Patents

Literature

41 results about "Anionic detergent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microparticles with adsorbent surfaces, methods of making same, and uses thereof

InactiveUS6884435B1Stimulate immune responseEasy to usePowder deliverySsRNA viruses positive-senseAntigenDisease

The present invention is directed to microparticles, to microparticle compositions containing the same, to methods of forming the same, and to uses for the same, including use for a vaccine, for raising an immune response, for treatment of a disease and for diagnosis of a disease. The microparticles comprise a biodegradable polymer, such as a poly(α-hydroxy acid), a polyhydroxy butyric acid, a polycaprolactone, a polyorthoester, a polyanhydride, or a polycyanoacrylate, and a detergent selected from a cationic detergent and an anionic detergent. The microparticles further comprise an antigen adsorbed on the surface of the microparticle.

Owner:NOVARTIS VACCINES & DIAGNOSTICS INC

Methods for the isolation of nucleic acids and for quantitative DNA extraction and detection for leukocyte evaluation in blood products

InactiveUS6958392B2Sugar derivativesMicrobiological testing/measurementWhole blood productWhite blood cell

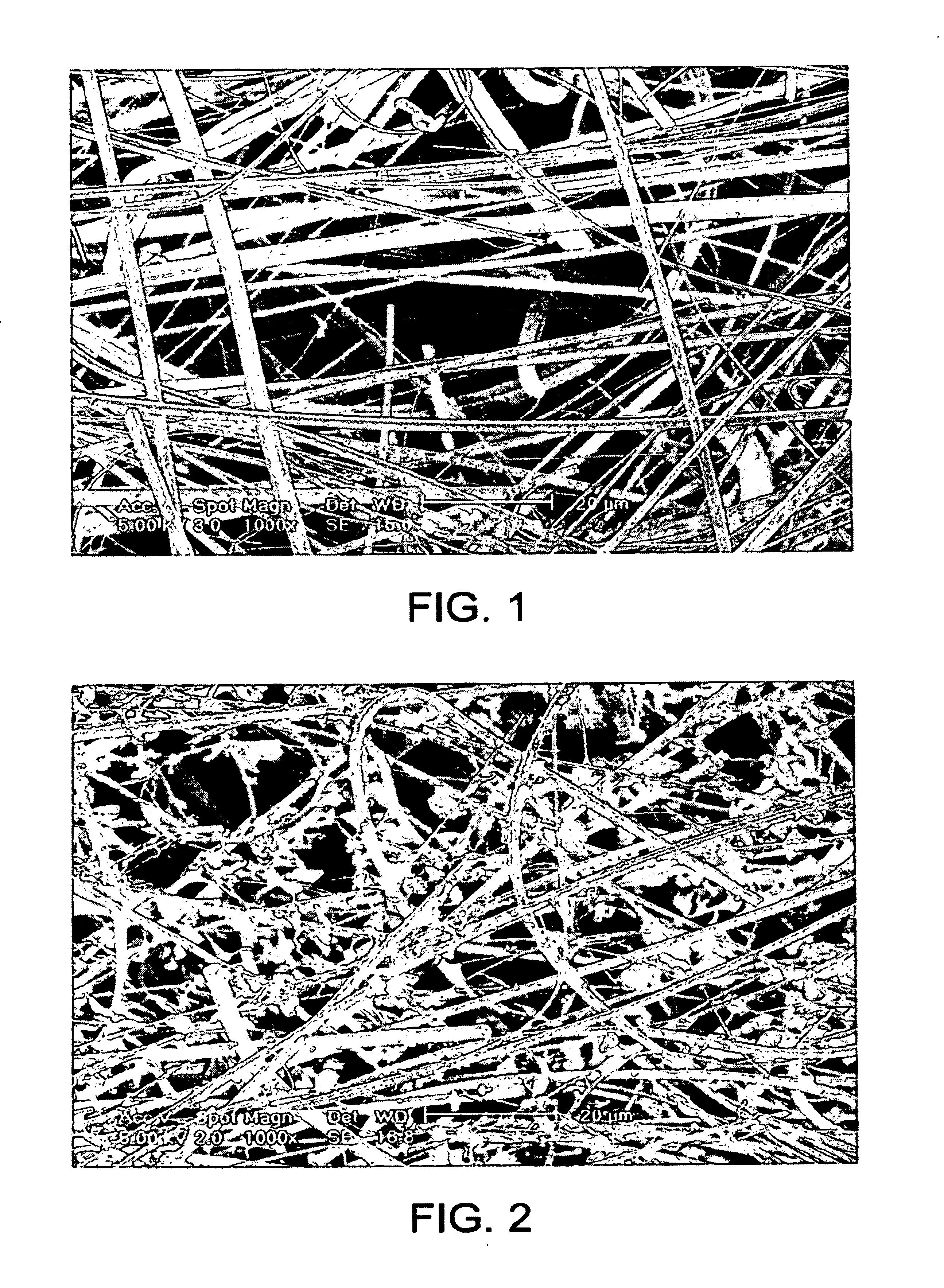

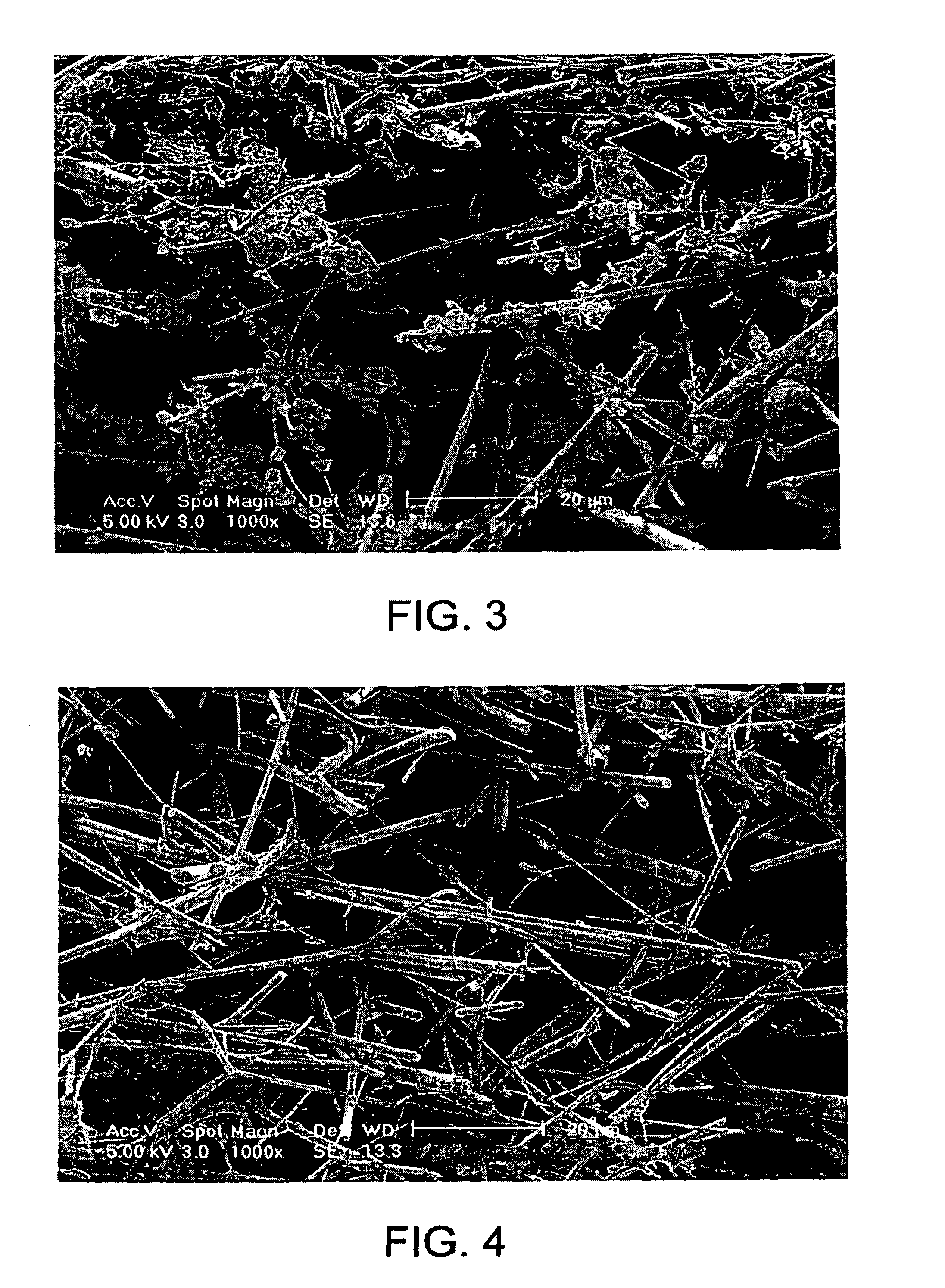

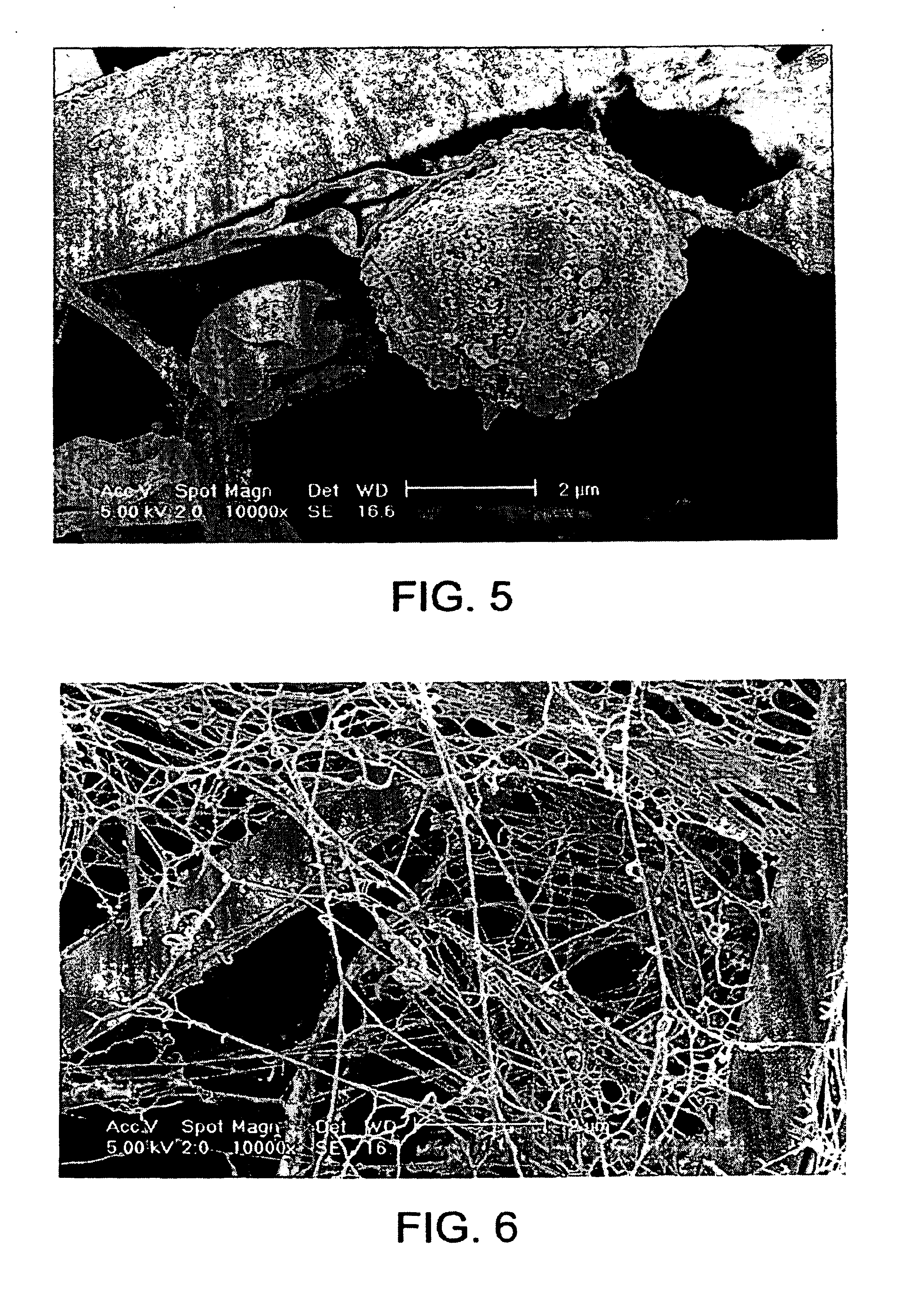

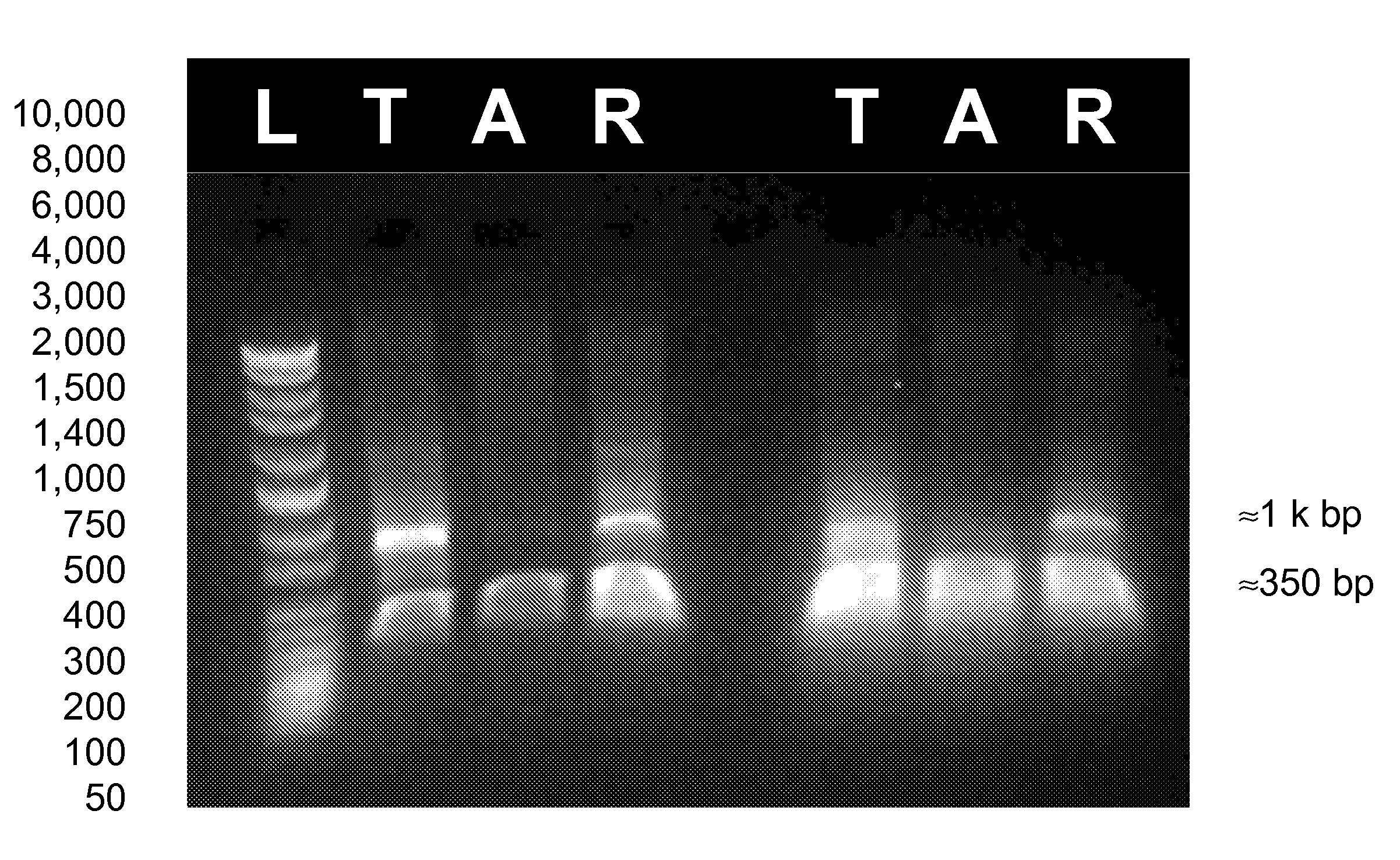

A method for isolating nucleic acid which comprises:(a) applying a sample comprising cells containing nucleic acid to a filter, whereby the cells are retained as a retentate and contaminants are removed;(b) lysing the retentate from step (a) while the retentate is retained by the filter to form a cell lysate containing the nucleic acid;(c) filtering the cell lysate with the filter to retain the nucleic acid and remove remaining cell lysate;(d) optionally washing the nucleic acid retained by the filter; and(e) eluting the nucleic acid, wherein the filter composition and dimensions are selected so that the filter is capable of retaining the cells and the nucleic acid.Additionally, there is provided a substrate for lysing cells and purifying nucleic acid having a matrix and a coating and an integrity maintainer for maintaining the purified nucleic acid. Also provided is a method of purifying nucleic acid by applying a nucleic acid sample to a substrate having an anionic detergent affixed to a matrix, the substrate physically capturing the nucleic acid, bonding the nucleic acid to a substrate and generating a signal when the nucleic acid bonds to the substrate indicating the presence of the nucleic acid. A kit for purifying nucleic acid containing a coated matrix and an integrity maintenance provider for preserving the matrix and purifying nucleic acid is also provided. Further, there is provided a method for quantifying DNA, such as double-stranded or genomic DNA, isolated from cells, such as leukocytes to determine the numbers of leukocytes in a sample of leukoreduced blood.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

