Method for recycling and treating semi-coke and coke production wastewater

A technology for the production of waste water and treatment methods, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as difficulty in meeting discharge requirements, substandard waste water treatment, and affecting production output. , to achieve the effect of increasing utilization value, low cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The coke production wastewater of a certain blue coke factory is black and red after being deaminated by the deammonization tower and extracted and dephenolized by the extraction tower.

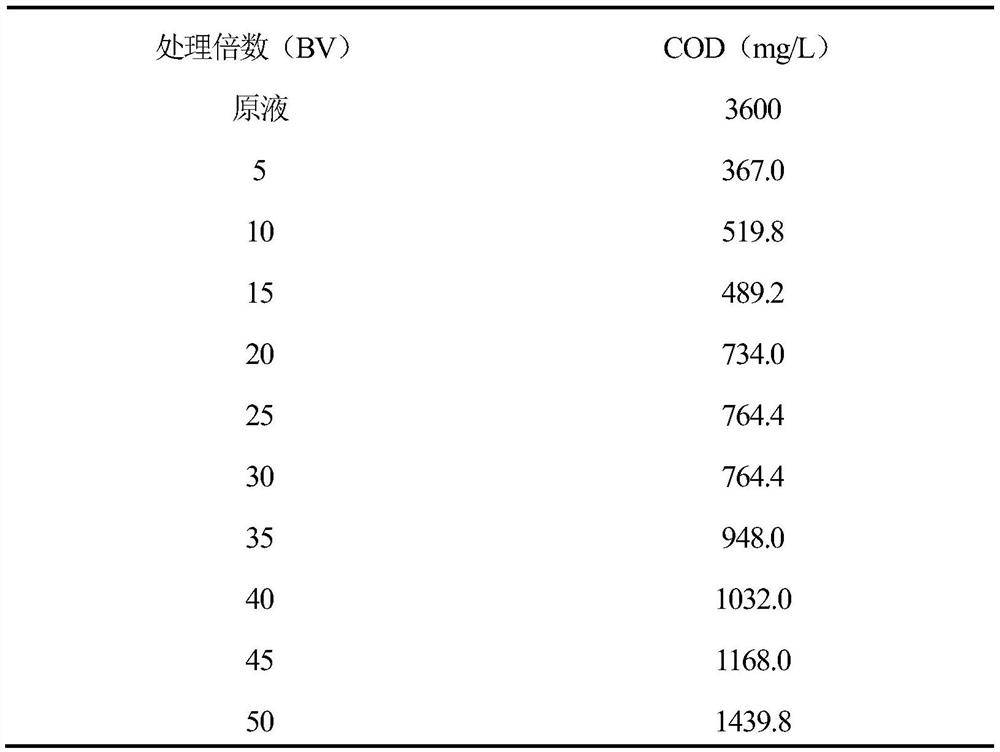

[0022] 1. At room temperature, use sulfuric acid to adjust the pH of the semi-coke coke production wastewater that has been deaminated by the deamination tower and dephenolized by the extraction tower to 4-5, and pass through the 60mL Innovate-16 at a flow rate of 1BV / h. Resin column of macroporous adsorption resin (Φ20×300mm). After testing, the content of mixed phenols in the column liquid (absorbed water) is reduced to below 20ppm. Part of the column liquid is reused or discharged after further biochemical treatment up to the standard.

[0023] 2. Rinse the resin column adsorbed with mixed phenol in step 1 with 180mL tap water at a flow rate of 1BV / h to remove residual waste water and inorganic salts in the resin pores, and then drain the residual water in the resin column with com...

Embodiment 2

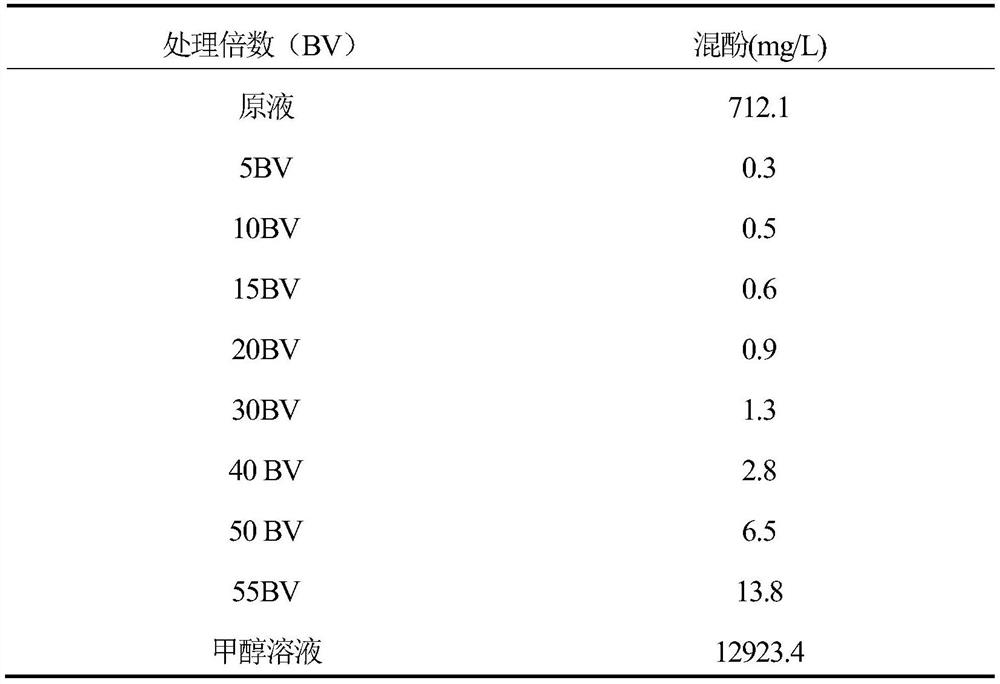

[0031] According to the method of Example 1, the blue charcoal coke production wastewater after deamination by deamination tower and extraction and dephenolation by extraction tower is recovered and treated, and the column liquid is taken once every 300mL until 3000mL is received, and the national standard method is used for treatment. The column liquid was tested for COD, and the test results are shown in Table 2.

[0032] Table 2 Adsorption effect of Innovate-16 adsorption resin on semi-coke coke production wastewater

[0033]

[0034] It can be seen from Table 2 that the application of Innovate-16 macroporous adsorption resin in the recycling of semi-coke coke production wastewater has obvious effects and can be widely promoted.

Embodiment 3

[0036] The coke production wastewater of a certain blue charcoal factory is black and red after being deaminated by the deamination tower and extracted and dephenolized by the extraction tower.

[0037] 1. At room temperature, mix 7×10 5 The blue coke coke production wastewater after deamination by the deamination tower and extraction and dephenolation by the extraction tower is adjusted to pH 4-5 with sulfuric acid, and is filled with 5×10 at a flow rate of 1BV / h. 3 L Innovate-16 resin column of macroporous adsorption resin (Φ1.2×4.8m). After testing, the content of mixed phenols in the column liquid (absorbed water) is reduced to below 20ppm. Part of the column liquid is reused or discharged after further biochemical treatment up to the standard.

[0038] 2. Use 1 × 10 4 L20~25℃ tap water for rinsing with a flow rate of 1BV / h to remove residual waste water and inorganic salts in the resin channels, and then drain the residual water in the resin column with compressed air....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com