Texaco gasifier grey water treatment and recovery system

A gasifier ash and water treatment technology, which is applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of low benefit, high cost, difficult removal, etc., and achieve the extension of production cycle, Improve water quality and solve the effect of easy scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

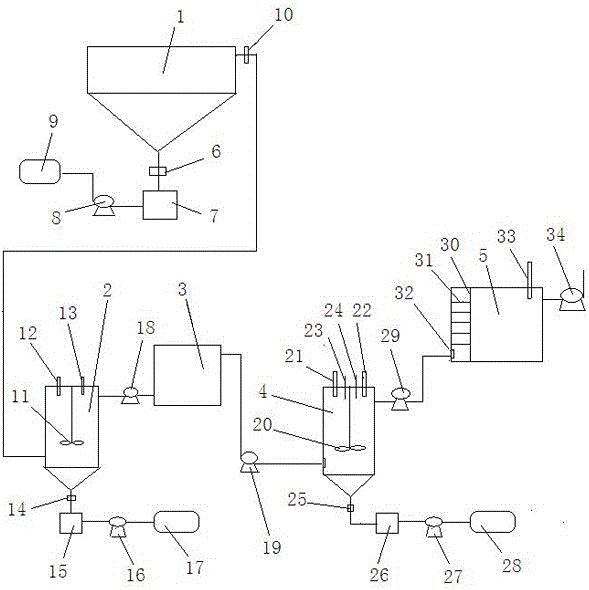

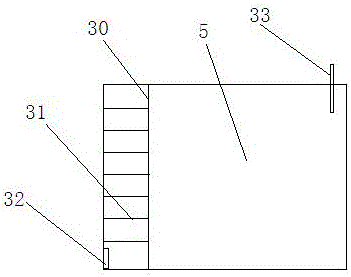

[0027] see Figure 1~2 , in an embodiment of the present invention, a Texaco gasifier ash water treatment and resource recovery system, including Ca 2+ , Mg 2+ Sedimentation tank 2, filter feed tank 7 connected to the bottom of black water settling tank 1, first filter feed pump 8 connected to filter feed tank 7 outlet, connected to first filter feed pump 8 outlet The coarse residue filter 9, with Ca 2+ , Mg 2+ The first drainage pump 18 connected to the upper outlet of the sedimentation tank 2, and Ca 2+ , Mg 2+ The bottom of the settling tank 2 is connected to the first sediment collection tank 15, the second filter feed pump 16 connected to the first sediment collection tank 15 outlets, the sediment filter 17 connected to the second filter feed pump 16 outlet, The gray water tank 3 that links to each other with the first drainage pump 18 water outlets, the second drainage pump 19 that links to each other with the gray water tank 3, the MAP reaction sedimentation tank 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com