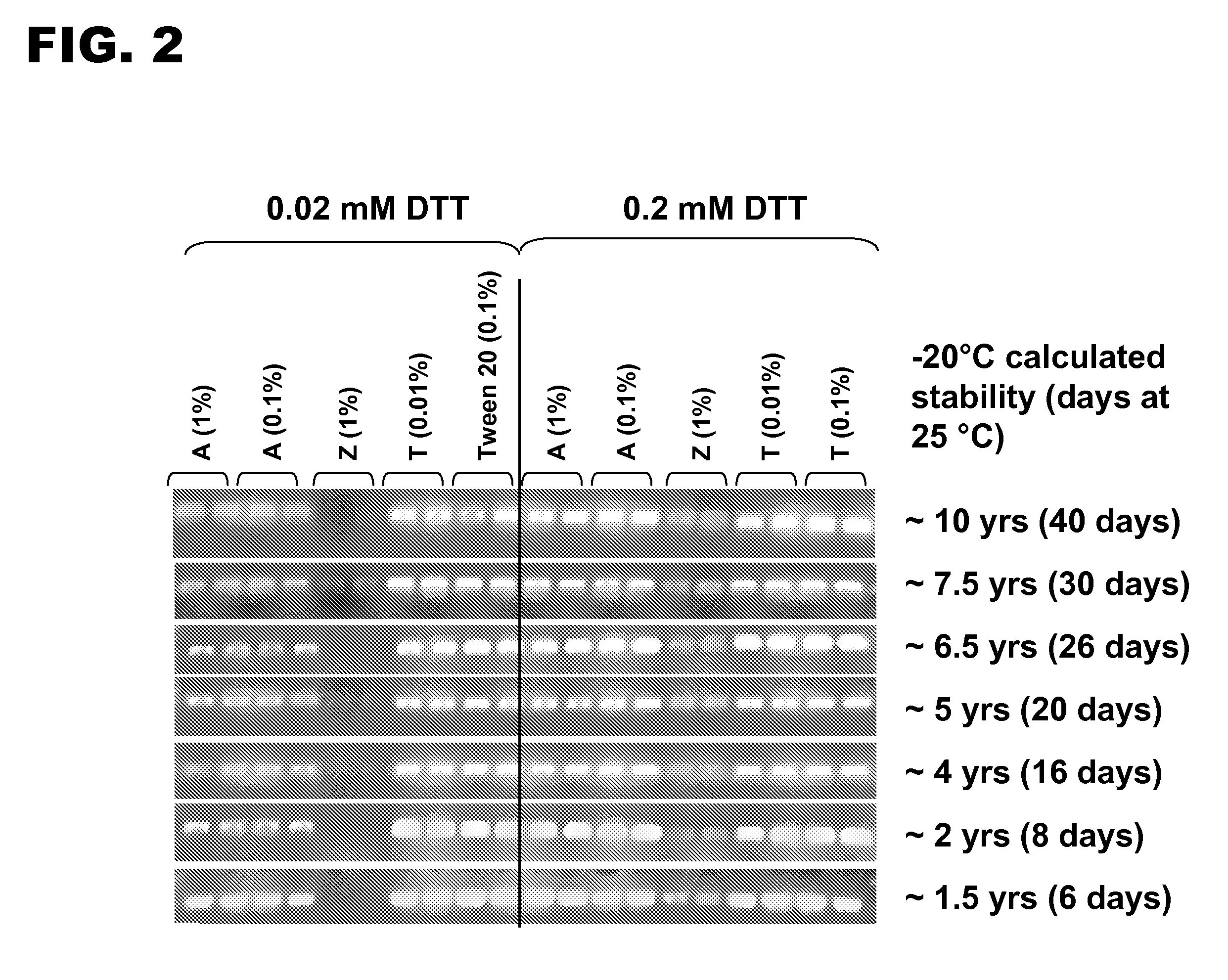

Stabilized compositions of thermostable DNA polymerase and anionic or zwitterionic detergent

ActiveUS20080145910A1Avoid inactivationMicrobiological testing/measurementTransferasesAnionic detergentOrganic chemistry

The present invention provides compositions, methods, and kits for protecting thermostable DNA polymerase during amplification reactions conducted at a temperature ranging from about 40° C. to greater than 100° C. The composition comprises a thermostable DNA polymerase and an anionic detergent or zwitterionic detergent.

Owner:SIGMA ALDRICH CO LLC

Stabilized compositions of thermostable DNA polymerase and anionic or zwitterionic detergent

The present invention provides compositions, methods, and kits for protecting thermostable DNA polymerase during amplification reactions conducted at a temperature ranging from about 40° C. to greater than 100° C. The composition comprises a thermostable DNA polymerase and an anionic detergent or zwitterionic detergent.

Owner:SIGMA ALDRICH CO LLC

Decellularisation of matrices

InactiveUS7354749B2Low toxicityDifferent temperatureBiocideHydrolasesProteinase activityAnionic detergent

A method of preparing matrices or tissue engineered biomaterials for implantation, and in particular to a method of improving decellularisation of matrices or tissue engineered biomaterials prior to implantation. The method employs a single anionic detergent in combination with protease inhibitors.

Owner:TISSUE REGENIX +1

Liquid cleaning composition containing an anionic polyacrylamide copolymer

ActiveUS20050101510A1Maintain good propertiesImprove cutting performanceOrganic detergent compounding agentsNon-ionic surface-active compoundsAdditive ingredientAnionic detergent

An improvement is described in all purpose liquid cleaning compositions which are especially effective in the removal of oily and greasy soil and contains an anionic detergent, and / or ethoxylated nonionic surfactants, an anionic polyacrylamide copolymer, olefin / maleic acid copolymer, a hydrocarbon ingredient, and water.

Owner:COLGATE PALMOLIVE CO

Method for Decellularization of Tissue Grafts

ActiveUS20160030636A1Encourage graft implantationReduced CD4+ T-cell mediated immune responseCell dissociation methodsMammal material medical ingredientsCellular componentCell-Extracellular Matrix

The subject invention pertains to materials and methods for processing tissue to produce a natural, acellular replacement tissue that is immunocompatible with a recipient. According to the subject invention, harvested tissue is subjected to wash solutions wherein only amphoteric detergent(s) are used (e.g., anionic detergents are excluded). Following extraction by amphoteric detergent(s), the tissue is washed with a buffer system to facilitate the clearance of cellular components and detergent. In one embodiment, the subject invention pertains to a replacement tissue that is a nerve graft that supports axonal regeneration, guides axons toward the distal nerve end and / or is immunologically tolerated. Preferably, the nerve graft retains essential extracellular matrix scaffolding as well as biological components that promote nerve regeneration through the nerve graft.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Decellularisation of matrices

InactiveUS20040157206A1Low toxicityDifferent temperatureBiocidePeptide/protein ingredientsProteinase activityAnionic detergent

A method of preparing matrices or tissue engineered biomaterials for implantation, and in particular to a method of improving decellularisation of matrices or tissue engineered biomaterials prior to implantation. The method employs a single anionic detergent in combination with protease inhibitors.

Owner:TISSUE REGENIX +1

Liquid cleaning composition containing an anionic polyacrylamide copolymer

InactiveUS7049281B2Maintain good propertiesImprove cutting performanceOrganic detergent compounding agentsNon-ionic surface-active compoundsAnionic detergentPolyacrylamide

Owner:COLGATE PALMOLIVE CO

Method for decellularization of tissue grafts

ActiveUS9572911B2Simple preparation stepsDisrupt immunogenic cellular componentsCell dissociation methodsMammal material medical ingredientsCellular componentCell-Extracellular Matrix

The subject invention pertains to materials and methods for processing tissue to produce a natural, acellular replacement tissue that is immunocompatible with a recipient. According to the subject invention, harvested tissue is subjected to wash solutions wherein only amphoteric detergent(s) are used (e.g., anionic detergents are excluded). Following extraction by amphoteric detergent(s), the tissue is washed with a buffer system to facilitate the clearance of cellular components and detergent. In one embodiment, the subject invention pertains to a replacement tissue that is a nerve graft that supports axonal regeneration, guides axons toward the distal nerve end and / or is immunologically tolerated. Preferably, the nerve graft retains essential extracellular matrix scaffolding as well as biological components that promote nerve regeneration through the nerve graft.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Extraction of high-purity DNA and RNA

InactiveUS20060199203A1Improve bindingMicrobiological testing/measurementNucleic acid reductionEmulsionRna expression

The present invention is directed to a method of extracting nucleic acids from samples containing prokaryotic cells and / or eukaryotic cells by (a) lysing the cells under conditions that minimize RNA expression or enzymatic degradation of RNA; (b) dispersing and diluting the lysed cells; (c) mixing the dispersed and diluted lysed cells with a buffered solution containing cationic and anionic detergents; (d) separating non-nucleic acid contaminants from the nucleic acids by mixing with an organic extraction solvent to generate an emulsion that separates into an organic phase, an interface containing the contaminants and an aqueous phase containing the nucleic acids; (e) separating the phases, and retaining the aqueous phase; and (f) precipitating the nucleic acids in the aqueous phase.

