Acid wastewater treatment device utilizing membrane technique

A technology of wastewater treatment and membrane technology, applied in membrane technology, return water treatment, water/sludge/sewage treatment, etc., it can solve the problems of salt concentration and pH limit of hydrophobic microporous membrane sewage, and achieve high-quality and stable effluent quality. The effect of efficient separation and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

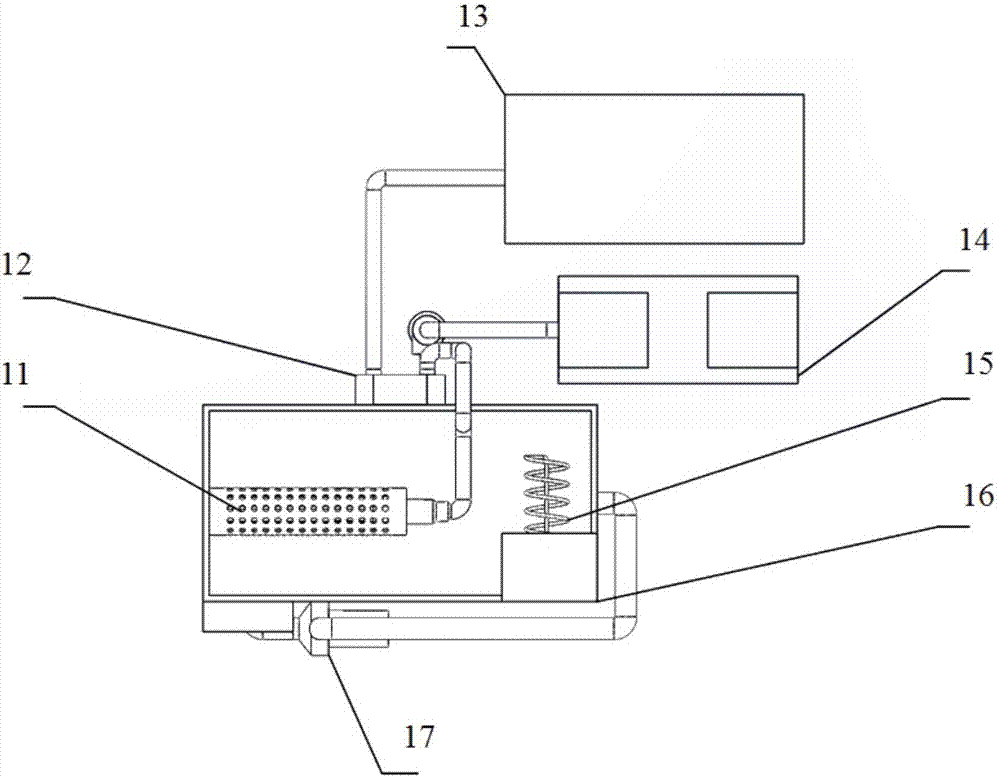

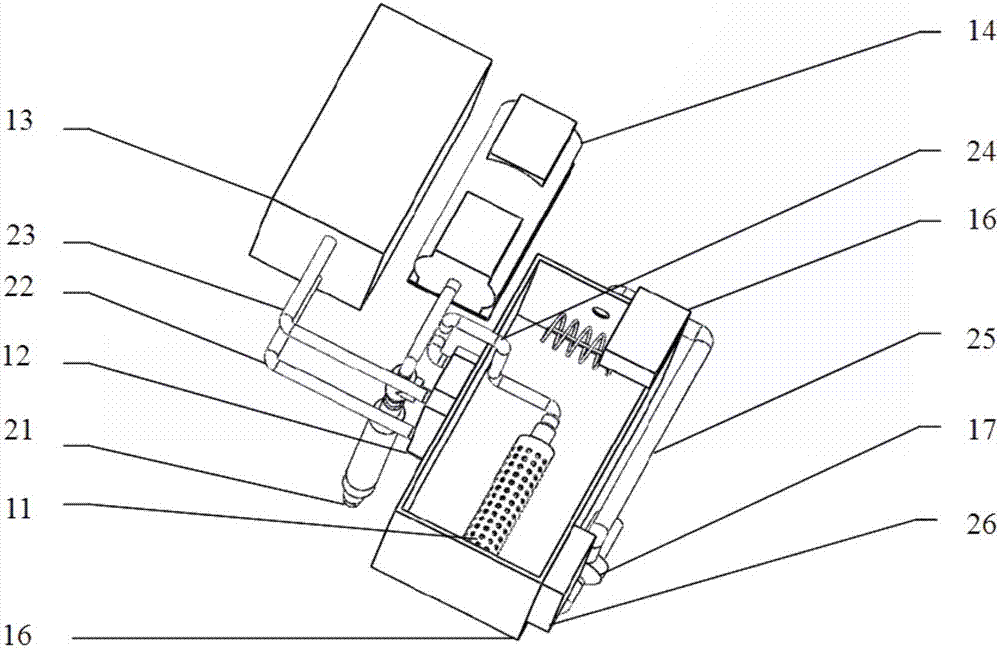

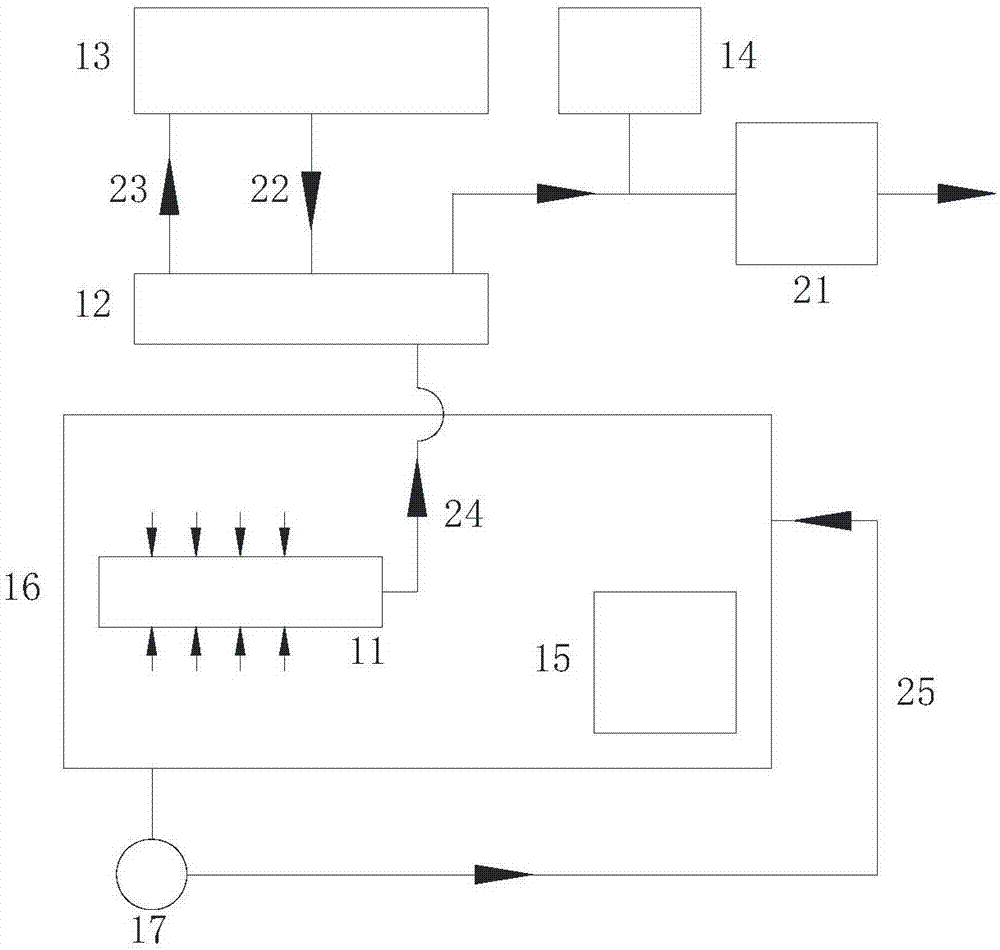

[0059] like figure 1 , figure 2 , image 3 Shown is embodiment 1 of the present invention, in this embodiment, a kind of acid waste water treatment device that adopts membrane technology, comprises sewage treatment tank 16, is provided with membrane module unit 11 in the sewage treatment tank 16, filters through membrane module unit 11 acid waste water. The membrane module unit 11 includes a pressure-bearing housing 11-6, and a plurality of external-pressure membrane tubes 11-1 are arranged inside the pressure-bearing housing 11-6, and water inlets 11-9 and outlets are respectively provided at both ends of the pressure-bearing housing 11-6. Nozzle 11-10.

[0060] like Figure 4 , Figure 5 As shown, the external pressure membrane tube 11-1 includes a support layer 11-3, and a separation layer 11-2 is arranged on the outside of the support layer 11-3. The separation layer 11-2 adopts a multifunctional graphene / polymer composite water permeable membrane. The pore diameter...

Embodiment 2

[0094] In this embodiment, the difference from Embodiment 1 is that, as Figure 8 As shown, the separation layer 11-2 is wrapped on the support layer 11-3 in a spiral wound structure, and is bonded with epoxy resin or polyurethane at the seam, or welded by heat and pressure, so that the separation layer 11-2 and the support layer 11-3 3 tightly connected together.

