A mbr membrane sewage treatment system

A sewage treatment system and sewage technology, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the complex pollution treatment of MBR membranes, large area, and energy consumption for stirring. Large and other problems, to achieve the effect of high quality and stable effluent quality, small footprint, and thorough disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

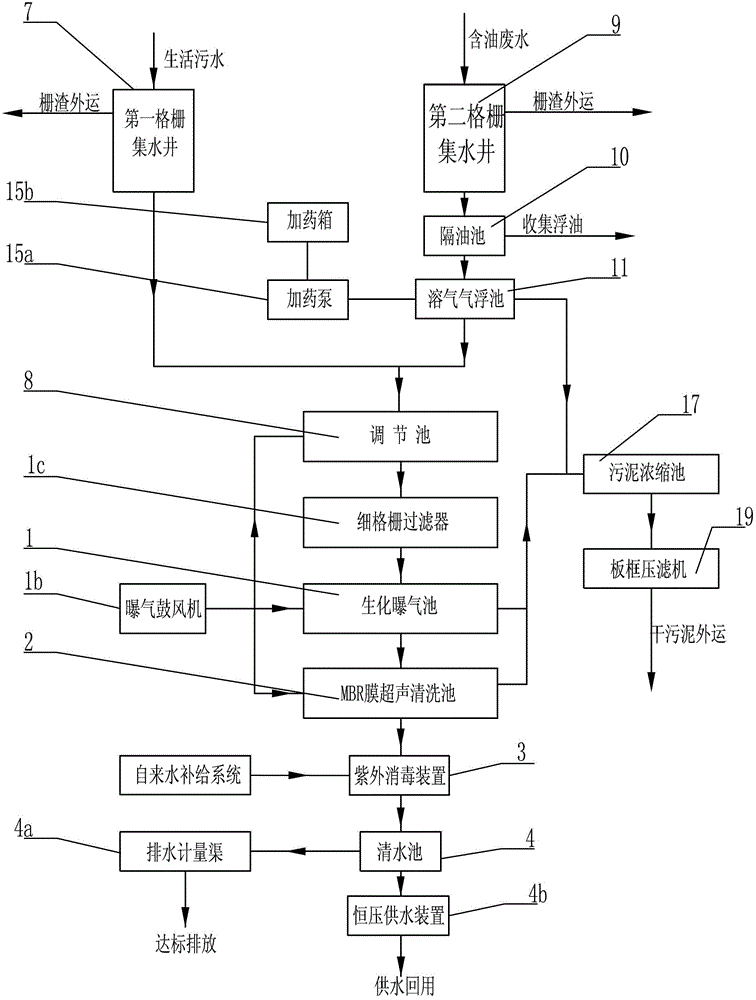

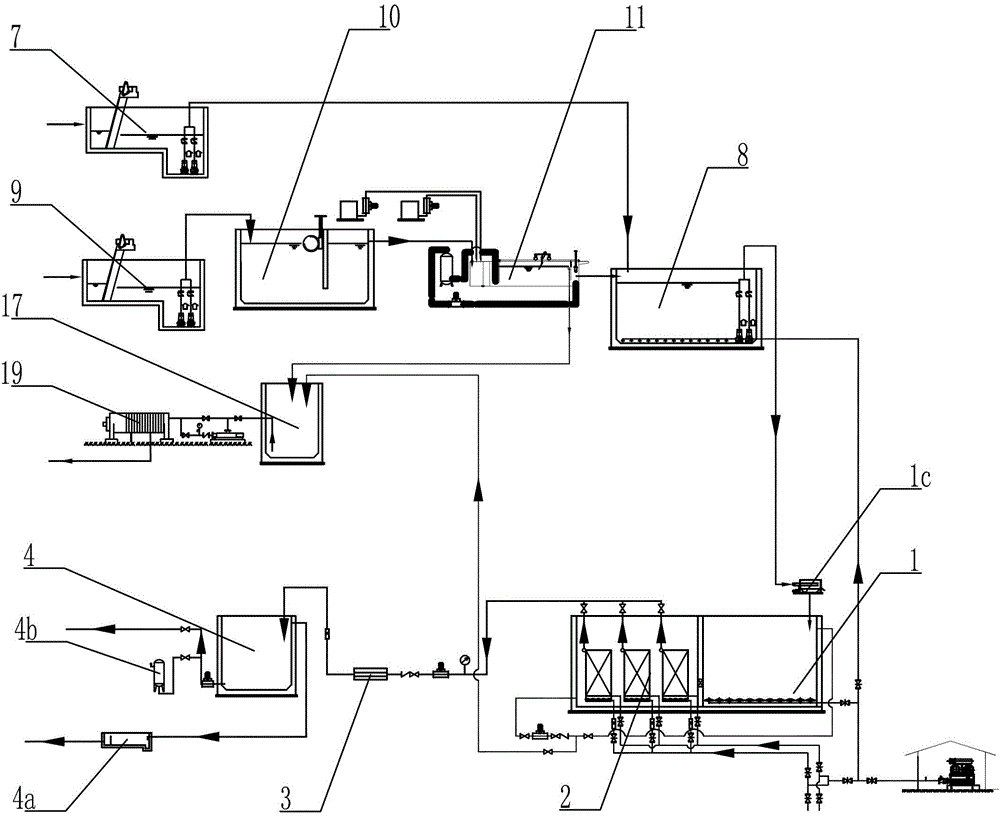

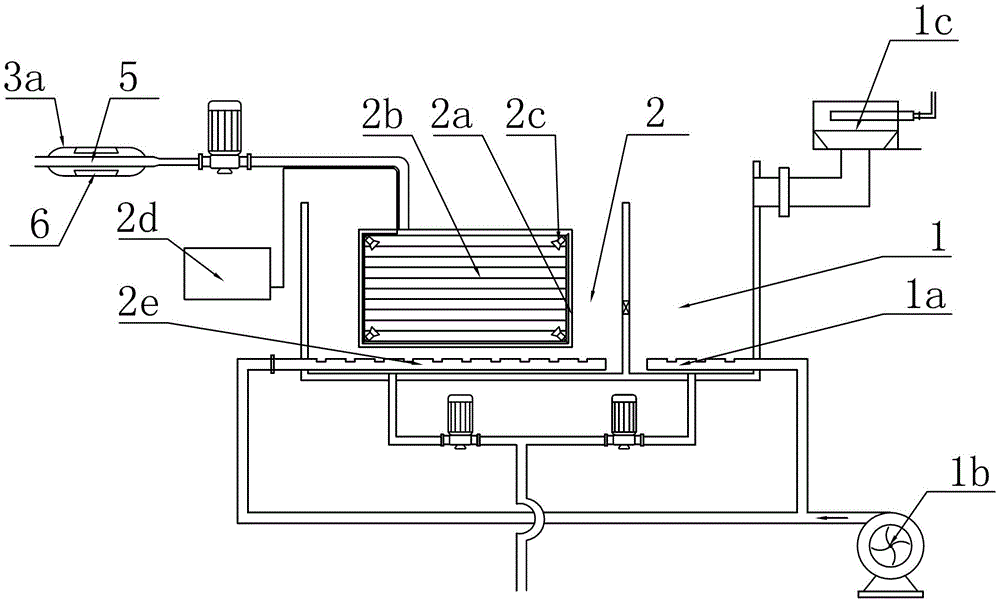

[0034] Example: such as figure 1 and figure 2Shown: a MBR membrane sewage treatment system, including a pretreatment system and a sewage treatment system, the pretreatment system includes a first grid water collection well 7 and a regulating tank 8 communicated with the first grid water collection well 7, The regulating tank 8 is also connected with an oily wastewater pretreatment system. The oily wastewater treatment system is composed of a second grid water collection well 9, a grease trap 10 and a dissolved air flotation tank 11 in series. The dissolved air flotation tank 11 The sewage treatment system is connected with the regulating tank 8 through pipelines; the sewage treatment system is composed of a biochemical aeration tank 1, an MBR membrane ultrasonic cleaning tank 2, an ultraviolet disinfection device 3 and a clear water tank 4 in series through pipelines, and the regulating tank 8 is connected in series through pipelines. The biochemical aeration tank 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com