Owner:ATOM SCI

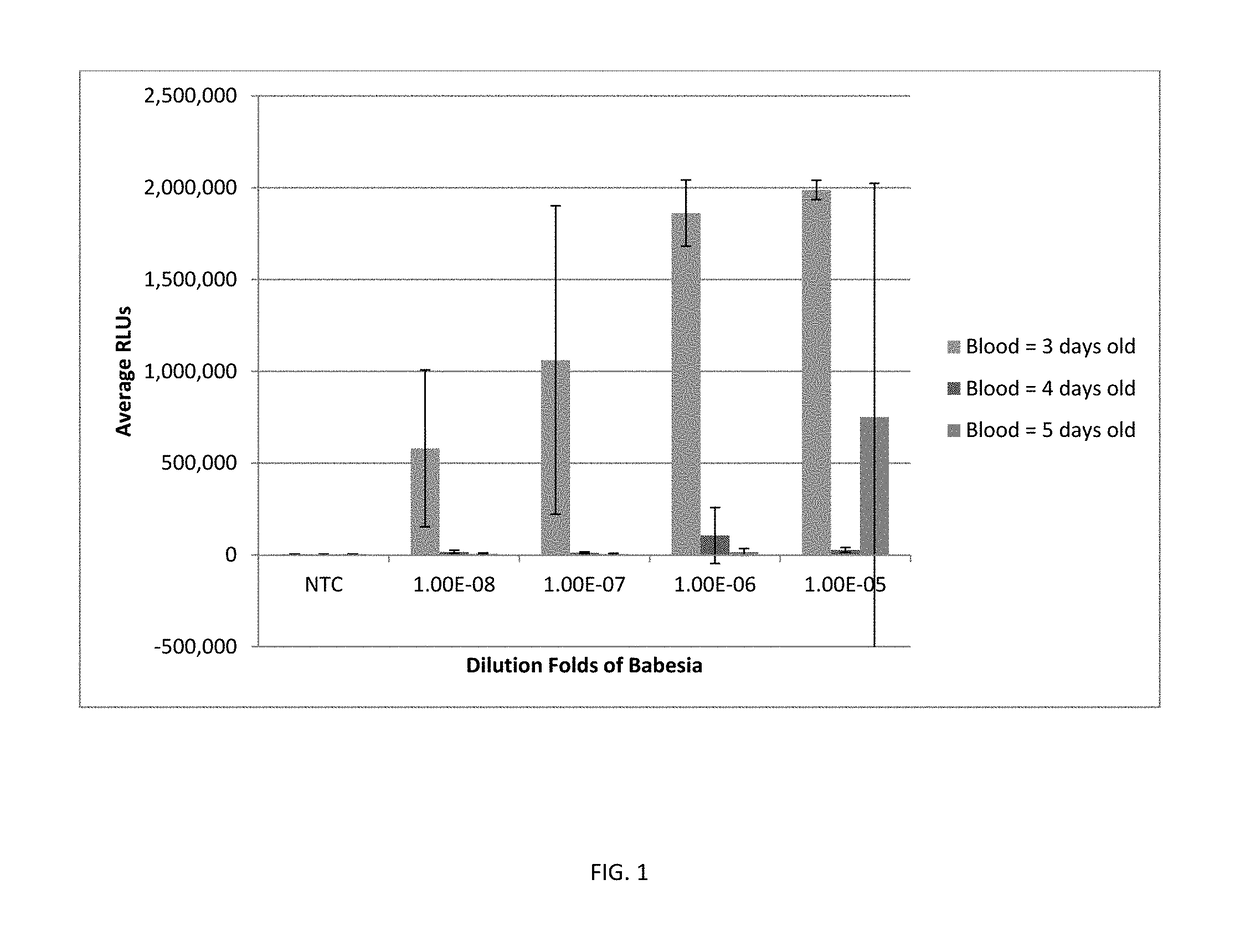

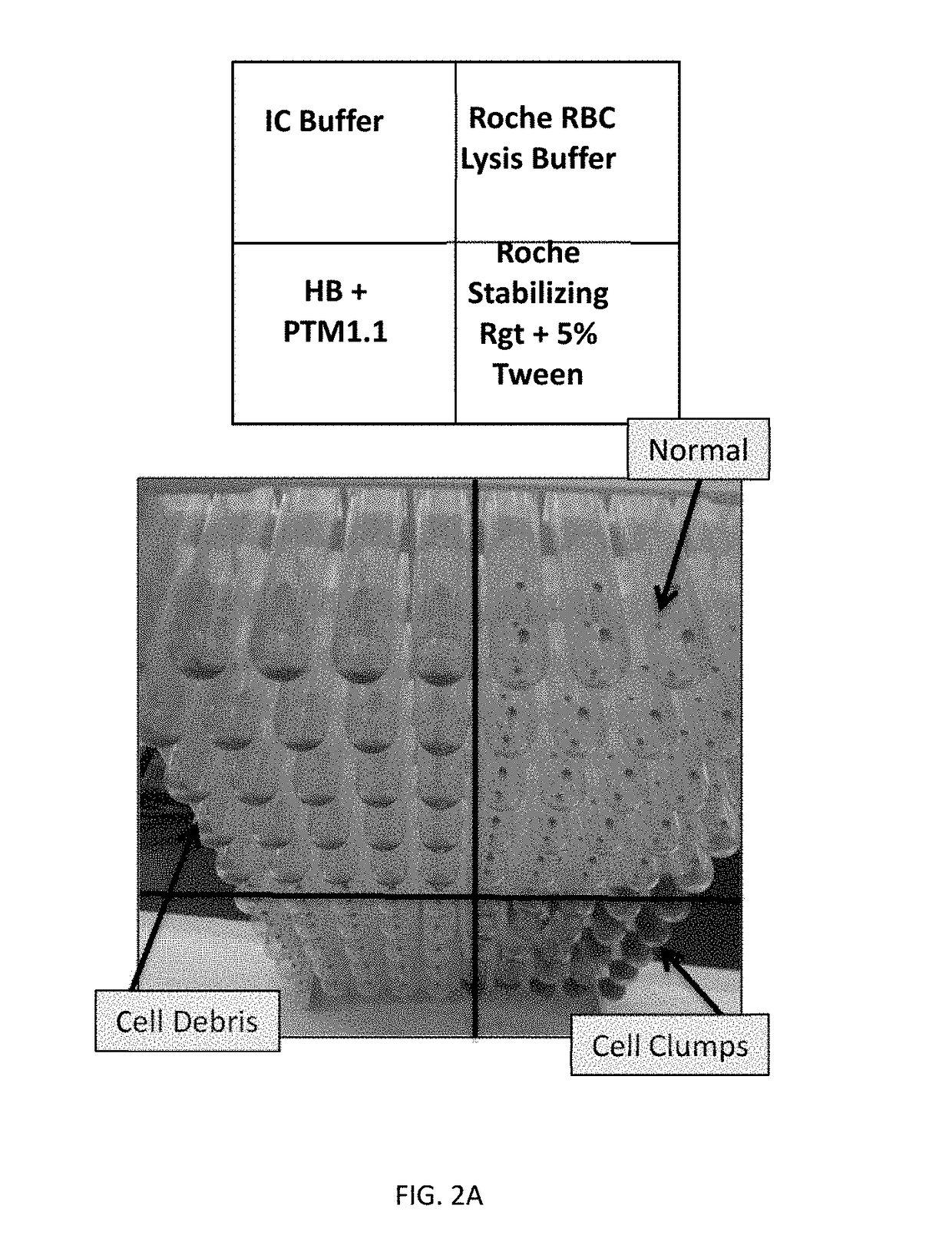

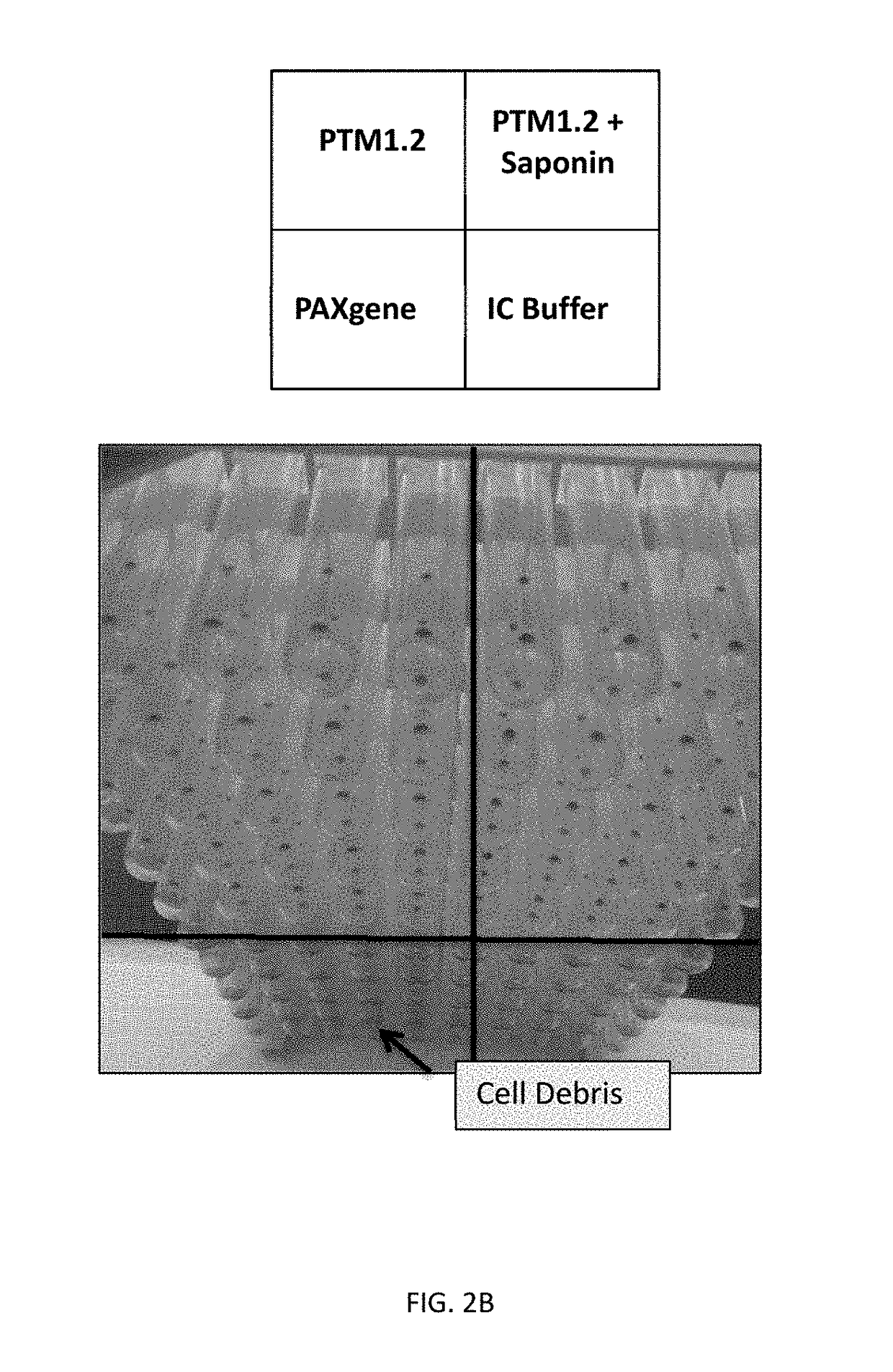

Red blood cell lysis solution

The invention provides a lysis reagent for lysing red blood cells, thereby releasing a target, such as RNA from a parasitic organism, in a form suitable for analysis. The reagent includes at least ammonium chloride and an anionic detergent, and may include an anti-coagulant. The reagent serves to lyse red blood cells, protect the released target from degradation in the lysate, and is compatible with subsequent steps for analysis of the target such as target capture, amplification, detection, or sequencing.

Owner:GEN PROBE INC

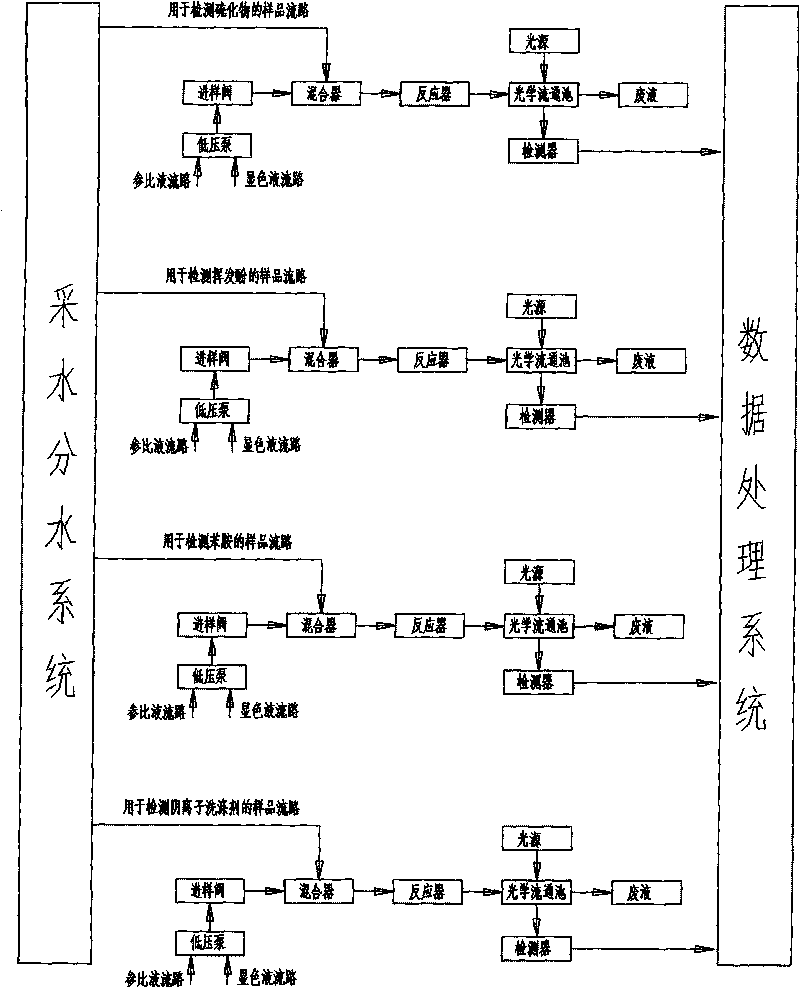

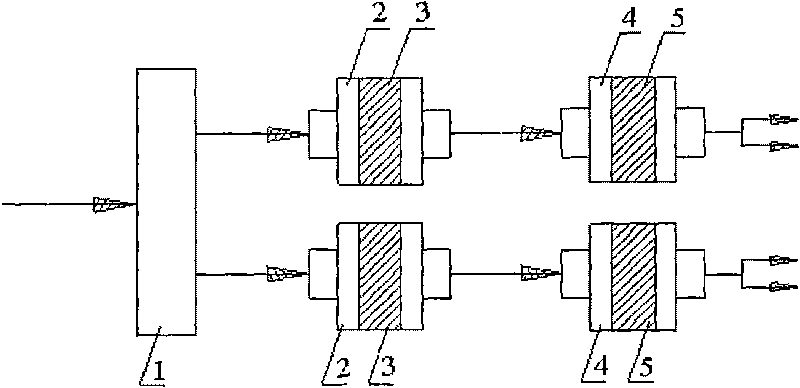

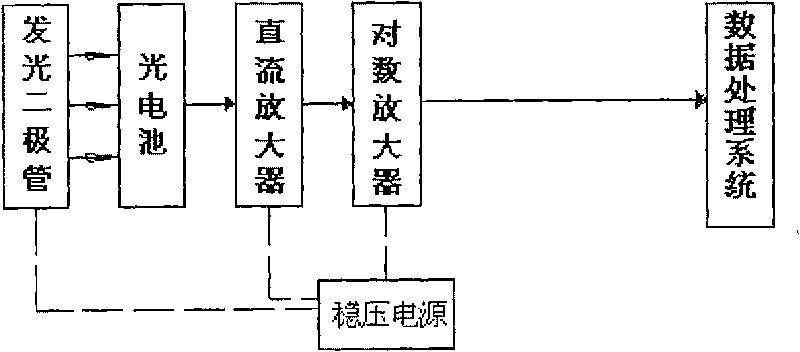

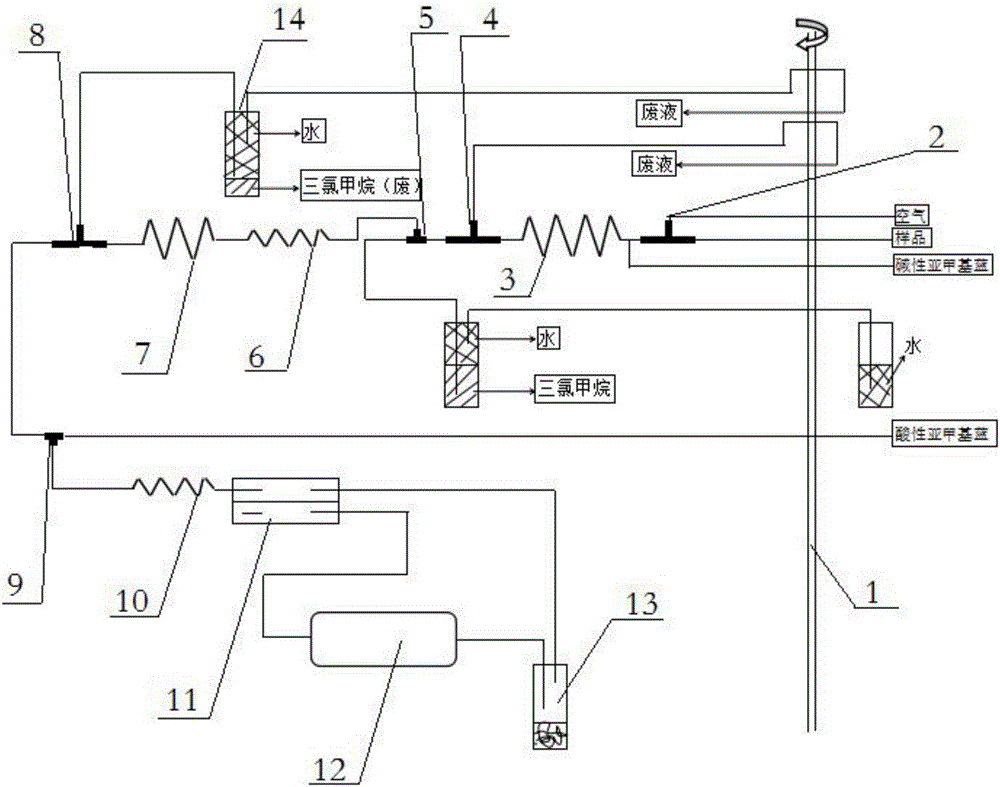

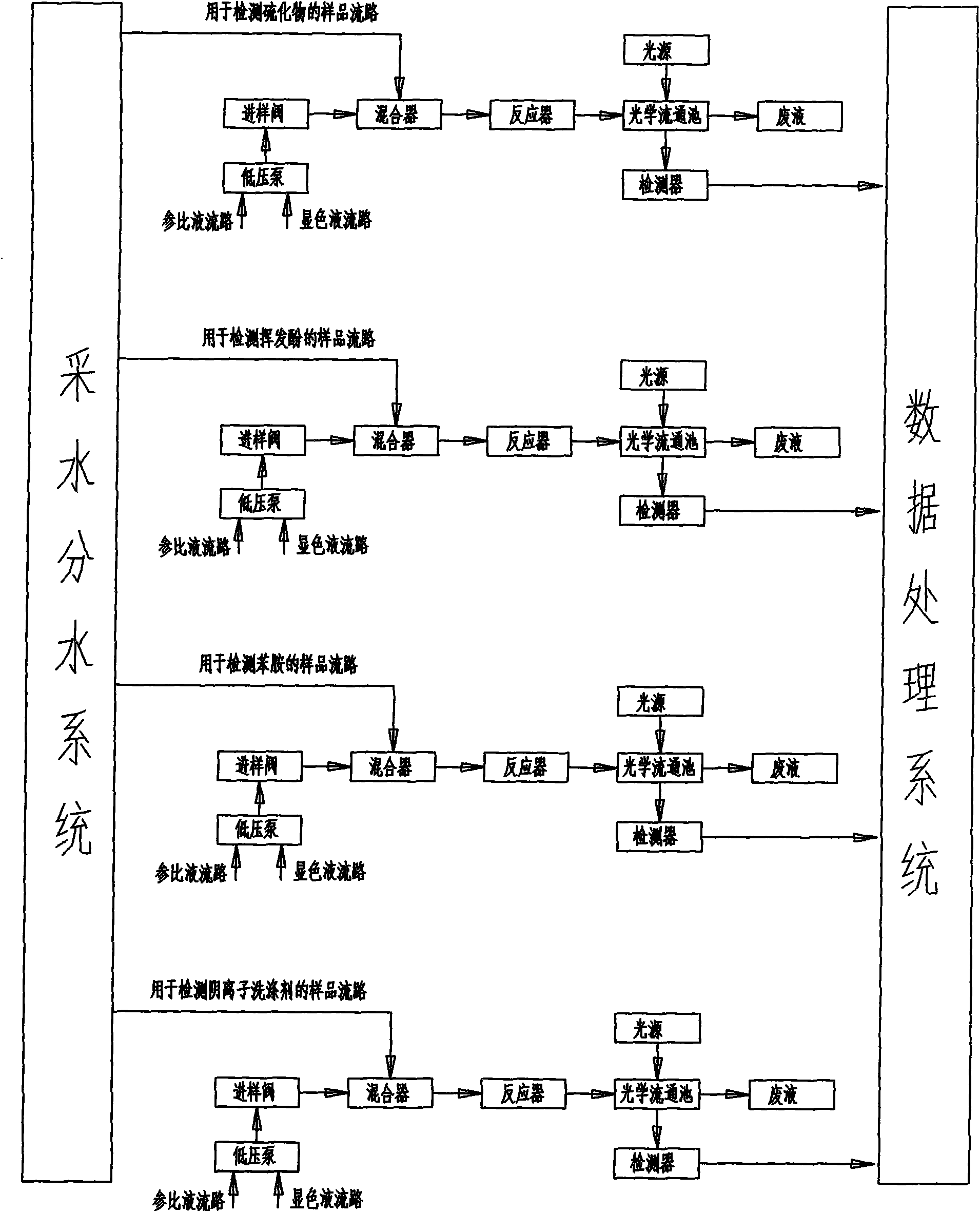

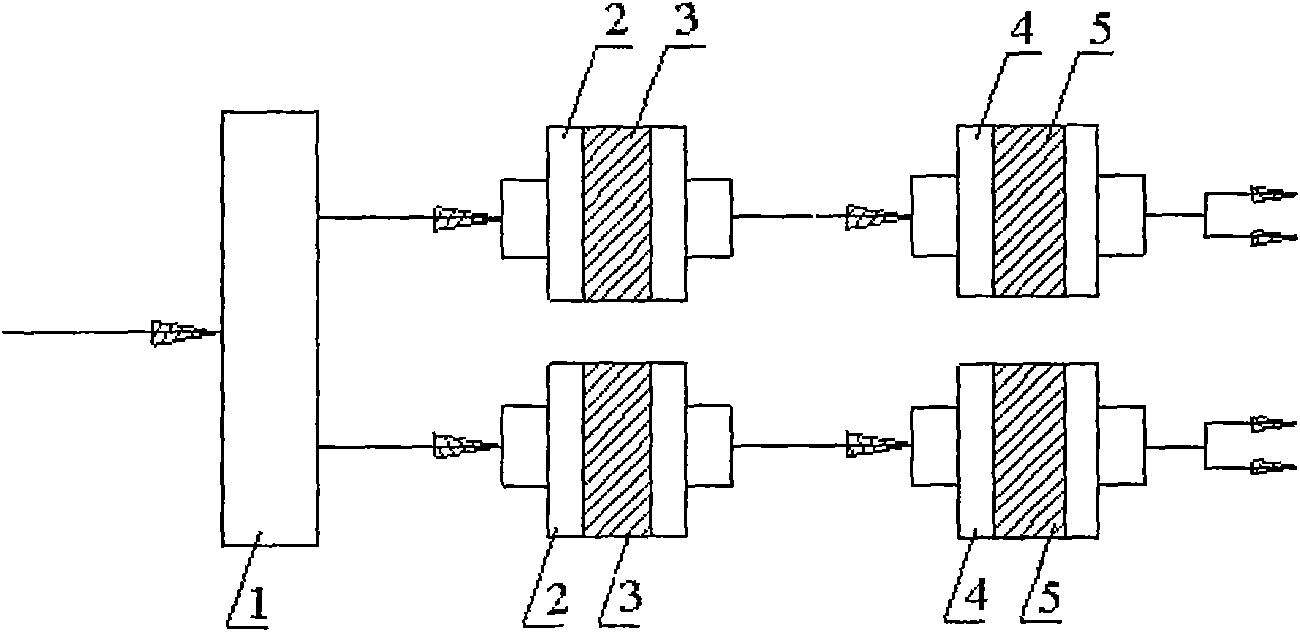

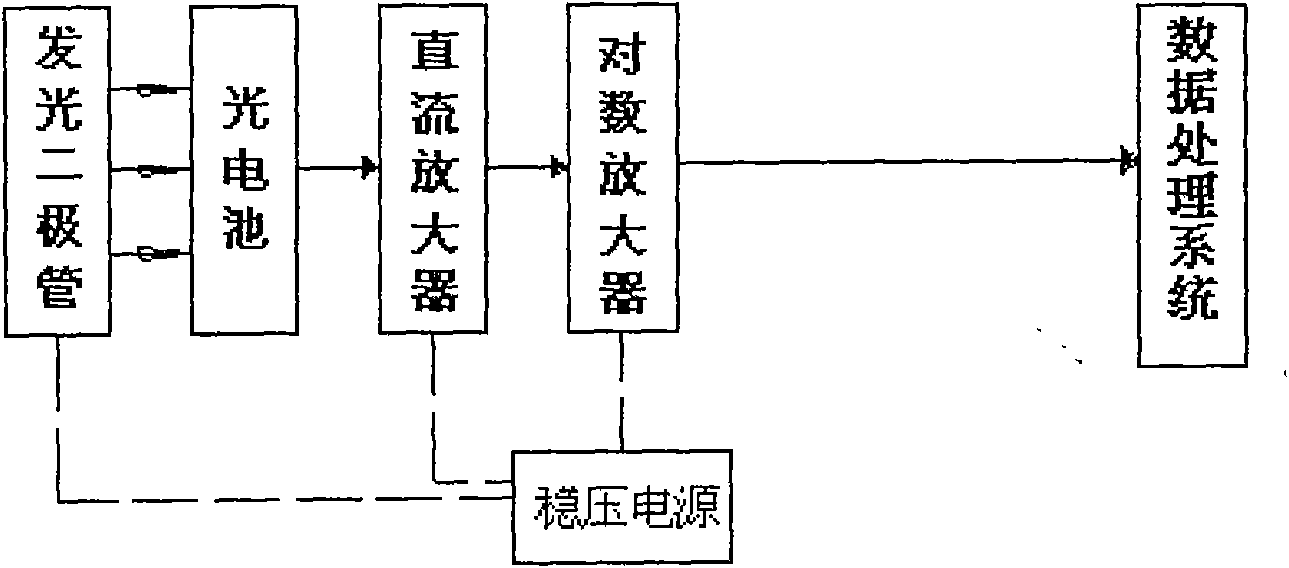

Automatic analyzing instrument of sulphide, phenolic compounds, anionic detergents and aniline in seawater

