of the sedimentation tank is connected with a concentration tank which is communicated with the waste liquid storage tank through a wastewater pipeline. The concentration tank is sequentially connected with a pickling waste acid tank,a filtering device and a reaction kettle through a residue discharging pipeline, a scrap iron tank is connected to the top of the pickling waste acid tank, and a stabilizer tank and an oxidizer tank are connected to the top of the reaction kettle. Wastewater and waste acid produced by steel pickling in steel machining enterprises are comprehensively treated and utilized, and no wastewater, waste gas or waste residues are produced, so that the enterprises can truly achieve harmless clean production.

Owner:高密天福家纺有限公司

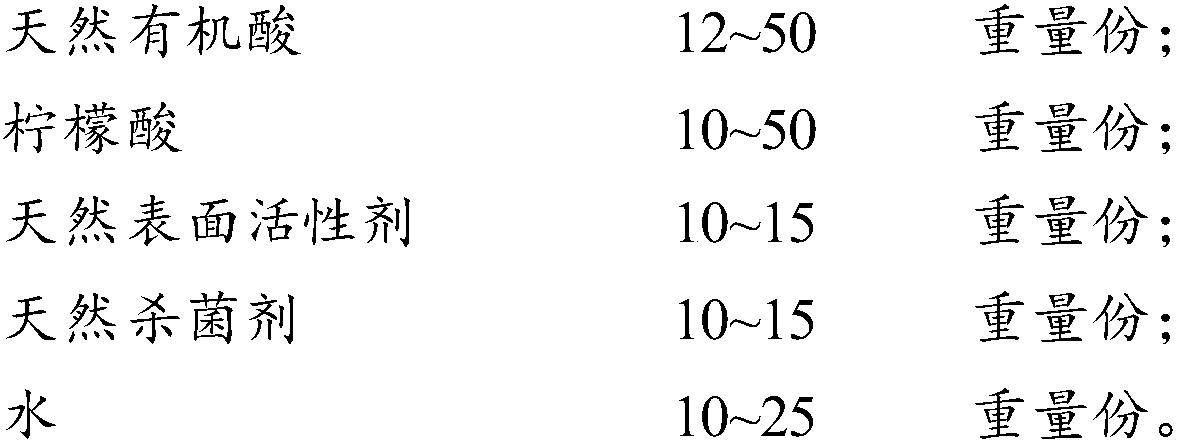

Drinking water pipe cleaning agent, and cleaning and maintenance methods of drinking water pipe

