A method for refining and decalcifying aluminum chloride

A technology of aluminum chloride and sulfate, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of affecting the purity of aluminum and difficulty, and achieve the effects of low cost, small discharge of waste liquid and controllable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

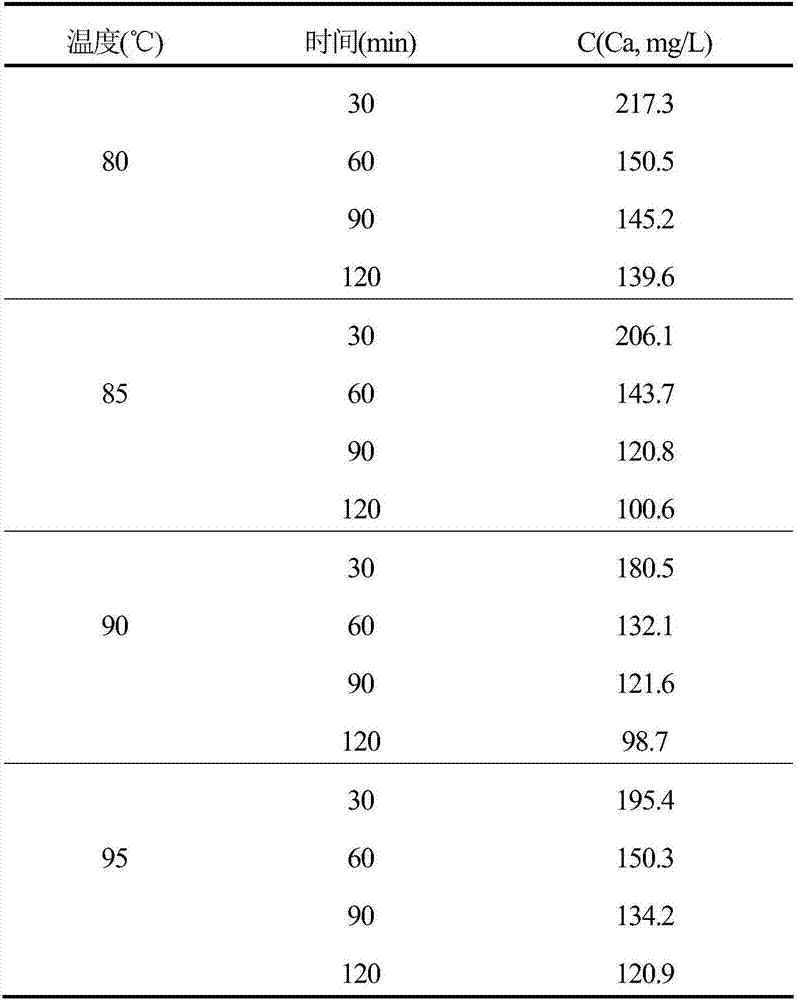

[0020] 1. Dissolve 10g of high-alumina fly ash in 100mL of distilled water, and adjust its pH value to 1 with hydrochloric acid to obtain an acid dipping solution, in which the concentration of calcium ions is 5g / L.

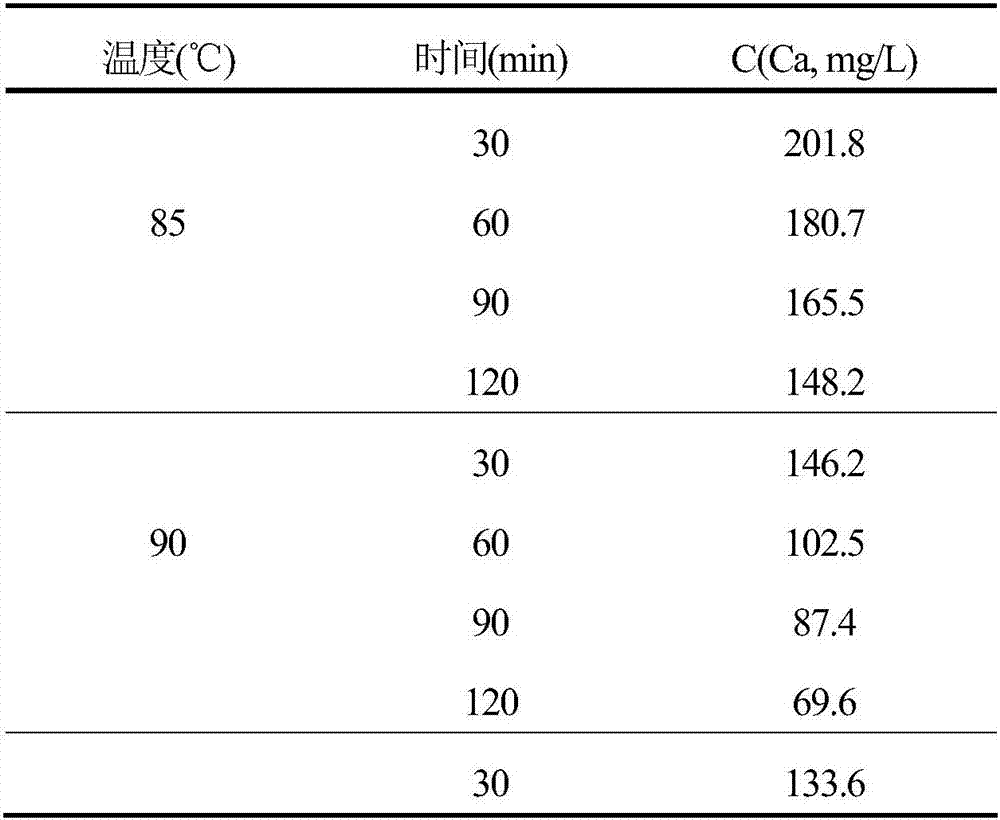

[0021] 2. First add 1.95g of aluminum sulfate to 100mL of pickling solution, stir at 90°C for 45 minutes, then add 1.55g of aluminum sulfate, continue stirring at constant temperature for 45 minutes, and then suction filter the reaction solution while it is hot.