InactiveCN101696978AShort analysis timeReduce volumeMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesData processing systemTest sample

The invention relates to an automatic analyzing instrument of sulphide, phenolic compound, anionic detergent and aniline in seawater, characterized by comprising a water mining and shunting system, four mutually independent flowing paths and a data-processing system. The water mining and shunting system is connected with the four mutually independent flowing paths by pipe fittings and respectively conveys standard sample or test sample for detecting sulphide, phenolic compound, anionic detergent and aniline to the four mutually independent flowing paths; and detectors in the four mutually independent flowing paths are respectively connected with the data-processing system and respectively convey detection result signals of the sulphide, the phenolic compound, the anionic detergent and theaniline in the standard sample or the test sample to the data-processing system to be processed, stored and displayed. The instrument can carry out the simultaneous online automatic analysis of sulphide, phenolic compound, anionic detergent and aniline in seawater and simultaneously acquire detection results of the four pollutants after one test sample is input.

Owner:SICHUAN UNIV

Method for treating oily wastewater in catering industry

InactiveCN101643251AEasy to operateGood demulsification effectFatty/oily/floating substances removal devicesLiquid separationWater insolubleIron(III) sulfate

The invention belongs to the technical field of wastewater treatment, and particularly relates to a method for treating oily wastewater in catering industry. The invention provides the method for treating the oily wastewater in the catering industry with simple operation and good oil removing effect. The method comprises that (1) a polyferric sulfate demulsifying agent is added into the oily wastewater, the adding amount of the demulsifying agent is 0.2 to 2 milligrams per liter, and the mixture is stirred evenly, wherein the polyferric sulfate is cationic, reduces the surface activity of anionic detergent, and breaks hydrated films of emulsified liquid oil droplets and double electrode layer structures thereof so as to separate out oil; and meanwhile the polyferric sulfate is acid, and can covert fatty acid soap in the emulsified liquid into water-insoluble fatty acid so as to reduce surface active substances in the water and increase the demulsifying effect; (2) sodium humate flocculating agent and polyacrylamide are added into the wastewater obtained in the step (1), the adding amount of the sodium humate is 0.1 to 0.4 milligrams per liter, the adding amount of the polyacrylamide is 40 to 100 milligrams per liter, and the mixture is stirred evenly; and (3) the oil and the water are separated by using the gravity principle.

Owner:韩刚

Bamboo fiber and silk interlaced fabric dyeing and finishing process

InactiveCN103103830AGood coloring rateFeel goodDry-cleaning apparatus for textilesDyeing processSodium bicarbonateDisperse dye

The invention discloses a bamboo fiber and silk interlaced fabric dyeing and finishing process which comprises the following steps: (1) sewing a gray fabric; (2) presetting the fabric; 3) performing pretreatment, namely desizing the preset fabric, wherein a desizing solution contains sodium hydroxide, hydrogen peroxide and amylase, and the temperature of the desizing solution is 30-65 DEG C; (4) dyeing, namely soaking the fabric for 25-35 minutes in 75 percent of an alcohol solution, and dyeing bamboo fibers by low-temperature disperse dyes at 50-100 DEG C and in a dye bath with the pH value of 5.2-6.1, performing reduction clearing on the dyed bamboo fibers for 10-18 minutes at the clearing temperature of 55-60 DEG C, and performing silk dyeing after reduction clearing, wherein a reduction clearing solution comprises 0.3g / L-1.2g / L sodium hydrosulfite, 1.2g / L-2.3g / L an anionic detergent and 0.3g / L-1.2g / L sodium bicarbonate; (5) dehydrating; and (6) performing after-treatment, namely padding the dyed fabric in a hydrophilic aminosilane softening agent, and drying and performing tentering setting on the padded fabric at 85-95 DEG C. The fabric has a high degree of dyeing, integrates the advantages of silk and bamboo fibers, and is cool as well as good in hand-feeling.

Owner:CHANGSHU ZHAOSHI HUADA DYEING & FINISHING

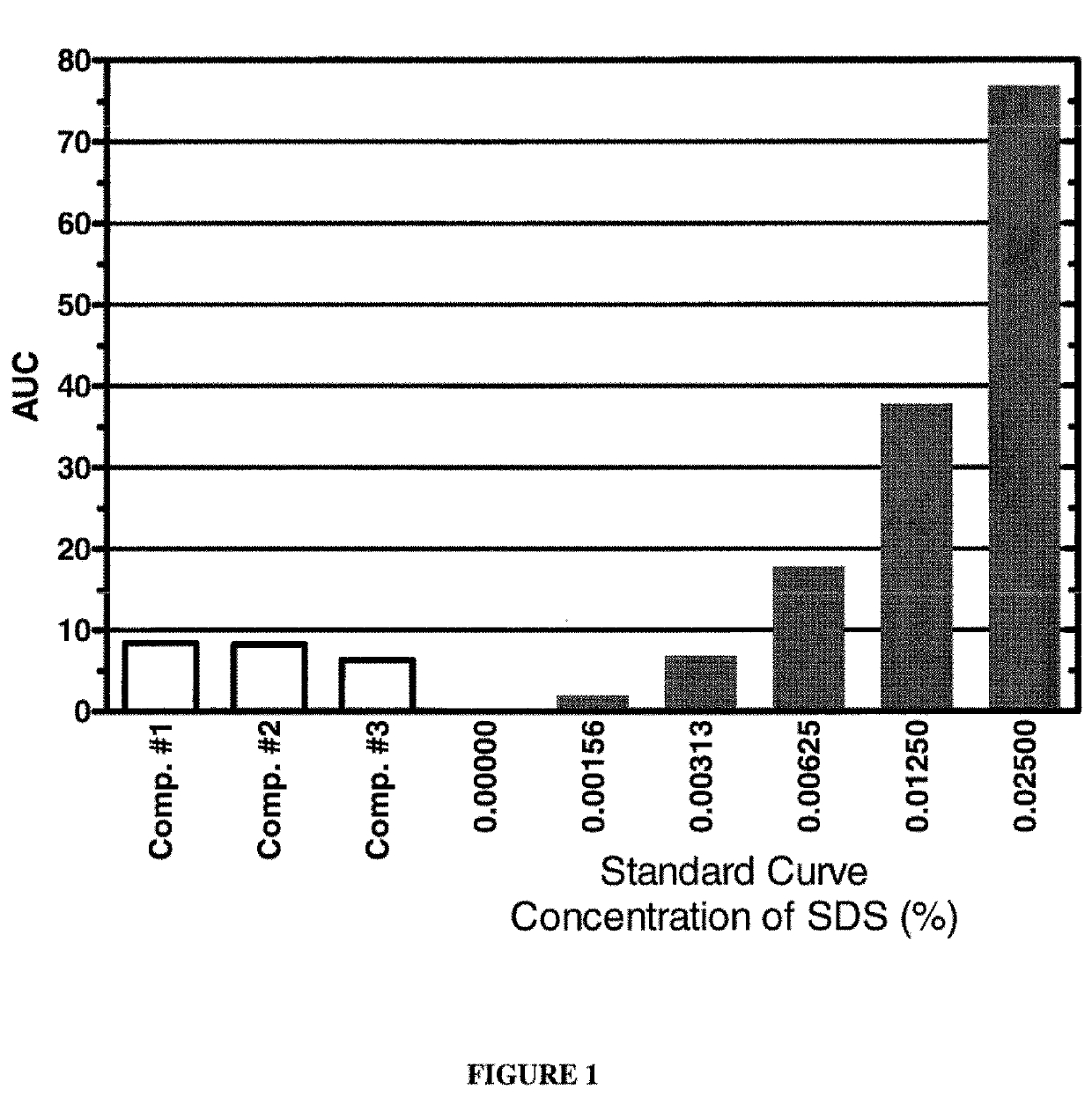

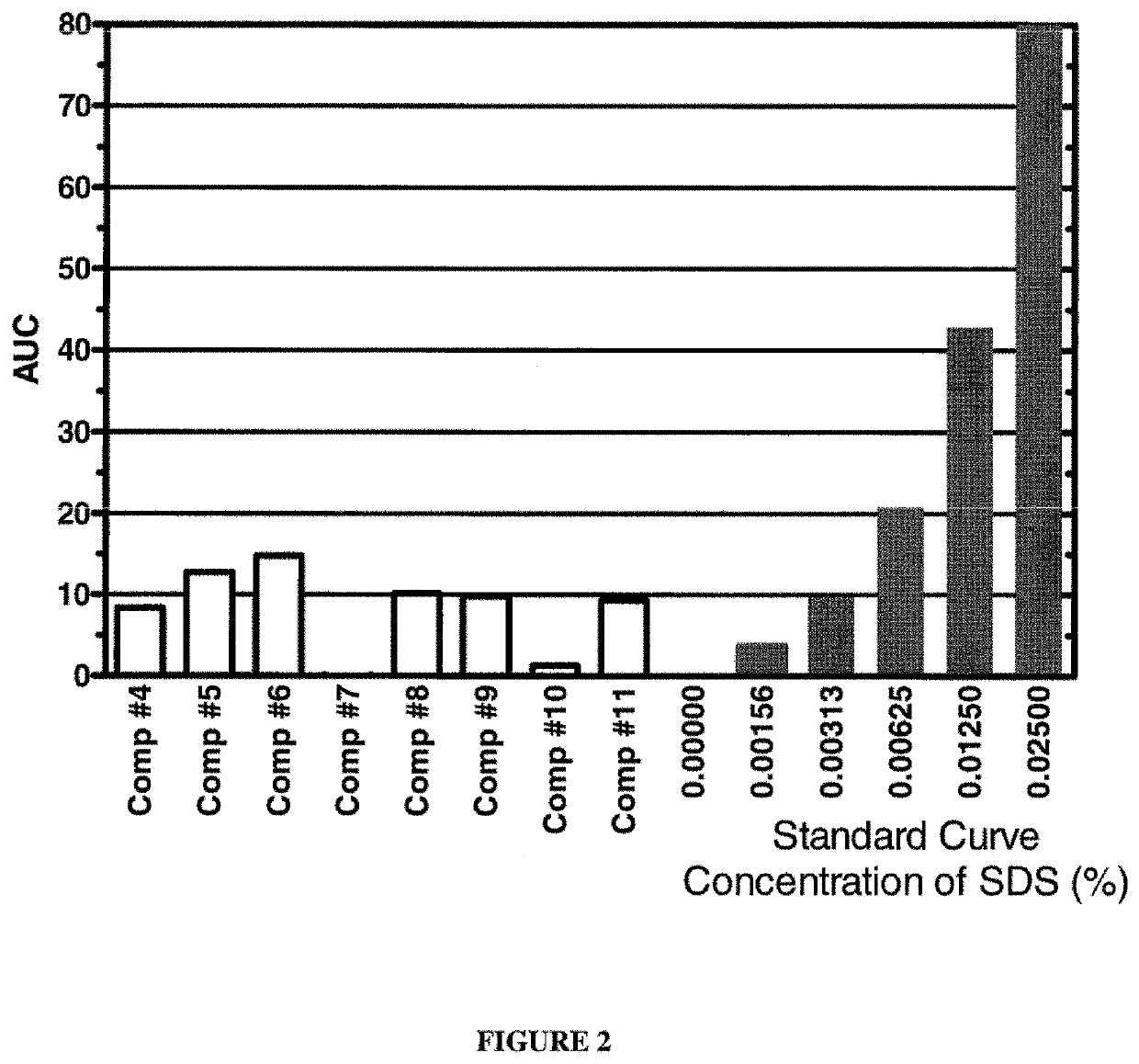

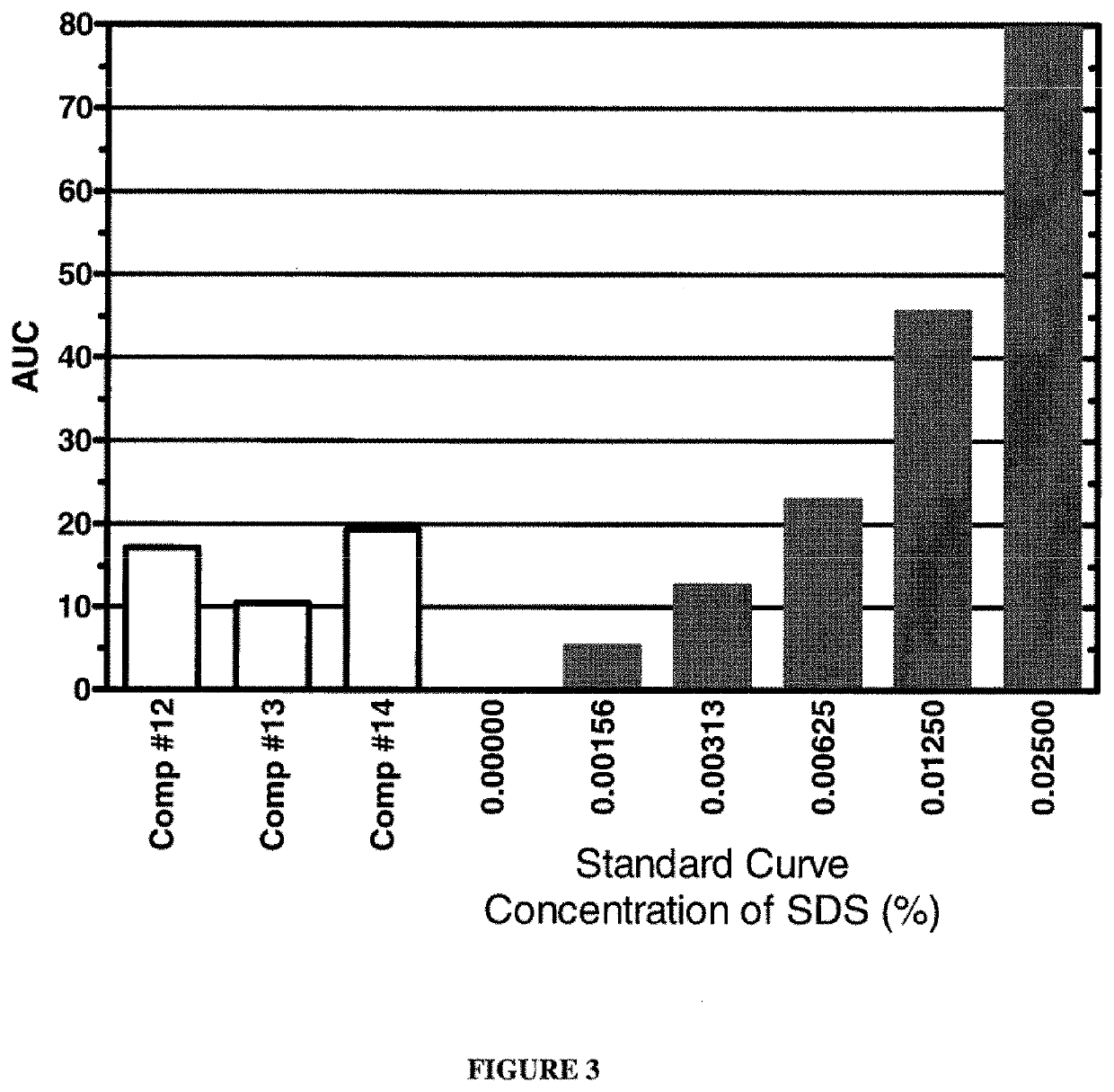

A composition, system and method for removal of detergents from aqueous solutions

PendingUS20200316493A1Water/sewage treatment by centrifugal separationOrganic chemistryHalohydrocarbonAlcohol

A system, composition, method and kit for removing a detergent, such as an anionic detergent, from an aqueous solution, comprising a salt, a water immiscible alcohol of Formula I:R1—OH (Formula I)where R1 is an optionally substituted, linear, branched or cyclic C4-C12 alkyl; and a water immiscible halocarbon, wherein said halocarbon is miscible with said alcohol of Formula I. The system can be used on aqueous solutions that contain detergents (such as Sodium Dodecyl Sulphate (SDS), for example), and any detergent-associated or detergent-bound molecules that may be present in the aqueous solution, to form an aqueous phase and a non-aqueous phase, for effectively removing the detergent and any detergent-associated or detergent-bound molecules, and sequestering them into the non-aqueous phase.