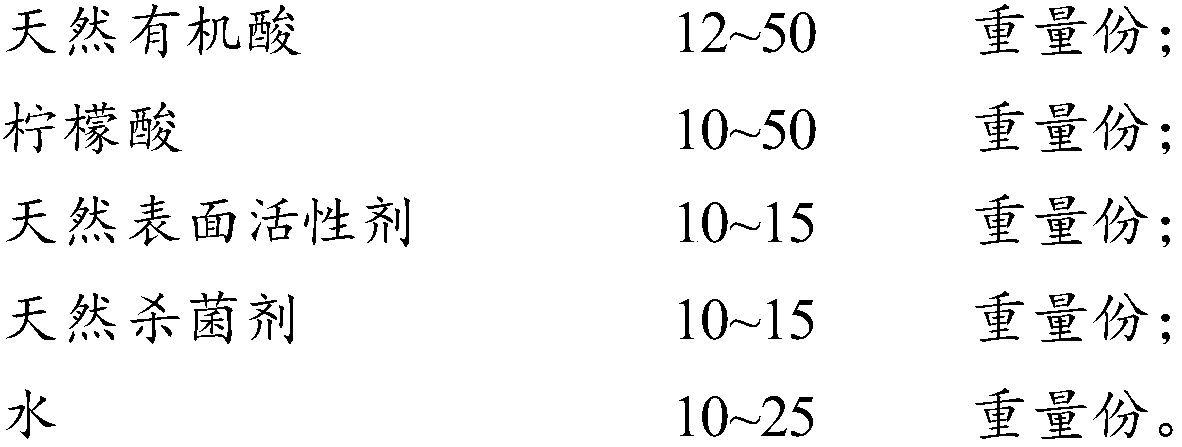

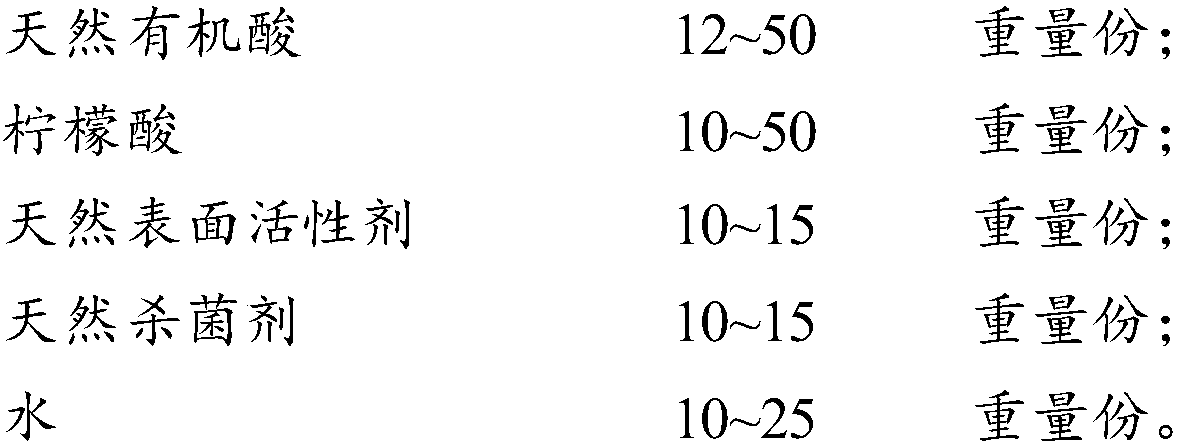

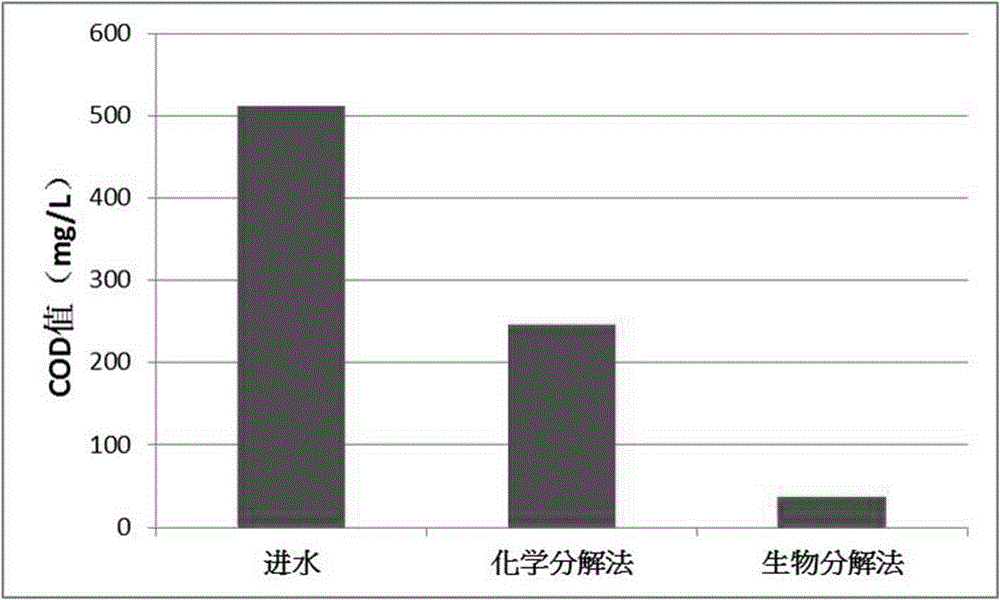

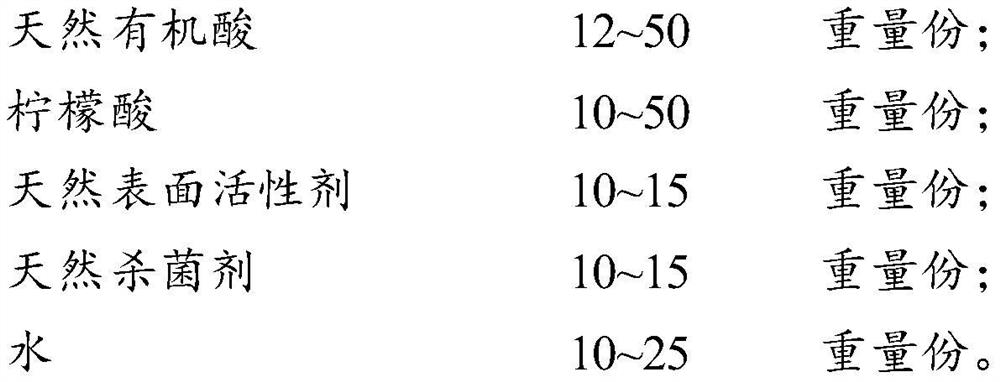

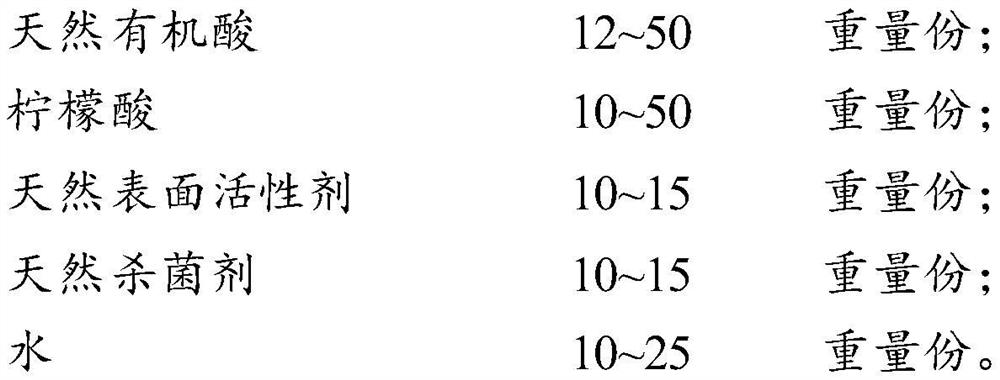

ActiveCN109234024AEfficient removalEffective sterilizationBiocideOrganic detergent compounding agentsChemical reactionSludge

The invention provides a water pipe cleaning agent. The water pipe cleaning agent is prepared from the components in parts by weight:12-50 parts of natural organic acid, 10-50 parts of citric acid, 10-15 parts of natural surfactants, 10-15 parts of natural sterilizing agents, and 10-25 parts of water. According to the water pipe cleaning agent, the cleaning agent produces physical and chemical reactions with water scale, iron rust and sludge on the inner wall of a water pipe, thus the water scale, the iron rust and the sludge can be effectively removed, and efficient sterilization is achieved. The water pipe cleaning agent is prepared from edible materials, secondary pollution to the water pipe is avoided, and even if the cleaning agent remains, no damage is caused to a human body; and the cleaning process is easy and convenient, cleaning equipment is simple and easy to obtain, the costs of the cleaning agent and the cleaning process are low, the acceptance degree is high, and the water pipe cleaning agent is suitable for large-scale application and popularization, and has wide development prospects.

