Drinking water pipe cleaning agent, and cleaning and maintenance methods of drinking water pipe

A cleaning agent and water pipe technology, applied in the preparation of detergent mixture composition, detergent composition, detergent compounding agent, etc., can solve the problem that only sludge and part of scale can be removed, but rust and bacteria cannot be completely removed. Remove rust and scale and other problems, achieve the effect of simple and easy cleaning equipment, suitable for large-scale promotion and application, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

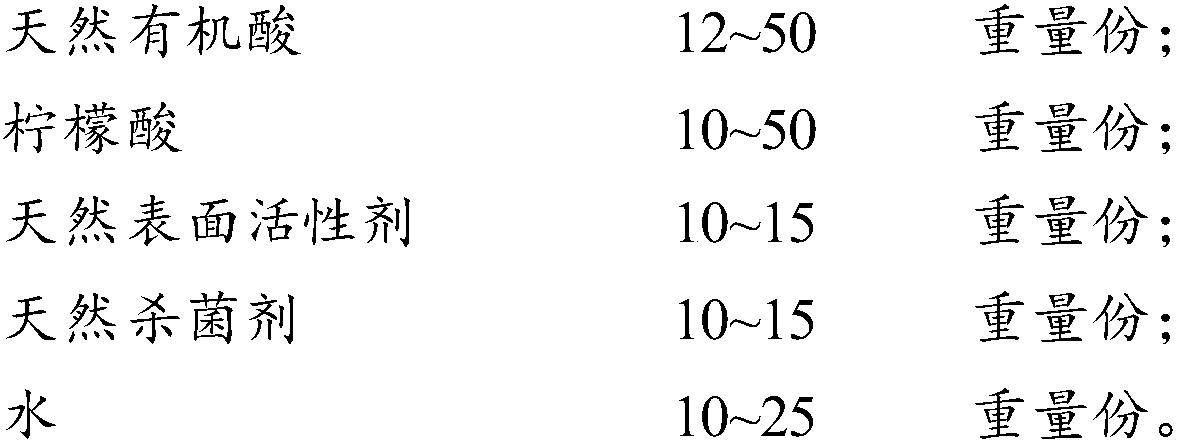

[0090] Cleaning agent formula:

[0091] Acetic acid 30

[0092] Citric acid 40

[0093] orange oil 10

[0094] Allicin 10

[0095] Corn starch modified water absorbent 5

[0096] Purified water 20

[0097] the cleaning method:

[0098] Add a water inlet and valve at the entrance of the household water supply, and transport the water pipe cleaning agent and water (1:10) prepared according to the above ratio to the indoor water pipe through the water pump, through the cleaning agent and the scale on the inner wall of the water pipe, Rust and sludge undergo physical and chemical reactions to effectively remove scale, rust and sludge. Use the bactericidal effect of allicin, orange oil and citric acid to effectively kill harmful bacteria in the water pipe. After the cleaning agent stays in the water pipe for 60 minutes, after the sewage is discharged, the water pipe cleaning agent and water (1:20) are transported to the water pipe again with a pump to stay for 30 minutes. A...