Owner:DNA GENOTEK

Process for bone tissue decellularization

ActiveUS20170021059A1Good result of decellularizationThe process is simple and effectiveHydrolasesTissue regenerationMedicineBone tissue sample

A process for preparing decellularized isolated bone tissue samples, comprises the steps of a) providing an isolated bone tissue sample, b) treating said sample by immersions in: a solution comprising at least one chelating agent, a solution comprising at least one anionic detergent, a solution comprising at least one non-ionic detergent, a solution comprising at least one enzyme, a solution comprising at least one antibiotic. Decellularized bone tissue samples as obtainable by a process according to the invention can be used as grafts.

Owner:INCI ILYAS

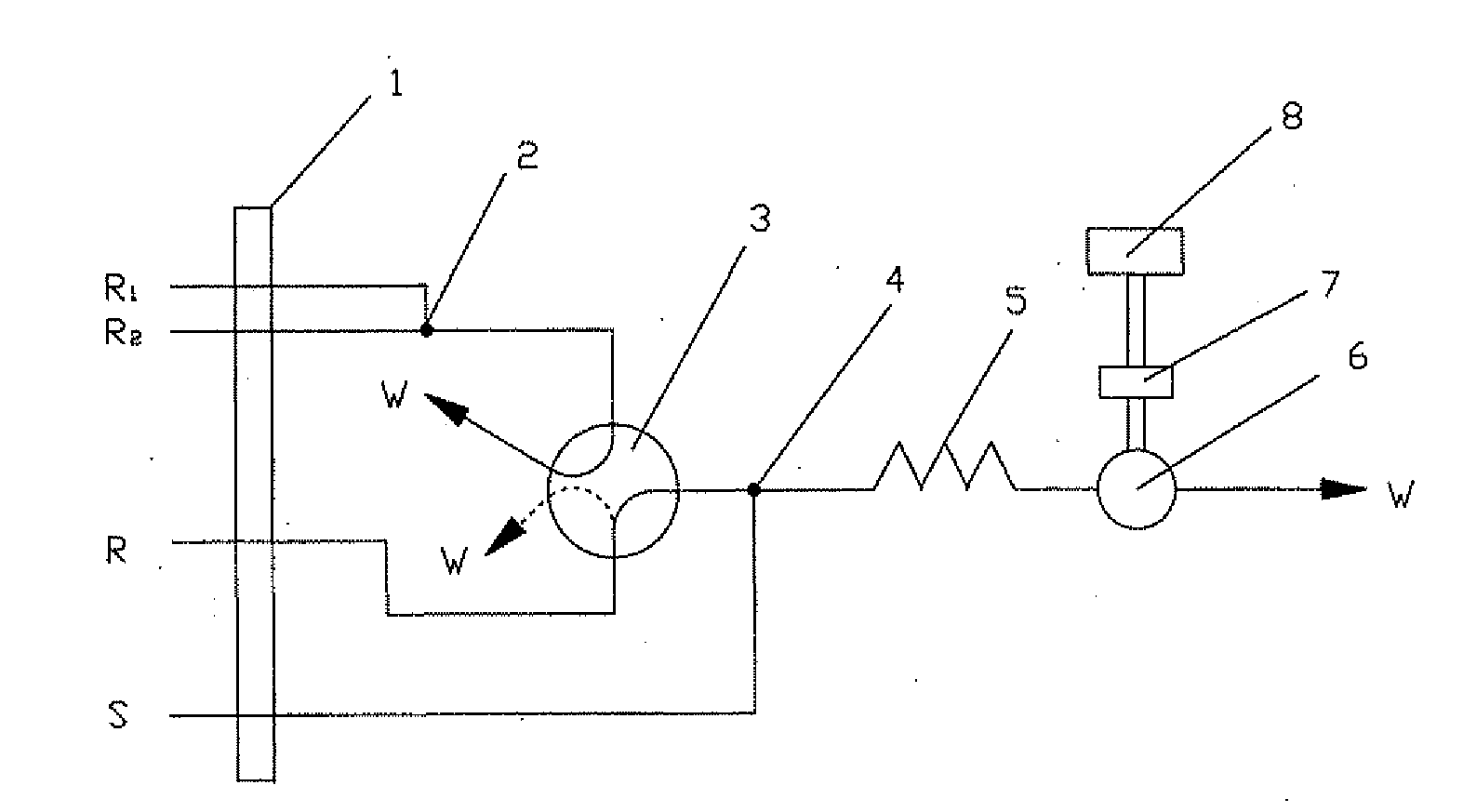

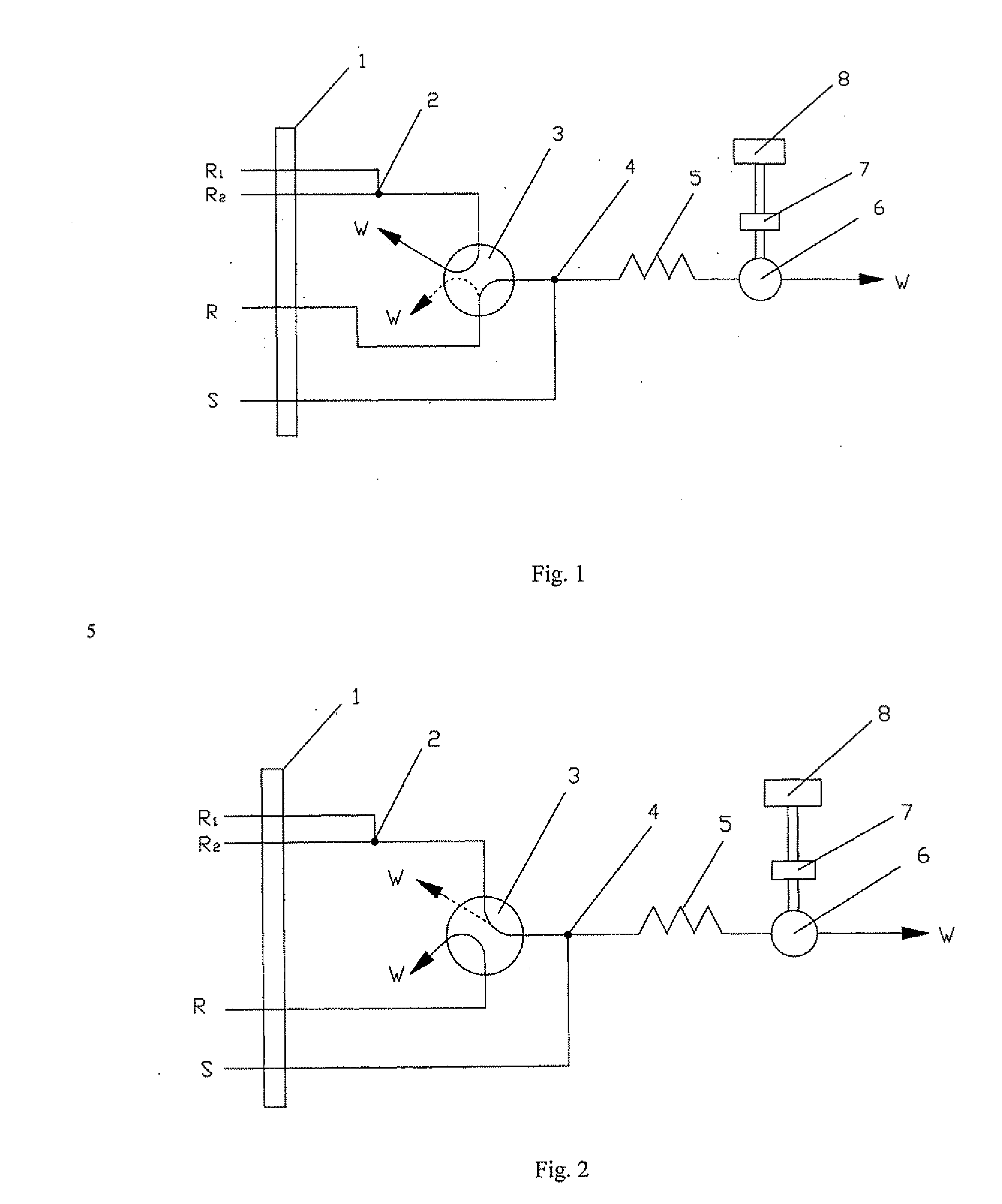

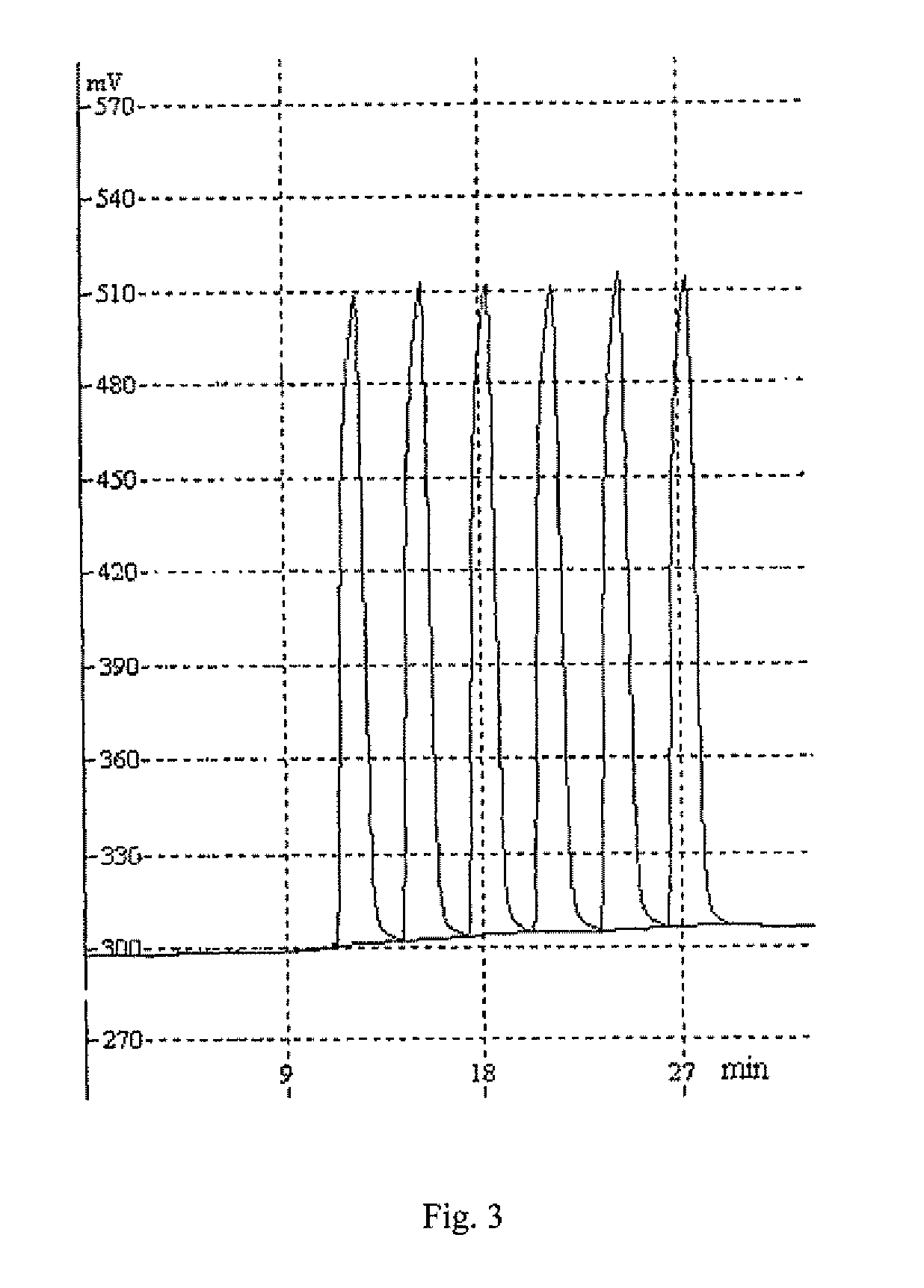

Method for automatic assay of anionic detergents in seawater

InactiveUS20090233370A1Easy to carryQuick analysisAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorAnionic detergentSeawater

A method for assaying anionic detergents in seawater comprises: (1) flow a sample through a sample system and an analysis-detection system; flow a reference solution through a reference system, a valve, and the analysis-detection system; where the sample and reference are mixed; and flow the mixture into an optical cell to produce a baseline, (2) flow a sample through the sample system and analysis-detection system; flow a buffer through a buffer system and a color developing system; where the buffer and a color developer are mixed; and flow the resulting mixture through the valve and analysis-detection system; where the sample is mixed with the buffer and developer mixture; and flow the resulting mixture into the cell to produce the sample spectrogram, (3) repeat (1) and (2) with standards of known detergent concentrations for corresponding spectrograms, and (4) compare the sample spectrogram with the standard spectrograms to determine the sample detergent content.