Owner:广东顺德三阳化学有限公司

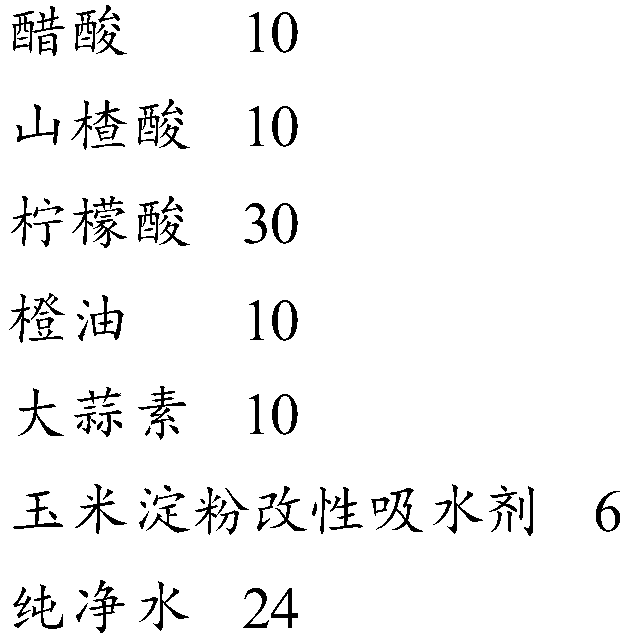

Condensed oil sewage degradation method for chemical oxygen demand standard

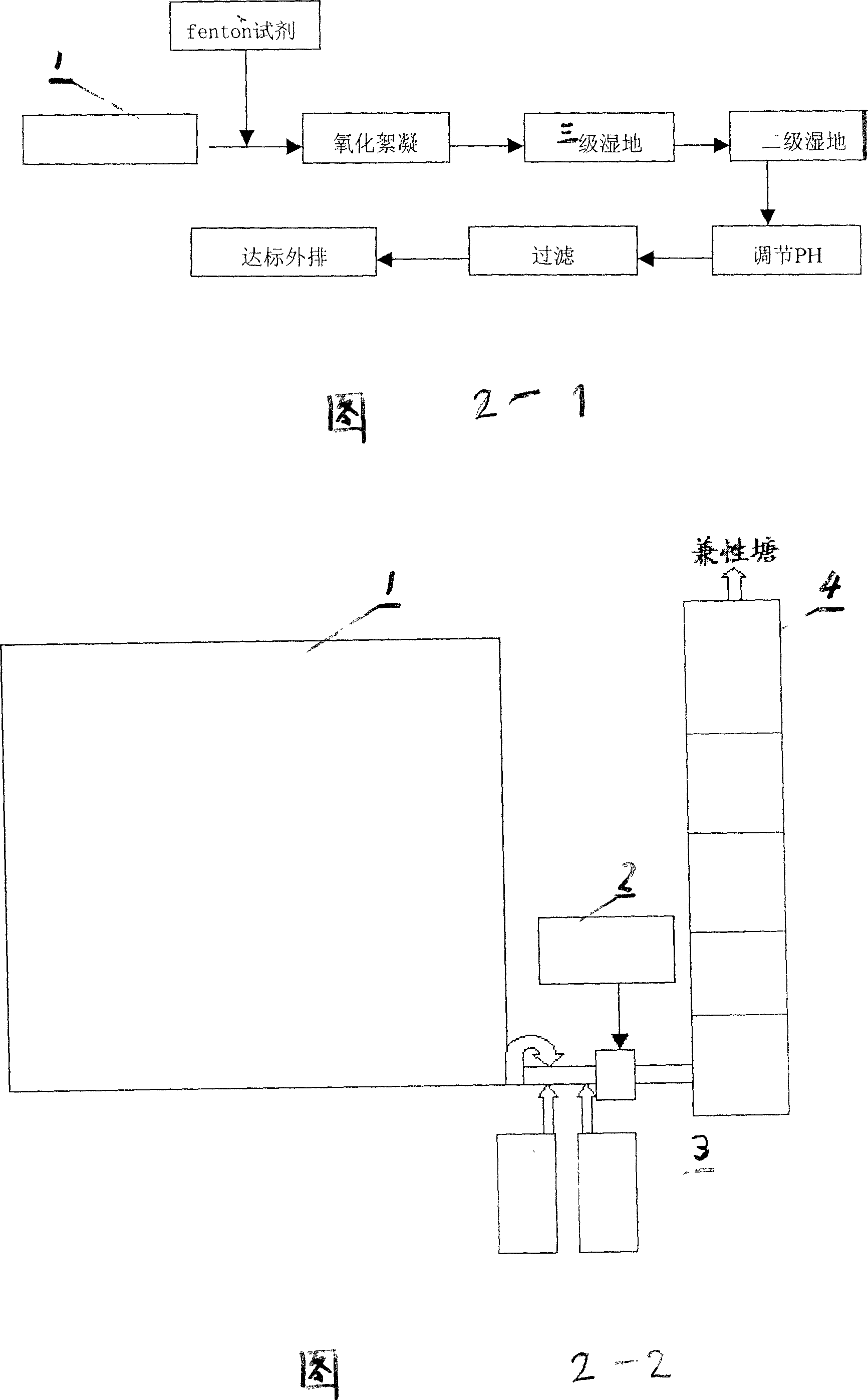

InactiveCN1994939AFast responseImprove efficiencyTreatment with anaerobic digestion processesMultistage water/sewage treatmentChemistryToxic material

The invention discloses a decomposing method of viscous oil effluent chemical oxygen demand, which is characterized by the following: fetching water from anaerobic pond; adding H2O2 solution and FeSO4 solution sequently; blending to react with effluent; making effluent not generate toxic material; dissolving water in the oil acid, alcohol and water; depositing after 2h; forming transparent non-odor oil chemical oxygen demand water to satisfy draining standard.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Acid wastewater treatment device utilizing membrane technique

PendingCN107321187AExcellent and stable effluent qualityGood separationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisExternal pressureSewage treatment

The invention discloses an acid wastewater treatment device utilizing a membrane technique. According to the acid wastewater treatment device, the technical problem that acid wastewater cannot be treated by virtue of a membrane material in the prior art is solved. The acid wastewater treatment device comprises a sewage treatment tank, wherein a membrane assembly unit is arranged in the sewage treatment tank, is used for filtering acid wastewater and comprises a pressure-bearing shell, a plurality of external pressure type membrane tubes are arranged in the pressure-bearing shell, a water inlet and a water outlet are respectively formed in two ends of the pressure-bearing shell, the external pressure type membrane tubes comprise support layers, and separation layers are arranged outside the support layers and are produced from multifunctional graphene / high molecular composite materials. According to the acid wastewater treatment device, the graphene / nanostructure multifunctional high molecular material separation layers adopted by the external pressure type membrane tubes have very strong corrosion resistance, acid-alkali resistance and mildew resistance and can be used for treating various acid wastewaters.

Owner:中山市创思泰新材料科技股份有限公司

Medicament preparation process flow for purifying and treating wastewater from xylose production and use method thereof

InactiveCN101585613AThe water quality is clear and transparentWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentChemical industryChemical Linkage

