Food waste treatment process

A technology of kitchen waste and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, organic fertilizer, etc., can solve the problems of high investment cost and difficulty in tail gas treatment, and achieve the effect of reducing COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

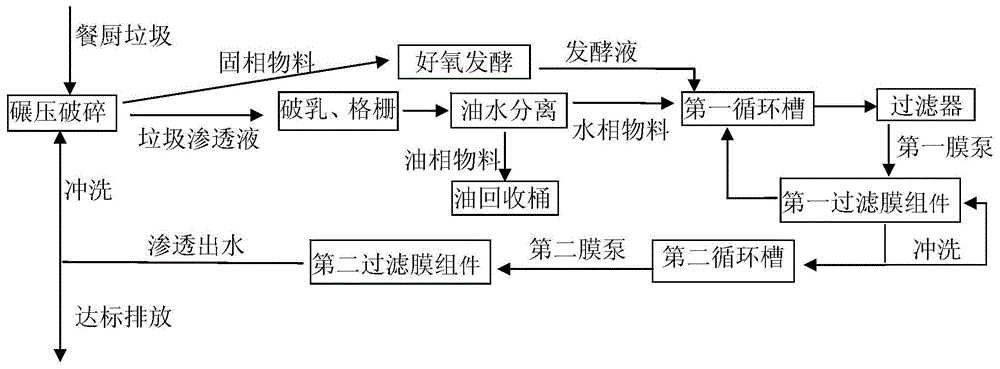

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0048] The treatment system for treating kitchen waste in this embodiment includes a pretreatment system, a first filter system and a second filter system connected in sequence.

[0049] Wherein, the pre-treatment system includes a rolling crushing device, a demulsification grid device and an oil-water separation device connected in sequence, and the oil-water separation device is connected with the first filtration system.

[0050] The first filtration system comprises a first circulation tank, a filter and a first filtration membrane assembly capable of cross-flow filtration connected in sequence, the input end of the first circulation tank is connected with the output end of the pretreatment system, and the first filtration membrane assembly The output end is connected to the input end of the second filtration system; the first filtration s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com