[0095] Figure 8 It is only a schematic diagram of the structure. During the winding process of the separation layer 11-2, each turn of the separation layer 11-2 needs to closely connect and transition with the upper and lower turns.

[0096] In the spiral-wound structure, the support layer 11-3 can be wrapped with a narrow separation layer 11-2.

[0097] Other structures of the tubular membrane module in this embodiment are the same as those in Embodiment 1, and will not be described again here.

[0098] In addition to providing the above acid wastewater treatment device using membrane technology, the present i...

experiment example 1

[0106] A kind of iron-containing waste hydrochloric acid water with an electrical conductivity (abbreviated as EC value) of about 120ms / cm is selected for concentration and separation treatment. The wastewater has been pretreated to remove particulate impurities and some organic components above 25 μm (microns); the chlorine ion content of the sewage is 1.51×10 4 mg / L, the pH value of raw water is less than 1, and the iron ion content is 2.14×10 3 mg / L.

[0107] In order to study the influence of different sewage treatment temperatures on the effluent water quality, the sewage temperature of the sewage treatment tank 16 was respectively set at 50°C, 60°C and 70°C to conduct a membrane module sewage concentration and separation experiment. The parameters of other parts of the acid wastewater treatment device are kept the same, that is, the condensed water temperature of the condensing device 13 is set at 18°C, and the vacuum degree of the negative pressure system 14 is kept at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com