Owner:李界文

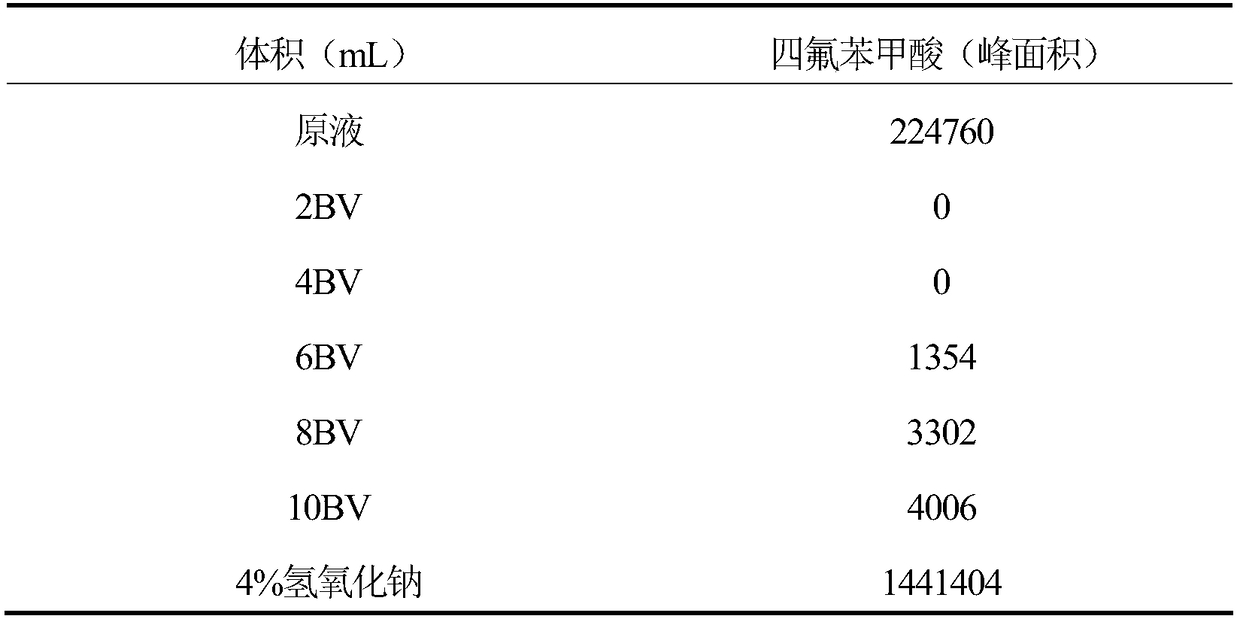

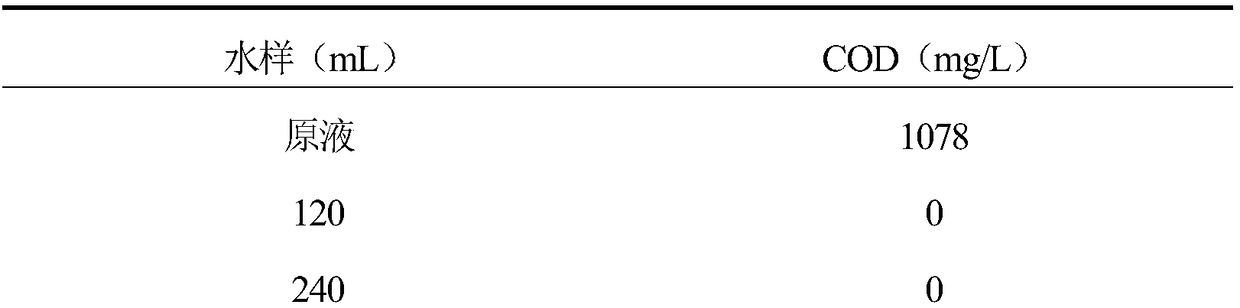

Tetrachloride phthalic anhydride waste water recovery and treatment method

ActiveCN109081777ASingle inputReduce contentCarboxylic compound separation/purificationResource utilizationFixed bed

The invention discloses a tetrachloride phthalic anhydride waste water recovery and treatment method. According to the method, tetrachloride phthalic anhydride waste water is precipitated and filteredto obtain waste water without suspended matters, the waste water without the suspended matters passes a fixed bed adsorption column with macroporous styrene adsorption resin, tetrachloride phthalic anhydride is adsorbed on the adsorption resin, inorganic salt and sulfuric acid are not adsorbed, the resin after saturated adsorption is eluted by sodium hydroxide water solution, and eluted sodium tetrachloride phthalic anhydride is concentrated, returned to a workshop and used. The tetrachloride phthalic anhydride waste water is treated, 95% or more of tetrachloride phthalic anhydride is recovered, and waste water treatment and resource utilization are unified.

Owner:西安瀚宇树脂科技有限公司

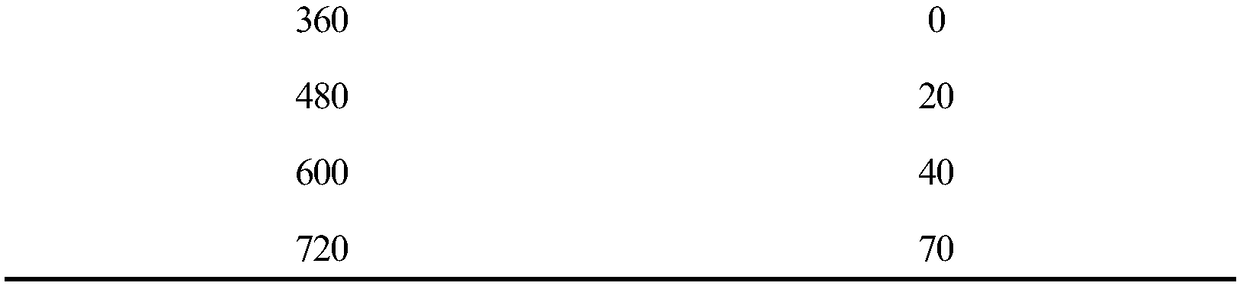

A treatment method and device for erythromycin thiocyanate extraction waste water

InactiveCN106946319ANo cloggingReduce extractionWater treatment parameter controlWater contaminantsFiltrationFilter system

A treatment method for erythromycin thiocyanate extraction waste water is disclosed. The method includes a) feeding the extraction waste water to a first membrane filtration system to obtain a first concentrated liquid and a first clear liquid; b) feeding the first concentrated liquid into a second membrane filtration system to obtain a second clear liquid; and c) combining and reusing the first clear liquid and the second clear liquid, and feeding a second concentrated liquid into a biochemical treatment system, wherein the first membrane filtration system ensures that the membrane flux of the extraction waste water under an operating pressure of 12-15 bar is 14-16 lmh and that the recovery rate is 55-60%; and the second membrane filtration system ensures that the membrane flux of the first concentrated liquid under an operating pressure of 26-30 bar is 17-20 lmh and that the recovery rate is 55-60%. A treatment device used for the method is also disclosed. Through the method and the device, ideal treatment effects on the extraction waste water can be achieved, and device blockage in a treatment process does not occur.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

Phosphorus trichloride production wastewater purification treatment method

InactiveCN106517480AReduce processing difficultyReduce lossesNature of treatment waterWater/sewage treatment by oxidationChemistrySewage treatment

The invention discloses a phosphorus trichloride production wastewater purification treatment method, characterized by adding an oxidizing agent into phosphorus trichloride production wastewater to obtain a mixture, stirring the obtained mixture, then reacting at room temperature, standing for layering after the reaction to obtain a mixture, filtering the mixture to obtain clear liquid, sending the clear liquid into a sewage treatment plant and discharging after treating and reaching standards, and feeding obtained dregs into an incinerator for incineration. The method provided by the invention has the following advantages: 1, the method can be used to effectively remove total phosphorus pollutants in the wastewater, the quality of the wastewater after treatment is clean and transparent, the COD is less than 50mg / l, the total phosphorus is equal to or less than 0.5mg / l, national emission standards are met, the treatment difficulty of the sewage treatment plant is reduced, the loss of useful materials is reduced, the equipment utilization rate is improved, and the environment is improved; 2, the technological process of the method is simple and convenient, the operation is simple, the cost is low, and the pollutant removal rate is improved, so the method provided by the invention has good popularization value.