Owner:SICHUAN UNIV

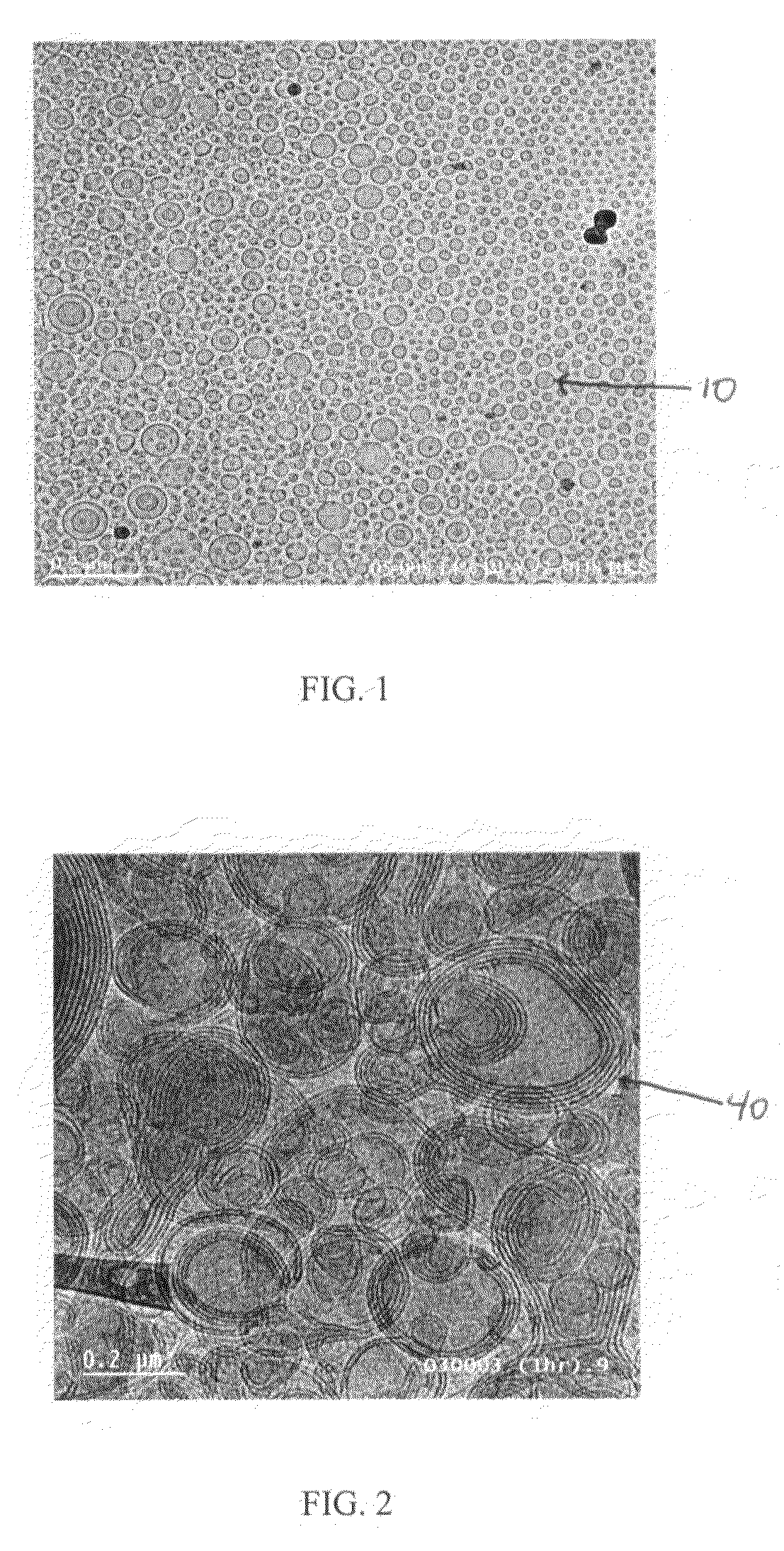

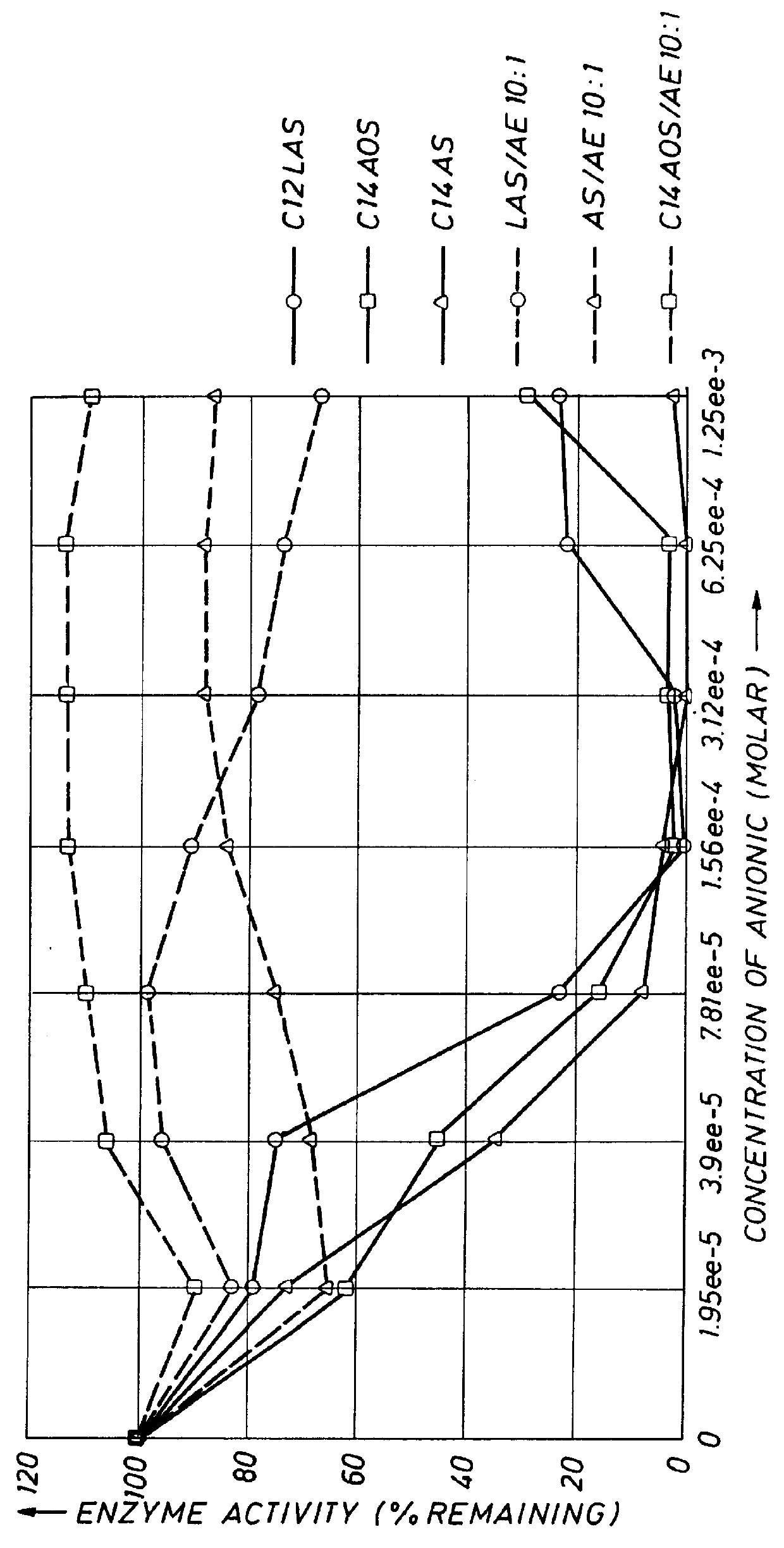

Fabric enhancing compositions comprising nano-sized particles and anionic detergent carry over tolerance

ActiveUS7833961B2Lower the volumeCationic surface-active compoundsDetergent mixture composition preparationMedicineAnionic detergent

A fabric enhancing composition comprising: at least one fabric softening active, wherein said fabric softening active comprises a plurality of particles comprising a intensity weighted particle size distribution wherein at least about 50% said particles have a particle size below about 170 nm.

Owner:PROCTER & GAMBLE CO

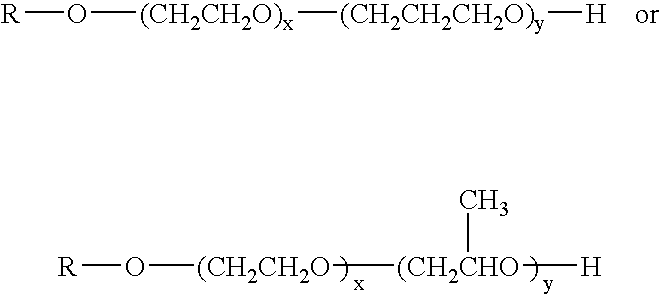

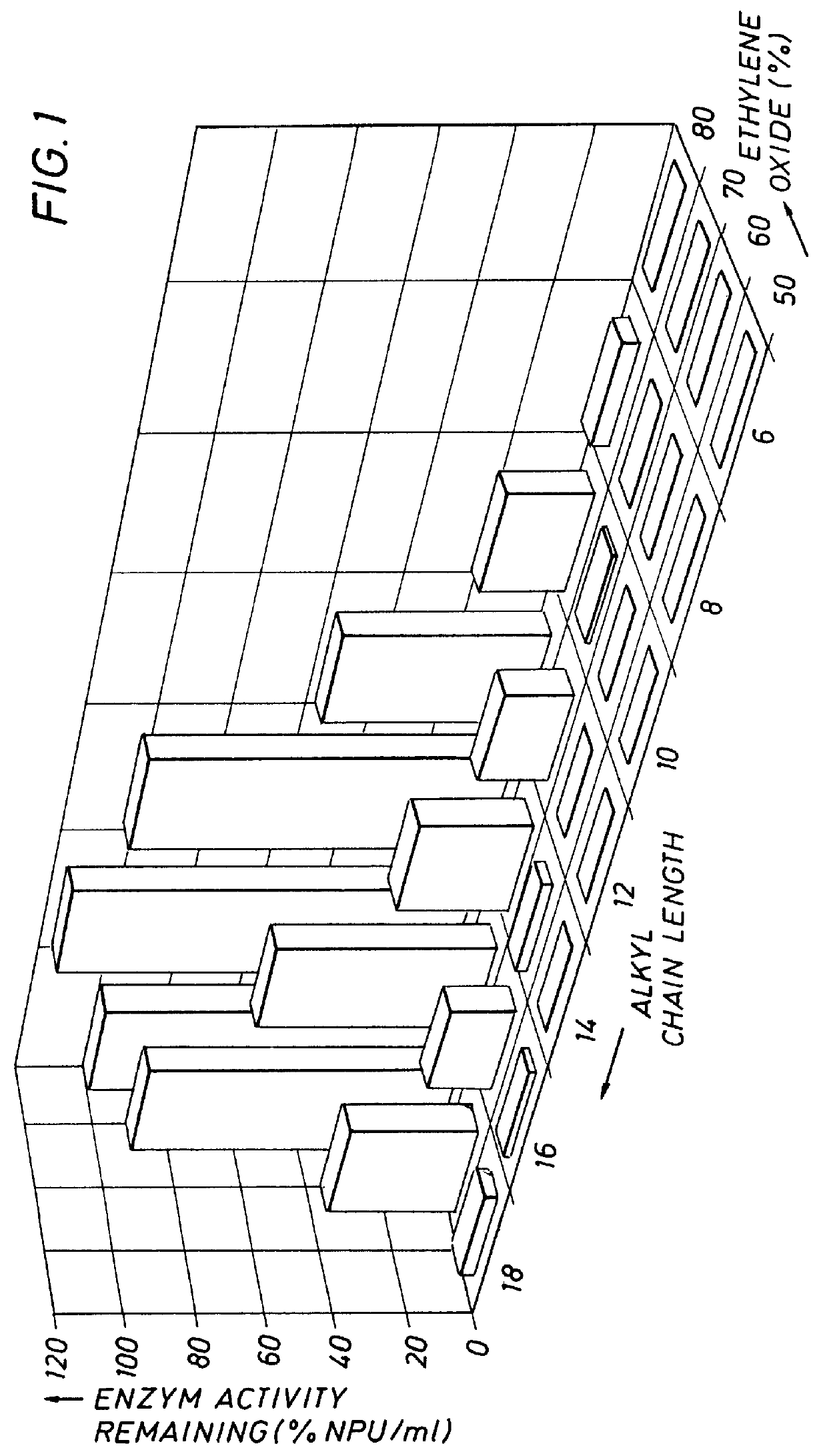

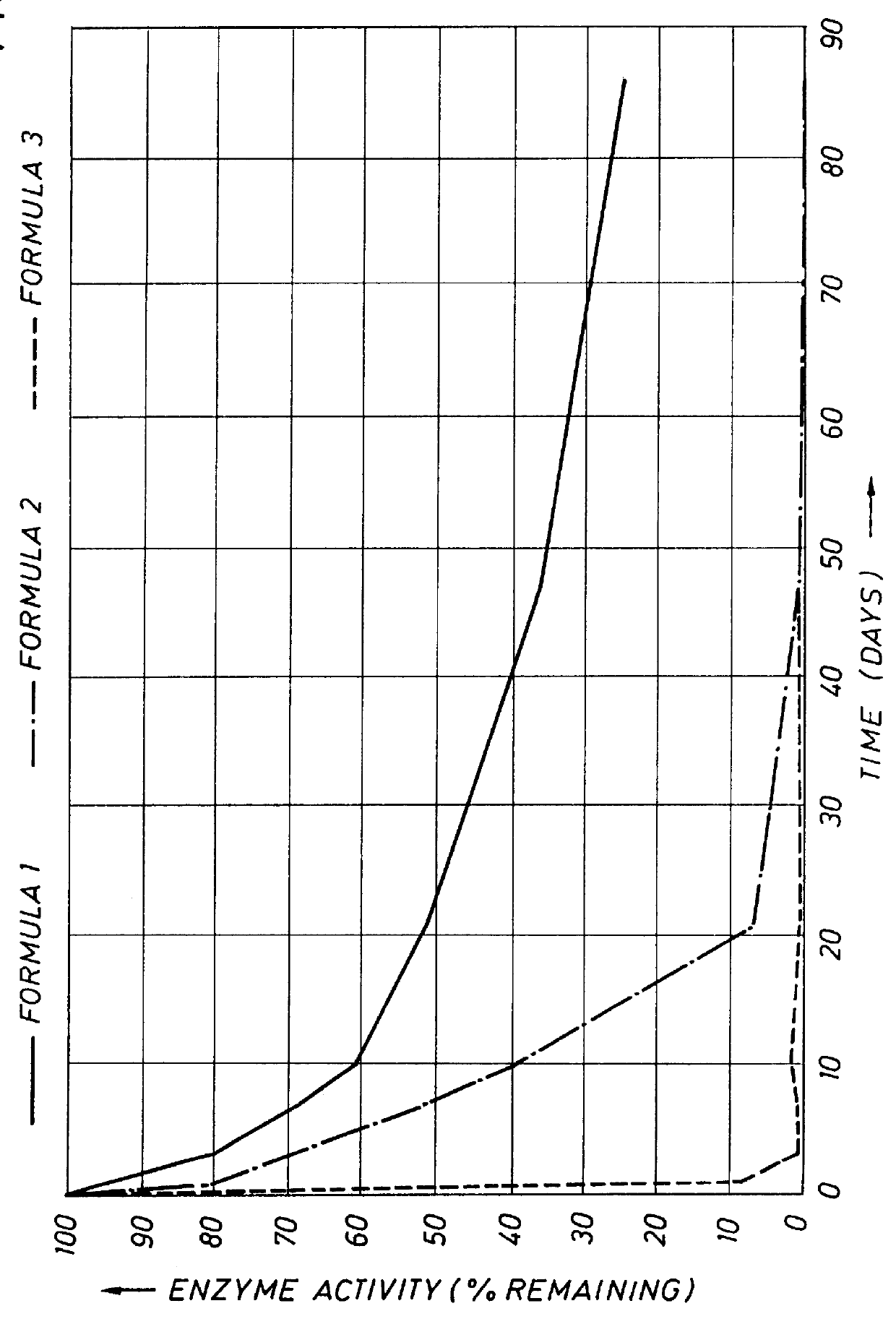

Stable aqueous enzyme compositions

InactiveUS6121225AOrganic detergent compounding agentsNon-ionic surface-active compoundsAnionic detergentChemistry

A stabilized aqueous enzyme composition comprising water, from about 0.1% to about 75% by weight of a detergent surfactant selected from the group consisting of anionic surfactants or anionic surfactants and one or more non-anionic detergent actives, from about 0.001% to about 10% by weight proteolytic enzyme, and an effective amount of an enzyme stabilizer having the formula: X-O-(CnH2nO)a-H [I]wherein "X" is an organic radical having from 14 to 22 carbon atoms, "a" is an integer from 10 to 26, and "n" is an integer from 2 to 4, and provided that "X" has a hydrophobicity similar to a linear alkyl group having from 14 to 22 carbon atoms.

Owner:SASOL NORTH AMERICA

Liquid Detergent Compositions That Include A Mixture Of Ecologically-Responsible Surfactants

ActiveUS20210054305A1Low cleanlinessUnacceptably-low viscosityNon-ionic surface-active compoundsDetergent mixture composition preparationActive agentDodecyl sulfate

A detergent composition includes an anionic detergent surfactant blend including alkyl ethoxylate sulfate (AES) and sodium lauryl sulfate (SLS). A weight ratio of AES to SLS is from about 5:1 to about 1:5. The detergent composition further includes a nonionic detergent surfactant. A weight ratio of the anionic detergent surfactant blend to nonionic detergent surfactant is from about 3:1 to about 1:3. Still further, the detergent composition includes water. A bio-based carbon content of the detergent composition based on ASTM D6866 is from about 50% to about 100% by weight of the overall detergent composition.

Owner:HENKEL KGAA

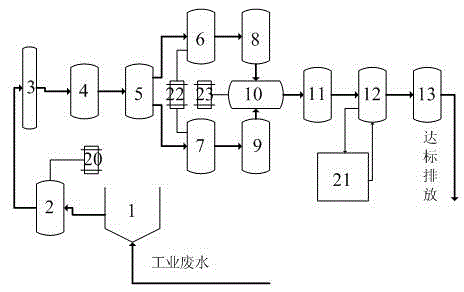

Treatment system for industrial oily wastewater

InactiveCN104609674ASimple process conditionsEasy to manageMultistage water/sewage treatmentPetroleumTotal phosphorus

The invention discloses a treatment system for industrial oily wastewater. The treatment system comprises a water storage tank, an oil separation tank, a fine grid, a primary settling tank, a regulating tank, a first bacteria digestion tank, a second bacteria digestion tank, a first aeration buffer tank, a second aeration buffer tank, a sludge remaining tank, a high-temperature and high-pressure tank, an MBR tank, an emergent accident pool, a backwashing chamber, an automatic dosing device, an oil storage tank, a mud storage tank and the like. Compared with the prior art, the treatment system has the advantages that the pollutant removal capacity is remarkably improved, the removal rate of chemical oxygen demand reaches 98.4%, the removal rate of ammonia nitrogen reaches 97.6%, the removal rates of petroleum, animal oil and vegetable oil reach 99.4%, the removal rate of five-day biochemical oxygen demand reaches 96.7%, the removal rate of suspended solids reaches 99.9%, the removal rate of total phosphorus reaches 98.6%, and the removal rate of an anionic detergent reaches 97.2%; membrane pollution is controlled by virtue of chemical cleaning and powdered activated carbon adsorption in a backwashing process of the MBR tank; the whole system is completely controlled by virtue of an automatic program, and functions of comprehensively and automatically opening and closing a gate of a water pump are achieved.

Owner:中国通用机械工程有限公司

Weak ethoxylation dehydrated sorbitol ester composition of washing keratin material

The present invention relates to compositions for washing keratinous materials comprising a cosmetically acceptable medium containing at least one C 8 -C 30 Sorbitan esters of fatty acids. These compositions have anionic detergent surfactant / C 8 -C 30 The weight ratio of sorbitan esters of fatty acids is 0.5-5.

