A kind of highly stable hydrogen bond-containing hydrophilic macroporous adsorption resin and method for treating hydrogen peroxide tail gas waste gas

A macroporous resin and hydrophilic technology, which is applied in the field of polymer separation materials, can solve the problems of tail gas discharge that cannot meet the standard, and achieve the effects of low cost, improved utilization rate, and single input of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

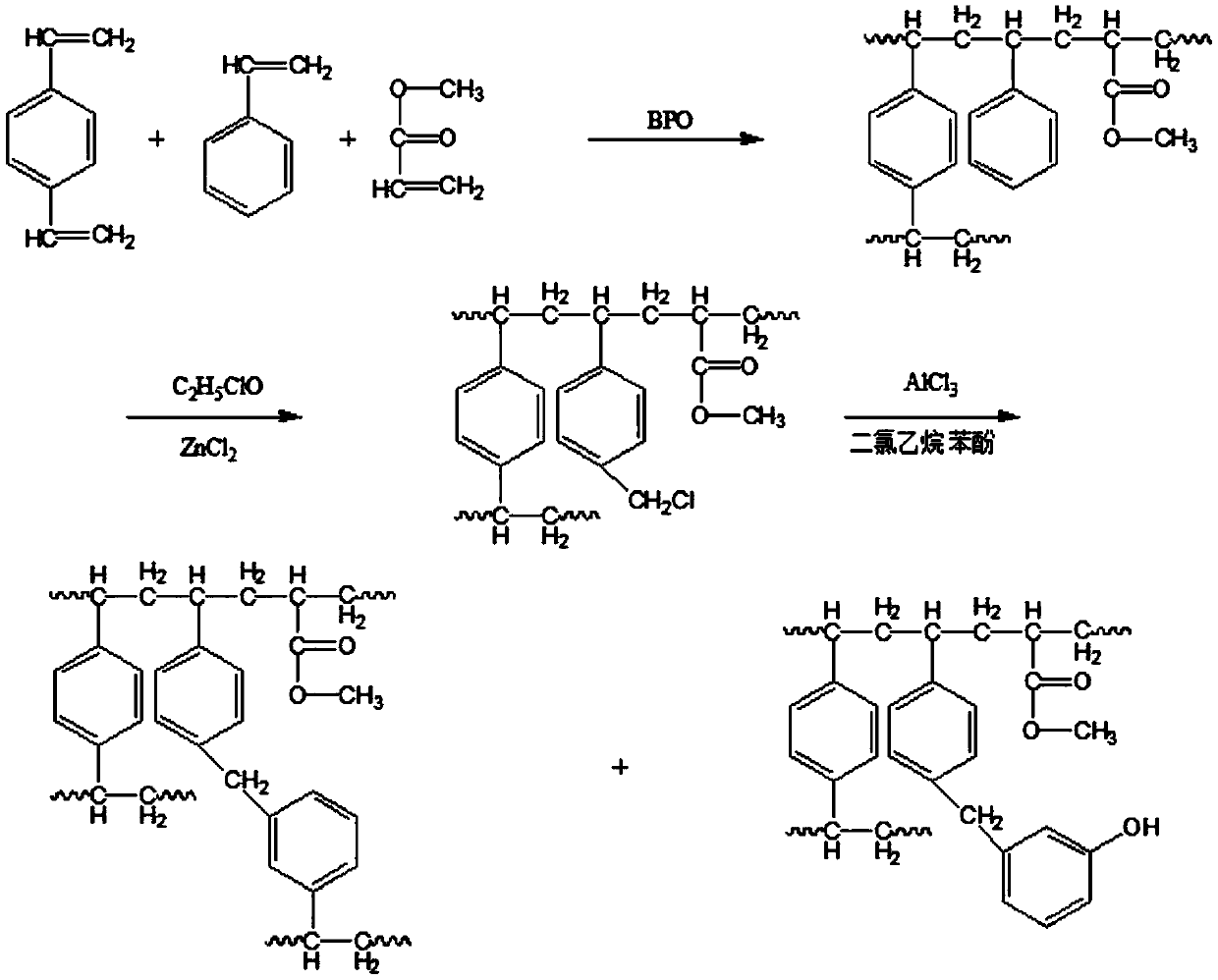

Method used

Image

Examples

Embodiment 1

[0032] 1. Synthesis of styrene / divinylbenzene / methyl acrylate macroporous resin balls

[0033] Dissolve 4g of magnesium sulfate, 5g of gelatin, and 0.2g of methylene blue in distilled water to prepare 1000mL of water phase.

[0034] Add 258g of styrene, 30g of divinylbenzene, and 12g of methyl acrylate into a mixture of 150g of gasoline and liquid wax with a volume ratio of 2:5, and mix well as the oil phase.

[0035] Add 1000mL water phase into 2000mL reactor, heat to 55°C, then add 550mL oil phase, stir to disperse the oil phase into the water phase, control the particle size to 0.3-1.0, raise the temperature to 75°C, react for 3h, continue to heat up to 90°C, reacted for 3h, raised the temperature to 95°C again for 5h, stopped the reaction, and cooled. After the cooled resin balls are discharged, they are washed with hot water above 90°C, extracted with 5 times the volume of resin in methylal, washed, boiled, and dried at 80-90°C for more than 10 hours to obtain benzene wi...

Embodiment 2

[0041] In step 2 of this example, 100 g of styrene / divinylbenzene / methyl acrylate macroporous resin balls with a crosslinking degree of 6% and 500 g of methyl chloride ether were added to the reaction kettle, and swelled at room temperature for 2 hours. After the swelling was completed, Add 50g of zinc chloride, raise the temperature to 45°C, keep it warm for 2 hours, then add 40g of zinc chloride, and continue the reaction for 12 hours; after the reaction, recover the chloromethyl ether mother liquor, wash with chlorine balls, and dry. The chlorine content in the obtained chlorine spheres was 19%. The other steps were the same as in Example 1 to obtain a hydrophilic macroporous adsorption resin containing hydrogen bonds.

Embodiment 3

[0043] In step 1 of this example, 255 g of styrene, 30 g of divinylbenzene, and 15 g of methyl acrylate were added to a mixture of 150 g of gasoline and liquid wax at a volume ratio of 2:5, and mixed well as the oil phase. The other steps were the same as in Example 1 to obtain a hydrophilic macroporous adsorption resin containing hydrogen bonds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cross-linking degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com