Owner:安道麦股份有限公司

Deoiling treatment method for restaurant waste water

InactiveCN109231539ASimple structureSolve difficult governance problemsFatty/oily/floating substances removal devicesTreatment involving filtrationWater qualityPolyacrylamide

The invention discloses a deoiling treatment method for restaurant waste water. The method comprises the following steps: (1) waste water collection: filtering the restaurant waste water through a filter device, and pouring the filtered waste water into a waste water box to be treated; and (2) oil-water separation: adding a mixed liquid of polymeric ferric sulfate, sodium humate and polyacrylamideinto the waste water box, reducing the surface activity of an anionic detergent by means of the catholic polymeric ferric sulfate, and destroying hydration shells of emulsified oil beads and double electric layer structures thereof, wherein oil is separated out. The oil content of purified water is 4.5 mg / L, the chemical oxygen consumption is 61.5 mg / L, the settling time is 2 minutes, the effluent is clear and transparent, the demulsification efficiency reaches 95%, and the clear liquid residual amount is lower than national state, and meanwhile, the chemical oxygen consumption is reduced toa great extent, so that the problem that the waste water treatment difficulty is great as a pipeline is easily blocked because existing oil-water treatment equipment is hard to separate oil from wateris solved.

Owner:许昌涉步餐饮管理有限公司

Texaco gasifier grey water treatment and recovery system

PendingCN106379985AImprove water qualityThe water quality is clear and transparentCalcium/strontium/barium carbonatesWater treatment parameter controlWater treatment systemSlag

The invention discloses a Texaco gasifier grey water treatment and recovery system which comprises a Ca<2+> / Mg<2+> precipitation tank connected with a black water settling tank water outlet, a filtering machine feeding tank connected with a black water settling tank, a crude slag filtering machine connected with the filtering machine feeding tank, a first drainage pump, a first precipitate collecting tank and a grey water tank which are connected with the Ca<2+> / Mg<2+> precipitation tank, a precipitate filtering machine connected with the first precipitate collecting tank, a MAP reaction precipitation tank connected with the grey water tank, a second precipitate collecting tank and a clear water tank which are connected with the MAP reaction precipitation tank, a MAP recovery device connected with the second precipitate collecting tank, and a shock cooling water inlet pump connected with a clear water tank overflow weir water outlet. The system is simple in process and easy to operate, is a novel grey water treatment system capable of quickly and efficiently removing Ca<2+>, Mg<2+> and NH4<+>-N in grey water, and prolongs the equipment overhaul cycle and production cycle by more than 6 months.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Method for preparing and using medicament for purifying and treating percolate waste water from household garbage field

InactiveCN101585612AThe water quality is clear and transparentWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentWaste dumpWater quality

The invention discloses a method for preparing and using a medicament for purifying and treating percolate waste water from a household garbage field, which relates to the field of waste water and air environment quality purification in the environment protection industry. In the invention, various chemical medicaments are prepared and diluted into liquid according to a certain proportion, and the liquid is dissolved in the garbage percolate waste water in three or four stages in different time, thus harmful impurities in the wastewater, such as COD, NH3-N, SS, heavy metal, colon bacillus, and the like are damaged and eliminated and completely separated from water and deposited, thus the water is clear and transparent, the household garbage burying pollution control standard GB16889-1997 and the integrated wastewater discharge standard GB8978-1996 can be reached or the water is reused for irrigating farmlands, forests, and the like. The wastewater can be continuously purified two or three times, and the reagent and the method can not cause secondary pollution to a water body.

Owner:李界文

Film coating liquid used in drinking water pipe and method for coating metal drinking water pipe with film

InactiveCN109468618ASolve cleaningSolve the bactericidalNon-ionic surface-active compoundsOrganic detergent compounding agentsOxygenWater pipe

The invention provides film coating liquid used in a water pipe, which comprises, by weight, 15-30 parts of bactericidal metal salt, 0.01-0.3 part of complexing agent and 60-85 parts of water. According to the film coating liquid used in the water pipe provided by the invention, through chemical replacement, the silver ions in the soluble silver salt are replaced by metals such as iron and aluminum in the metal water pipe, so that a compact bactericidal metal layer is formed on the inner wall of the water pipe, and the cleanness of drinking water is guaranteed by using the bactericidal performance of the bactericidal metal. A method for coating the inner wall of the water pipe with the film by adopting the film coating liquid can prevent dirt and bacterial colony from being generated again, and after film coating, the bactericidal metal layer can effectively prevent the pipe wall of the metal water pipe from being oxidized by oxygen in water and prevent dirt from being generated, so that the generation of rust and bacteria is fundamentally reduced, the problems of continuous secondary pollution and dirt generation of the metal water pipe are solved, and the problems of cleaning andsterilizing the water pipe are solved.

Owner:广东顺德三阳化学有限公司

Efficient sewage COD (chemical oxygen demand) treatment method

InactiveCN105384306ALow costNo secondary pollutionWater treatment parameter controlTreatment using aerobic processesChemical treatmentWater quality

The invention discloses an efficient sewage COD (chemical oxygen demand) treatment method, relating to the field of sewage treatment. The efficient sewage COD treatment method adopts the four steps of domestication and biofilm formation, anaerobic hydrolysis acidification treatment, aerobic bio-contact oxidation treatment and flocculation treatment and is low in cost; secondary pollution is avoided by adopting microorganisms to decompose sewage; compared with conventional chemical treatment methods, the treatment method has the advantages that the sludge amount is smaller; the COD of the treated sewage is less than 100mg / L; the water is clear and transparent and completely reaches the wastewater discharge standards.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

