Tetrachloride phthalic anhydride waste water recovery and treatment method

A technology of tetrafluorobenzoic acid and its treatment method, which is applied in the field of chemical wastewater treatment and utilization, can solve the problems of high cost and unstable quality, and achieve the effects of low cost, improved utilization rate, and single input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

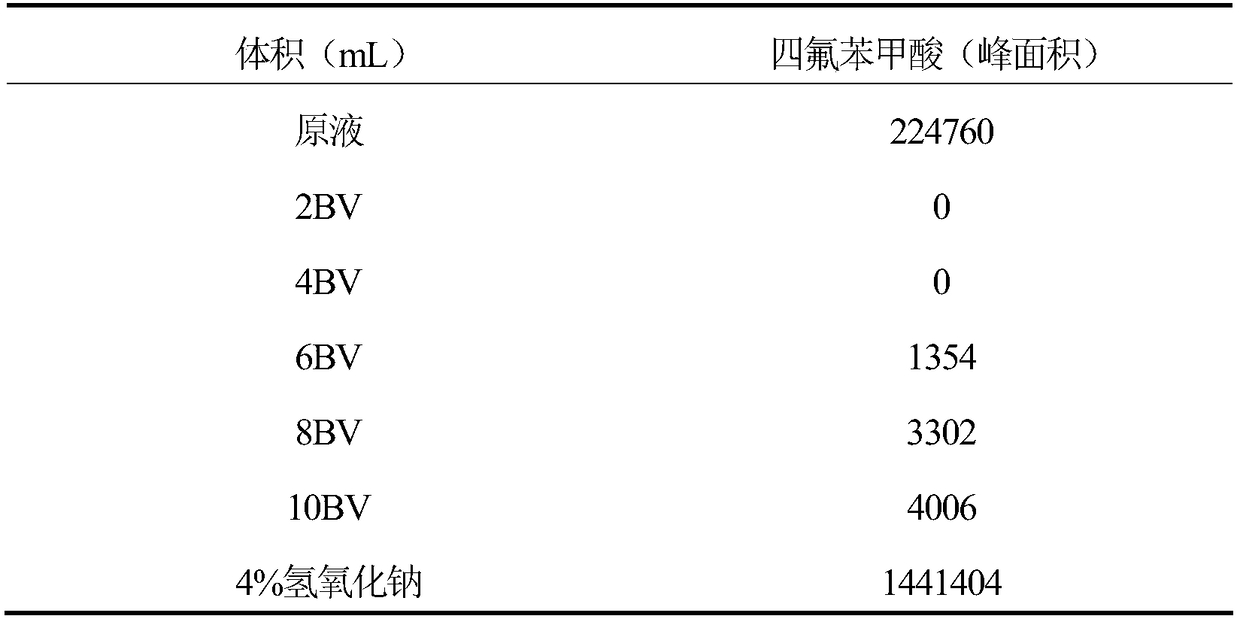

Embodiment 1

[0017] The tetrafluorobenzoic acid production wastewater of a factory is black and red, the content of tetrafluorobenzoic acid is 0.5%, the pH is 1-2, and it has peculiar smell. The specific recovery and treatment methods are as follows:

[0018] 1. At room temperature, after the tetrafluorobenzoic acid wastewater is left to settle, filter it with a precision filter, take 600mL of the clarified wastewater obtained after suction filtration, and pass it through a large hole filled with 60mL HYA-105 at a flow rate of 1BV / h. Resin column for adsorbing resin (Φ20×300mm). After testing, the content of tetrafluorobenzoic acid in the column liquid (adsorbed water) drops below 20 ppm, and the sulfuric acid in the column liquid can be further recovered.

[0019] 2. Rinse the resin column adsorbed with tetrafluorobenzoic acid with distilled water to remove residual waste water, sulfuric acid and inorganic salts in the resin pores, and then drain the residual water in the resin column.

...