Owner:LOREAL SA

Deoiling treatment method for restaurant waste water

InactiveCN109231539ASimple structureSolve difficult governance problemsFatty/oily/floating substances removal devicesTreatment involving filtrationWater qualityPolyacrylamide

The invention discloses a deoiling treatment method for restaurant waste water. The method comprises the following steps: (1) waste water collection: filtering the restaurant waste water through a filter device, and pouring the filtered waste water into a waste water box to be treated; and (2) oil-water separation: adding a mixed liquid of polymeric ferric sulfate, sodium humate and polyacrylamideinto the waste water box, reducing the surface activity of an anionic detergent by means of the catholic polymeric ferric sulfate, and destroying hydration shells of emulsified oil beads and double electric layer structures thereof, wherein oil is separated out. The oil content of purified water is 4.5 mg / L, the chemical oxygen consumption is 61.5 mg / L, the settling time is 2 minutes, the effluent is clear and transparent, the demulsification efficiency reaches 95%, and the clear liquid residual amount is lower than national state, and meanwhile, the chemical oxygen consumption is reduced toa great extent, so that the problem that the waste water treatment difficulty is great as a pipeline is easily blocked because existing oil-water treatment equipment is hard to separate oil from wateris solved.

Owner:许昌涉步餐饮管理有限公司

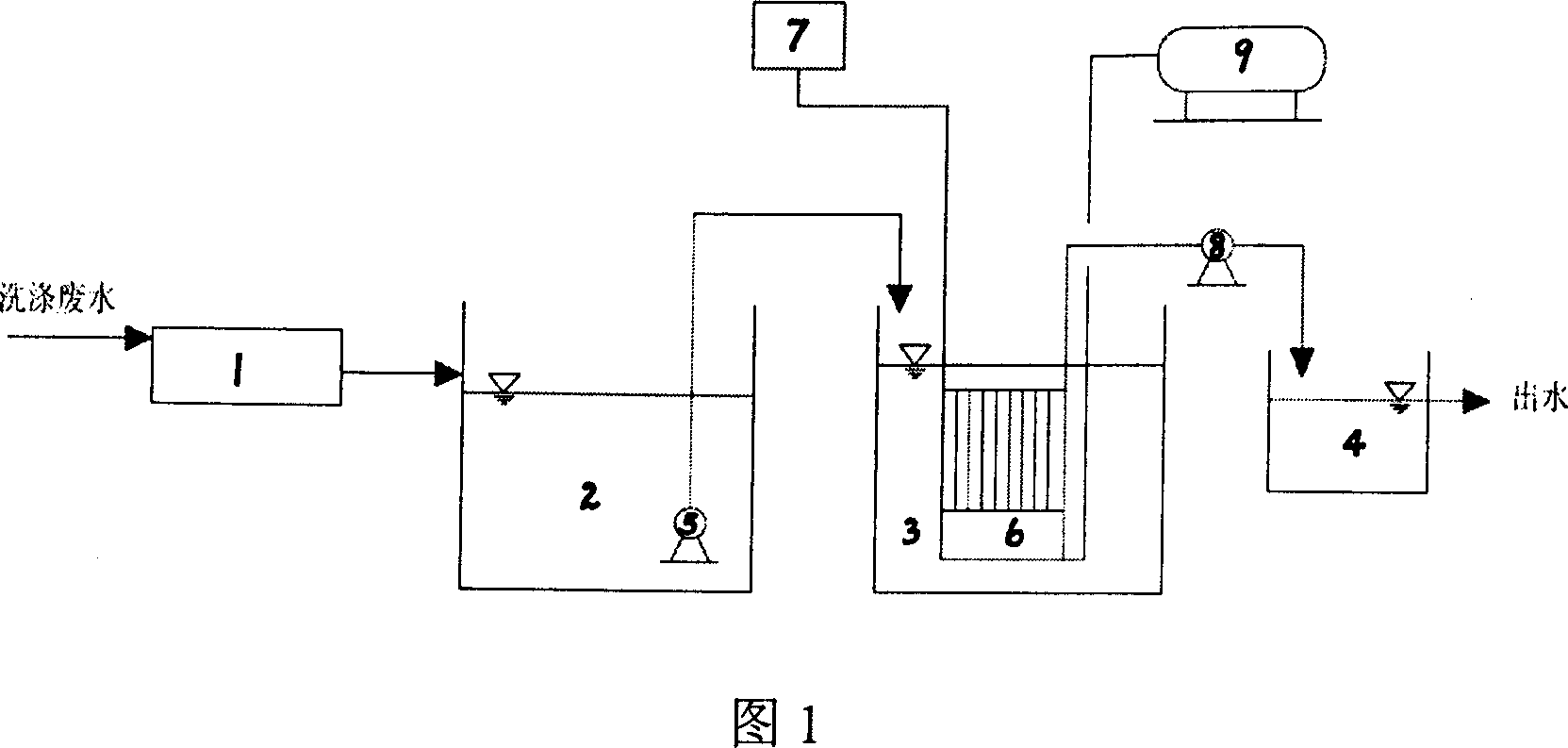

Treatment system for washing waste water

InactiveCN101104543ARealize automatic controlReduce outputTreatment using aerobic processesMultistage water/sewage treatmentFiberTreatment effect

The present invention relates to a washing wastewater treatment system which belongs to the sewage treatment technical field. The system is mainly composed of a grid, a regulating tank, a flat-panel membrane bio-reaction tank, a cleaning and dosing box, an auto-control system and various pump valves. In the washing wastewater, the ratio of the biochemical oxygen demand (BOD5) for five days to the chemical oxygen demand (COD) is relatively lower and the biodegradability is poor while the content of anionic detergent is high and is hardly biodegradable, and also the wastewater contains filiform suspended substances. The invention overcomes the shortcomings of the prior art, and has the advantages of good treatment effect, simple technology process, convenient operation and management, less investment and lower operating costs. Each index of the effluent treated through the system reaches or excels the first-level standard for the maximum allowable pollutant emission concentration in the sewage discharge standards (GB8978-1996).

Owner:TORAY FIBER RES INST(CHINA) CO LTD

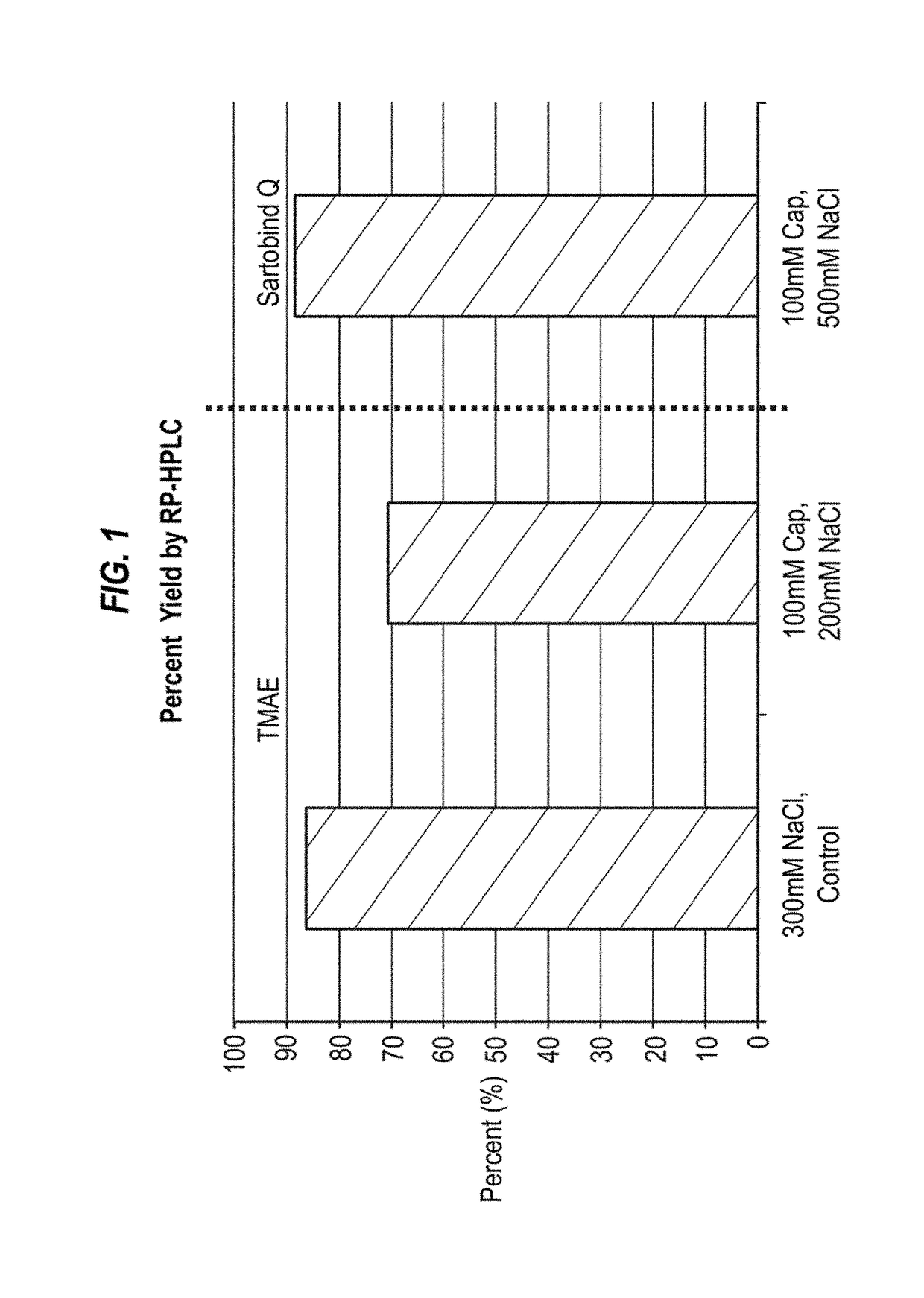

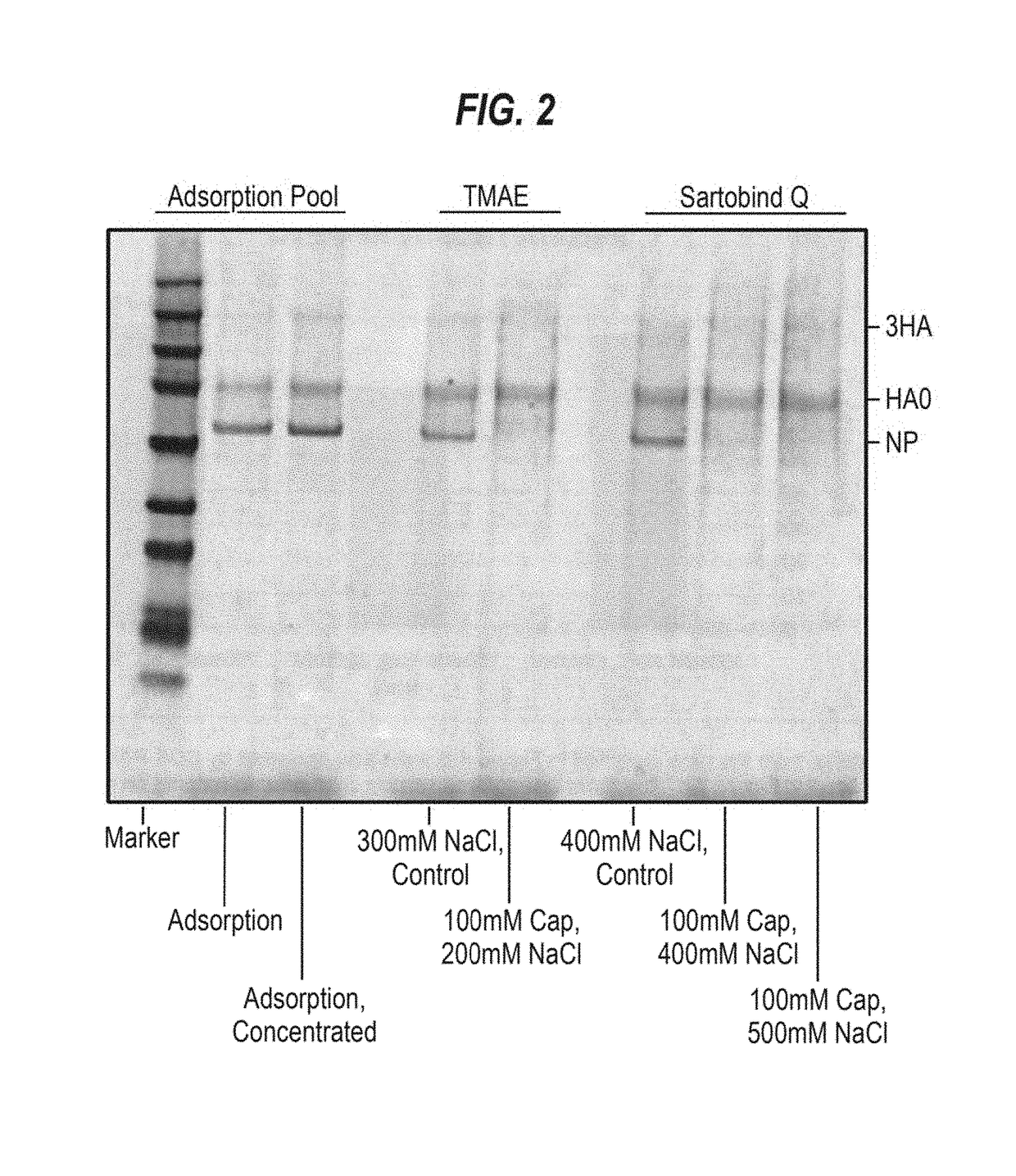

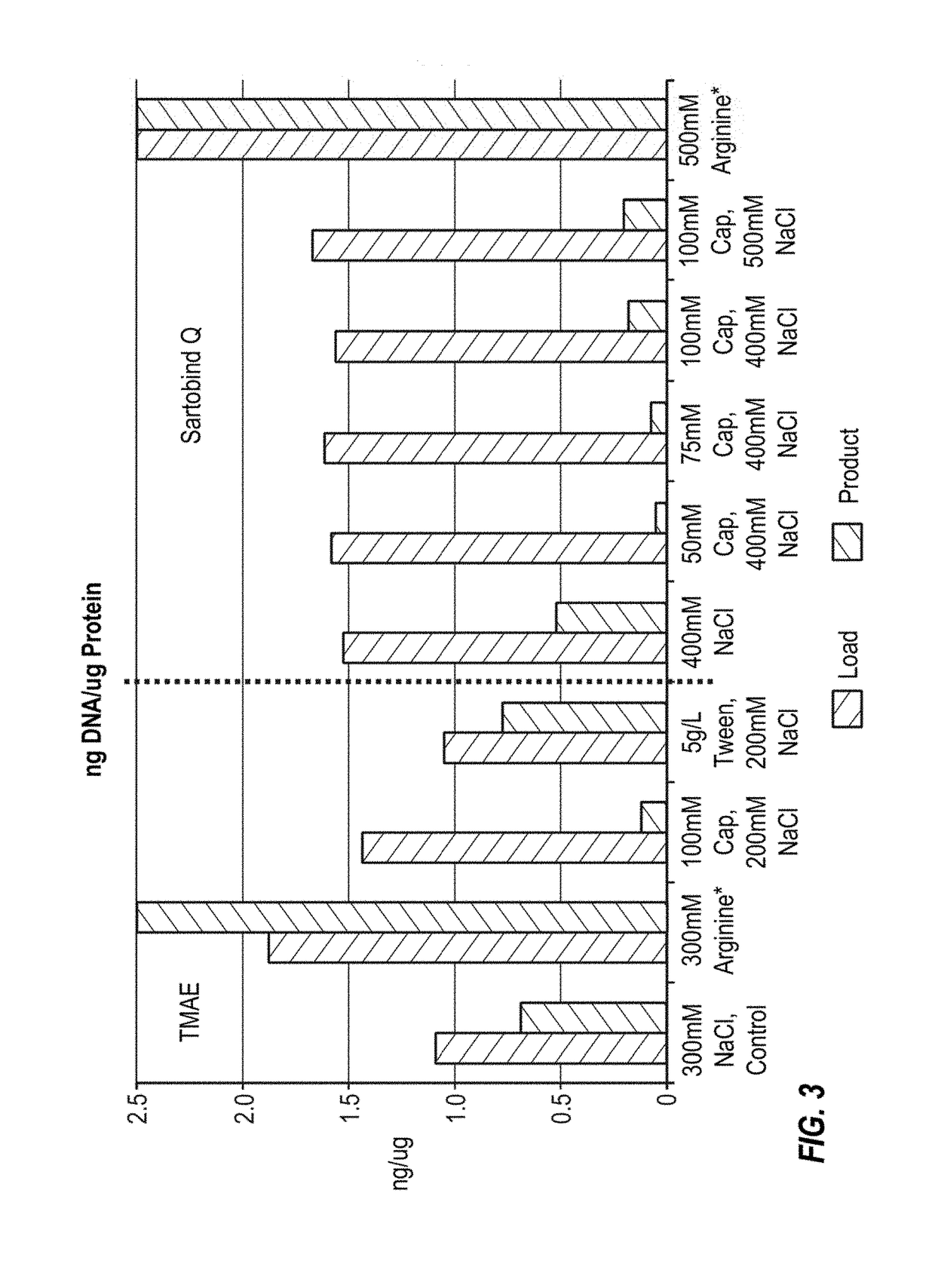

Removal of residual cell culture impurities

ActiveUS20190083603A1Increase yield and purity and safetyHigh product yieldSsRNA viruses negative-senseViral antigen ingredientsIon exchangeAnionic detergent