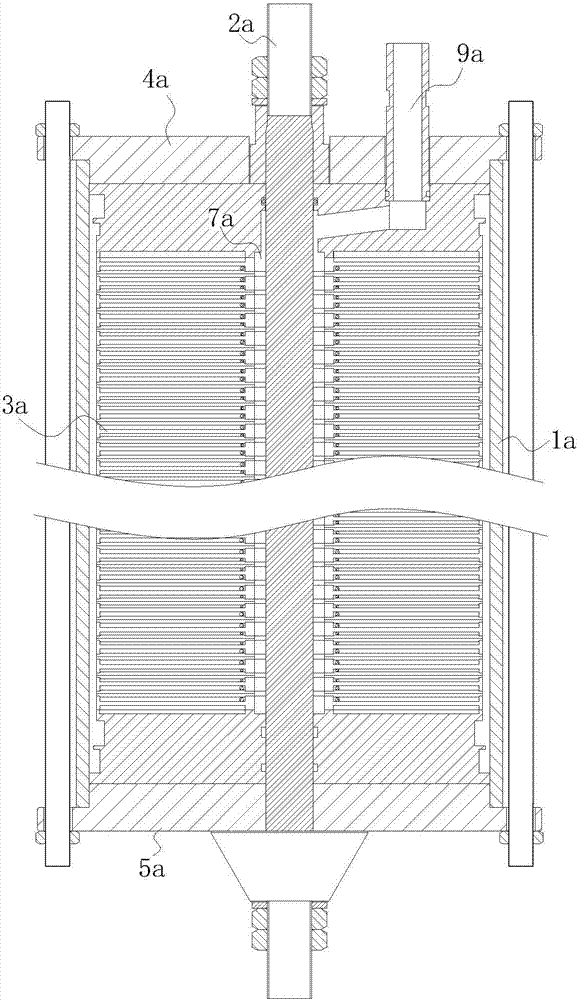

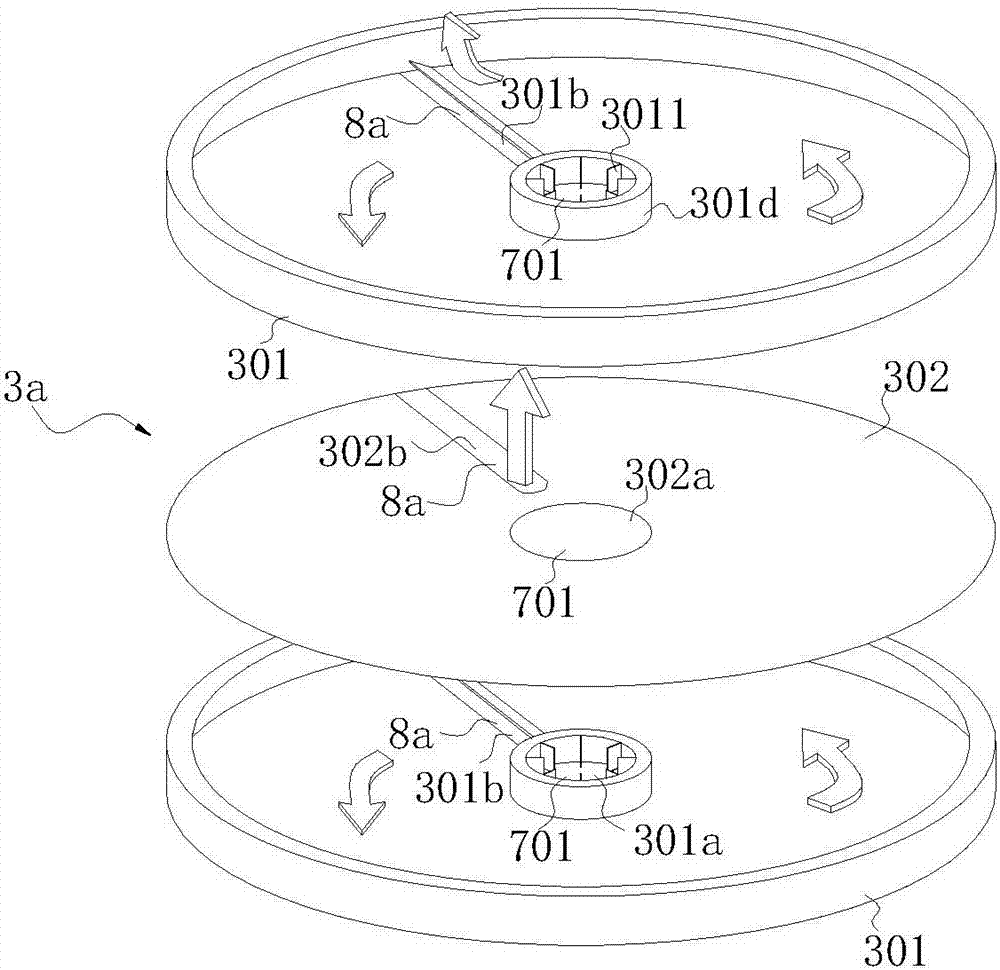

Method for advanced treatment of wastewater by using combination of catalytic ozonation and internal circulation biological filter

ActiveCN101863589BBreak through the biochemical limitImprove biodegradabilityMultistage water/sewage treatmentChemical industryBiological filter

The invention discloses a method for the advanced treatment of wastewater. The method comprises the following steps of: 1) filtering off-standard wastewater, delivering the wastewater into a catalytic ozonation tower, and simultaneously adding ozone for contact oxidization reaction; 2) delivering the effluent of the catalytic ozonation tower into an oxidization buffer stabilization basin for stabilization; 3) and after the stabilization, delivering the effluent into a BAF basin for treatment, and delivering discharged water into a clean water basin. The method reduces the addition amount of the ozone, improves the utilization efficiency of the ozone, converts the ozone into hydroxyl radicals by using a metal catalyst, and reduces the activation energy of hydroxyl radical oxidation reaction to promote hardly biodegradable macromolecule organic substances in the wastewater to be oxidized into easily biodegradable micromolecule substances, so that the biochemical limit to refining the wastewater is broken through and the biodegradability of the wastewater is increased; and the water quality of the effluent can meet the provincial standard of Jiangsu province, namely Chemical IndustryMain Water Pollutant Discharge Standard, completely by further treatment in the BAF basin.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A cleaning agent for drinking water pipes, a cleaning method for drinking water pipes and a maintenance method for drinking water pipes

ActiveCN109234024BEfficient removalEffective sterilizationBiocideOrganic detergent compounding agentsFungicideOrganic acid

The invention provides a water pipe cleaning agent, which comprises 12-50 parts by weight of natural organic acid, 10-50 parts by weight of citric acid, 10-15 parts by weight of natural surfactant, 10-15 parts by weight of part of natural fungicide and 10-25 parts by weight of water. The invention provides a cleaning agent for a water pipe, which can effectively remove the scale, rust and sludge and realize high-efficiency sterilization through physical and chemical reactions between the cleaning agent and the scale, rust and sludge on the inner wall of the water pipe. The water pipe cleaning agent of the present invention is all edible materials, has no secondary pollution to water pipes, and will not cause other harm to the human body even if there is residue; and the cleaning process is simple, the cleaning equipment is simple and easy to obtain, and the cost of the cleaning agent and the cleaning process is low. It has a high degree of acceptance, is suitable for large-scale promotion and application, and has broad development prospects.