Embodiment 2

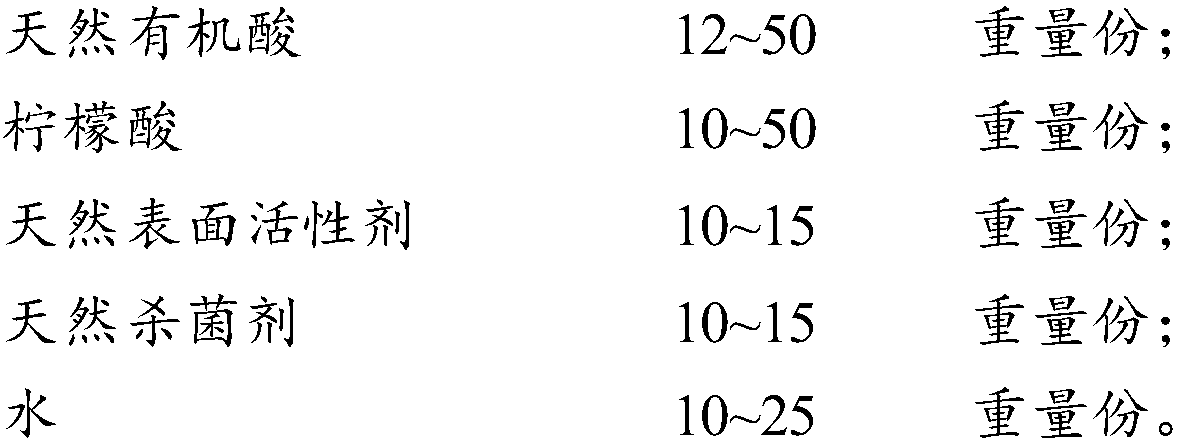

[0103] Cleaning agent formula:

[0104] Maslinic acid 20

[0105] Citric acid 30

[0106] orange oil 10

[0107] Allicin 10

[0108] Corn starch modified water absorbent 8

[0109] purified water 22

[0110] Add a water inlet and valve at the entrance of the household water supply, and transport the water pipe cleaning agent and water (1:10) prepared according to the above ratio to the indoor water pipe through the water pump, through the cleaning agent and the scale on the inner wall of the water pipe, Rust and sludge undergo physical and chemical reactions to effectively remove scale, rust and sludge. Use the bactericidal effect of allicin, orange oil and citric acid to effectively kill harmful bacteria in the water pipe. After the cleaning agent stays in the water pipe for 60 minutes, after the sewage is discharged, the water pipe cleaning agent and water (1:20) are transported to the water pipe again with a pump to stay for 30 minutes. After the clear water is disch...

Embodiment 3

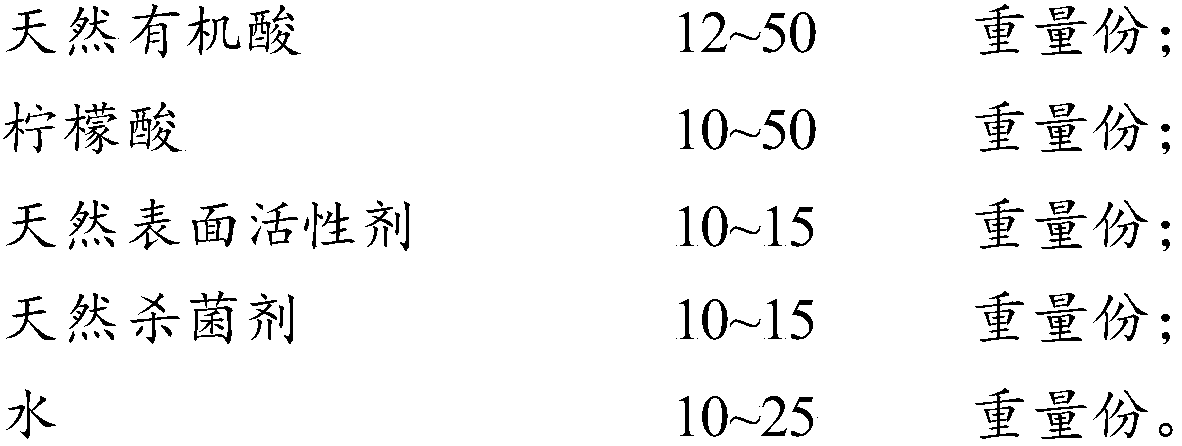

[0114] Cleaning agent formula:

[0115] Acetic acid 10

[0116] Maslinic acid 10

[0117] Citric acid 30

[0118] orange oil 10

[0119] Allicin 10

[0120] Corn starch modified water absorbent 6

[0121] Purified water 24

[0122]Add a water inlet and valve at the entrance of the household water supply, and transport the water pipe cleaning agent and water (1:10) prepared according to the above ratio to the indoor water pipe through the water pump, through the cleaning agent and the scale on the inner wall of the water pipe, Rust and sludge undergo physical and chemical reactions to effectively remove scale, rust and sludge. Use the bactericidal effect of allicin, orange oil and citric acid to effectively kill harmful bacteria in the water pipe. After the cleaning agent stays in the water pipe for 60 minutes, after the sewage is discharged, the water pipe cleaning agent and water (1:20) are transported to the water pipe again with a pump to stay for 30 minutes. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com