Embodiment 2

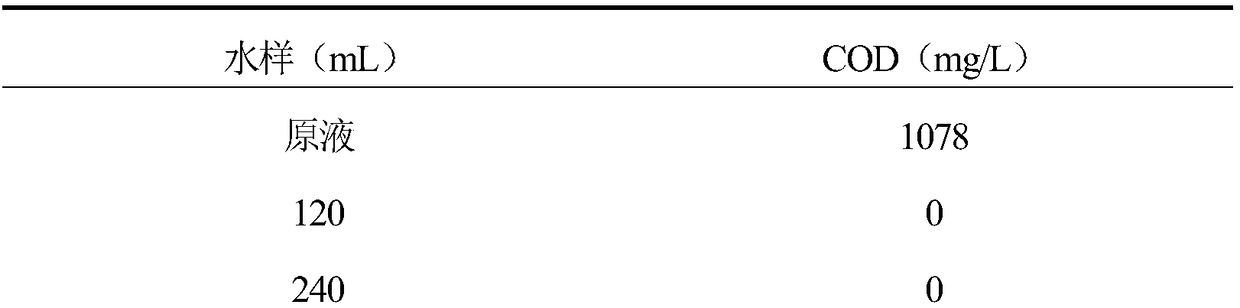

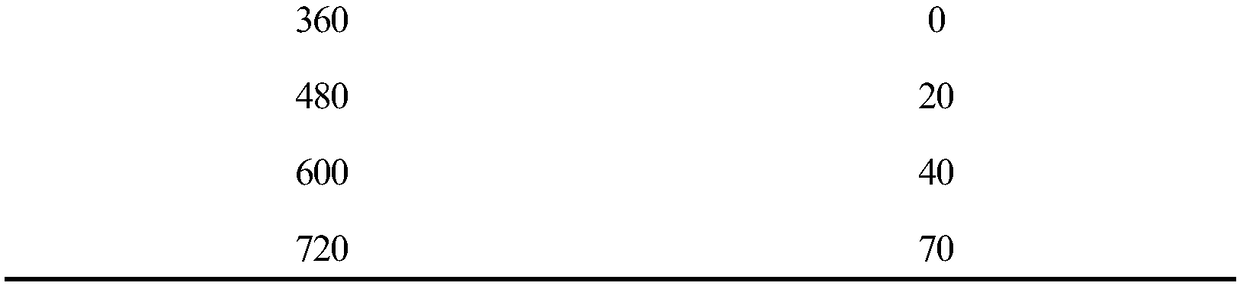

[0027] According to the method of embodiment 1, the tetrafluorobenzoic acid aqueous solution of 720mL 0.1g / L is recovered and processed, every 120mL gets the column liquid once, until receiving 720mL, and adopts national standard method to carry out COD detection to the column liquid, test result See Table 2.

[0028] Adsorption effect of table 2HYA-105 adsorption resin on tetrafluorobenzoic acid

[0029]

[0030]

[0031] It can be seen from Table 2 that the application of HYA-105 macroporous adsorption resin in the recycling of tetrafluorobenzoic acid wastewater has obvious effects and can be widely promoted.

Embodiment 3

[0033] The tetrafluorobenzoic acid production wastewater of a factory is black and red, the content of tetrafluorobenzoic acid is 0.5%, the pH is 1-2, and it has peculiar smell. The specific recovery and treatment methods are as follows:

[0034] 1. At room temperature, after the tetrafluorobenzoic acid wastewater was left to settle, filter it with a precision filter, take 600mL of the clarified wastewater obtained after suction filtration, and pass it through a filter filled with 60mL Amberlite XDA-7 at a flow rate of 1.5BV / h. Resin column of macroporous adsorption resin (Φ20×300mm). After testing, the content of tetrafluorobenzoic acid in the column liquid (adsorbed water) drops below 20 ppm, and the sulfuric acid in the column liquid can be further recovered.

[0035] 2. Rinse the resin column adsorbed with tetrafluorobenzoic acid with distilled water to remove residual waste water, sulfuric acid and inorganic salts in the resin pores, and then drain the residual water in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com