Owner:广东顺德三阳化学有限公司

Method for recycling and treating semi-coke and coke production wastewater

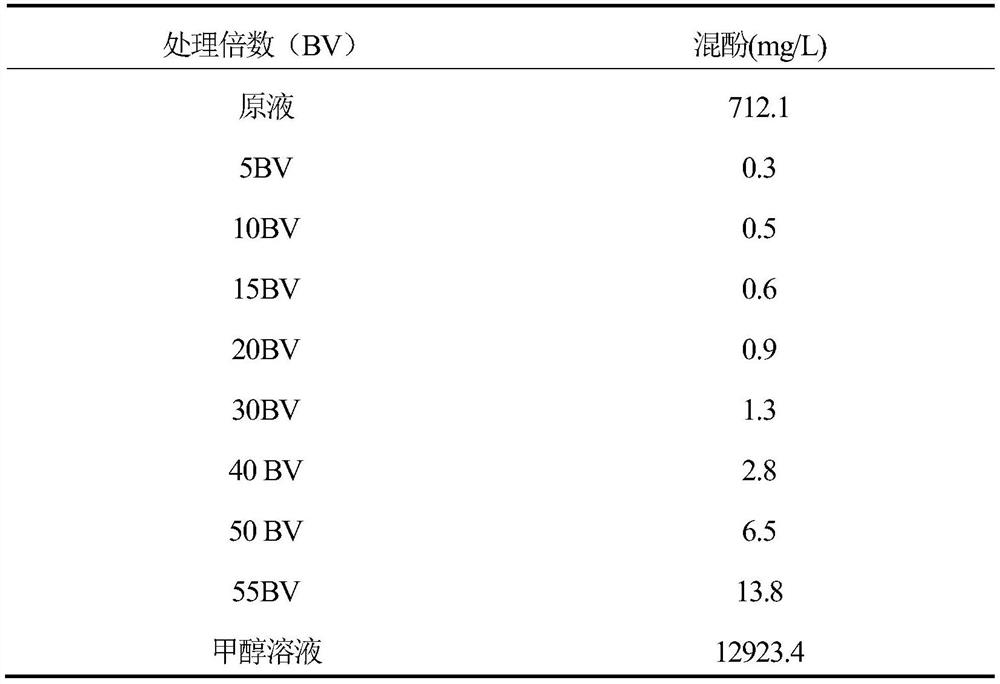

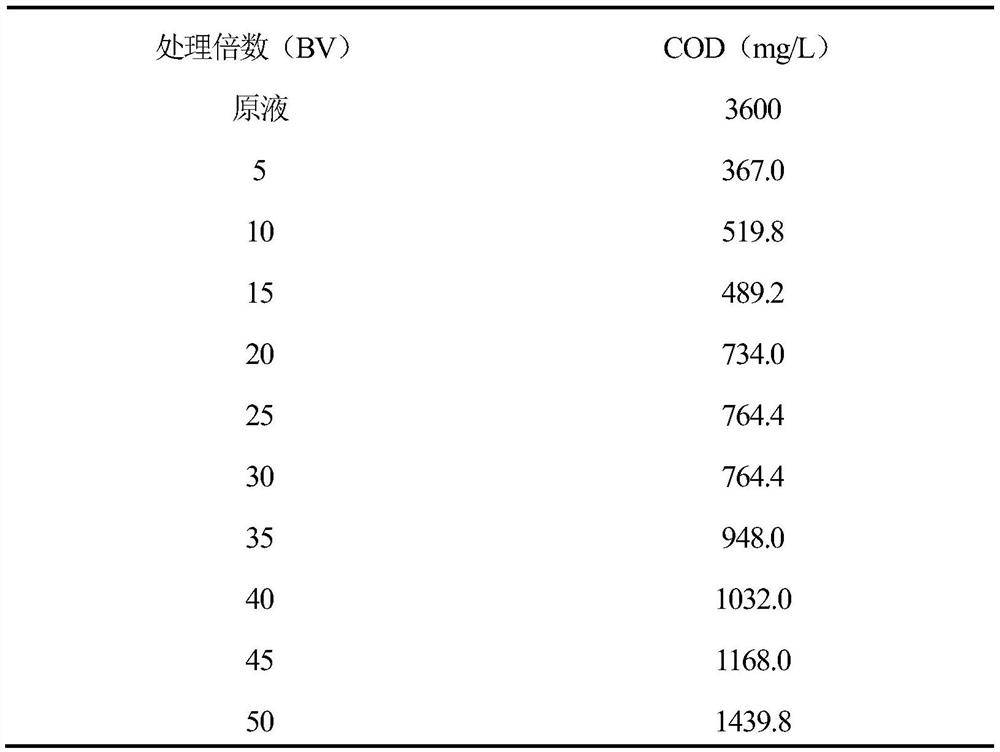

PendingCN112723459ASingle inputLess quantitySpecific water treatment objectivesWater contaminantsFixed bedEngineering

The invention discloses a method for recovering and treating semi-coke and coke production wastewater, wherein the method comprises the steps: enabling the semi-coke and coke production wastewater subjected to deamination in a deamination tower and dephenolization in an extraction tower to pass through a fixed bed adsorption column filled with macroporous styrene adsorption resin, so that phenolic substances are adsorbed on the adsorption resin, the phenol content of effluent is less than 20 mg / L, and the CODCr is less than 2000 mg / L; the saturated resin is eluted with methanol, the eluted methanol-phenol mixed solution is rectified to recover the mixed phenol, and the methanol is recycled. According to the method for treating the semi-coke and coke production wastewater, 92% or above of mixed phenol is recycled, the wastewater subjected to adsorption treatment is subjected to micro-electrolysis, flocculation oxidation, biochemistry and the like and then completely meets the discharge or reuse requirements, and unification of wastewater treatment and resource utilization is achieved.

Owner:西安金沃泰环保科技有限公司

A synergist for the treatment of sewage containing high-concentration nonionic surfactants and its preparation method and application

ActiveCN109678221BImprove adsorption capacityQuick removalWater contaminantsWater/sewage treatment by flocculation/precipitationAlcoholAfter treatment

The invention discloses a synergist for treating sewage containing high-concentration nonionic surfactants, a preparation method and application thereof. The synergist is prepared from the raw materials in the following weight percentages: C 1 ~C 5 Primary alkyl alcohol 1~10%, C 1 ~C 3 1-30% of aldehydes, 1-40% of pH regulators, 1-20% of amine polymers, and the balance is water. The synergist provided by the present invention is a high-molecular polymer, which contains a large amount of anchoring groups such as -OH, -NH, COO-, etc., and can quickly absorb the micelles formed by non-ionic surfactants in sewage, so that it can be simply and quickly Remove high-concentration non-ionic surfactants in sewage; in addition, after the synergist is used in conjunction with PAC and PAM, it can significantly reduce the sewage turbidity from 1200NTU to 12NTU, and the water quality after treatment is clear and transparent. The synergist uses The process is simple, convenient and fast, and is suitable for the treatment of a large amount of high-concentration non-ionic surfactant sewage, with a wide range of applications.