[0022] 3. Add the filtrate obtained after the suction filtration in step 2 into the HYA-300 chelating cation exchange resin column while it is hot for decalcification. The injection volume of the filtrate is 10 times the volume of the HYA-300 chelating cation exchange resin column. The injection flow rate was 2mL / min to obtain a high-purity aluminum chloride solution after calcium removal, in which the calcium ion concentration was 25.5mg / L.

Embodiment 2

[0024] 1. Dissolve 10g of high-alumina fly ash in 100mL of distilled water, and adjust its pH value to 1 with hydrochloric acid to obtain an acid dipping solution, in which the concentration of calcium ions is 5g / L.

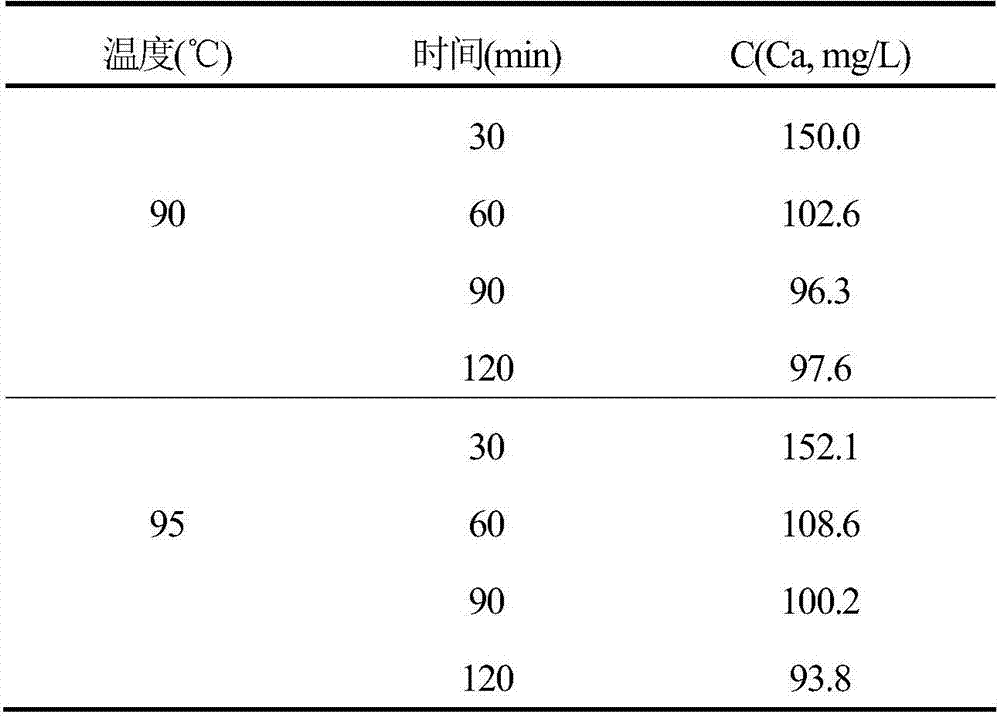

[0025] 2. Add 3.5g of aluminum sulfate to 100mL of pickling solution, stir at 90°C for 90 minutes, and then suction filter the reaction solution while it is hot.

[0026] 3. Add the filtrate obtained after the suction filtration in step 2 into the HYC-300 chelating cation exchange resin column while it is hot for decalcification. The injection volume of the filtrate is 10 times the volume of the HYC-300 chelating cation exchange resin column. The injection flow rate was 2mL / min to obtain a high-purity aluminum chloride solution after calcium removal, in which the calcium ion concentration was 30.5mg / L.

Embodiment 3

[0028] 1. Dissolve 10g of high-alumina fly ash in 100mL of distilled water, and adjust its pH value to 2 with hydrochloric acid to obtain an acid dipping solution, wherein the concentration of calcium ions is 5g / L.

[0029] 2. First add 1.5g of aluminum sulfate to 100mL of pickling solution, stir at 90°C for 30 minutes, then add 1.2g of aluminum sulfate, continue stirring at constant temperature for 30 minutes, and then suction filter the reaction solution while it is hot.

[0030] 3. Add the filtrate obtained after the suction filtration in step 2 into the HYC-300 chelating cation exchange resin column while it is hot to remove calcium, and the injection volume of the filtrate is 4.5 times the volume of the HYC-300 chelating cation exchange resin column. The injection flow rate was 1.5mL / min to obtain a high-purity aluminum chloride solution after calcium removal, in which the concentration of calcium ions was 31mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com