Owner:NOVARTIS AG

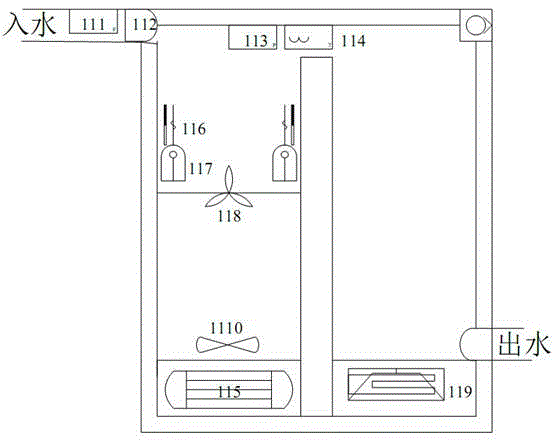

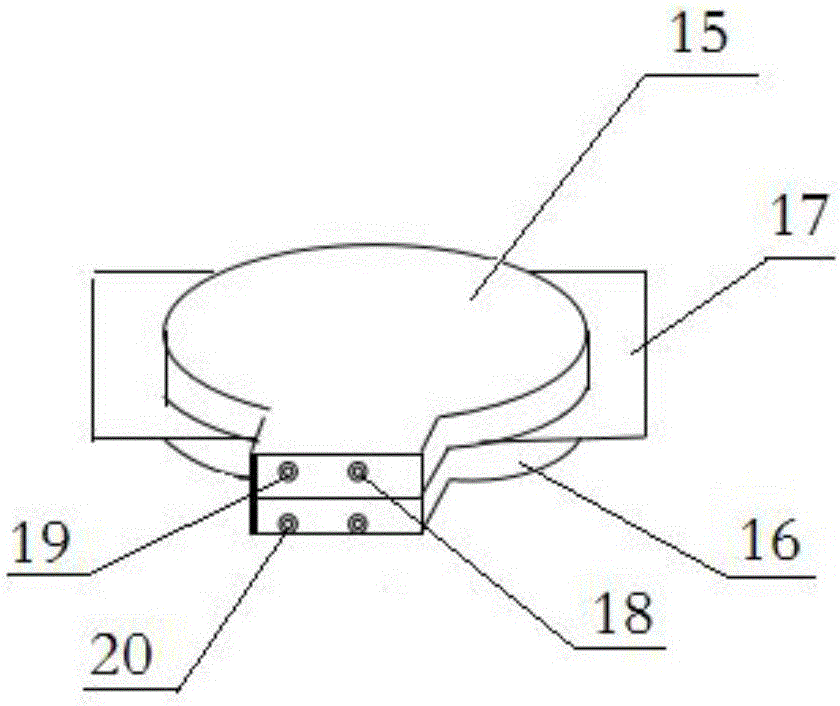

Detection system of anionic detergent

ActiveCN106770257AReduce the effects of stressAvoid problems that cannot continue to detectMaterial analysis by observing effect on chemical indicatorPeristaltic pumpMicrofiltration membrane

The invention discloses a detection system of an anionic detergent, and relates to the technical field of environmental protection and detection devices. The detection system comprises a peristaltic pump, a sample extraction module, a sample separation module and an anionic detection module, wherein the sample extraction module comprises a sample mixing device and a single extraction device which are sequentially communicated; the sample separation module comprises a gravity separation device and a back-extraction device; the anionic detection module comprises a microfiltration membrane phase separator, a detector and a second waste liquid bottle.With the adoption of the design, a hydrophobic membrane allows a water phase not to permeate into a lower layer of the microfiltration membrane phase separator; an influence of equipment pressure is small; no water phase enters the detection system; the problems that the water phase and a trichloromethane phase separation interface are unbalanced due to large whole pressure change of equipment, the water phase enters the detection system and detection cannot be continued are avoided.

Owner:REALSCI TECH BEIJING

Automatic analyzing instrument of sulphide, phenolic compounds, anionic detergents and aniline in seawater

InactiveCN101696978BShort analysis timeReduce volumeMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesData processing systemTest sample

The invention relates to an automatic analyzing instrument of sulphide, phenolic compound, anionic detergent and aniline in seawater, characterized by comprising a water mining and shunting system, four mutually independent flowing paths and a data-processing system. The water mining and shunting system is connected with the four mutually independent flowing paths by pipe fittings and respectively conveys standard sample or test sample for detecting sulphide, phenolic compound, anionic detergent and aniline to the four mutually independent flowing paths; and detectors in the four mutually independent flowing paths are respectively connected with the data-processing system and respectively convey detection result signals of the sulphide, the phenolic compound, the anionic detergent and theaniline in the standard sample or the test sample to the data-processing system to be processed, stored and displayed. The instrument can carry out the simultaneous online automatic analysis of sulphide, phenolic compound, anionic detergent and aniline in seawater and simultaneously acquire detection results of the four pollutants after one test sample is input.

Owner:SICHUAN UNIV

Effective teeth whitening composition utilizing bromelain enzymes

PendingUS20210386643A1Less evasive methodStable teeth whiteningCosmetic preparationsToilet preparationsAlcohol sugarsCalcium Binder

The present invention embodies an effective teeth whitening composition that utilizes bromelain enzymes as the primary active ingredient and the main source of whitening. Further, the invention is a method for preparing the effective teeth whitening composition. The composition of an effective teeth whitener includes a sugar alcohol, calcium carbonate, a binder, an anionic detergent, a fluoride agent, sodium benzoate, and bromelain.

Owner:AMARILLO JUNIOR COLLEGE DISTRICT

Structured Liquid Detergent Compositions That Include A Bacterial-Derived Cellulose Network

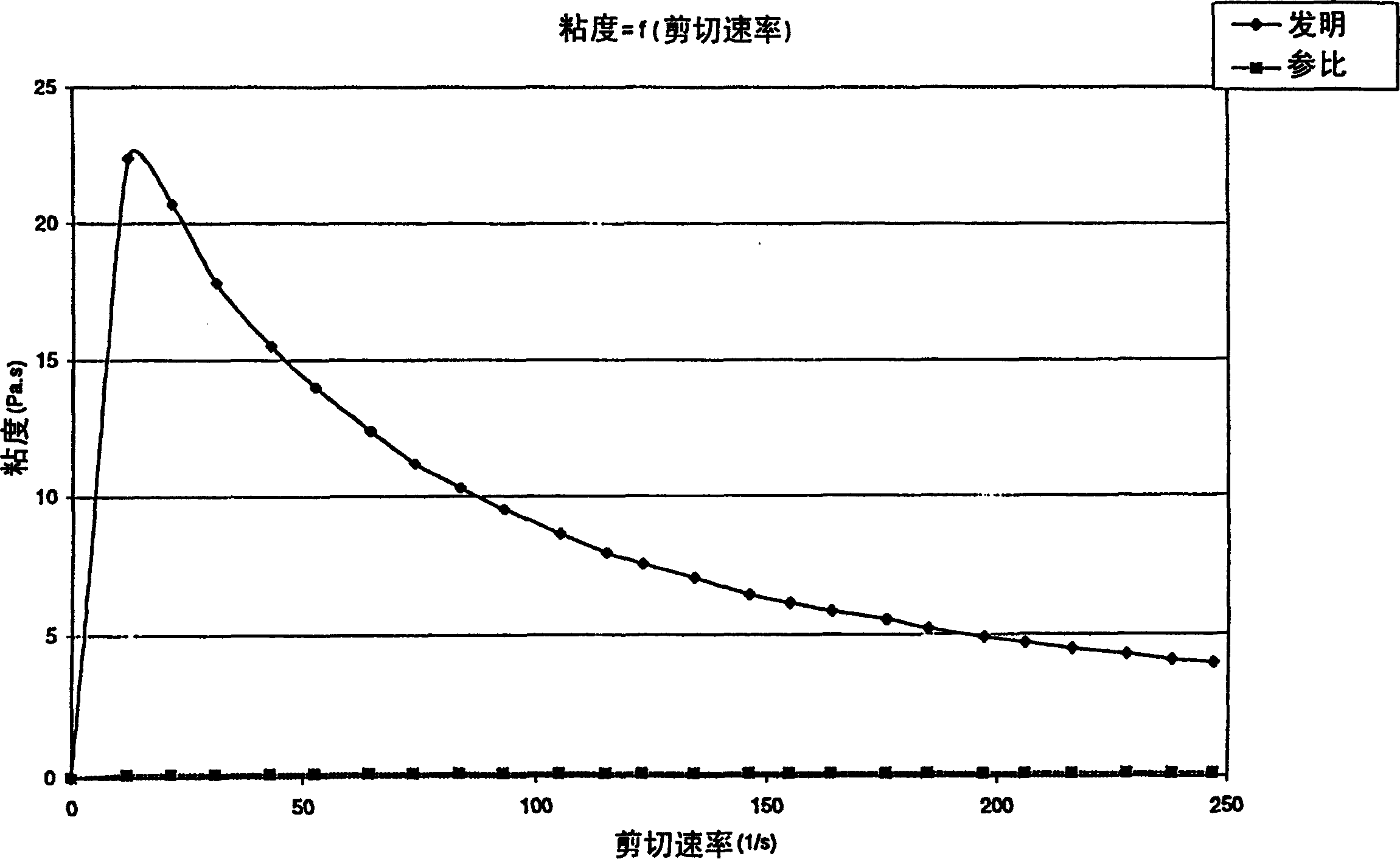

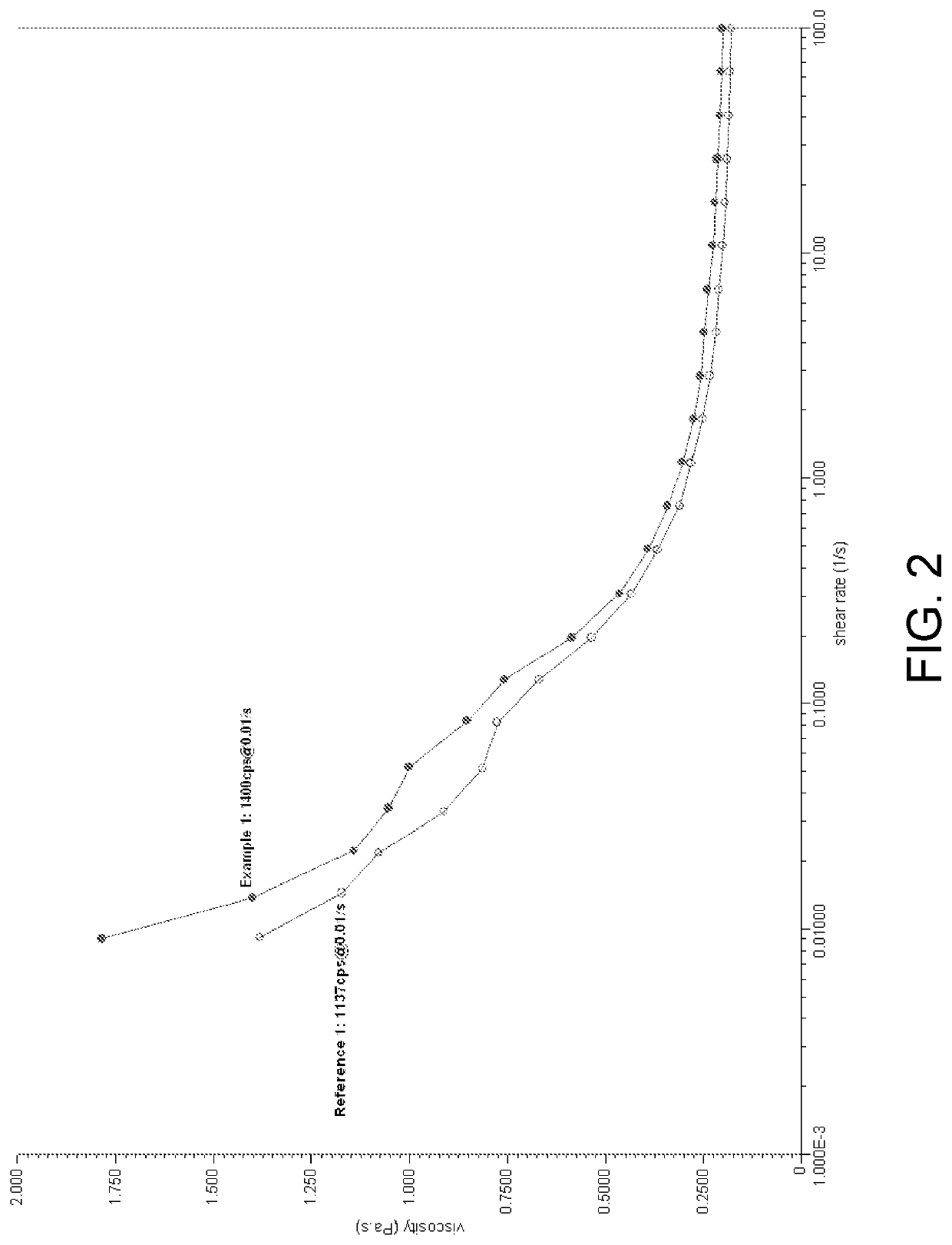

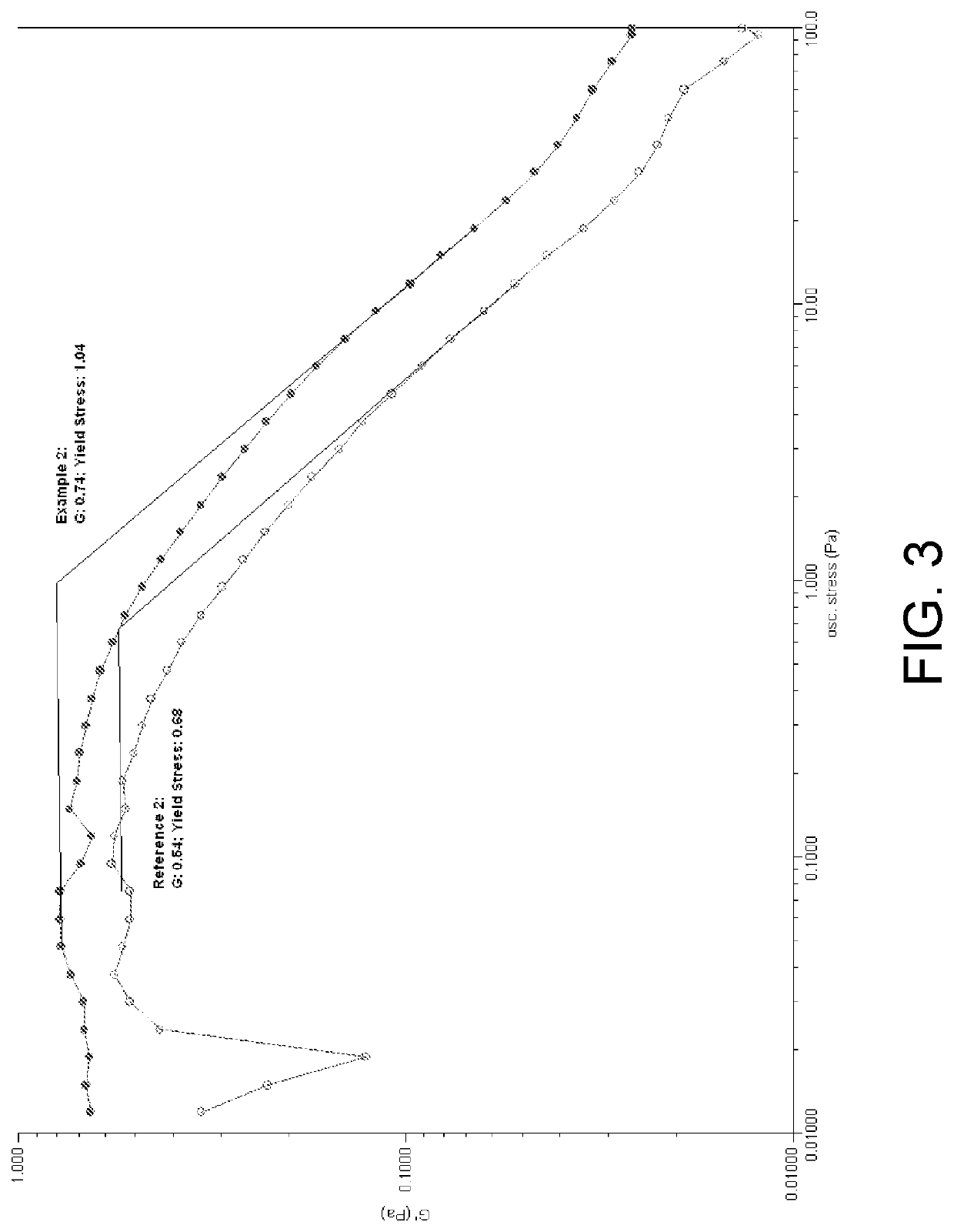

ActiveUS20210062118A1Avoid problemsSmall storage modulusInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAnionic detergentChemistry

A structured liquid detergent composition includes water, an anionic detergent surfactant, and a nonionic detergent surfactant. A ratio of the anionic detergent surfactant to the nonionic detergent surfactant is from about 0.5 to about 20. The structured liquid detergent composition further includes a zwitterionic or amphoteric surfactant and a bacterial-derived cellulose network. The structured liquid detergent composition exhibits improved rheological properties.

Owner:HENKEL KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com