Integrated processing method of fracturing flow-back fluid

A fracturing flowback fluid and treatment method technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as high technical achievability requirements, cumbersome processes, and expensive treatment costs. , to reduce costs, strengthen processing efficiency, and simplify equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1. Integrated treatment of fracturing flowback fluid

[0035] The fracturing flowback fluid of an oil well in an oilfield has a pH value of 6, and the COD, oil content and suspended solids content are 4020mg / L, 30mg / L and 340mg / L respectively, all of which are higher than the national standards of 300mg / L and 12mg / L and 200mg / L.

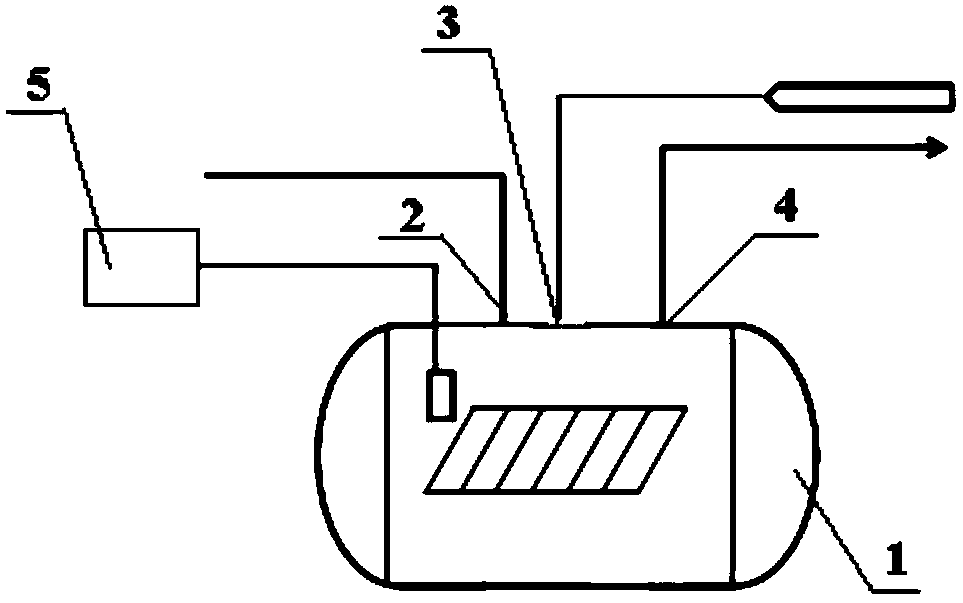

[0036] Put 4L fracturing flowback fluid in figure 1 In the three-dimensional electrode-ultrasound-advanced oxidation coupled reactor shown, the electrode plate combination is set as a ruthenium-iridium composite electrode (anode)-aluminum electrode (cathode)-activated carbon electrode (third electrode), and the effective area of the electrode plate is related to the fracturing The ratio between flowback liquid is 0.1cm 2 / L. Adjust the pH value to 3, the distance between the electrode plates to 6.0cm, the electrolysis current to 5.5A, the ultrasonic power to 200W, the frequency to 60kHz, add potassium ferrate (5.0g / L), and trea...

Embodiment 2

[0037] Embodiment 2. Integrated treatment of fracturing flowback fluid

[0038] The fracturing flowback fluid of an oil well in an oilfield has a pH value of 6, and the COD value, oil content and suspended solids content are 4020mg / L, 30mg / L and 340mg / L respectively, all of which are higher than the national standards of 300mg / L and 12mg / L L and 200mg / L.

[0039] Put 4L fracturing flowback fluid in figure 1 In the three-dimensional electrode-ultrasound-oxidation coupled reactor shown, the electrode plate combination is set as a ruthenium-iridium composite electrode (anode)-aluminum electrode (cathode)-activated carbon electrode (third electrode). The ratio between drains is 0.1cm 2 / L. The pH value was adjusted to 3, the distance between the electrode plates was 6.0cm, the electrolytic current was 5.5A, the ultrasonic power was 200W, and the frequency was 60kHz, and Fenton’s reagent (oxidant (H 2 o 2) is 5.0g / L, exclusive catalyst (Fe 2+ ) 1.2g / L), after 60 minutes of tr...

Embodiment 3

[0040] Embodiment 3. Integrated treatment of fracturing flowback fluid

[0041] The fracturing flowback fluid of an oil well in an oilfield has a pH value of 6, and the COD value, oil content and suspended solids content are 4020mg / L, 30mg / L and 340mg / L respectively, all of which are higher than the national standards of 300mg / L and 12mg / L L and 200mg / L.

[0042] Put 4L fracturing flowback fluid in figure 1 In the three-dimensional electrode-ultrasound-oxidation coupled reactor shown, the electrode plate combination is set as a ruthenium-iridium composite electrode (anode)-aluminum electrode (cathode)-activated carbon electrode (third electrode). The ratio between drains is 0.1cm 2 / L. Adjust the pH value to 3, the distance between the electrode plates to 6.0cm, the electrolysis current to 5.5A, the ultrasonic power to 200W, and the frequency to 80kHz, adding (oxidant (H 2 o 2 ) is 5.0g / L, exclusive catalyst (Fe 2+ ) 1.2g / L), after 90 minutes of treatment, the COD value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com