Condensed oil sewage degradation method for chemical oxygen demand standard

A chemical oxygen demand and heavy oil sewage technology, applied in the field of oil production sewage treatment, can solve the problems of complex COD degradation process, increased treatment cost, high oxidant price, and achieves a solution to COD degradation, reduced production and operation costs, and fast reaction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

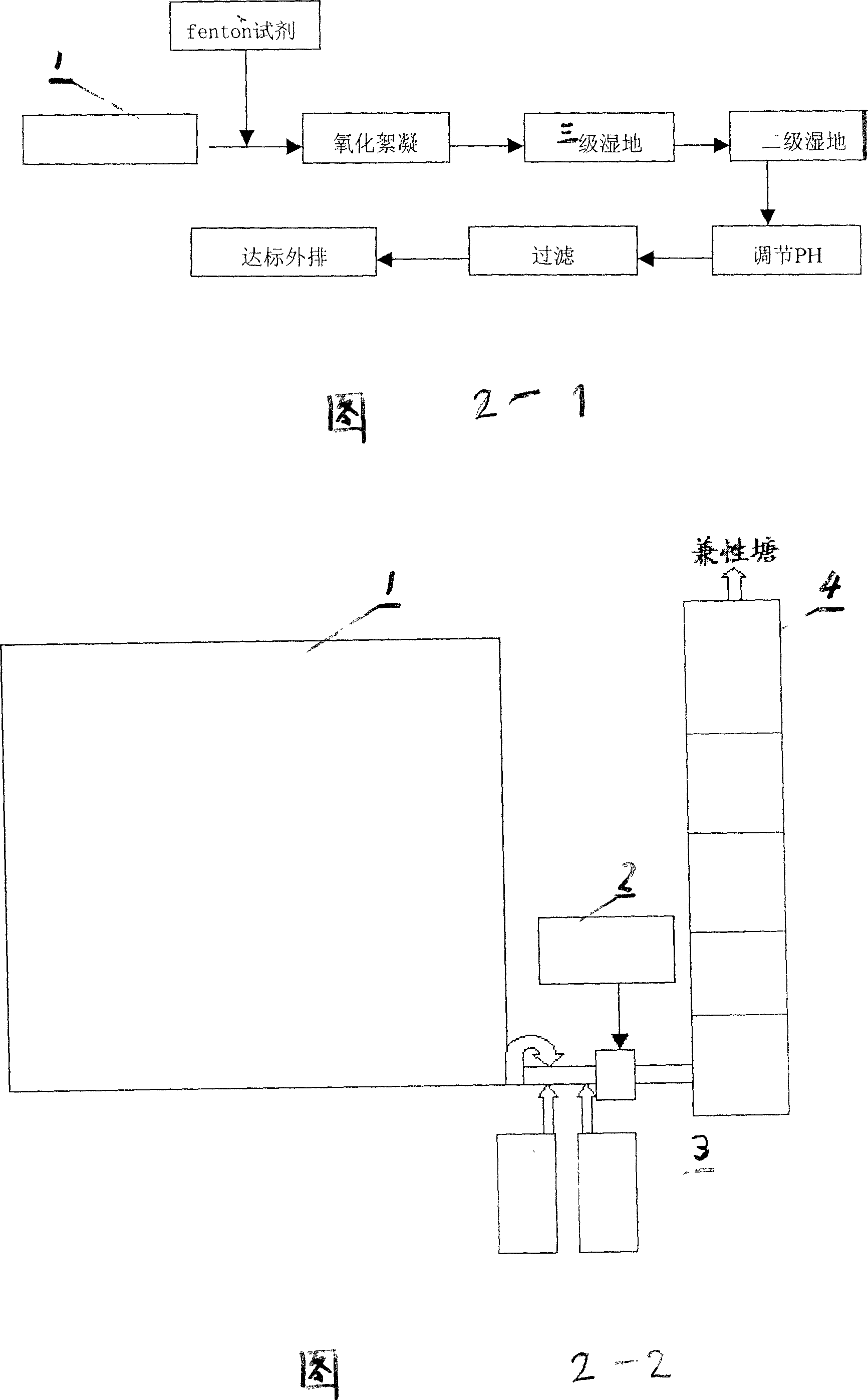

[0019] Process flow of the present invention: in Fig. 2-1 and Fig. 2-2

[0020] Take water from the anaerobic tank, add Fenton reagent, mix it through the mixer 2, enter the sand filter 3 sedimentation tank for catalytic oxidation, flocculation reaction and stay for 10 hours, then enter the third-level facultative pond 4 facultative, the residence time of sewage is about 15 days, after being biodegraded by facultative bacteria, enter the secondary artificial wetland, through the mixed action of plant root absorption, microbial degradation and cold-resistant animal digestion, stay for 15-20 days, and then further degrade, then enter the filter tank, add The PH value adjuster is adjusted to 6-9, and the suspended solids are removed and discharged.

Embodiment 2

[0022] Its reaction mechanism is as follows in implementation process among the present invention:

[0023] H added to sewage 2 o 2 Rapidly added Fe 2+ catalytically decomposes into OH with strong oxidation ability, and at the same time Fe 2+ is oxidized to Fe 3+ , some Fe 3+ is reduced to Fe 2+ , continue to catalyze the decomposition of H 2 o 2 , the formation of Fe 3+ It has a strong hydrolysis-polymerization-precipitation tendency with water, and some organic pollutants can be removed by coagulation adsorption during this process.

[0024] Fe 2+ +H 2 o 2 → Fe 3+ +OH - +OH 1.1

[0025] Fe 2+ +OH→Fe 3+ +OH - 1.2

[0026] Fe 3+ +H 2 O → Fe 2+ +HO 2 ·+H + 1.3

[0027] Fe 3+ +HO 2 · → Fe 2+ +O 2 +H + 1.4

[0028] When the reaction reaches 120min, alkane substances, phenolic compounds, polycyclic

[0029] When the reaction reaches 120 minutes, the alkanes, phenolic compounds, and polycyclic aromatic compounds in the water have been co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com