Owner:广州正利金属表面处理剂有限公司

Food waste treatment process

ActiveCN104959367BReduce CODEasy to handleSolid waste disposalClimate change adaptationCross-flow filtrationFilter system

The invention relates to a kitchen waste treatment process. The kitchen waste treatment process comprises the following steps: (1) carrying out pretreatment for dividing the kitchen waste into a solid-phase material, an oil-phase material and a water-phase material through a pretreatment system; (2) carrying out primary filtering treatment for introducing the water-phase material into a first filtering system, wherein the first filtering system comprises a first filtering film component, the water-phase material is filtered by a cross flow filtration manner through the first filtering film component, the obtained filtrate is primary treatment water, and the trapped molecular weight of the first filtering film is 250000; and (3) carrying out secondary filtering treatment for introducing the primary treatment water into a second filtering system, wherein the second filtering system comprises a second filtering film component, the primary treatment water is filtered by a roll type filtering manner through the second filtering film component, the obtained filtrate is dischargeable water, and the trapped molecular weight of the second filtering film is 100. The treatment process is capable of effectively removing pollutants in the kitchen waste; the obtained water is clear and transparent and meets the discharge standard; in addition, the water production rate of the treatment process reaches over 85 percent.

Owner:SHENZHEN LONGJISHUN IND DEV

A kind of ship clearance oil dehydrating agent and preparation method thereof

InactiveCN104531207BReduce dosageImprove dehydration effectDewatering/demulsification with chemical meansHydrocarbon oils treatmentWater qualityEther

The invention discloses a ship clearance oil dehydrating agent and a preparation method thereof and relates to clearance oil. The ship clearance oil dehydrating agent comprises the following components in percentage by mass: 25-60 percent of three-block-polyether, 1-5 percent of a demulsifying compound and 35-70 percent of a solvent. The three-block-polyether can be selected from imidazoline poly-oxypropylene polyoxyethylene polyoxypropylene ethers and polyethylene polyamine poly-oxypropylene polyoxyethylene polyoxypropylene ethers by mixing; the demulsifying compound can adopt NaCl aqueous solution; and methanol or ethanol can serve as the solvent. The preparation method comprises the following steps: heating and dissolving the three-block-polyether, uniformly mixing with the demulsifying compound and the solvent, thereby obtaining the ship clearance oil dehydrating agent. The amount of the ship clearance oil dehydrating agent is small and is about 100-250ppm. The dehydration effect is good, the dehydration rate can be over 99.5 percent, the oil-water interface is clear, and the water is clear and transparent. The dehydration speed is high, and the time from the operation of adding the ship clearance oil dehydrating agent to the operation of allowing an oil-water transition layer to completely disappear is only 15 minutes. The broad spectrum property is high, and the cost is low.

Owner:宁夏捷全油气技术服务有限公司

Paint mist coagulant

PendingCN110902788AReduce moisture contentThe water quality is clear and transparentPaint waste treatmentWater/sewage treatment using germicide/oligodynamic-processHazardous substanceThiazoline

The invention provides a paint mist coagulant, which is especially suitable for paint-containing wastewater treatment after a spraying process in various industries. The composite coagulant comprisesthe following main components by concentration: 0.1-0.8g / L sodium hydroxide; 0-0.06g / L isothiazolinone; 0.05-0.1g / L of a melamine polymer; 0.001-0.01g / L of polyacrylamide; 0.2-0.6g / L an additive; 0.05-0.1g / L a sterilizing agent; and 0.01-0.1g / L a decolorizing agent. The paint mist coagulant has the advantages of high flocculation speed, low consumption, thorough destruction to overspray paint andhigh efficiency; the paint slag floating rate reaches 98%, and the water content is low; the water is clear, transparent, environment-friendly, free of harmful substances and free of peculiar smell; the paint mist coagulant is effective for any solvent type or aqueous paint; and the control range is wide, and the circulating water change period is long.

Owner:浙江九合环保科技有限公司

Ship clearance oil dehydrating agent and preparation method thereof

InactiveCN104531207AReduce dosageImprove dehydration effectDewatering/demulsification with chemical meansHydrocarbon oils treatmentWater qualitySolvent

The invention discloses a ship clearance oil dehydrating agent and a preparation method thereof and relates to clearance oil. The ship clearance oil dehydrating agent comprises the following components in percentage by mass: 25-60 percent of three-block-polyether, 1-5 percent of a demulsifying compound and 35-70 percent of a solvent. The three-block-polyether can be selected from imidazoline poly-oxypropylene polyoxyethylene polyoxypropylene ethers and polyethylene polyamine poly-oxypropylene polyoxyethylene polyoxypropylene ethers by mixing; the demulsifying compound can adopt NaCl aqueous solution; and methanol or ethanol can serve as the solvent. The preparation method comprises the following steps: heating and dissolving the three-block-polyether, uniformly mixing with the demulsifying compound and the solvent, thereby obtaining the ship clearance oil dehydrating agent. The amount of the ship clearance oil dehydrating agent is small and is about 100-250ppm. The dehydration effect is good, the dehydration rate can be over 99.5 percent, the oil-water interface is clear, and the water is clear and transparent. The dehydration speed is high, and the time from the operation of adding the ship clearance oil dehydrating agent to the operation of allowing an oil-water transition layer to completely disappear is only 15 minutes. The broad spectrum property is high, and the cost is low.

Owner:宁夏捷全油气技术服务有限公司

Method for preparing and using medicament for purifying and deslagging waster water in aluminum fluoride production

InactiveCN101407351AThe water quality is clear and transparentWater/sewage treatment by flocculation/precipitationChemical LinkageChemical industry

The invention relates to a reagent for the purification and slag removal of aluminum fluoride production wastewater and a using method, relating to the chemical industry wastewater treatment purification field. In the invention, a plurality of chemical reagents are prepared according to proportion, diluted to liquid, and dissolved in the aluminum fluoride production wastewater in three or four stages in different time, then chemical bonds and relatively balanced ionic layers in the wastewater are damaged, property of the wastewater is changed, impurities such as fluorine ions of the wastewater and water are fully separated and precipitated, water quality is clear and transparent, the fluorine ions, COD, SS, pH value in the water can reach the industrial wastewater pollution emission standard of the environmental protection department or can be reused for a production system. Continuous purification for 2 times or 3 times can be realized by using the method and secondary pollution can not be caused to water by using the reagent and the method.

Owner:李界文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com