Petrochemical wastewater advanced treatment method

A petrochemical wastewater and advanced treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of substrate selectivity, high energy consumption, and low utilization rate of ozone oxidation , slow response speed and other issues, to achieve the effect of ensuring normal and stable operation, wide applicability, and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

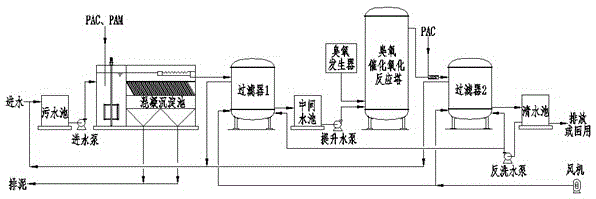

[0022] A refining and chemical company in Jiangsu has a daily wastewater treatment volume of 2000m3 / d, which is currently treated by a secondary biochemical process. In order to realize the comprehensive reuse of sewage, it is planned to upgrade the existing process and add an advanced treatment unit on the basis of the original secondary biochemical treatment process. Using the coagulation precipitation + ozone catalytic oxidation + micro-flocculation combined process method of the present invention (see attached figure 1 ) for advanced treatment of secondary biochemical effluent.

[0023] 1) The secondary biochemical effluent (see Table 1 for water quality analysis) is lifted by the pump and enters the coagulation sedimentation + filter 1 for pretreatment. The concentrations of PAC and PAM added to the coagulation sedimentation tank are 10-30mg / L and 0.2 -0.8mg / L, the dosing concentration needs to be determined by field test;

[0024] 2) The effluent from filter 1 enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com